If you purchased a suburban site and decided to independently engage in construction ...

|

|

One of the most problematic stages of the organization of ventilation or chimney is their ... |

More than 30 companies represent aluminum composite panels on the market. Products from ... |

Roofing roofs made of galvanized steel

Today there are a large number of different building materials for the roof, but, of course, metal remains the most common for many years. This fact is easily explained by durability, reliability, strength of metal roofing coatings, along with their attractive appearance. The article will describe in detail about the installation of a roof of galvanized steel, as well as the methods of its repair and approximate cost.

Content:

- Roofing steel: types, characteristics, GOST

- Classification of roofing steel

- The roof device made of sheet steel

- The advantages and disadvantages of roofing galvanized steel

- Repair of individual damaged sheets

- Overhaul

- Galled steel roof tips

- The cost of a roof made of galvanized steel

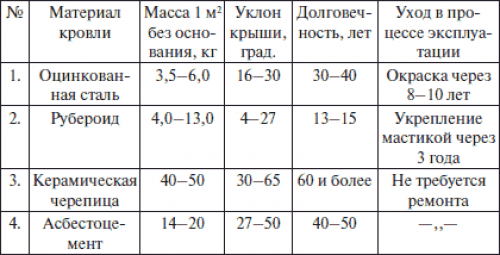

Metal roofs are made, as a rule, of steel, copper and aluminum. But due to the high cost of the last two, an indisputable leader can be called a roofing of galvanized steel, which happens in the form of corrugated board, sheet or rolled material.

In addition to the coating of the roofs themselves, roofing steel is used for the installation of cornice overhangs, gutters, drainage systems, m lands and other elements.

Roofing steel: types, characteristics, GOST

In addition to the fact that this material has a relatively low cost, it is light, due to which it is very convenient to use it for a roof to even a complex geometric shape. By the way, the fact that roofing steel should have such a light weight is marked by GOST, which also has a requirement to cover the material on both sides with a layer of zinc. In this case, zinc serves the protection of steel from corrosion, because uncovered steel itself has a short service life.

For this reason, the non -circular metal today is practically not used as roofing material.

To get the material that meets all the requirements of GOST (GOST 8075-56), the cold rolled steel is cleaned, after which it is annealed and placed in a zinc melt, obtaining a hot-valked cold-roll roofing metal as a result.

As a rule, sheets for roofs are produced with a width of 50-75 cm, 2 m long, 0.45-0.5 mm thick.

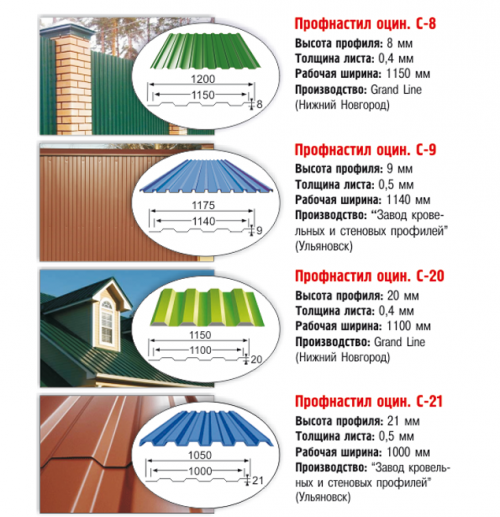

As for the corrugated board, it is a profiled sheets, also made of galvanized steel. It is used not only in roofing, but also as a finishing material (for wall cladding) or in the construction of fences. Its sheets have a maximum length of 12m, thickness 0.4-1.2 mm. The main quality criterion is compliance with the requirements of GOST 24045-94. Its main advantage is that it has a wide selection of color scheme.

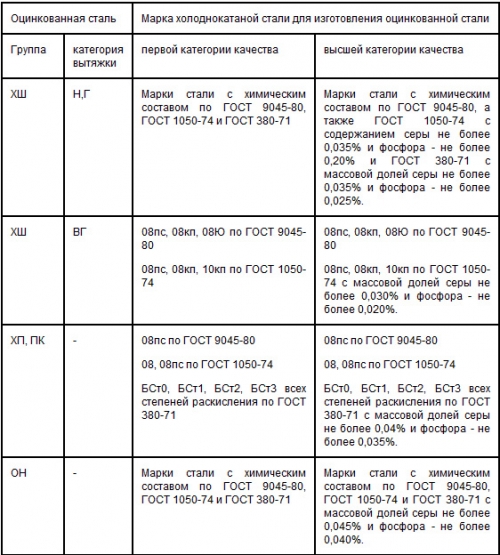

Classification of roofing steel

Roofing steel is carbon and alloyed. Carbon is obtained by rafting iron and carbon. The alloyed have one or even several special elements that provide improved physical and mechanical properties. Moreover, depending on the additives included in the composition, they are low alloyed, average and highly alloyed.

