Sooner or later, the question arises of the need to dismantle the old double -glazed window. By...

|

|

The correct choice of insulation will reduce the heat loss of the insulated building and extend its term ... |

Own estate requires the owners much more effort than an apartment in the city. AND... |

How to fill the foundation at home

The word foundation has entered the Russian language, from the Latin language, translated means the basis. This is the lower part of the building, houses, buildings, which carries all the loads from structures. The upper, aboveground part is called the base, the lower part of the sole foundation. Before starting construction work, it is necessary to draw up a project of the whole house, how many floors will be, what will be the roof, whether the basement will be. The thickness of the foundation will depend on this, from which materials it is better to make. Because a qualitative base for the home is the key to reliability. If the foundation is weak, then it can crack, no matter what expensive materials are used for the construction of walls, roofs, the structure will be destroyed in the future. Strong strong base, the key to the strength and durability of the house.

Content:

- Basic rules when filling the foundation

- Pour zero

- Fill the basement

- The technique of pouring concrete depends on the type of foundation

- Ribbon foundation for houses with stone walls

- Column foundation for a brick house

- TISA foundation for a frame house

- Shallow foundation for a wooden house

- Monolithic slab for a home from foam blocks

Basic rules when filling the foundation

- Be sure to conduct geological studies of the soil that will be used for development. The humidity of the soil, the depth of groundwater, surface relief, slopes, slopes, the depth of freezing of the soil should be taken into account. If, the soil is not stable, over time the house will give a precipitate, he will sag, as if to slide. It is best to use an even plot of land under the foundation, without stones, without excess moisture, near the planned place it is desirable not to plant trees and shrubs that require watering. Having chosen the most suitable site for construction, you can proceed to the next stage.

- This is an engineering calculation of loads on the base. Since the quality of the house depends on the quality of the foundation, the calculation of the loads is better to order from the engineer. But if you decide to think over everything yourself, you need to determine the approximate total weight of the structure that will be erected from above, while the number of floors is taken into account. From calculating the approximate weight of structures, the depth of the foundation, the quantity and quality of materials will be calculated.

- The third stage is the choice of the design model most suitable for building a house, the purchase of the necessary material. Be sure to purchase a device for concrete kneading - concrete mixer. There are different volumes, it is better to use a stirrer with a volume of more than 100 liters for building a house.

Pour zero

Construction work should be started with the marking of the site. For these purposes, you can use pegs, ropes, polypropylene twine.

The next stage is digging the necessary depth of the trench, along the entire perimeter, including internal, with the help of technology or manually. For the base of the foundation, the basis of compacted sand is used, a filtering pillow. On the very bottom, 10 cm are laid. Crushed stone and 5 cm. Sand. The litter must be tamped tightly, using a piece of wood for this, periodically watered with water for better seal.

The first portion of concrete should be kneaded, to pour the lower layer of the base, about 20 cm high. Two, three or more reinforcement with a thickness of at least 14 mm, along the entire perimeter, is laid on top of concrete. The reinforcement is tied with a 6mm wire for the reliability of the foundation.

Concrete is poured on top, evenly distributing throughout the zone. They compact a vibrator with a special device for free from air bubbles. Actions are stopped with the advent of milk. Gradually poured to the zero level of the height of the sole. Before the basement, the reinforcement should be put again, tightly tie the wire, finally pour concrete. If it is very hot, the sole must be moistened, watered with water. The terms of solidification of concrete are about a month. This is called zero filling.

Fill the basement

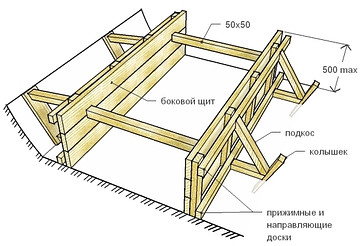

To begin with concrete work, it is necessary to install the formwork. The formwork is a home -made template, it is mainly made of cut boards about 30 cm wide, about 25 cm thick. In order not to stain the boards, use in the future, the forest can be covered with parchment, using a stapler. Parchment must be drowned for ten centimeters in the ground to protect against concrete leakage. Shields are used to avoid a breakthrough of the solution during filling, they are fixed with pegs. The formwork is made on the surface of the earth, installed on top of the sole. The design should be vertically, you can check with the help of ribs or levels. For reliability, the spacers are installed.

If the formwork is made of wood, it needs to be waterproofed, or instead of boards, water-resistant-laminated plywood. You can make a metal formwork. After installing the formwork, the entire area is poured with concrete. For the reliability and strength of the basement, it is necessary to reinforce the foundation. Metal reinforcement is mainly used, but very often used, popular fiberglass rods.

The technique of pouring concrete depends on the type of foundation

Ribbon foundation for houses with stone walls

To create a tape foundation for the home, cement, fittings, sand, but, formwork are used. The tape is an iron strip consisting of 8mm reinforcement with a thickness, interconnected by a wire that is laid around the entire perimeter, including internal, external walls, attaching great importance to the corners of the building. The technology of this type is simple, you can pour concrete manually using one concrete mixer, but this is a lot of physical labor. This model uses in the construction of houses with concrete and stone walls, with floor slabs, metal or reinforced concrete.

Column foundation for a brick house

The foundation for a brick house can be used any structure, it can be concrete, strip. It is good to use the pillar type of structure, provided that the soil allows you to dig a very deeply. Supports are installed in the form of pillars from reinforced concrete in the corners, around the entire perimeter, while the interval of about two meters is maintained. They take on the entire load of a brick house.

TISA foundation for a frame house

Which foundation for a frame house is best suited? For the construction of houses made of light materials, a frame, a tree, it is better not to use a powerful strip foundation, it is money, buried deep in the ground, a more light and economical version called Tisa is suitable for it.

This is a hybrid of a strip and columnar type of base. It is piles or pillars that are installed throughout the inner and external perimeter of the load -bearing walls, which are immediately filled, the formwork will be located around them to form the foundation tape. Architects very often use a floating plate for the construction of frame houses. The design is a reinforced concrete plate located around the perimeter, which is poured on the surface of the soil, an auto-mixer will be needed to fill the plates.

Shallow foundation for a wooden house

The foundation for a wooden house is usually used not a heavy structure. As for the frame model, the design of TIS is quite suitable for the construction of houses on hills, slopes. The only minus of the structure cannot be used on wet, sandy soils. It is good to use the model of the strip foundation called fine -chained. This is a regular model of a strip foundation in which zero is not dug deeply.

You can use screw piles under the base, which are widely used. Metal piles are screwed into the soil due to the blade at the bottom of the pillar. The foundation of such material will not cost, but guarantees of the strength and durability of this model are very doubtful.

Monolithic slab for a home from foam blocks

Nowadays, foam block houses are very popular. Considering that foam blocks, as the material is much lighter than brick, concrete, wood, the most optimal option will be a monolithic slab, especially if the soil has the properties periodically settling. If the soil is stable, you can use the usual strip foundation.

Good afternoon!

Good afternoon! The construction of the house is 10na10, the basement (sand block 400mm), the residential floor (gas block 300mm + insulation 100mm), and residential attic. Glubin freezing of 1.8 m. The capacity has a slope of 1.8 m at 60m length of the site. I want to use This is for the installation in the basement of the garage, the workshop, the boiler room and entrance to the house. Companies at home pour a strip foundation on stilts or you need a full -fledged freezing depth, but in this case you will have to dig a pit in the front of the house 2.5 meters deep and in the rear 4m!