The construction of a strip foundation is a rather complicated process, the correct implementation ...

|

|

Stretch ceilings are quite durable and reliable coating that serves ... |

A great option for exterior decoration of the house will be installation of siding ... |

DIY Ceiling Warming

If you have taken up the insulation of the bath, keep in mind, insulation of the ceiling in the bath will require special accuracy, thoroughness and attention. Otherwise, according to the laws of physics, hot steam will simply run away from the room.

In the presence of all the necessary materials, tools and, of course, desires, insulation of the ceiling of the bath with your own hands, work is quite feasible. The process itself requires such stages:

- vapor barrier;

- thermal insulation;

- waterproofing.

Most manufacturers of insulation materials claim that the use of their products will save the owners of baths from additional troubles, for example, with vapor barrier or do not require a waterproofing layer. But, alas, such statements are nothing but an advertising move. Effective insulation of the ceiling of the bath requires the presence of three barriers, certainly in the sequence that is indicated above.

- Warming for the ceiling of a bathhouse

- Insulation of the bearing ceiling in the bath

- Insulation of the flooring in the bath

- Insulation of panel ceiling in the bath

Warming for the ceiling of a bathhouse

Naturally, before starting insulation of the ceiling in the bath, you need to decide on the type of insulation. Moreover, in the building materials market their darkness is a thank. If you prefer environmentally friendly materials by the old fashioned way, then you should opt for sand, shavings, ground or sawdust soaked in clay solution.

Adherents of modern technologies are recommended to use expanded clay or mineral thermal insulation materials (as an option, stone cotton wool Rockwool). How to use mineral wool insulation of the ceiling of the bath? Video video will help you do it right.

Most experts do not recommend insulation with foaming the ceiling of the bath. Some argue their opinion with high fire hazard, second toxicity. The steam ceiling itself should not be made of fiberboard, plastic or plywood. Wood production materials under the influence of moisture are quickly deformed. The plastic ceiling, as well as the coating of the ceiling with olifa or varnish, is also toxic, so it is better not to use them during construction.

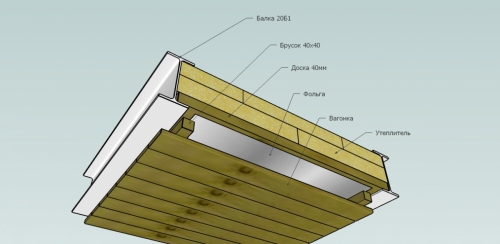

In the baths from a beam or logs, the ceiling is sewn with boards with a thickness of 6 cm. The boards are covered with a layer of vapor barrier (aluminum foil or waxed paper).

The next layer of clay and laying of mineral wool or other insulation.

It can be sawdust mixed with clay, bulk expanded clay, if in the old fashioned way - then sand or soil.

If new materials are growing aerated concrete.

Your attention is the new method of insulation of the ceiling of the bath: the video will show how this is done by a growing aerated concrete.

The total thickness of the thermo -insulating layer should be at least 15 cm. Particular attention is paid to the junction of the insulation and pipe. Indeed, according to the rules of fire safety and sanitary standards, the distance between the pipe and other materials on the roof should be about 20 cm. For this, they arrange a box of rafter legs (see photo above), thus separating the pipe from steam and thermal insulation. The films are cut with an envelope and fixed with nails to the rafters. The zone inside the box, between the box and the pipe, is filled with non -combustible insulation. Stone cotton wool is suitable for this.

In a wooden structure, the steam ceiling can be equipped with a flooring, panel or bearing method. The choice of the option of its insulation also depends on the type of ceiling.

Insulation of the bearing ceiling in the bath

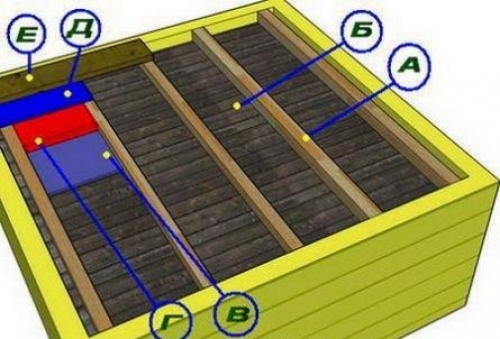

The bearing ceiling implies the presence of a supporting frame consisting of an overlap beam, with the rest of the components attached to it. Ceiling beams laid down in a special way are sheathed with a trimmed or dodgy board. Directly, the insulation is placed between vapor barrier and waterproofing layers. On waterproofing from the attic side, as a rule, a plank floor is placed.

