The modern market for insulation materials is quite dynamic. Requirements change ...

|

|

Any person dreams of living in a private house with a personal plot, and very often ... |

Protection of any structure from moisture penetration The most important event ... |

We build a house on screw piles on our own

Screw piles are becoming increasingly popular in the construction of various types of buildings. They allow you to build a house on a short time and in a short time. We will consider further about the features of houses on screw piles.

Table of contents:

- The foundation of the house on screw piles - characteristics and features

- Piles under the foundation of the house of screw: the advantages and disadvantages of use

- Technology for building a frame house on screw piles

- The construction of the extension to the house on screw stilts

- Finishing the basement of the house on screw piles

The foundation of the house on screw piles - characteristics and features

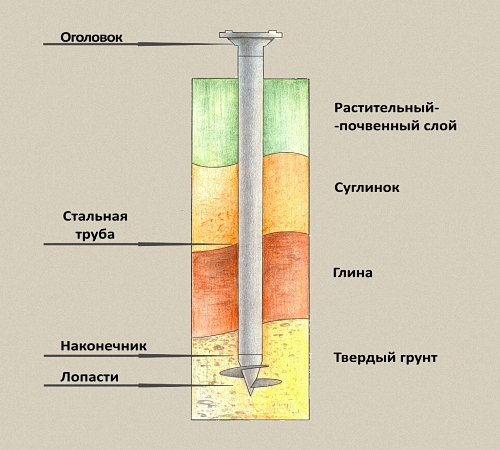

Screw piles are steel pipes processed using a special composition that makes them more persistent before corrosion. On the bottom of the screw pile is a blade that has the shape of a screw. With the help of this design, the piles are screwed into the ground like self -tapping screws, while there is not destruction, but soil compaction, which becomes even more durable. The bearing abilities of the soil remain at a high level.

There are three variants of screw piles for the foundation:

1. Rifle piles that have a screw blade - these pile options are relevant for soil with poor supporting abilities. Most of the pile has a cutting element that cuts the soil during its passage through it. This variant of the pile is also relevant if the soil is constantly freezing.

2. Piles, the diameters of the pipes of which have different sizes. Its weight depends on the size of the pile diameter, as well as the ability to withstand heavy loads. That is, when choosing such piles, it is necessary to focus on the total mass of the building, and in the relationship with this indicator, you should choose the diameter of the pile. If the pile diameter exceeds 10 cm, then specialized equipment will be required to install it.

3. The blades that differ in diameter on one pile. If the soil on the site contains a large amount of moisture, then the diameter of the blades on stilts increases.

Also, piles differ in the relationship with their shape and type. They depend on the producer of piles, materials that were used in the production process.

In relation to the type of tip, screw piles are:

- welded;

- cast.

The first option is cheaper and economically appropriate, a pipe is present in its composition, at the end of which a drill blade is welded. These piles are of low quality, so they are not used in the construction of massive structures. They are suitable for the manufacture of households or garages. With poor welding of the blade, it departs from the vertical axis and the foundation loses power.

A pile, which has a cast version of the tip has a higher strength. They are most often used in the construction of residential buildings. For the manufacture of the tip, a special casting method is used. The thickness of the blades in such a pile is about 12 mm, and in a diameter of about 30 cm. At the same time, the geometric properties of such piles have high accuracy.

For the manufacture of the pile trunk, a steel pipe is used, which has a tip at the end. Such piles are distinguished by high supporting abilities, they can withstand a load of 5 tons or more. The cost of a cast tip on piles is a quarter more than welded.

In addition, piles differ in type of coating. Some steel is treated with special anti -corrosion solutions, and the other with a polymer coating. The life of the foundation from steel piles exceeds a hundred years, with the correct calculation of the load on its base.

When buying piles in the market, be sure to require certificates of their compliance with all standards and factory standards. Since there are a large number of fakes that are difficult to distinguish from the appearance from real piles.

