Although the garage is not a living room, it also needs insulation ...

|

|

A wide variety of putty mixtures for repair work is presented on sale .... |

The strip-tower foundation for frame houses this is... |

Penophol: technical characteristics, advantages and disadvantages

The modern market for insulation materials is quite dynamic. The requirements for thermal insulation of the premises are changed, SNiPs are reviewed, customer requirements are tightened by energy -saving parameters of construction facilities. In response, the range of materials is expanding, and popular models improve their qualities.

One of the discoveries in the field of insulation was reflecting thermal insulation. The material is produced in rolls and has universal properties that combine the functions of heat, steam, hydro- and soundproofing at the same time.

- The structure and principle of the action of the foam

- Advantages and disadvantages of thermal insulation material

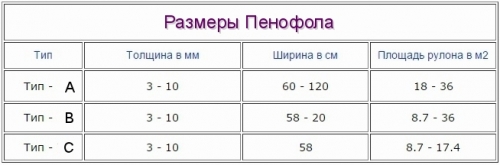

- Penophol: Technical characteristics

- The scope of the foam

- Types of foil foam

- The choice of the optimal type of foam

- Features of the styling of foam

The structure and principle of the action of the foam

Penophol foil multi -layer material from the class of reflective insulation. The main functions of the foam is the protection of structures from draft and wind, moisture and condensates, vapors rising up from the lower tiers of the structure, as well as from external sounds and noise. Penophol is universal with insulating material, since it is inherent in the quality of sound, steam, hydro- and thermal insulation. These properties are due to the structure of the material and the technology of its production.

The basis of the heat insulator is foamed polyethylene with closed pores that are filled with air. Polyethylene foam is used by various thicknesses, density and structure. On one or two sides (depending on the purpose of the foam), polyethylene is covered with aluminum foil. The foil undergoes pre -treatment to the maximum reflection coefficient (97% or more). Application of aluminum foil occurs by heat welding, providing a reliable coupling of materials.

The thickness of the base is 2-10 mm, foil of about 12-30 microns. The total thickness of the foam can reach 40 mm. The use of such an insulator is relevant only for regions with severe climatic conditions.

The principle of action of the penofol is based on the work of the vessel Dewar. James Dewar, at the beginning of the twentieth century, found out that any substance has a certain resistance to heat transfer. Regardless of the value of this indicator, the material can only slow down the process of heat transfer, but not stop it completely. At the same time, the substance accumulates thermal waves, thereby accumulating energy in itself. After a while, oversaturation occurs, and the material begins to secrete heat.

During the experiments, James Dewar determined a number of substances that do not have to absorb the energy of heat, but to reflect it. Such materials include: precious metals (gold, platinum, silver) and clean, polished aluminum. Heat rays, reaching the surface of the metal, are reflected by almost 99%. But, reflectors are good heat conductors, so they must be used in tandem with materials capable of absorption of heat.

A similar principle of work has a regular thermos, and the scientist’s research was based on the creation of spacesuits for astronauts and thermal insulation materials of the reflective type.

The use of one- and bilateral reflective insulators reduces the costs of heating the premises in the winter, and in the summer, in hot weather, slows down the heating of the house.

Advantages and disadvantages of thermal insulation material

The following qualities include the following qualities:

- The versatility of the Penophol material is used in the conduct of many repair and construction work, both outside and indoors. The insulation of the balcony with foam: photo

- The low vapor permeability of the insulation allows you to use the material independently, without arranging additional vapor barrier.

- High degree of sound insulation. Penophol is often used to protect houses, workshops from acoustic noise.

- The subtlety of the material is compared to other heat insulators. Bilateral foam 4 mm thick can replace a mineral wool layer of 8.5 cm, a wooden layer (pine) of 1.8 cm or 3 cm of extruded polystyrene foam.

- Simplicity of installation. The ease of material allows for self -insulation independent installation. At the same time, for work, it is not necessary to buy special tools of the fenophol canvas is easily cut with a knife, and fastened with a furniture stapler, tape or small nails.

- Environmental friendliness. Materials used in the manufacture of foam are used to store foods. Some manufacturers declare that the foam protects against radiation.

- Fire safety. The insulation belongs to the class of difficult and difficult materials.

- In thin foam, rodents will not be able to settle, which often arrange their holes in thicker heater.

- Convenience of transportation. Penophol canvases are twisted into rolls that are placed in the trunk of a car.

With all the diversity and indisputability of advantages, some disadvantages are also inherent in the insulation:

- Excessive softness limits the scope of foam. It is not suitable for insulation of walls for plaster or wallpaper.

- For fastening the penopol, special glue may be needed. This downside is deprived of the foam self -adhesive.

- Despite the good characteristics, experts do not recommend using foam as an independent insulation of external walls of buildings. It is attached as an additional layer to reflect thermal energy and protect the structure from moisture.

