The arrangement of warm floors is especially relevant for rooms with high humidity, ...

|

|

Each motorist simply dreams of his warm garage. He represents how in ... |

The roof is the most important part of the house, on the quality of which the comfort of living depends ... |

Installation of vinyl siding

Recently, siding has been used for facade decor, although it has been represented on the market for more than half a century. It is allowed to finish the walls of the building of any purpose: whether it is a residential or administrative building, hangar or economic building. Domestic consumers praised the ease of installation of vinyl siding. In addition, finishing work quickly resolves the issue of changing the appearance of the facade, skillfully hiding its some imperfections. The article will talk about the choice and rules for installing vinyl siding.

Content:

- Design feature of vinyl siding

- Types of siding

- Production of vinyl siding

- Properties and characteristics of vinyl siding

- Tips for buying vinyl siding

- Leading manufacturers of vinyl siding

- Calculation of the amount of material

- Proper storage of vinyl siding

- Vinyl siding installation technology

- Caring for siding

Back in the middle of the last century, residents of North America finished their frame houses with wooden strips. Laying was carried out vertically overwhelming, which did not allow the wind and sediment to get between the boards. The only drawback of such a skin was a short service life. Under the influence of atmospheric precipitation, the wood was dry, forming the cracks, and the paint was cracking and exfoliated. Therefore, the bar had to be stained regularly, if necessary, replace both individual elements and the entire casing completely.

The development of the polymer industry was in the second half of the 50s. Then a new material was developed, which was significantly distinguished by its operational properties from natural wood. Today, vinyl siding is the most popular material for facing private houses.

Design feature of vinyl siding

Vinyl siding is a panel with a thickness of 0.96-1.5 mm, with a length of 3 to 4 m, and the width depends on the presence of strips. It can be single, double or triple. On the length of the product on the one hand, the working holes are located, which serve to attach the building to the facade, and are equipped with a curved edge, which is a response part of the lock.

Basically, the products have the following profile:

- Christmas tree;

- Ship beam;

- Log;

- Vertical siding.

Economy class sheets are made with a smooth surface. More expensive products have a surface resembling a string board. The relief can be either in depressed or convex.

Marking on the package looks like this:

- S (single) single;

- D (Double) double;

- T (triple) triple.

The number after the letter designation indicates the width of each plank in inches. For example:

- T5 triple panel, where the width of each rail is 5˝ 127 mm.

It should be noted that in the manufacture of unified standards, not all manufacturers adhere to. Even in the same company, products can vary in shape, dimensions, and a shade depending on the manufactured series. Therefore, it is so important at the procurement stage to correctly calculate the required amount of building material. Otherwise, buying identical panels will be very problematic.

Types of siding

The cladding with vinyl siding has become popular due to its not only protective functions from the negative influence of the external environment, but also with high decorative properties. For purpose, siding is divided into basement and wall.

Basement siding

- Separately, it should be noted the material for decorating the lower thickened part of the structure, namely the basement. It is most affected by various weather phenomena (melt water), as well as mechanical influences (hit with a foot or shovel when cleaning the adjacent territory from snow).

- In this regard, the finish material should be strong, persistent and preserve a presentable look under any conditions. Such qualities are different from polyvinyl chloride siding, created specifically for these purposes.

- Typically, its surface copies masonry of brick or natural stone. And in combination with wall panels, it allows you to create a harmonious ensemble. Basal siding is often used not in their direct purpose, they are sheathed with the corners of the house, pipes, balconies and other facade elements.

- Panels for finishing the foundation are quite expensive, which significantly limits their use.

Siding for walls

Wall elements are available from various materials, each of which has both positive and negative characteristics.

- Fiber cement siding.The panels are made of a mixture of cement, sand, cellulose fibers, water and special additives.

- Pros.Such a product is characterized by high strength and non -combustibility.

- Cons. The weight of the facing material is quite significant, in this regard, the load on the foundation increases. Complex installation and high price make this type of panels not very popular. But it is great for the lining of the basement of the house.

- Price. 50-500 rubles/m

- Aluminum siding.The metal sheet passes through pressing equipment and special videos, which form the profile of the future panel. The finished product is painted or laminated.

- Pros. The refractiveness, affordable cost, resistance to ultraviolet rays and minimal lining are the main advantages that guide the consumer when choosing siding.

