Parquet is one of the best, natural flooring and with ...

|

|

The scope of the polyurethane foam is quite wide, but most often it is used in ... |

Even homeowners, far from the basics of construction, will not occur to it ... |

Linoleum welding: video, step -by -step instructions

To make a docking of two linoleum paintings inconspicuous and durable welding is used. There are several technologies for conducting this process, each of which differs in its own characteristics. About how to glue linoleum and which way is better to choose to consider further.

Table of contents:

- Linoleum welding - features and varieties

- Cold welding for linoleum - features of conducting

- Glue for linoleum welding - recommendations for use

- Tips for conducting and choosing the type of welding of linoleum seams

- Hot welding of linoleum - technology and characteristics

- Feng for welding linoleum: Features of application

Linoleum welding - features and varieties

Linoleum coating is characterized by high strength, affordable and durable in use, so this finishing material is in high demand among consumers.

The only difficulty that occurs in the process of laying linoleum is its combustion. When arranging a small room with the shape of a square, linoleum is laid with a whole sheet. But, in most cases, it is required to equip the premises of irregular shape, in which two or even three areas are jointed. In this case, the right decision is required in choosing a conjure. If this is not done, then over time, the end areas of linoleum will bend and twist.

In addition, if there is a linoleum with a certain pattern, it is necessary to make sure that it coincides at the junction.

Experts distinguish two types of linoleum welding:

- hot welding;

- Cold welding.

The first option is common when laying industrial linoleum in public institutions. The procedure for carrying out this method of joining is the processing of the end sections of linoleum using a high temperature of more than 350 degrees. Next, a special cord is sewn in them, which ensures the strength of the connection. It is on this seam that the docking of linoleum takes place.

This method of laying linoleum is also called industrial, due to its distribution when laying linoleum in public places or enterprises. In residential premises, this method of laying is practically not used. Since specialists are required to perform such work. Hot welding is common when laying linoleum in cinemas, cafes, bars, schools, etc.

The second option is cold welding, is used in the combustion of linoleum intended for installation in residential premises: houses, apartments or cottages.

For work, a special tool and special skills in working with it are not required.

Cold welding for linoleum - features of conducting

One of the most modern methods of incorporation and compounds of linoleum is cold welding. It is based on the use of a special adhesive composition, with which the formation of a colorless seam is formed, which is determined by the touch, but in appearance it is absent on the surface.

Among the advantages of the use of cold welding in everyday life, they distinguish:

- The formation of a monolithic coating - seams that remain after welding reliable and neat, at the same time, when using hot welding, the surface is rude, and in some cases, even a change in color;

- It is not required to use special equipment to heat the surface of the linoleum up to 350 degrees, in the work it is necessary to use standard tools, so the cost of such a connection is significantly reduced;

- This method does not require the use of special physical efforts or special experience, the procedure is easy and simple.

Several varieties of cold welding methods are distinguished, we offer to familiarize themselves with them:

- cold welding using glue A;

- the use of glue C when welding;

- A less popular way with gluing by glue T.

Each of these options is characterized by special criteria for its choice. Therefore, in order not to make a mistake with glue, you should accurately determine the type of linoleum, its composition and the specifics of the combustion.

The most liquid consistency is the use of the first type of glue. A significant part of its composition is occupied by a solvent. It is because of this that it quickly and easily dissolves when gluing. Glue A is convenient when connecting linoleum with small seams, since in the presence of areas requiring a connection exceeding two millimeters, it is necessary to use a different type of glue. This option will not be able to welcome quality, due to too liquid shape.

Among the advantages of using this type of glue should be highlighted:

- compound strength;

- ease of application;

- accuracy and invisibility of seams;

- The duration of gluing.

It is recommended to use glue A to glue the newly purchased linoleum, since its sheets are cut at the factory and have a perfectly flat surface. When linoleum is cut at home, the end areas are not so neat, but, accordingly, the appearance of the coating also suffers. For such linoleum, it is recommended to use glue C with a more thick and rich composition.

The composition of the glue C contains a large amount of polyvinyl chloride, respectively, the solvent in it is present in a small amount. Due to its density, glue is able to fill large cracks. This type of glue copes with the restoration of already damaged linoleum. The use of glue is allowed in the presence of gaps, the size of which does not exceed four centimeters. Upon completion of the work, a durable and neat seam is formed, which is almost invisible.

The third version of glue - T - is less common among non -professionals. Its use is associated with the gluing of a multicomponent type linoleum, which consists of polyvinyl chloride and polyester substances. This type of cold welding provides a reliable, elastic, neat connection.

Instructions for cold welding for the collection of linoleum:

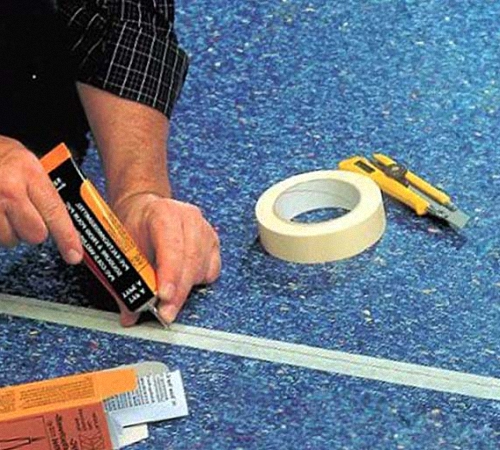

1. At the place of installation of the seam, a strip based on double -sided tape should be glued, thus it will be possible to avoid spreading cold welding on the floor or on linoleum.

2. Then cut this strip at the junction, while do not touch the coating.

3. The use of glue should be carried out with the presence of a special nozzle, in the form of a needle, which contributes to uniform squeezing of glue.