There is another version of piles, for the manufacture of which a thick -walled pipe is used. The reliability of the operation of such piles is at the same level with their cast options. They provide a strong base for massive buildings, they are also more stable before corrosion.

Piles under the foundation of the house of screw: the advantages and disadvantages of use

Among the advantages of using piles for the foundation, we note:

- speed of work on the construction of the foundation;

- lack of need to wait for the foundation;

- The ease of installation, small piles can be installed independently, for large piles, specialized equipment will be required;

- affordable cost, compared with the construction of a strip reinforced concrete base;

- the ability to use on various soil composition;

- lack of need for preliminary leveling of the site, since alignment is carried out by installing various piles in height;

- high resistance to loads;

- long life, in some cases exceeding a hundred years;

- lack of need for excavation.

However, this type of foundation also has certain shortcomings:

- The choice of poor -quality piles leads to their rapid destruction, uneven subsidence of the building;

- Installation of piles on soil with a high content of stones is quite difficult;

- The above advantages of the pile foundation are relevant only if the installation technologies are fully observed.

Technology for building a frame house on screw piles

In the process of erecting frame houses, screw piles are most often used. For these purposes, it is not necessary to hire specialized workers, a few people are enough.

The piles should be installed strictly in an upright position. Keep in mind that re -screwing piles is categorically not allowed, since their supporting abilities will be very reduced. Even if the pile is improperly installed, you do not need to remove it and screw it up.

In the ratio with the technology of building a house on screw -type screw stilts, two options are distinguished:

- Finnish;

- Canadian technological standards.

However, there are the same requirements for the construction of frame home, used in any case. We offer to get acquainted with them:

1. In order to build a frame house, separate frames should be used. For their manufacture, wood or steel is used. Ground frame constructions are more common. Among their advantages, environmental safety, ease of installation and accessibility is noted. The cost of steel frames is an order of magnitude higher than wooden, but their weight is slightly easier than that of wooden ones, so they do not create such a large load on the base. To connect wooden structures to each other, bent fasteners are used, and steel frames are interconnected using steel elements.

2. The floors in the house on screw stilts are equipped with a wooden beam. Initially, waterproofing should be equipped with roofing material. Next, a timber is installed, which will become a black floor. Before installing the draft floor, the manufacture of lag and installation inside from the insulation are made. Before laying wooden boards, they must be treated with antiseptic compounds. The type of insulation, which is installed on the floor is determined individually, taking into account the climatic features of the region in which its installation is performed.

3. After the manufacture of the floor, walls are installed. They are assembled on a flat horizontal surface, and then installed in place. Try to avoid distortions when connecting the frame with each other. To support the racks of the frame wall, ugsins are used.

4. When setting the walls, take into account the heights of the ceilings in the room, the optimal value is 250 cm.

5. After installing the frame, wall sheathing, installation of insulation is carried out, doors and windows are mounted.

6. Next, install the roof, perform its finish. After that, the internal and external decoration of the walls of the house is performed.

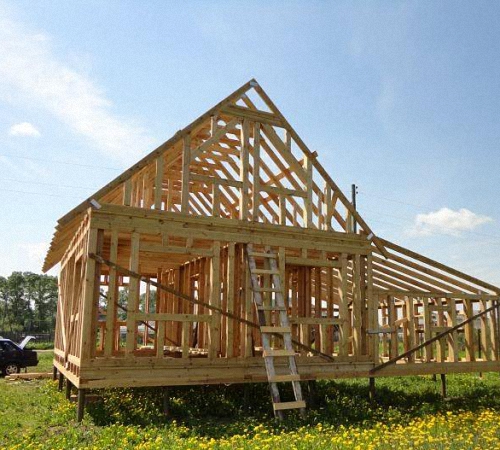

Houses on screw piles photo:

In order for the frame house to be suitable for living in it at any time of the year, you should take care of its insulation. Before starting insulation, decide on the type of thermal insulation material used in the process of work. It is preferable to perform insulation both outside and inside the building. To perform the interior decoration of the house, mineral wool and drywall are used.