Penophol: Technical characteristics

Penophol has the following characteristics:

- scatter of operating temperatures from -60C to +100C;

- the coefficient of thermal reflection of the surface 95-97%;

- the heat conductivity coefficient depends on operating conditions and varies in the range of 0.037-0.052 W/ms;

- watering in volume of 0.35-0.7% - this indicator indicates reliable protection of the elements of the frame and ceilings from moisture penetration;

- with a 4 mm material thickness, the share is 44-74 kg/m3 (the value depends on the type of foam);

- the vapor permeability is not more than 0.001 mg/m h. This value allows you to name the foaming good barrier for evaporations;

- strength of strength during compression of 0.035 MPa;

- specific heat capacity 1.95 J/kgf;

- sound absorption of at least 32 dB.

The scope of the foam

For insulation of summer cottage houses and thermal insulation of high -rise buildings, universal foam is suitable. The characteristics of the material determined its wide popularity and demand, both in the construction of fundamental buildings, and when performing repair work at home.

Penophol is used for the following purposes:

- Thermal insulation:

- residential buildings;

- bath and saunas;

- administrative and industrial buildings;

- social premises (kindergartens, hospitals);

- heated and cold hangars and warehouses;

- mobile, stationary and capital trade pavilions and shops;

- pipelines of any purpose;

- refrigeration chambers;

- air conditioning, heating, water supply and ventilation;

- refrigerators, cars, auto -furgies and railway wagons;

- technical insulation of equipment (boilers, ventilation boxes, etc.).

- Processing elements of the structure:

- internal and external walls of the building;

- steam, hydro- and thermal insulation of the roof, attic roofs;

- floors and ceilings;

- overlap over cold basements;

- insulation of door and window systems;

- screening of heating radiators.

Important! Penophol reflecting not only will help protect the heat in the house in winter as much as possible. Laid under the roof, he will not let the scorching summer heat penetrate into the room

Types of foil foam

Manufacturers offer several types of foam for different purposes. Three classes of material are distinguished in the traditional classification:

- Type aOne -sided foam (a layer of aluminum film is applied on one side of foamed polyethylene). This species is used mainly as an addition to the main thermal insulation of foam or styrence.

- Type B.Bilateral foil penofol, universal and can be used as autonomous insulation.

- Type C. Self -adhesive type of insulation. On the one hand, a reflective layer of aluminum, and on the other, polyethylene with a moisture -resistant glue, protected sticker. The self -adhesive foam is convenient when finishing uncomfortable areas of the structure, so additional installation tools will not be required to work.

In addition to the standard types of Penophol, a number of modifications were also developed that occupied their niche in the construction market:

- type Alp Laminated foam, one of the foil sides of the insulation is covered with polyethylene film; ALP class foam is used to warm agricultural structures, which are operated in conditions of a slightly aggressive environment;

- types mand Rinsulation with one -sided foil, has a relief surface;

- penophol Airdesigned for arranging air -outing structures;

- penophol Super Net(translated from the English network) The main task of heat and vapor barrier of pipelines, air excrees and heating mains.

The choice of the optimal type of foam

The main parameters that should be taken into account when choosing a foam:

- type of insulation (one- or bilateral);

- the manufacturer is the company (it should be noted that the foam is the name of the brand, not the type of insulation; other construction companies make it under other commercial items);

- price category;

- the thickness of the material.

Here are some recommendations that will help you choose the optimal type of foam:

- The cost of the foam is primarily affected by its thickness and the number of aluminum layers. Standard dimensions of the material: 3.4.5.8 and 10 mm. One -sided foam with dimensions of type 3 and 4 mm of type A can be purchased for 50 rubles/m2. The 10 mm type P is considered the most durable and expensive, its price ranges from 100-130 rubles/m2.

- In the assortment of construction stores there is a mark of Penofol 2000 a cheaper analogue of standard penofol (you can buy material at a price of 35 rubles/m2). However, experts note that Penophol 2000 is inferior in strength to branded insulation.

- The optimal ratio of cost and operational characteristics demonstrates 5 millimeter foam (the price of such insulation is about 70 rubles/m2).

- For insulation of roofs, basements, saunas, balconies, ceiling and walls, type A foam and walls are suitable, it is better to use class B to arrange a tree floor, and for isolation of the machine and metal structures, Penophol type S.

Video: Comparative characteristics of the foam and its analogues

Features of the styling of foam

The maximum effect of insulation with foam will be achieved subject to some rules:

- When installing one -sided foam, the foil layer should look towards the heat source.

- A gap for ventilation of about 2 cm should remain between the insulation and structural elements.

- To seal the joints between the sheets of the foam, the foil tape must be used.

- The connection of the sheets of the joint in the joint will ensure the uniformity of thermal reflection. However, when insulation of the loggia, a docking is allowed to overlap 10 cm wide.

Important! During the fastening of the foam, we must not forget that the aluminum foil is an excellent electric current conductor. Therefore, with a close location of the insulation with electrical wiring, you need to take care of thorough insulation of the wires

By choosing foil foam, the characteristics of which correspond to the operating conditions of the material, you can not use additional steam, heat and waterproofing. In addition, it will be possible to save on the purchase of auxiliary and installation tools.