4. Insert the needle into the surface between the sheets of linoleum, using a light press, begin to introduce glue into the gap.

5. Leave linoleum fifteen minutes until the glue dries completely.

6. Remove the tape from the surface and check the evenness and accuracy of the seam.

Glue for linoleum welding - recommendations for use

To facilitate cold welding, you should take into account several recommendations that help avoid small flaws in work and conduct it as efficiently as possible:

1. When buying linoleum, keep in mind that the size of the overlap between the joints should be about 60 mm. With its help, it will be possible to carry out the maximum smooth section of the linoleum canvas. The surface of the joint will reach maximum evenness.

2. During the work, use special protective gloves that help protect the surface of the skin from the aggressive effects of glue.

3. The use of the needle tip contributes to the maximum filling of the cracks.

4. If glue gets onto the surface of the linoleum, it is necessary to wait for its complete drying, and only then remove the glue from the surface. To do this, use a stationery knife.

Tips for conducting and choosing the type of welding of linoleum seams

When choosing the type of welding of linoleum sutures, you should proceed from the type of coating and the complexity of the seams that need to be connected. For example, complex rotary seams are more difficult to combine, while curly and straight lines are easier.

Hot welding is carried out only after the installed linoleum has already been fixed on the floor using glue. This procedure requires special experience, since work should be carried out very quickly. Even before the cord cools, it should be cut and polished in order to make the surface invisible.

To create a hermetically closed seam, it is necessary to cook linoleum panels. Using a conventional electric soldering iron, this procedure is almost impossible.

For a correct and even connection, a linoleum overlapping a few centimeters should be laid, and cut linoleum with an even line.

When using an electric soldering iron, the connection of a copper wedge at a right angle should be provided. In addition, the wedge of the wedge is required for several millimeters. To ensure a light sliding of the wedge on the surface between the joints of linoleum, it should be sharpened on both sides.

The soldering iron is carried out between two canvases in such a way as to ensure its uniform sealing and softening. This type of welding should be used when welding a domestic type linoleum. Although when using it, you should be extremely careful, since it is characterized by a too high level of softness and seams, and after a certain time will begin to crack.

Commercial type linoleum has increased strength, while its cost is also higher. In addition, when combining complex seams, it is better to use the cold welding method.

Hot welding of linoleum - technology and characteristics

Linoleum, which contains a large number of natural components joins using hot welding. For work, special equipment will be required, which heats and cord for welding linoleum. It consists of illuminated materials, which, under the influence of high temperature, pass from a solid to a liquid state.

With the help of solidification of polymers, which occurs in the process of reducing the temperature, joints are sealing, which become almost invisible.

To create a certain temperature, for welding, it is necessary to have a device for welding linoleum. This device is compact and works from a standard power grid.

Instructions for hot welding of linoleum sutures:

1. Before starting work, it is necessary to prepare a special knife with which the processing of the end sections of linoleum will be processed.

2. A surface in the form of a groove reaching the main part of the coating should be obtained.

3. Clean the docking surface of debris or dust.

4. Turn on the device to heat linoleum, and warm it to the mark of 360-390 degrees.

5. Install a special nozzle in which a welding cord will be located.

6. Install the cord in a pre -prepared groove, while measuring its length, the size of a slightly larger than the docking seam.

7. Start heating the surface with a hairdryer, gradually running along the docking line.

8. Pay attention to how the cord melts.

9. When the welding is completed, begin to remove the excess cord, it is recommended to use a sickle -type knife and special equipment in the form of a nozzle for cutting the cord.

10. Follow the accuracy of the work, set the knife with a nozzle in parallel to linoleum to prevent its damage.

11. The brewing of one cord occurs in two stages. Start working on the opposite side, and complete the overwhelming of two parts of linoleum at the site of the overlap.

Tip: Despite the ease of conducting the above process, its execution requires special skills in working with tools, so you should not carry out hot welding yourself, unattended or helping a specialist, since there is a risk of damage to linoleum.

Feng for welding linoleum: Features of application

To carry out the welding procedure, you will need:

- flange for welding linoleum;

- Feng nozzles;

- The addicted rod, in its quality is a polyvinyl chloride cord used in the filling of the seams, is oval, rectangular or triangular, its melting begins when heated up to 320 degrees, when choosing a rod, pay attention to its composition, it must coincide with the composition of linoleum;

- sickle knife.

The use of an industrial construction hairdryer will help to carry out hot welding. Its main difference from the domestic hairdryer consists in a higher heating temperature. A high -quality construction hairdryer has the ability to heat up to 600 degrees. Maintaining a given temperature is carried out using special sensors. When choosing a hair dryer, follow the number of degrees of temperature adjustment.

With prolonged welding of linoleum, the presence of sufficient hairdryer power is required, which will prevent it from overheating.

Before the soldering, it is necessary to remove the chamfer from the coating strips. Thus, a wedge -shaped groove will be obtained. It is it is designed to fill with polymer solution. A special nozzle dressed on a hairdryer will allow the polymer solution to this groove. This is followed by the lacing of the cord into the guide inclusion and heating of the hairdryer.

Clutch the hill gutter to the seam tightly and heat it until the polymers are completely melted. Follow the uniform work of the hairdryer in all areas of linoleum. With the thinning of the polymer layer, it is recommended to increase the temperature of the hairdryer. Keep in mind that the polymer should not protrude on top of linoleum. In order to avoid this process, the excess cord should be cut with a sickle knife. Thus, it will turn out aesthetically attractive and neatly conjured.

Tip: the use of a hair drying hair dryer is relevant when the dense linoleum is welded. Otherwise, too thin linoleum simply will be pasted and deteriorate.

Linoleum welding video: