For a long time, the apartment renovation was limited to the arrangement of the interior, ...

|

|

The facade of the building and the quality of its insulation is the main factor that determines the value ... |

To make a docking of two linoleum paintings invisible and durable is used ... |

DIY transparent roof

Private housing construction has not been complete for several years without arranging a transparent roof. If at the end of the last century the houses with a roof of transparent materials hit the gaze, being considered original and unusual, today the introduction of the latest technologies into the construction industry determines the widespread spread of a transparent roof, which has become not only a whim of creative people, but also an affordable way to diversify the appearance .

Content

- Transparent roofs: ordinary or architectural sophistication?

- Transparent materials for roofing

- Polycarbonate: main varieties

- Advantages of transparent roof from polycarbonate

- The main design features of the transparent roof

- Materials used to install profiles

- Polycarbonate roof: installation features

Transparent roofs: ordinary or architectural sophistication?

Adherents of conservative construction, who want to give their home a certain highlight, get the opportunity to abandon the construction of a transparent roof for the whole house, limiting themselves to the construction of such a roof only for a terrace, a summer or winter garden or even an independent room with a covered basin. The transparent dome of the roof ceased to be an architectural stake and in the external structures of cozy houses for picnics, arbors and other independent rooms.

Thinking about the construction of a transparent roof, the photo presented in the article will help not only decide on the design solution for the roof, but also choose the most suitable building materials.

Transparent materials for roofing

As for transparent materials for the roof, they can be very diverse. The modern market provides the opportunity for developers to choose the most suitable material for a transparent roof, having familiarized themselves with a wide range of materials proposed made in accordance with the latest technological solutions. The most common materials are:

- Glass with not only aesthetic, but also functional characteristics, among which it is necessary to note protective, heat and sound insulation qualities;

- Wheel -glazed windows that imply the presence of two or more glasses, hermetically connected along the contour, the gaps between which are filled with inert gas. For the production of double-glazed windows, the use of various types of glasses is practiced, and the features of their design allow a transparent roof to provide effective heat and sound insulation.

- Polymeric materials, among which manufacturers offer to pay attention to polyester, polyvinyl chloride and acrylic, used by manufacturers that specialize in the implementation of the Euro -Shitter for the manufacture of transparent wavy sheets and their modifications. They will be an ideal option for developers who decided to equip the desired architectural structure with a transparent wavy roof. However, each of the three materials listed, despite the common optical transparency for everyone, has special characteristics. For example, according to the results of the studies, the most resistant to high temperatures was a polyester that withstanding a temperature of -40 to +100 degrees, while Acryl demonstrates the best properties at a temperature of -20 to +70. In addition to resistance to temperature conditions, transparent roofs from PVC, has proven itself as the most moisture -proof structure.

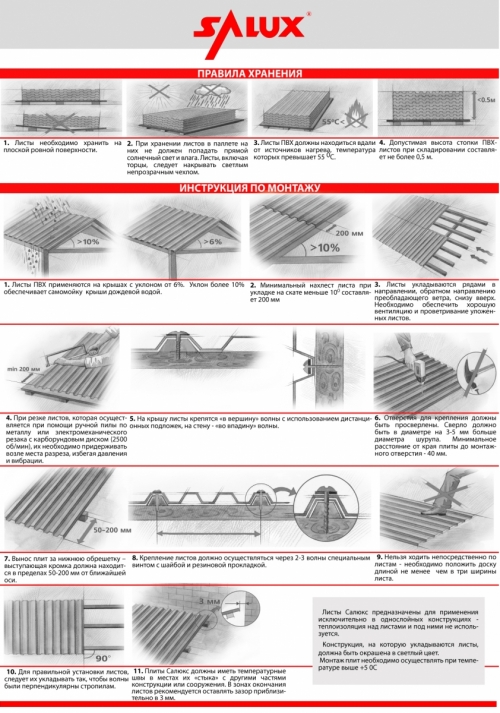

One of the companies specializing in the production of PVC sheets is Salux. The transparent roof of Salux, made of profiled PVC sheets, will become an ideal light -transmitting constructive addition of the building that protects from wind and characterized by low weight and self -cleaning ability.

Polycarbonate: main varieties

Another optically transparent material is polycarbonate. The transparent roof of polycarbonate is the most resistant to record high temperatures, which is considered one of the reasons for their high cost. Manufacturers produce polycarbonate in the form of monolithic and structured panels.

Monolithic polycarbonate will be the perfect choice for both flat and curved structures, however, in most cases, the owners of suburban sites prefer structured polycarbonate in view of its lower cost.

