In case of violation of the technology of mounting the wallpaper on the walls, after drying them, the surface ...

|

|

A reliable barrier on the path of cold or uninvited guests is the front door ... |

In each room, the floor is more subjected to mechanical influences ... |

How to sheathe a house with polystyrene

Foam was actively used already in the middle of the last century, but in recent years its popularity has increased significantly. This material is insulated with various types of houses and other structures. Foam is well stored heat and does not decompose under the influence of various microorganisms, it is also very light and convenient in installation. The distinctive properties of this material are versatility, environmental friendliness, long life and cost savings.

Content:

- The need for foam lining

- Foam characteristic

- The advantages of polystyrene

- House sheathing with foam

The need for foam lining

Warming your own home is a necessary stage of construction. The strength of the walls can provide blocks, brick or concrete. Our country is distinguished by a harsh climate, so ordinary stone walls will not be able to provide a proper level of thermal insulation.

There are many options for insulation of houses on the market, but recently, polystyrene is gaining more and more popularity. It is most actively used by Europeans who are known for their critical attitude to the choice of material. Foam sheets are inexpensive and easy to install.

Foaming the house with foam will help you insulate the building and provide comfortable living conditions. In addition to the heat -insulating function, the foam performs a protective and moisture -releasing function. You can apply plaster or facade paint to the surface of the foam to achieve a pleasant external effect.

This material is endowed with long life. If you install the foam correctly, neither the bright sun, nor frosts, nor moices of humidity will not affect it. The walls can be sheathed outside and inside. You can immediately feel additional warmth and comfort, which will help to spend less electricity in the future.

Foam characteristic

Today, polystyrene can be called one of the most popular heater. The material was invented by German scientists in the fifties. It consists of 2% of polystyrene and 98% of the air. Polistyle foam is obtained from oil, through a phased technical process with the economical use of natural raw materials.

The structure of the material is small cells filled with air. It is worth noting that technologically the process requires appropriate protective equipment, since harmful substances evaporate during it. But the finished foam is absolutely harmless! Many people claim that when heated, the material throws out harmful substances.

But this is false information. Foam is harmful only when melting, when it comes into contact with open fire. It has high thermal insulating properties, provided that the temperature of operation, which will not be able to exceed the temperature of its destruction.

When choosing a foam, always pay attention to quality. Good material should have appropriate examinations and sanitary and epidemiological conclusions. Unfortunately, foams are found on the market that can harm the building and health of living organisms. But from good foam, you can make not only insulation, but also toys for children and containers for storing products.

Before sheathing the house with foam, carefully study its characteristics. It is known that polystyrene foam can be destroyed due to some technical fluids and their vapors, which you should know in advance. Consider this when choosing paints and varnishes for decoration.

The advantages of polystyrene

Why is the polystyrene is so popular? Let's look at some reasons that justify the choice of this particular material.

- Ease. Everyone knows that the foam is very light and always lies on the surface of the water. Materials with density below water are always very popular. Due to the low weight, the foundation and walls will not overload too much.

- Small density. The low density allows you to use the material even for lining with foam of old and dilapidated buildings, when the possibility of using heavy materials is excluded.

- Purity. Foam is environmentally friendly material. It is chemically clean and inert biologically, which makes it safe and not toxic. Such material will never hit mold or fungus. Foam does not contain and does not secrete toxic products.

- Thermal insulation properties. A high effect is achieved even when using a thin layer. The foam leaf of 10 cm will maintain heat better than a brick of 80 cm, a wooden beam of 35 cm and a reinforced concrete layer of 1 m.

- Noise protection. Foam not only saves heat, but also reduces the level of outdoor noise, bringing even more comfort to your house. Additional protection against wind is not required.

- Water confrontation. The material retains its thermal insulation properties under moist conditions. With prolonged exposure to water, the foam absorbs only a few percent. This is what allows you to use it for lining the facades with foam and insulation of foundations, since it will retain its properties even with direct contact with soil or water.

- Chemical inertia. Modern foam is endowed with good resistance to various chemical influences - salt solutions, gypsum, lime, bitumen, acids, concrete. It does not affect these materials at all and does not react with them.

