The destructive effect of moisture is subject to all structural elements of the building that ...

|

|

Due to its strength, durability, unpretentiousness and multifunctionality ... |

Houses made of double beams are characterized by a large number of advantages, in front of ordinary ... |

DIY soft roof laying

Private construction and use of a soft roof The topic is quite relevant. This material has a lot of advantages. Among them are small weight, absolute tightness, visual attractiveness, the possibility of using the roof of the most diverse form, a long period of useful service and the low cost of a soft roof. Moreover, the rain does not drum on such a roof, but quietly rustles. In addition to high operational and technical characteristics, the material allows the installation of a soft roof on their own, without involving specialists to work.

Table of contents:

- The concept of a soft roof

- Laying tools

- Ventilation device

- Lining layer

- Preparatory work

- Subtleties of installation of soft roof

- The choice of mastic

- Making bitumen mastic

- Laying a soft roof

- Laying near ventilation pipes

- Repair of a soft roof

The concept of a soft roof

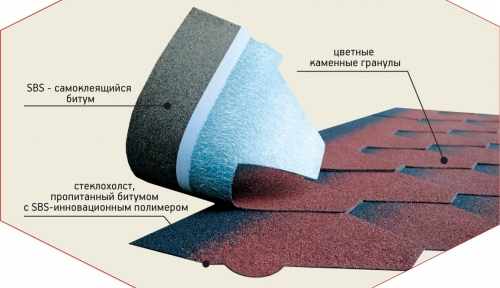

Soft roofing is a modern material, the basis of which is fiberglass sheets impregnated with rubberobitum on both sides. The rubber band is characterized by high tightness and moisture resistance, so the soft roof spread so during the construction of buildings. Also, the soft roof in its composition has a special sprinkle, which increases wear resistance and does not allow a roll coating to glue.

Soft roof is considered an ideal coating for roofs, in which the angle of inclination is at least 11 degrees. Therefore, when choosing a material for such strict requirements, be careful. A soft roof is often called bituminous tiles, which is used as the upper layer of the roof pie and differs from other materials with its structure, which resembles roller materials.

Laying tools

A flexible roof will be able to lay 1 person. The only requirement that we already mentioned is put forward to the surface of the roof - the slope is no more than 11. But the maximum angle of the slope is not limited. With your own hands, laying the soft roof with your own hands require the presence of such materials and tools: a hammer, a knife, mastic, sealant, trowel for mastic, roofing nails, cornice and end strips, a waterproofing carpet, a skate-carnious strip and working gloves.

Ventilation device

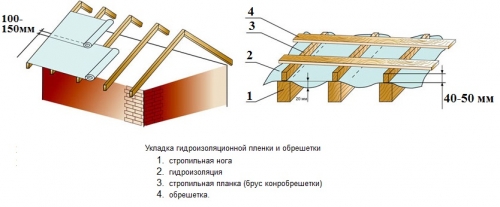

The ventilation system can provide air circulation, which is necessary to prevent the occurrence of condensate on the lower part of the base. The neglect of this stage when laying a soft roof on the roof will cause that the rafter system begins to rot, and ice and icicles will form in the winter.

The component elements of the roof ventilation system are ventilation purges and outputs, the gaps between waterproofing and the base (at least 5 millimeters). Natural ventilation can be provided with ventilation holes, which are distributed evenly under the cornice overhang.

Lining layer

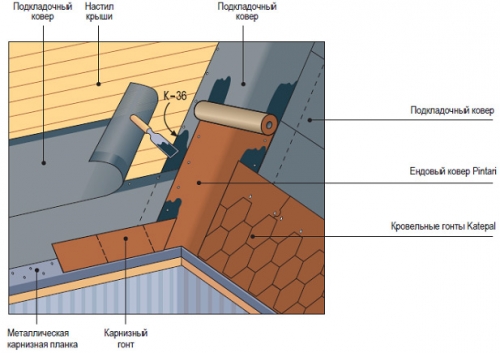

Cades are made of metal and mounted on the overhanges over the lining. They are required to protect the edges of the crate. The pediment strips are also produced from metal, they are fixed in the ends of the roof to protect the edge of the crate. The apple carpet provides additional protection of the roof from atmospheric precipitation. Choose it according to the color of flexible tiles.

