For a long time, the apartment renovation was limited to the arrangement of the interior, ...

|

|

We all live in difficult times, and sometimes the only safe place is our ... |

It is not news that the ceiling in the corridor is considered one of the most difficult ... |

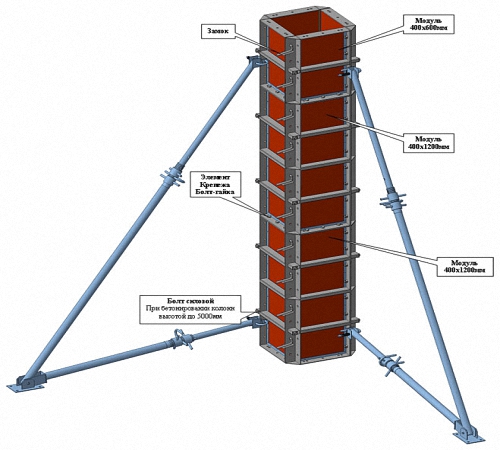

Formwork columns step by step instructions for installation

The formwork of the column is intended for the formation of the area of \u200b\u200ba square or rectangular area, which will correctly mount the column. There are different types of formwork that are intended for certain types of construction work. In this article, we will consider the features and parameters of the formwork for columns with detailed step -by -step instructions.

Table of contents:

- Types of columns

- The purpose of the formwork and the requirements for the product

- Formwork for columns: disposable, reusable, non -removable

- Installation of columns: Features of installation and dismantling

- Step -by -step instructions for installing shield formwork for columns with your own hands

- Installation instructions

Types of columns

The main purpose of creating formwork is the formation of a certain shape for columns of the desired height and parameters. There are two types of work, the first with which it foresees the installation for universal columns, and the second formation of the formwork of columns with a fixed section. When making installation, you need to remember the features of the installation of additional shields.

Previously, columns were used as a decorative element of buildings. However, in the modern world, this type of product is intended as supporting elements for different types of buildings. Several types of columns are distinguished, which differ in geometric form:

- round or cylindrical;

- square;

- multifaceted;

- rectangular.

It is worth noting that the universal formwork of the columns is carried out for different types of columns and anticipates the installation of standard shields with special holes under the shkvoren, the step for which has 5 cm. For a fixed installation circuit, it is necessary to fix the column using four angular elements and some formwork locks.

The purpose of the formwork and the requirements for the product

The formwork of the walls and columns is carried out to fill the concrete base under the supporting elements. This is necessary so that the mixture does not spread and after hardening has a square or other form. Without this stage of work, it is almost impossible to carry out the installation of the column. Experts highlight some requirements for the formwork:

- compliance with the size of the structure;

- stability and strength of the installed product;

- the formation of the form through which the solution will not flow;

- smooth inner side;

- dismantling is not laborious.

Formwork for columns: disposable, reusable, non -removable

The simplest and most convenient option is the construction of disposable formwork. This design consists of cardboard, which is hung in a spiral. The formwork product has water -repellent properties, which does not allow the solution to be saturated into the structure of cardboard. Inside the cardboard formwork for columns, you can put PVC film with thicker walls.

The approximate diameter of such a formwork can be from 20 to 115 cm, and the maximum product length can be 12 meters. Depending on the parameters of the column, the height of the formwork may vary, as well as the thickness of the walls. For example, in the lower part of the structure, the thickness of the walls can be larger, which is determined by the maximum load of the concrete solution. The technology of work is not complicated, with large volumes of installation, lifting mechanisms can be used. Only two people can be enough to perform installation.

Another option for the formwork of columns is the construction of a reusable structure. As a rule, the formwork can be used several times to install several columns. The following features of the work are distinguished:

- the need to build formwork at the construction site;

- pouring into the design of a solution of concrete;

- withstanding several days until the concrete dries completely;

- removing the formwork design and installing it in a different place.

When performing such work, it is necessary to remember the observance of the rules for installing the column. When choosing a reusable formwork of columns and floors, it is necessary to calculate the height of the product that should not be higher than the indicated forms. When choosing this form of formwork, filling will no longer be monolithic. Therefore, you should carefully familiarize yourself with the requirements and characteristics of the implementation of this type of formwork in compliance with the height of the column.

The reusable formwork is expensive than disposable, which is determined by such parameters:

- The necessary costs for storing the structure.

- Transportation of formwork for installing other types of columns and caring for it.

- Additional embezzlement for the use of lifting equipment.

There are different types of reusable formwork:

- shield structure;

- beam-riginal;

- steel formwork;

- plastic structure;

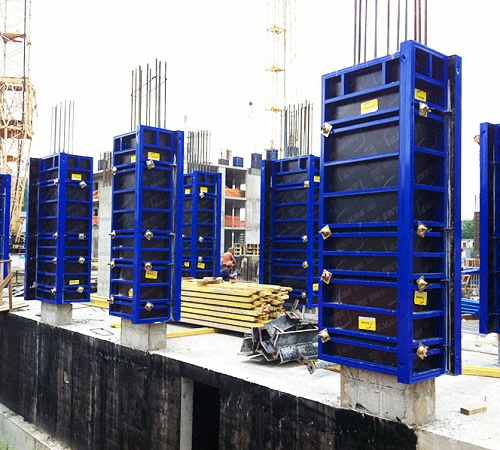

Formwork using shields is intended for square columns. Shields made of metal must be fastened with each other using different fixation items. In the middle of the shields, it is important to place a laminated plywood. Next, a concrete solution is poured after solidification, which the formwork can be removed and moved to another working site.

A similar type of work has a beam-rigel formwork of columns, to perform which you need to use such products:

- shields;

- rigels made of steel;

- beams.