- Resistance to external factors. The material is very resistant to temperature extremes. The upper limit of the preservation of its characteristics can be noted at a temperature of 90 degrees, it also withstands a very low temperature and is not afraid of high atmospheric pressure.

- Fire protection. For safety, special substances are added to the polystyrene that contribute to self -substitution during fire. This is done even at the production stage, when antipyrene is added to the material - a substance that opposes combustion. Therefore, we can say with all the confidence that polystyrene is firewall. In case of fire, he can even reduce fire.

- High quality. Throughout the entire period of use, the material is not shifted in the design, does not sit down and does not change in size. If the thermal insulation layer is applied very high quality, it will serve for a long time and slow down the process of wall destruction. High -quality foam will serve from 50 years or more.

- Durability. It was found that high -quality foam is not plunged to destruction, so you can safely use it for many years. It also has high strength and elasticity. The plaster and paint, which is applied from above, will help increase the durability of foam.

- Universality. In winter, you have to spend various coolants, and use air conditioning in the summer, but they are not able to provide a comfortable microclimate in the room. But the foam successfully copes with this task. The versatility of this material makes it simply indispensable. Foam can be used inside and outside the room. Absolutely any surfaces are sheathed, whether it is walls, attic or floor.

- Availability. The use of foam is very profitable. Buying sheets and installing will cost you much cheaper, in comparison with other heater. It is worth noting that wall insulation will help you reduce the energy costs of additional heating and air conditioning.

- Prevalence. In the end, you can buy polystyrene foam in almost any store with building materials, which is another dignity. As a result of wall insulation with polystyrene, you will enjoy the perfect temperature in any season.

House sheathing with foam

A simple skin of polystyrene sheets will make your home much more comfortable and more comfortable. The installation process is very simple and does not require professional labor or specialized tools. Foam is an environmentally friendly material, also has a good density, steam and water resistance, thermal conductivity.

Preparatory work

Before sheathing the house with a foam, you should take measurements and determine the required amount of the required foam. To correctly make measurements, you need to measure the walls, and then multiply the length of the walls by their height. You will receive the number from which it is worth taking the sizes of windows and doors.

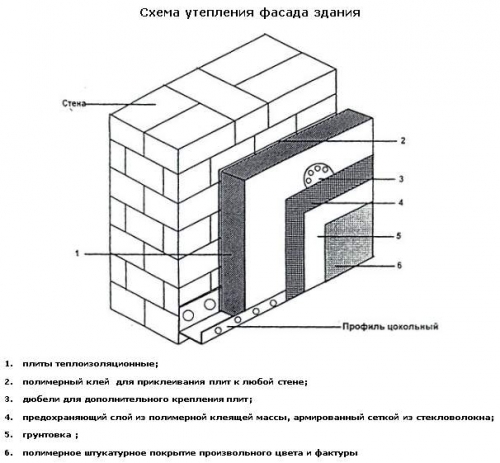

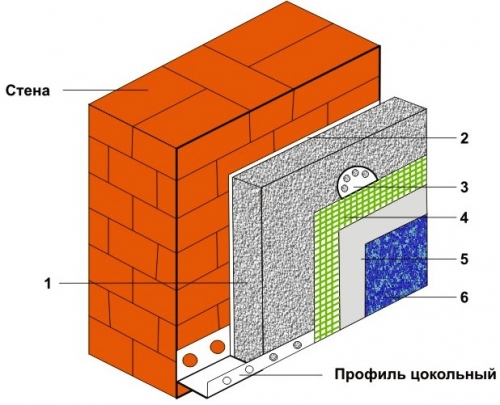

After that, it is necessary to make a list of materials that may be needed for the installation of foam sheets. You will definitely need polystyrene, painting corners, a fiberglass for reinforcement, glue mixture, a basement, a dry mixture for plaster, soil with deep penetration, as well as mineral wool blocks, which are used for window slopes. While compiling the list of the necessary materials, consult with a specialist.

When lining the building with a foam, you will need the following tools: a construction knife, a punch or a good shock drill, a special nozzle for a mixer drill, a grater with metal teeth, a drill, level, roulette, a brush that is applied, a construction stapler and brackets, dowels, a fishing line. , the container, into which glue and solutions, spatula of different sizes and the starting profile will be poured.