Most often, carbon steel and low alloy steel are used for the roof (which contains not more than 2.5 % of special alloying substances), and the average -aged and highly alloyed is used for this quite rarely, since they are designed for structures that require increased corrosion resistance.

Depending on the purpose of the roofing steel (in what conditions the roof will be), it is customary to divide it into:

- Ordinary;

- High -quality;

- High -quality;

- Especially high -quality.

The difference between them is the content of harmful impurities, such as phosphorus, sulfur, non -metallic particles, the presence of which worsens the characteristics of the material.

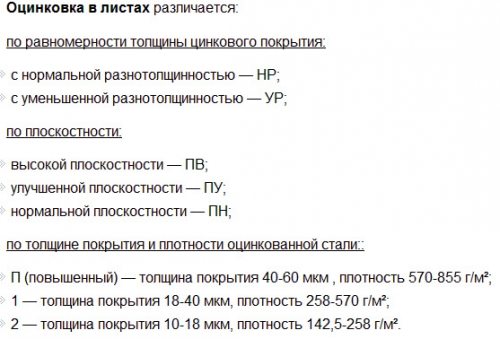

In addition, roofing steel, depending on the thickness of the sheet, differs in:

- Thin -leaf (thickness up to 0.39 mm);

- Sweetial (thickness more than 0.40 mm).

But it is worth noting that according to the requirements of GOST, it should be not thinner than 0.45 mm, which is why thick -faced steel is much more often used.

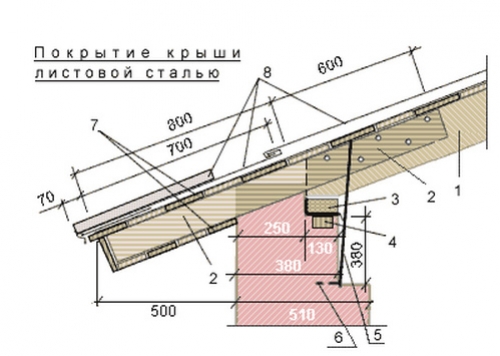

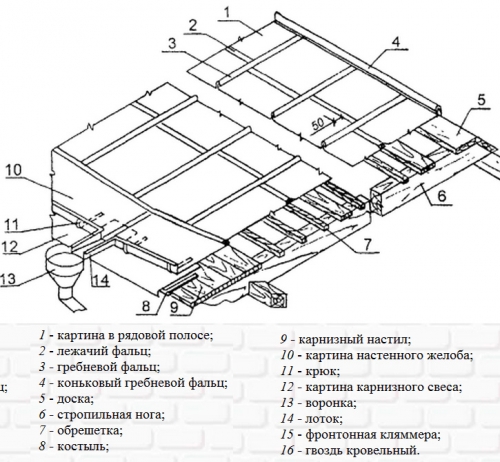

The roof device made of sheet steel

- rafter leg;

- mare under the overhang;

- mauerlat under the rafters;

- cork for Mauerlat;

- wire twisting for Mauerlat;

- crutch for twisting;

- rafter sheathing;

- the roof is made of steel sheet.

The advantages and disadvantages of roofing galvanized steel

Galchained steel does not have a pernicious effect on human health and the environment. In addition, due to the high reflective properties of zinc, the material prevents the roof overheating in summer sunny weather. Also, due to zinc, the life of the roof is 20-30 years or more.

The alloyed steel includes a polymer plastisol, which makes the coating also plastic and with increased mechanical strength.

The roofing galvanized steel also has its own disadvantages, one of which is low sound insulation - inside the house the noise of rain and hail can be heard.

When the zinc coating is not very high quality, matte gray stains may appear on the surface of the roof, which indicate the beginning of metal corrosion, and this is a sign that the roof may need repairs.

