The modern world is very demanding on the characteristics of materials. Everyone is trying ...

|

|

Excellent appearance, excellent technical characteristics and enough ... |

The ceiling is filled with siding is an inexpensive and practical option for its repair. Besides,... |

DIY DRIVEN

Drying wood is an important stage in the preparation of lumber for work, as a result of which excess moisture is removed from wood by evaporation. Why is this being done? Dry wood is characterized by high strength. It is much less bonded, easily glued, not subject to decay and cracking. Finished products are easily decorated and are distinguished by enviable reliability. Thus, the process of drying wood is mandatory if desired to get products of impeccable quality.

Content:

Wood drying methods

Types of wood drying are quite diverse. But they all pursue the same goal to obtain a reliable building material with improved physical properties.

Old drying methods

It is noteworthy that the evaporation technique was first used in ancient times.

A piece of wood was placed in a tank with water (70 degrees), sprinkled with sawdust on top and left to scachby. As a result, wood not only did not crack, but also acquired a dense flexible structure.

Another method of paraffinating was also used. The blanks were lowered into a liquid paraffin (40 degrees) and left for several hours. The tree, received in this way, did not deal, acquired a beautiful dark shade. Paraffination was most often used in the production of dishes. Wooden cups and spoons remained only painted with straightforward patterns and varnish. Interestingly, the products were so strong that they did not crack under any circumstances.

Natural drying of wood

Good material in a short period of time is not so simple. The way out of the situation may be fast drying of wood. If the tree is a churak (ridge) in the bark, then it is better not to remove the bark, but to make cutting across it across the barrel. You can leave a bark 10 cm wide only along the edges of the churak.

It is important!

Olha, birch, aspen, linden (even completely emphasized) with moderate drying dry without cracks. However, the ends of the logs should be covered with oil or resin.

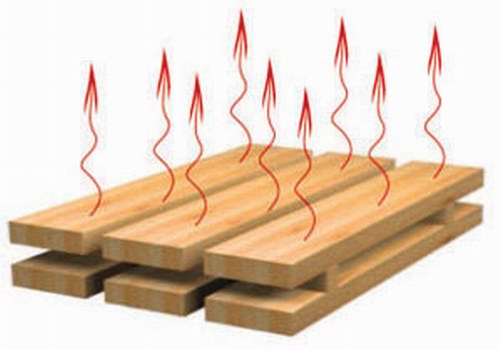

Dry lumber in a natural way in a well -ventilated, dry room. If you dry in the sun, then the outer surface will heat up, and the internal will remain wet, which will lead to the appearance of defects. The blanks are laid on stands with a height of at least 60 cm with stacks. There should be ventilated gaps between them.

There is an opinion that the boards installed on the edges dry twice as soon as possible. However, keep in mind that they will be more to deal. The technology of drying wood on the ends also gives cracks, you will have to cut the bars. That is why the blanks should be more than the required length.

Drying time of wood naturally is 2-3 years. This is one of the minuses of the method, because It is not always possible to wait for so much time. The pluses include the simplicity of the procedure and the lack of large financial costs.

Chamber drying

If the cost of drying wood does not matter much, because The itself is an excellent result, it is worth paying attention to other options.

Chamber drying is highly effective, allows you to monitor the process of the process and receive material of strictly necessary humidity. It is carried out in industrial conditions. Tara with a board is driven into drying installations, where, under the influence of a gaseous medium, fluid is evaporated. Wood drying modes are allowed to be changed at its discretion.

Dad chambers metal devices with aerodynamic heating. In the process of drying, it is necessary to add low pressure to the chamber of pairs. The process of operating difficulties is not. But such wood drying has a significant price, which is explained by a large energy consumption.

Roting drying

This method is based on the use of centrifugal force. Pilomaterial stacked with stacks are installed on a special platform inside the heated room. Centrifugal force helps to move moisture to the ends and external surfaces of the bars.

The intensive movement of hot air creates favorable conditions for uniform drying of lumber in the most red time. Special plates or lamps act as heat sources. The infrared radiation flow quickly spreads and penetrates to a depth of 12 mm. This means that the wood of conifers of wood with a thickness of up to 25 mm can be dried in a few minutes, which is several times faster than chamber drying.

Contact drying

Contact, or conductive, drying is realized by transmission of heat from the heated surface. The method is especially effective when working with thin materials with plywood or veneer. The sheets are clamped by the press between two warmed plates. The heat to the wood is transmitted through close contact, which explains the name of the method.

Atmospheric drying

One of the most common ways to obtain dry wood. It does not require additional energy resources and can be used at home.

The productivity of atmospheric drying of wood of the house depends on several factors. In particular, from moisture in the surrounding air, time of year, temperature of the medium. It is also worth noting that warehouse equipment for drying wood will require a lot of free space and compliance with some conditions.

- you can dry the wood under a canopy or in the barn, but necessarily with intense through ventilation;

- boards are laid in several rows with small intervals;

- to reduce the risk of warping, you can put something heavy on top.

In dry weather, the atmospheric drying method allows you to get wood with a moisture content of 12-48%. If necessary, then you can dry up to a smaller percentage in a well -heated room.

Drying in liquids

It is used as an additional measure before impregnation with oil antiseptics. The role of a liquid agent is aqueous solutions of mineral salts or hydrophobic substances (molten metals, paraffin, sulfur).

The duration of the process is limited by the intensity of heat redistribution in the dried lumber and the heat exchanger of the drying chamber. The wood is immersed in the liquid and brought to a boil. The constancy of the temperature regime remains until free moisture is completely removed. Drying duration 3-20 hours.

It is important!

On average, the duration of natural drying is from several weeks to several months. Artificial from several hours to several days.

Of course, this is far from a complete list of wood drying methods. There is still radiation, induction drying, drying in in the electric floor of the TVHR or using refrigeration equipment.

DIY DRIVEN

Not everyone has the opportunity to use professional drying units, but you should not despair. You can dry wood at home.

- we are determined with the place. The drying site should be in open space. It can be the middle of the garden or a flat roof of a low structure. Cover the surface with roofing material and sprinkle with sawdust;

- we lay the material. It is important to take into account the direction of the wind, the stack is laid across, and not along the wind flow. Stack width 1.2 meters (maximum). Optimally 0.8. The height can be any, but not less than 0.5 m;

- arrangement of supports. The goal is to raise the lower boards. The most reliable design is a well from a beam with a cross section of 50x50 mm. Put 2 wells 0.7 m high, lay the supporting gasket with a cross section of 60x80 mm. The recommended distance between the supports is 1.5 m. It is important that the surfaces of the upper gaskets are in a strictly horizontal plane;

- stuffing stack. The gaskets are additionally laid on the upper layer of the blanks, after which the ends of the lower and upper boards are pulled out with a rubber tape carved from a car chamber. Tape width 40 mm;

- wood protection. Boards should be protected from precipitation. However, there is no need to completely close the stack. Put several dry poles on the upper gaskets (along the length of the stack). On the poles, lay sheets of roofing iron until a visor is formed 15 mm. Put the dry poles on top, and so that they do not blow off the wind, pull it with a rope. The air interval of 8 cm should form.

That's all. Homemade drying installation is ready. Now you know how to avoid cracking of wood and significantly increase its operational characteristics. Let the products from their own dried wood will not only be beautiful, but also durable!

We dry lumber: video

Our company is engaged

Our company is engaged in the production of houses from a profiled timber 150x150 and 150x200.

During the construction of houses, customers have problems with the fact that Yurus is cracking. Is it possible to avoid cracks on the beam by drying of material in drying chambers?

What cameras can you choose for this?

If there is an opportunity to help, decide on the choice of drying chambers for the beam.

Sincerely, I'm waiting for an answer

Sergey Vostryakov

+79214919233

--

Chamber drying, baguette

Chamber drying, baguette workshop, platbands on windows, frames for paintings, wood carving

https://ncena.ru

Chamber drying

Chamber drying of lumber, production, lumber, board, timber, lining, imitation of timber, floor board, https://ncena.ru/proizvodstvo

Chamber drying

Chamber drying of lumber, baguette workshop, platbands on windows, wood workshop, wood carving. https://ncena.ru