Then you should prepare the surface and eliminate all the irregularities for maximum fitting sheets. In no case do not stick foam on the old peeling paint or wallpaper. You must wash and clean the walls well, remove the lamps, wires, sockets, old putty and everything that exfoliates, breaks away and sleeps from the walls.

Be sure to fill in cracks and chips. The walls must be primed and left so until the morning. The primer will help strengthen the wall plane and absorbs all the dust, which will help layers to gain a foothold very firmly. In the lower part of the wall, it is necessary to install basement profiles that correspond to the width of the foam sheets. The thickness of the sheets should be at least 5 cm. There are sheets on sale at 10 cm.

Installation of sheets of foam

Foam sheets can be fixed using mounting glue or liquid nails. You can replace the adhesive mixture with glue, which is used for tiles and putty. To cook it, you need to thoroughly mix the composition of the water. The result should be a homogeneous mass, a cream -shaped consistency.

The process of warming the house is very light and fast. But this procedure must be performed in dry and calm weather so that the glue grabs well. It is very useful before work to watch a video about the line of the house with foam. The polystyrene must be treated with glue and leveled with a tile spatula, and then fixed on the wall so that the width of the seams between the sheets is about two millimeters.

The walls should also be processed with glue using the same technology - using a spatula. You must retreat 2 cm from the edge of the sheet and apply glue around the perimeter and to the center. Press the material to the wall well, it is better to do this using a special polystyrene grater for plaster.

If gaps of more than 10 mm are formed between the plates, it is necessary to pierce them with mounting foam. Lay the second row of tiles with a displacement relative to the first to provide a bunch. In the places where the slopes and in the corners of the structure, make a pressure so that the panels are better to join with the walls.

The material must be additionally fixed with dowels at the joints in the center, this will provide mechanical fixing. To do this, you must drill five small holes in each sheet and score nails in them. One hole should be in the center, the remaining four are located in the corners.

Pay attention to the hats of dowels, they should be strictly at the same level with foam sheets. For the final fixation of the dowel, it is necessary to score nails with a hammer into the technological hole. Try to use only metal dowels, since plastic can simply break. It is advisable to achieve the deepening of the nails into the polystyrene cavity by 1-2 mm.

The final stage

The glue will dry for about three days. Only after lining the house outside the polystyrene can begin to putty sheets, which is carried out in a layer of two millimeters. You can use a special mixture or tile glue. For putty, a special foam grater is used. As for gypsum solutions, they are completely not suitable for this purpose, since they absorb moisture well.

You must wipe the seams in such a way as to provide a good surface and remove all protruding corners. You need to apply a glass wiper on the plaster, but if you used a reinforced foam, this can be skipped. Before this procedure, it is recommended to cover the surface with a primer. At the corner joints, it is necessary to install the corner profile.

A reinforced mesh is glued using glue-cement. It should be cut into the same pieces as the foam. Glue is applied to the surface of the foam and leveled with a wide spatula. After that, the grid is applied and is also leveled with a spatula. It will be ideal if the solution completely covers the mesh, so you can add a little more adhesive substance.

Then it is necessary to grout using a grater with interchangeable sandals. This procedure is carried out after the final solidification of the material, usually there is enough day for this. After that, a primer and then the leveling mixture is applied to the surface again, while a spatula is also used.

You must achieve good surface quality so that in the future you can apply decorative plaster, paint, mosaic or a stone cladding. But remember that it is not enough just to see how to sheathe the house with foam on the video and follow the instructions. Small flaws will always remain during leveling. After drying, they can be removed using ordinary sandpaper. For convenience, you can fix the emery on the bar. After the final stage - decorative finishes, the building will become much warmer and more comfortable.

Foam can be called an ideal option for protecting your walls from freezing, fungi and other negative factors. All of the above qualities will help you use it most effectively. In addition, polystyrene foam is simply indispensable for insulation of foundations, basements, floors, underground parts of the building, roofs, walls and basement floors. In addition to these advantages, it protects waterproofing from the harmful effects of the environment, and the pipelines from freezing.