Repair of individual damaged sheets

If you need to get rid of minor traces of corrosion, then the rusty spots that appear should be removed with a soft steel brush. After that, the surface is cleaned of dust, dirt, old paint, washed, degreased, dried and painted over with oil paint. It should be borne in mind that for this purpose, not any coloring composition is suitable, for example, alkyd paint when interacting with zinc will lose its adhesive properties due to the oxidation reaction, and the service life of such a coating will be reduced to one year, or even less. It is required to use special paint with great elasticity and good adhesion. Acrylic soil-enamel that has a long service life is best suited for this. The only thing is that the cost of such paint is higher than the cost of ordinary oil paints.

But in any case, such a measure will cost cheaper than replacing the roof, and the painted roof looks more elegant than just galvanized. The paint is applied with a roller, brush or spray gun.

If it is necessary to eliminate the cracks between the sheets, then they can be sealed. First, the joints are cleaned from rust with sandpaper, and then the connected sheets are tightly fitted to each other. The next step is surface processing with chloride zinc. To solder the surfaces, a soldering iron is required, which is previously rubbed with ammonia and heats up. After that, a solder is applied to the ends of the sheets. When everything cools down, an extra solder removes.

In this case, chloride zinc should not be prepared independently, since improper mixing of the components can lead to an explosion. Such work needs to be left to professionals who will do everything according to GOST.

But soldering on the roof is a very difficult procedure, so today it is increasingly replaced by gluing with various modern sealants and adhesives. You can use epoxy automobile putties and putty. There are sealants in tubes intended specifically for the repair of the roof. In this case, it is convenient in this case that when buying such a sealant, in a construction store should tell in detail about the method of its use.

To repair individual leaked sheets, you can use patches, which use burlap, or other dense fabric.

The burlap is cut into squares or rectangles of the desired size, after which they are placed for 1-2 hours in a densely diluted paint so that the material is saturated. Then, the prepared patch is laid to the damaged place and carefully smoothed. Particular attention should be paid to the edges. When the patch dries well, if possible, the entire surface of the roof should be painted, including patches. For the best effect, color should be done in 2-3 thin layers.

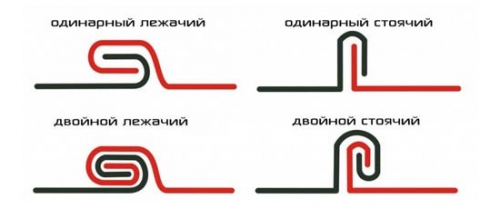

Also, for the repair of individual places, you can use sheets that are slightly exceeding the area of \u200b\u200bworn area, so to speak, with a allowance. This allowance is needed for connection. The damaged place must be opened and a sheet of patch must be laid on it. To connect the patch with the old leaf, standing and lying folds are used, on especially gentle slopes, it is best to compound the seap of seams.

Before installing the patch, it must be in -line, and at the end of its installation, it is painted with atmospheric colorful composition. Also, this colorful composition needs to paint the places of all connections in order to provide protection against corrosion.

Rolled galvanized steel is also used as patches. In this case, after the surface of the roof is cleaned of rust and garbage, the roll material is covered along and across the roof falsettes. Such patches are fixed, as a rule, by applying hot bitumen. Metal patches can be fixed with the same sealants and adhesives.

Such types of repairs are rational if damage occupies less than 40 % of the area, otherwise it will be more advisable to change the entire coating. Since with such extensive damage, repair repair will require much more labor and time than the device of a new roof made of galvanized steel.

Overhaul

Overhaul will include the following mandatory operations:

- full removal of the old coating;

- complete replacement or repair of load -bearing structures;

- antiseptic and fire -retardant impregnation of supporting structures;

- vapor barrier device;

- installation of a new roof;

- its coloring;

- drainage device;

- the device of fences around the entire perimeter of the roof.

