By finishing the basement of the building with a brick, it is possible to give him grace and ...

|

|

Foam was actively used already in the middle of the last century, but in recent years it ... |

One of the possible ways to get a perfectly even surface of the ceiling in the apartment or ... |

Eating slabs: features and characteristics of the material

The floor slabs are inexpensive, convenient and indispensable, in many cases, building materials. With their styling, you can complete the construction of the garage, separate the basement from the main building of the building, remove the floors or use as part of the overall roof structure. Like another similar building material from reinforced concrete, used in various fields of construction and laying of underground gas highways, the floor slabs have several varieties. They differ in several parameters with their characteristics.

Table of contents:

- The use of floor slabs in installation work

- The main advantages of building materials

- Varieties of floor slabs

- Basic technical parameters and labeling products

- Features of hollow floor slabs and marking

- The main technical parameters of the floor slabs

- Floor slabs as a foundation

- Storage and transportation of floor slabs

- Features of laying slabs laying

The use of floor slabs in installation work

The extensive scope of the use of floor slabs is understandable this excellent material for typical construction, for the high -speed construction of retail space, the construction of industrial enterprises and other facilities. It is occasionally used for private household, for example, for laying on the foundation on top of the basement or basement. They are great for the rapid construction of block, stone and brick buildings, with large -panel installation, as well as for the base under the house of rapid wood assembly.

There are also non -standard varieties of floor slabs, for example, tent is often cast for overlapping throughout the size of the room in the form of a dome or pyramidal shape. However, their cost can be many times higher than the cost of standard plates, and the size depends on the architectural project.

The main advantages of building materials

1. Thanks to the system of crossing beams and reinforcing with the filling of concrete, such reinforced concrete structures can withstand a rather impressive load.

2. Today, plates are made from high -strength concrete according to the latest technologies to obtain high -quality material. For example, they found widespread use in the zone of seismic activity.

3. Hollow building material has excellent thermal insulation properties, it is frost -resistant and contributes to fire safety.

4. With competent installation, standardized building materials provide water resistance in the building and performs other insulating tasks. For example, it prevents the penetration, noise, steam, gas in other parts of the structure.

5. Claus slabs are able to provide absolute horizontal surfaces, especially with competent adjustment of supports.

6. The material is durable and durable, does not require additional care and facilitates finishing with finish coatings, becoming the basis.

7. Some hollow varieties contain porous materials for additional frost resistance or counteracting temperature changes.

Varieties of floor slabs

Universal building materials are produced of different sizes, but all of them have their general shape. Plates are produced by 2 types of full-bodied and hollow.

1. A full -shaped monolithic floor slab has no internal voids, used on the lower floors and in the construction of production space. This building material has 3 subspecies:

- crazy slabs, monolithic smooth material for ceilings;

- cesson slabs that resemble a cell mesh of the same beams with a small layer of concrete used for industrial construction;

- the largest load is maintained by the floor slabs ribbed, for example, at the base in high -rise construction.

The manufacture of a monolithic floor slab is quite a simple process, which is often carried out at the place of installation. The frame from the reinforcement is loaded into a horizontal formwork, after which it is poured with concrete. The dimensions of such plates can vary.

Basic technical parameters and labeling products

An important factor for calculations in architecture and installation compliance with requirements for standardizing the release of floor slabs. They must correspond to GOST not only in dimensions, but also in strength, crack resistance, rigidity and other parameters in order to withstand the design load.

According to GOST, the sizes are different, but they must have their own standards. This is convenient for the design of buildings and their installation.

The letters of the product brand, 2 digits are measured in decimeters, the following numbers of the width are also in decimeters, the last number in the marking indicates its total calculated load, without taking into account the weight of the floor slab, that is, its bearing capacity in the structure of the ceilings. For example, when labeling PC 53-12-8T, this means that the plate is round-empty, that is, the parallel holes in it have a cylindrical shape. Its dimensions, length and width are indicated in decimeters, and T means that it is made of dense concrete M200.

The standard thickness of the floor of the reinforced concrete of the order of 220 mm, but there is a lightweight option, by 16 mm. This building material also has an important indicator of the third category of crack resistance, that is, in their operation, cracks are permissible, but this cannot affect the main supporting characteristics of the structure. Some plates are available with additional reinforcement of the ATV class. It is believed that the greatest bearing capacity of monolithic ceilings, when pouring these plates, is used corrugated board N.

Marking also involves other characteristics:

- 1PK is a multi -route by 220 mm, with a diameter of rounded voids 159 mm;

- 2PK a multi -empty slab for 220 mm, with a diameter of rounded voids 140 mm;

- 1P plate 1-layer continuous, production of 120 mm;

- 2P continuous plate of 160 mm;

- PB A multi -empty formation plate without formwork by 220 mm.

When labeling 1P in millimeters, standard sizes for floor slabs:

- 3000x4800, 3000x5400, 3000x6000 and 3000x6600;

- 3600x4800, 3600x5400, 3600x6000 and 3600x6600.

When marking 2p in millimeters, standard sizes for floor slabs:

- 2400x6000,

- 3000x4800, 3000x 5400, 3000x 6000;

- 3600x2400, 3600x3000, 3600x3600, 3600x4800, 3600x5400 and 3600x6000;

- 6000x1200, 6000x2400, 6000x3000 t 6000x3600.