Before finishing the facade, work is carried out on external insulation of a wooden house on screw stilts. Initially, a crate from a wooden beam is equipped on the walls of the house. Next, mineral wool or alternative insulation is laid. To close the cracks between the insulation, use the mounting foam. Take care of waterproofing and wind protection, since mineral wool is distinguished by instability to moisture.

Any room of the frame house should be protected from condensate. This is especially true for such a room as a kitchen, a bathroom. As a vapor barrier material, it is recommended to use a special membrane, which on the one hand protects the room from condensate, and from the second - removes condensate to the outside.

Since a tree is used for the manufacture of a frame house, the main part of the walls of the building is insulation. Preservation of its integrity is the key to long -term operation of the house. It is not recommended to install a plastic film as waterproofing material, since it negatively affects natural ventilation in the room. Use to protect thermal insulation material from moisture - breathing membranes.

Compliance with all technologies for the manufacture of frame houses is the key to successful and long -term operation.

The construction of the extension to the house on screw stilts

Using screw piles, you can quickly and without much effort build an extension to the main part of the house. Initially, you should determine the material from which the walls of the house will be made, then the number and type of piles used in the process of working on the extension are determined.

The easiest extension option is the use of frame shield structures that are insulated as necessary. Frame structures do not shrink, are easily and quickly installed.

First, the project of the future extension should be made, it clearly describes its size, the distance between the piles, their number. The condition of the soil on which work is carried out significantly affects the type of piles used in the construction of the foundation.

The best option - piles with a diameter of 10 cm. The length of the pile determines the evenness of the site, the presence of slopes on it, the load from the walls of the extension, etc. The first two piles are installed at an optimal distance of 400 mm between them. Further, the piles are installed in the ratio with a certain procedure specified in the project. To connect the piles, a corner, a channel or a profile pipe is used together. Keep in mind that the new pile foundation should not connect too much with the foundation of the new extension. Since in the process of shrinkage of the old foundation, the appearance of a distortion between two separate buildings is possible.

In the process of manufacturing an extension to the house made of wood, you should install piles, install headlines from steel on them, and mount the beam. After building the base, walls are built. The extension can be used as a hallway, verandas, kitchen, living room, etc.

The manufacture of the extension to the brick house also begins with the installation of piles, then the timber is installed. In this case, a beam or a channel is used for strapping piles. Also, screw piles allow you to build a terrace next to the house to receive guests.

Finishing the basement of the house on screw piles

There are several ways to close the space between the pile foundation and the floor of the building:

- manufacture of hinged basements;

- The construction of the foundation of a shallow type.

The first option is to install special wooden or steel guides on piles. Their fixation is carried out using self -tapping screws. Next, leaf material is laid, and the finishing of the ebb.

This version of the basement has the following advantages:

- economic feasibility - the performance of work on the manufacture of this type of base is much cheaper than the construction of a strip foundation;

- the presence of underground space and ventilation that prevents the appearance of mold or fungus;

- Aesthetic attractiveness, the ability to simulate expensive stones, wood and other materials.

The finish of the basement in this case is carried out:

- leaf slate;

- profiled sheet;

- thermal panels.

The second option is a fine -sized foundation of the tape type, involves pouring a concrete solution in a trench equipped with a screw pile. Masonry made of brick or cinder block is installed on the strip base, then it is finished.

Such a base is characterized by increased strength, does not need an additional insulation, allows you to create basements, has an attractive appearance.

House on screw piles video:

Build the house with your own

To build a house with your own hands is very time -consuming. It is much more convenient to entrust the construction of professionals. For example, the company "Daching Season" http://www.home-projects.ru/proekty_domov/ builds various types at an inexpensive price. It’s easier for me to turn to them.