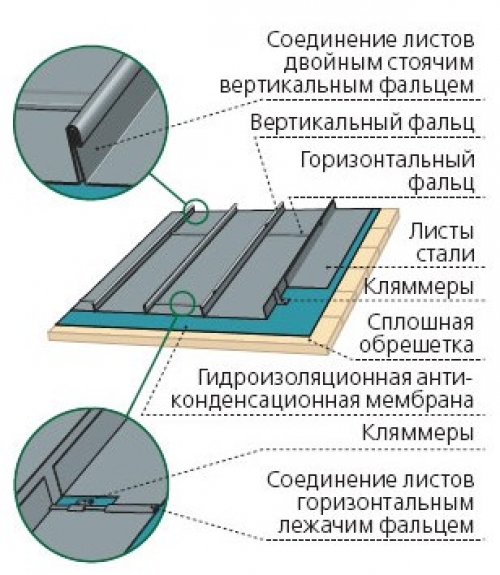

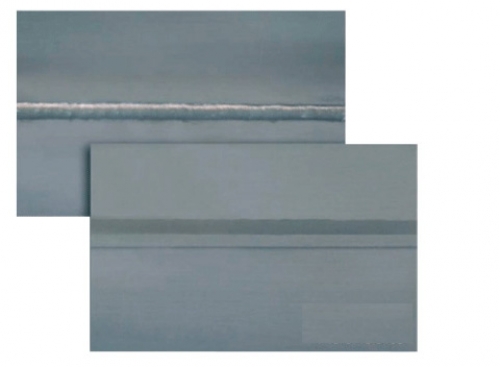

Installation of a new roof made of galvanized steel can be performed in two ways of fold (leaf and rolled) and using corrugated board. The folding method consists in traditional technology, when individual sheets are connected by an butt seam called a fold. It is lying (it goes along the length of the slope), and standing (goes in height of the slope).

If desired, this seam can be performed double, to enhance the strength of the connection. In this case, the steel sheets are attached to the crate not on the nails, but with the help of Klyammers (stripes of roofing steel), and one end of the Kleammer should be attached with nails to the crate, and the other bent behind the fold.

In order not to have to be repaired again, during installation, mechanical damage to steel sheets should be avoided. To do this, it is better to use special roofing self -tapping screws that have an elastic gasket made of silicone under the hat during operation.

More modern is folding roll technology. It consists in the device of the roof not of sheets, but from rolled material. This method involves a much smaller amount of transverse seams, and in some cases they are completely absent. For the Russian climate, such a technology is the most suitable.

During the overhaul, you should not neglect the quality of the crate, since the durability of the fold roof depends on its condition, because if the sheets are bend, then this will weaken the density of the joints, as a result of leaks and the destruction of the coating.

For the installation of corrugated board, there is a need for additional elements (skates, yends, etc.), since a small defect in this material may appear during the device, and additional elements will help to hide this. Most often, the installation of this type of roof from galvanized steel is made by professionals.

Galled steel roof tips

In order to alienate the need for repair, it is important not only to choose high -quality material and install it qualitatively, but also to operate correctly, observing a number of care requirements.

Firstly, immediately after installation, roofing galvanized steel should be painted, this will extend its service life. To extend the service life, you can also cover it with an anti -corrosion primer, which will serve as protection against natural destruction.

In addition, it is required to periodically remove the settled dust and dirt from the surface of the roof. It is best to do this with a soft broom.

About 10 years after the installation of a new roof, its surface must be completely painted again, and in the subsequent this operation will have to be repeated after 2-3 years.

Obviously, it is easier to eliminate minor defects than large ones. Therefore, the roof should be periodically carefully viewed in order to detect damage and eliminate them, so that they do not lead to extensive defects.

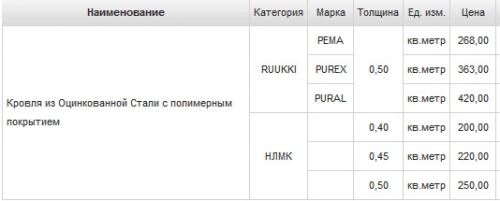

The cost of a roof made of galvanized steel

To calculate the final cost of the finished roof, first you need to calculate the total area of \u200b\u200bthe roof, the length of the skate, the total length of the apples, pediments and cornices.

The resulting dimensions are multiplied by the price of roofing material with delivery. Also, the cost of related materials, such as a vapor barrier film, fasteners, insulation, lumber, etc. should be taken into account. If the work is not carried out independently, then another amount is added to pay for installation work.

Below is the approximate cost of materials, and work on a roof made of galvanized steel.

Roofs made of galvanized steel photo

I work at a factory that

I work at the factory that specializes in the automotive industry. When we need a steel sheet with delivery, we contact the company "Steel-Pro" https://steel-pro.ru/list/list-stalnoy/. During cooperation, they have established themselves as a reliable partner providing high quality products. I recommend to all