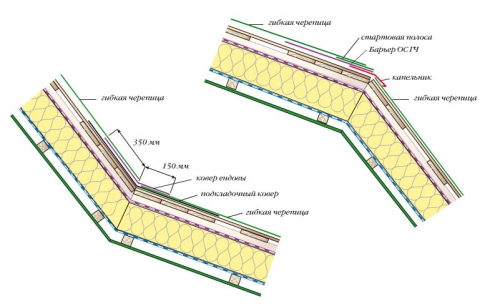

In places in which leaks are most likely, you need to create a lining layer: on the yndovs, ends of the roof and cornice overhangs. A feature of installation is compliance with the direction (from the bottom up) and overflow: in the longitudinal direction of 150 millimeters, in the transverse - 100 millimeters. It is customary to smear the places of overlap with bitumen mastic.

Endovs and skates are accordingly accepted to strengthen by 500 and 250 millimeters. At the same time, the values \u200b\u200bneed to be equipped on both sides with a lining layer, and along the ends and cornice over the width of at least 400 millimeters should be laid.

The lining to the base is nailed with galvanized roofing nails every 200 millimeters. The lining carpet not only protects the roof from moisture, but also from destruction, if the laying of the soft roof is suspended.

Preparatory work

The base to which you will attach a soft roof should be continuous. This is what the process of the roof of the roof made of soft tiles differs from the roofs for which other materials are used. For example, metal tiles should be laid on a crate in which a gap is allowed between the bars, which is explained by the high rigidity of the metal tile. The soft roof does not possess these qualities and therefore needs preliminary installation of a durable base.

To arrange the base, you can use a focusing stove, moisture-resistant plywood with a thickness of 9 millimeters, as well as a lapped or rubberized board. If you have chosen a board as the base, then it is recommended to pre -withstand it in a stack until the equilibrium level of humidity is reached.

Buy the material in winter, and use in the summer. The width of the boards is not more than 100 millimeters. It is desirable that the material has the same thickness and be sawn on a strip saw. The maximum moisture of the tree is 20%.

In the video about the technology of laying a soft roof, it is shown that such materials must be laid with a shift of the seams - scoring, leaving a gap of 1 centimeter between them. The surface should be dry, clean and smooth. The installation quality and the service time of the soft roof will depend on these conditions.

The roofing pie must have the following layers without fail: a waterproofing layer laid on the rafters; insulation from mineral wool, if you plan a device of attic; Waterproofing roofing carpet, laid on the base from the outside.

Subtleties of installation of soft roof

To cover the roof with a soft roof with your own hands, except for the presence of free time, you also need good weather. It is customary to carry out work in warm dry weather, while the air temperature should not drop below plus 5 Celsius. If, due to the need to lay a soft roof in the winter in the wrong time, the tiles before starting work must be kept in a building with room temperature. You can also use the heat -air burner.

The choice of such a temperature regime is explained by the features of the gunt of a sheet consisting of 3-4 tiles. It can be attached to the surface with nails or with the help of a self -adhesive layer, which is located on the inside. The tightness of the tile is ensured by the heat of the sun, under its influence, the sheets are soldered with the base and among themselves. This does not happen at minus temperatures, and the isolation of high -quality does not work.

Soft tiles should be used simultaneously from 5-6 packs and selected in turn one element in order to avoid sharp differences in shades in case of need to repair soft roofs from other packaging. It is in this property that another advantage of this material is: a small difference in shades facilitates the process of replacing the tiles and decorates its matte surface.

The choice of mastic

To lay the upper layer of the soft roof, the bitumen-polymer material should be used, which allows you to perform a continuous elastic coating, which withstands temperature and mechanical deformations of the base. According to the technology of laying soft roofs for attaching to the roof of roller material, it is recommended to use cold and hot mastics.

Cold mastics are used traditionally for the inner layers of the roof, and the hot substance is used as an external coating. Cold mastics include roofing roofing and bitumen, and hot tar and only. The used mastic should contain bitumen and a mixture of dusty type or a filler made of fiber. Among the dusty materials, lime, gypsum and ash are distinguished

Making bitumen mastic

You can buy bitumen mastic, but you can do it yourself. To do this, take bitumen, which is close to 80% of mastic, and filler. Having taken 2 servings of bitumen and diesel fuel for 1 portion of filler, you will receive a cold mixture. Bitumes need to be heated to 180 degrees, while the diesel fuel and filler are preparing in another place. Both boilers can be mixed only after the water evaporates in bitumen.

To make hot mastic, use the boiler. In it, bitumen should be heated to 200 degrees, while it is necessary to slowly add the filler. It is important that during the procedure the temperature does not drop below 160 degrees.

To check the quality of the mastic, you need to lay it at an angle of 45 degrees, after heating the mastic to 60 degrees. The video about laying a soft roof shows: if the coating is draining, then his quality is poor. If it does not flow out, then it is worth letting him dry. When dried up in quality material, cracks will not appear.