Advantages of transparent roof from polycarbonate

Roofs from structured polycarbonate, also called cellular, are characterized by the following advantages:

- Low weight that allows you to realize the most daring design ideas, raising light roofs, without spending prohibitive amounts;

- High heat and soundproofing characteristics;

- High flexibility that allows organizing a roof of various configurations;

- Increased resistance to the effects of chemical reagents and the lack of a tendency to fire;

- A long operational period reaching 10-12 years.

The main design features of the transparent roof

From the point of view of the design features of a transparent roof, experts suggest highlighting the following options:

- Light -transmitting roofs, the features of which imply the use of specialized systems;

- Transparent roofs from self -supporting elements;

- Roofs designed in the form of attic windows.

The most common constructive option is a transparent roof that implies the installation of specialized systems, carried out using light transmitting elements, in the role of which sheets of cellular polycarbonate often act.

In view of the fact that the transparency of the structure is the main reason for the use of this type of roof, the use of waterproofing materials and insulation is unacceptable in the process of installing a transparent roof. This necessitates the correct choice of materials for the manufacture of frame profiles, which are able to independently provide the necessary level of heat and waterproofing. Moreover, correctly selected profiles provide the strength of the structure, which is the fundamental property of a transparent roof.

Materials used to install profiles

- If you plan to organize a roof with large spans, your version is steel;

- For builders who decided to prefer small and medium spans, it is more profitable to choose aluminum;

- For a roof with small spans, it is preferable to opt for PVC profiles.

Polycarbonate roof: installation features

- If you plan to do the arrangement of a transparent roof for the terrace, the instructions presented in the article will help you deal with all the nuances of its construction.

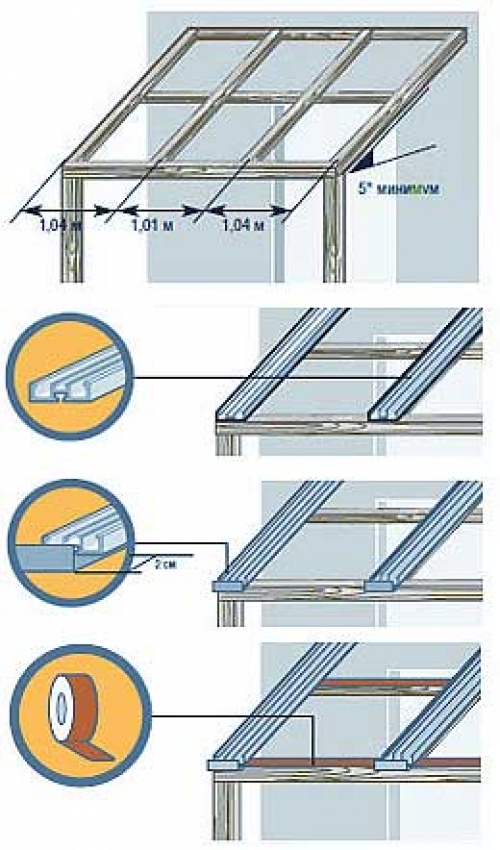

- First of all, a supporting roofing system is made, which is a fundamental link during the construction of a transparent roof, while the slope of the roof can range from 50 to 100 degrees.

- For this rafters, the sections of which reach 60x80 mm, are strengthened so that the distance between the opposite edges of the roof is 1.05 m, while between the centrally located axes of the rafters it should be 1.01 m, which is dictated by the width of polycarbonate plates.

- On the rafters, the end and then connecting profiles corresponding to the dimensions of the plate from polycarbonate are mounted.

- At a distance equal to at least 2 cm from the edge of the profiles, limiters are strengthened through rivets.

- At the end of the installation of the supporting structure, they proceed to the fastening of polycarbonate sheets. In view of the fact that the fasteners of cellular polycarbonate are characterized by increased water resistance, there is no need to process the seams using mastic.

- To protect the roof from reflected sunlight, the side surface of polycarbonate plates is glued with tape.

- The upper face of the plates is also glued with standard tape, and the lower perforated. This manipulation will protect the internal structures from the penetration of dust and small insects. If you use a polycarbonate treated with a protective composition, which prevents the effects of ultraviolet radiation, the plates are strengthened by marking up.

- Further, polycarbonate plates are fixed in the grooves of profiles so that the gap between them is at least 5 mm.

- Having fixed the plates using profile fasteners, a protective film is removed from polycarbonate and plugs are installed.

At the end of the work, the joints between the plates and the supporting profiles are processed with silicone mastic, while the compounds between polycarbonate plates do not need sealing.

The transparent roof, made in accordance with the above rules, does not need specialized care, as it is washed with the help of rain or, if necessary, with the help of a conventional sponge and soap, and is characterized by a long service life reaching 50 years.

who knows how to repair

who knows how to repair holes from the city in Salyks?