In the picture: a - ceiling beams, b - boards, B - vapor barrier, g - insulation, d - sheathing from boards.

In such a case, the ceramzitis ceiling ceiling is most often used. Although some prefer to insulate mineral wool or sawdust. Bearing ceiling is used in baths with a attic.

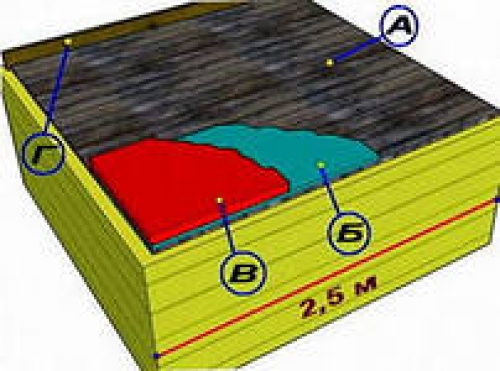

Insulation of the flooring in the bath

A similar type of ceiling is made using the flooring of the boards on the walls. At the same time, a prerequisite is the use of boards exceeding 5 cm wide, but the width of the span between the walls should not exceed 2.5 m. A vapor barrier layer is laid on the plank shield, on top of which finished mats from mineral insulation go. Those who want to insulate the flooring with bulk material will have to tinker with the installation of special fencing sides around the perimeter of the bath.

In the picture: a - the flooring of the boards, b - vapor barrier, c - thermal insulation.

The advantages of the flooring are its simplicity, low cost and speed of installation. The disadvantages are that the flooring is used only in small baths and inconvenience in preventive repairs, in case of damage to thermal insulation. Experts recommend using a flooring in bath buildings with the absence of an attic.

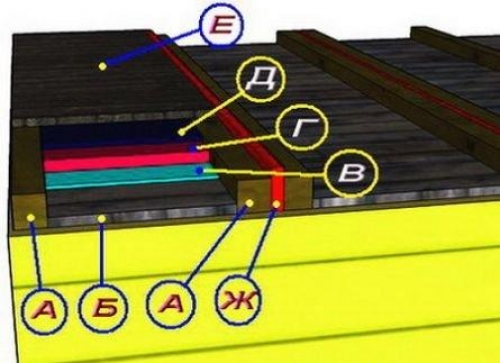

Insulation of panel ceiling in the bath

For equipment panel ceiling in the rooms of baths, saunas, steamers, special shields are used. The composition of such a shield includes supporting bars, internal sheathing, steam, heat and waterproofing layers, an external ladder. The thermal insulation layer, in order to reduce weight and improve the heat -saving properties of the shield, is mineral wool insulation or glass wool. It is important that the thickness of the insulation does not exceed 10 cm.

In the picture: a - bearing bars, b - ceiling, B - vapor barrier, g - thermal insulation, d - moisture insulation, e - external coating (floor of the attic)

The installation process of the panel ceiling is complicated due to the need to lay between the shields of the moisture -proof and heat -saving seal. Most often, a felt of foil with either polyethylene, or a finished bilateral foil insulation is used as such a material. Another unpleasant moment in the installation of the panel ceiling is the weight of the shield. For one person, he, as a rule, is beyond strength. Therefore, the builders are forced to cunning: to install empty boxes from the beginning, and then fill them with hydro-, heat, vapor barriers and equip the attic layer on top.

Which type of ceiling to choose and how to insulate you to solve, of course, to you, but the owners of baths and builders, wise with experience, recommend a bell ceiling. Despite the original high cost, it is strong, convenient, durable.

Having properly insulated the ceiling of the bath, laying a layer of vapor barrier, you will be sure that the room will remain warm, and the steam will not disappear, but will help restore strength to everyone who decides to take a steamer in your bathhouse.