Laying a soft roof

Before direct laying of the roof, go through a solution of bitumen and diesel fuel on the surface of wood. Further slowly coating with mastic, then lay the pergin and roofing material. Installation is customary to start from the middle part of the cornice and move to the ends to the right and left. On the wrong side of the soft tiles before applying, it is necessary to remove the film that protects the glue.

If you use cold mastic, you must wait 12 hours after applying the layer, only then you can apply a new layer. When coating with hot mastic, you can apply one after another. Each element of the roof must be nailed with nails in the amount of 4-6 pieces.

When laying rolls according to the instructions for laying a soft roof, make a 7-10-centimeter wrap. In all cases, it is recommended to comply with the overhead rule: place each upper row so that the joints of the attachment of the previous one are closed. There is a shift in the next new layer depending on their number (at 2 layers - half, and at 3 per third).

Cut the excess along the edges of the roof and glue with mastic. Due to the properties of modern soft roofing materials, the useful life of the roof covering is about 30 years. But this does not mean at all that one might forget about preventive measures.

Laying near ventilation pipes

Proper insulation of joints and neat fastening of the material requires a place around antennas and pipes. Installation of a soft roof here is easily provided, under the condition of using passing elements. Without such components, the tightness of the coating is disturbed. Even before laying bitumen tiles, you need to outline the places where you will install ventilation and pipes.

Then you need to cut the holes around which the edges of the lining carpet will be glued with mastic. Light the upper surface of the carpet along the contours of the elements that must be glued and nail with nails. Put the tiles on top of the mastic.

The junction of the upper part of the passage element and bitumen tiles is recommended to be treated with sealant. Having brought the work to the skate line, you need to use special skate elements of flexible tiles that are curved through it, are glued to mastic and nailed with nails.

Repair of a soft roof

The frequency of repair work that needs to be carried out with the roof of the house depends directly on the base on which you set the tiles, and on the cost of laying a soft roof. Wooden lumber, cement and concrete screed, they all react differently to the soft roof, which causes certain damage.

Cleaning the damaged area

Immediately before starting the repair, determine whether such work is needed in general and to what extent. To do this, evaluate the degree of damage present. If holes have formed in the roller coating, then it is recommended to fill them with mastic, observing the sequence of materials used for this.

Repair of roller roof should be carried out exclusively in the clean area. And this is very problematic, because on the roofing material there is a special sprinkle. For this reason, you need to carefully clean the site on which repair work will be carried out.

The crumbs can be removed using the use of technological oil. Anthraceen oil is best for cleaning the felts, and solar oil is used for roofing material. Clean the cleaning with an ordinary rag or brush. With this processing, you can remove sprinkling and soften the surface for further repair.

Repair work

After preparing the damaged area, you can go to the main work. With small defects, you can use ordinary mastic with a patch. But this solution is not suitable if all the roofing layers are broken.

In case of damage to several layers of the roof at the same time, it is recommended to clean the site from the old layer of mastic and dirt, and then dry. After that, it is necessary to prepare a mastic mixture with the addition of sawdust or sand. With this mixture, all existing damage should be spaced so as to level the edges. The mastic from all sides of the patch should go out by at least 10 centimeters.

With the help of hard brushes and brushes, mastic can be applied to the most inaccessible places. If you carry out work in a small area, it is advisable to use a simple spatula, which allows you to apply thick mastic and a mass with sawdust. If the water bubble occurs in the roof, the repair must be carried out in a similar way, as in the situation with the usual hole. The main thing is to determine the source from where the water comes from.

When the cracks appear in the roofing material, it should be cut to the lower layer. Then do cleaning of excess mastic and garbage, after which the site is dried and poured with new mastic. You can do without a cut if the cracks are small. They should be closed with a patch and mastic. If small cracks appeared throughout the soft roof, then it must be prepared and covered with heated mastic.

Restoration of sprinkling

After the repair of the soft roof, it is necessary to resume the remote layer of sprinkle to the place in order to avoid excess heating of the material and melting the mastic. To do this, smoothing the surface and cover the roof with sand. Excess spelling, which does not stick to the roof, will be removed over time. However, if you want, you can remove it yourself.

Now you have learned what advantages there is a soft roof - tightness, a long period of use and a tolerable price of laying a soft roof. Follow our instructions carefully to carry out the installation of flexible tiles correctly. Use recommendations about the choice of mastic and its preparation. And if during the operation of the roof there are small problems, re -read information about the repair of the soft roof.