This type of structure will form reliable formwork of different heights. As a rule, such a scheme is used to build round walls, columns, bridges, as well as for the formation of large vertical surfaces. The technology for performing formwork resembles the assembly scheme for the children's designer, and all parts are fixed using spacers.

Steel formwork of columns is intended for square and round products. The main characteristic of the design is that after its use it is necessary to clean and lubricate the sections. This type of formwork has a large weight, as well as a shield, so to move the services of lifting machines.

A more affordable and light option is a plastic formwork for columns. The main disadvantage of the product is the unreliability of the design, and for the implementation of work it will be necessary to seek the help of specialists. It is advised to work with this type of formwork with special tools so as not to damage the walls. All elements of the plastic structure are interconnected with different parts.

There is another type of formwork that is fixed. The use of this type of design is rarely carried out, however, such a design scheme is quite popular among builders. All blocks and blanks for the assembly of formwork are made on special machines. Thus, products with thin walls are created, which are quite strong and reliable.

Elements for formwork are made of high -strength concrete. The technology of preparing the solution foresees the use of cement, sand and water. The peculiarity of the preparation of concrete lies in the sealing of pores using rental. Thus, all the liquid is supplanted from the solution, which increases the properties of frost resistance and strength of concrete. Formwork products made in this way are increased resistance to temperature and humidity drops.

Installation of columns: Features of installation and dismantling

Before considering the installation technology for a certain type of formwork, it is necessary to study the standard characteristics of the work. Before installing the formwork on the surface of concrete, it is necessary to mark the parameters of the column. As a rule, the column should be installed around a pre -prepared frame of reinforcement. All work is important to carry out using design documentation. The shields for formwork must be assembled in a Mr.-shaped form, which are fixed using nuts and a shkvorny or through a corner, then is determined by the type of column. The second and other tiers of the assembly of the structure must be assembled using a mobile tower-tour or construction forests.

If the height of the formwork of round columns has an indicator above 4.2, it is important to mount a special crossbar on the column, which will align the structure. The installed column must be checked for a vertical position, which is carried out using braces or crowds. The dislocation is folded from the lower and upper areas of the product, as well as a special connector. The latter must be mounted in the surface of concrete, then, the upper part is attached to the highest point of fixation of the column, and the lower to the lower. Using special tools and nuts, the column should be leveled and fixed in an upright position.

The peculiarity of dismantling the formwork can be done when the concrete is completely dry. First of all, it is necessary to remove formwork braces, after which the locks from the upper part are dismantled and shields are removed.

It's important to know! If the height of the mounted column is more than three meters, then concrete solutions must be served through a special window. In the next tier, it is necessary to remove one of the shields, which forms a window of the required size. Next, the shield is installed in the same place, after which the concrete solution falls through the upper part of the column of the column.

Step -by -step instructions for installing shield formwork for columns with your own hands

The installation process must be started by marking the working area. It is important that it coincides with the parameters of the previously erected frame and reinforcement:

1. Installation is recommended to start with shields placed at the corners, which will allow you to form certain beacons.

2. After that, the formwork of shields on the one hand is collected, and it is important to fix all the details of the structure using locks.

3. Next, the installed panel is important to level using special braces, and fix it in the right position in accordance with the design documentation.

4. Having determined the thickness of the pouring of the concrete wall, you need to install the next formwork wall with the same technology.

5. In the upper part of the formwork, it is important to mount the running console.

6. After aligning all the walls of the structure, you can start further work on installing a column and filling the base.

It's important to know! To correctly install shields on one side, it is necessary to use a crossbar that will allow to align the formwork.

The dismantling method consists in the implementation of work in the reverse order: first, the running consoles and slants of the chopper are removed. After that, locks from the upper area of \u200b\u200bthe structure are dismantled, and formwork shields are removed.

Installation instructions

The beam-trigel formwork is a design that consists of beams and crossbars. All parts are fastened with clamps. The main material used in the work is a tree, so all work is not laborious. This material has low thermal conductivity, unlike aluminum formwork of columns.

Such a formwork assembly scheme has many advantages, which is indicated by reliability, strength and simplicity, the design used. Carrying out work does not require significant costs, while the formwork is considered universal. Using this type of construction of the structure, you can concrete columns of different sizes. Also, using the formwork beam-rigel scheme, you can build concrete walls of different parameters. To strengthen and formation of formwork, it is recommended to use only a screwdriver and a hammer.

Advantages of formwork:

- it is used to install columns and walls of different heights and sizes;

- it is intended for the formwork of buildings of various shapes, for example, radius, round and inclined without unnecessary waste;

- allows you to get good quality of concrete on the surface of the formwork;

- using this type of design of the structure, it will be possible to reduce the number of clearance and screeds;

- the formwork is able to withstand a large load of concrete, up to about 10 t/sq. m.

Detailed instructions for assembling beam-rigel formwork have the following sequence:

1. Prepare the work site for the installation of formwork.

2. Next, we place a template made of bars and plywood, but which is laid by a crossbar at a right angle.

3. The crossbars are perpendicular to the beams for formwork of the required length.

4. These beams must be attached to the crossbar using special clamps.

5. The approximate distance between the beams should be from 20 to 40 cm, which is determined by the design documentation.

It's important to know! When laying the beams, it is necessary to ensure that they do not coincide with the points for fastening under the fitting screws. On the installed beams, you need to put sheets of laminated plywood, while the place of joints should be in the middle of the beam. Plywood is fixed to the beams using screws, which are screwed every 35-40 cm. The length of the fastener should be 50 or 60 mm. The area of \u200b\u200binstallation of screws can be thrown, which will extend the shelf life of plywood for further use.

There are different options for installing formwork, however, not all work can be done with your own hands. The installation technology for each type of structure is determined by the height and cross -section of the columns. To better study the scheme of work on formwork, we recommend watching the video presented at the end of the article.