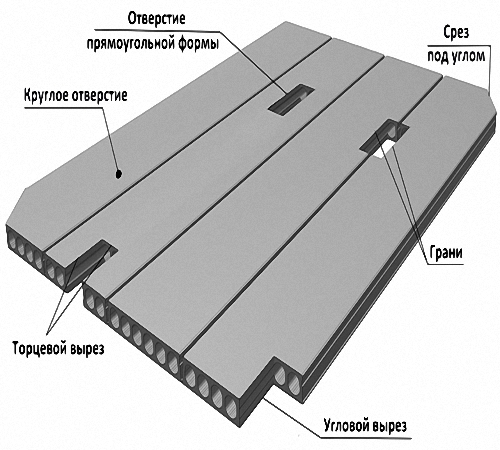

Such options in size make it possible to fit the most accurate fitting at individual layout objects of any configuration. Voids can have a different shape and interval between them.

Features of hollow floor slabs and marking

The void floor slab has parallel holes inside, round, oval or square shape. In fact, most voids have a cylindrical shape. There are reinforced and troublemaken plates. Although the reinforcement is heavier, they have the greatest margin of strength, therefore they are used in the lower part of the structures.

Each marking of the floor slab speaks not only about its main characteristics, but takes into account the features for the choice in one or another place of installation.

- PB plate with rounded voids of 159 mm in diameter, cut by a laser of any length during continuous molding. Standard: length 6-12 m, width 1, 1.2 and 1.8 m, thickness 260 mm. Installed on both ends on the wall;

- Pg plate with oval voids for installation on both ends, a thickness standard of 260 mm;

- 1PK plate with rounded voids with a diameter of 159 mm, thickness 220 mm, installation on both ends;

- 2PK plate with rounded voids of smaller diameter, 140 mm, a thickness standard of 260 mm, installation per 2 end;

- 2PCT plate with voids of diameter 140 mm, but thickness 220 mm, installation with support on 3 sides;

- 2PCK plate with the same parameters (220 mm 140 mm), support for 4 walls;

- 3PK plate of 220 mm thick with rounded voids of 127 mm, support for 2 ends;

- 3PTT PLAT with the same parameters and support on 3 sides, where 2 end and one is open long;

- 3PKK plate with voids 127 mm, thickness 220 mm, installation with support on 4 sides;

- 4PK plate with voids with a diameter of 159 mm, 260 mm thick, for installation on 2 ends;

- 5PK plate with a thickness of 260 mm with holes of 180 mm, installation with support on both ends;

- 6PK plate with rounded voids 203 mm, thickness of 300 mm, support on 2 ends;

- 7PK plate thickness 160 mm with a diameter of voids 114 mm, installation with a support of 2 ends;

- 1PKKT plate with the same parameters as the previous one, but on the walls is laid with support on the 3rd sides;

- 1PKK plate with the same parameters, installation on 4 sides.

By the type of reinforcement of the NV plate, I have such varieties:

- in the plates of HB, concrete B40 brands and single -ease reinforcement are used;

- in the NVK, concrete of the same brand and two -yard reinforcement;

- in the NSA, the reinforcement is two -yard, the concrete of the B45 brand is used.

The main technical parameters of the floor slabs

1. In reinforced concrete, concrete is used, which has an indicator for compression in terms of strength B22.5.

2. A brand of concrete for plates used in conditions of severe climate F200, taking into account the supply of frost resistance.

3. The density of concrete density is 2000-2400 kg/m3.

4. The concrete strength indicator must meet the parameters of 261.9 kg/cm2.

5. A brand of concrete for laying the plates below, taking into account moisture resistance w4.

6. The length of the floor slabs ranges in the standard in the range of 2.1-9.2 m.

7. Product width standards are about 1m, 1.2m, 1.5m, 1.8m.

8. Plates HB and PB are also made with a width of 0.55 m.

Floor slabs as a foundation

Domestic housing construction is widely used by a slab type of foundation laying. For this, monolithic, ribbed and hollow harvests are suitable, it all depends on the number of storeys and the overall load of the structure. Such a foundation has a slight pressure on the soil, so the building more easily tolerates seasonal fluctuations in the soil. The installation of such a foundation is the least laborious and is suitable for the quick installation of the houses of the prefabricated structure for season 1.

Before the start of laying, the foundation is aligned and poured the bottom with crushed stone, gravel or sand for laying the floor slabs. In a low-rise house, the foundation with hollow plates will be reliable, it will cost cheaper, such plates give better sound and thermal insulation. The seams between the plates must be blocked so that the prefabricated foundation design turns out to be the most integral. For this design, plates are suitable with a thickness of 100-120 mm, and for a more thorough building you need 200-250 mm slabs with stiffener ribs. In their voids, it is also very convenient to lay various communications.

Storage and transportation of floor slabs

The quality of the construction, respectively, the safety of the entire object, will depend on the correct storage and transportation of the floor slabs. They transport plates only by special vehicles that guarantee their integrity, and it also provides competent unloading and storage. Plates of the same size are stored with stacks, carefully laying on each other, but not higher than 2.5 m. It is advisable to lay the gaskets about 30 mm between them. Stacks can be covered with a protective film from the destructive effect of precipitation and an aggressive external environment. For years, it should not be stored in the open air and with significant changes in temperature of the floor slab, they damp and lose their properties.

Features of laying slabs laying

Any types of reinforced concrete are quite heavy, and the floor slabs including. But this is their only drawback during installation, which in itself is quite convenient. The main requirement for laying the horizontal and flat plane of the support on which the slabs will be mounted. When the wall is foam concrete, brick or laid from a crumble shell, then an additional concrete armo -pile is needed.

Another moment, the area of \u200b\u200bthe overlapping slabs during styling. The best option is when it is at least 120 mm on each end side. The solution that will be laid under the slabs is used in half -dry. In the use of floor slabs with voids, it is important to observe the conditions where the temperature regime and the general level of humidity will not be higher than the norm. A survey, or bunch of plates, is done by welding for connecting the plates with each other using a rod of 12 mm. Open voids during high -quality styling should be shut up at the edges with a mineral insulation and closed with a cement mixture. This protects the freezing of plates in frosty times.