- Cons. Mechanical strength and resistance to corrosion destruction are not the strongest sides of the aluminum product.

- Price. 200-250 rub./M

- Vinyl siding.Here, the liquid mass of polyvinyl chloride, more precisely, the vinyl powder with additives, is passed through the holes of the machine, which gives a certain profile the product. It is made with smooth and textured surfaces.

- Pros.High resistance to external influences and resistance to burnout, which allows the facade to operate for decades. Provides good air exchange. Needs minimal care.

- Cons. Panels are afraid of mechanical damage. From a non -stroke, for example, a pebble, a chip or light deformation may appear. The PVC products are not subject to repair, therefore, if necessary, the entire sheet is replaced.

- Price. 250-600 rubles/m

As for the price of installation work, it usually makes up more than 50% of the total cost of this lining material. Therefore, most owners of country houses prefer to install vinyl siding with their own hands.

Today, vinyl siding remains the most popular material for lining of facades of any type. It is characterized by an excellent combination of operational characteristics, decorativeness and price availability.

Continuous elements of vinyl siding

Components are intended for combustion of siding panels. All joints will be hidden behind these special elements. They will close all the cracks, creating an even surface and smooth transitions.

- The lower row of the panels is attached by means of starting bar. After installation, it will be partially hidden. Also concerns final barserving for fixing the last panel with a cut edge.

- J.-profile A universal element serves to finish corners of any complexity. Arkal openings are issued through a flexible J-shaped profile.

- F-profile It is used when sheathing the lower protruding part and roof fronts.

- H-profile Used as a panel connector.

- External and internal corners Need to install panels in corner places.

The manufacturer also offers wind planes, sophites, platbands and tows. Such elements allow you to organically complete all finishing work.

Production of vinyl siding

The manufacture of these products uses the extrusion method. So, raw materials, which include vinyl powder, stabilizers and other necessary additives, through the press passes through equipment, which gives a certain form.

For the production of panels, 2 technologies are used:

- monoecstrusia;

- coECSTRUSIA.

The first method implies the production of a monolithic sheet, where all modifiers and other additives are distributed homogeneous. The properties of the upper and inner sides of the product are not taken into account. This method is considered outdated and is extremely rare.

The second technology allows you to create 2 layers where each has the necessary technical characteristics.

- The upper layer contains special stabilizers that provide the desired resistance to atmospheric phenomena.

- For the production of the inside, a mixture with a slightly different composition is used, which achieves the strength of the product and the invariability of its geometry. Thus, the 2nd component panel is characterized by higher physical and technical properties than a similar product made according to the mono-eStrusia method.

It is worth noting that each manufacturer adheres to its own recipe. To reduce the cost of the final product, a secondary processing raw material (residues from the production of PVC and doors) is added to the compound. Especially unscrupulous manufacturers use up to 70-80% of secondary products.

Of course, there is no need to talk about high coefficients of strength and resistance here. Such siding is suitable for use in areas with soft climate. It is often used if only aesthetic requirements are imposed on the structure of the structure.

Properties and characteristics of vinyl siding

Vinyl sheets have been widely used in construction. Their use as facade casing is due to many positive characteristics. Such material is unpretentious and can last from 10 to 50 years. PVC Siding is different:

- safety. Polyvinyl chloride products are not toxic and do not support active burning;

- resistance to various atmospheric phenomena and moderate sour and alkaline environment. Does not deform at sharp temperature differences;

- durability. Such material does not rot, corrosion or insects is not afraid of it;

- unpretentiousness. Does not need staining. The facade care is minimal and does not require significant time costs. It is enough to wash off the dust with water, in rare cases you will need a rag and a soft detergent;

- all -season. A huge advantage is the possibility of installing installation work even at minus temperature;

- the possibility of insulation. So, the heat -insulating material is laid in the crate cells;

- high decorative qualities. Coloring in the mass makes panels resistant to ultraviolet rays;

- aesthetics. The panels have a wide range of coloring, which allows you to realize the most extraordinary design ideas and radically change the facade in a short time.

Of the negative sides, the following can be noted:

- although the material is non -combustible in itself, but, nevertheless, it melts, in connection with this it is not recommended to make fire near the walls (frying kebabs, carry out welding, etc.);

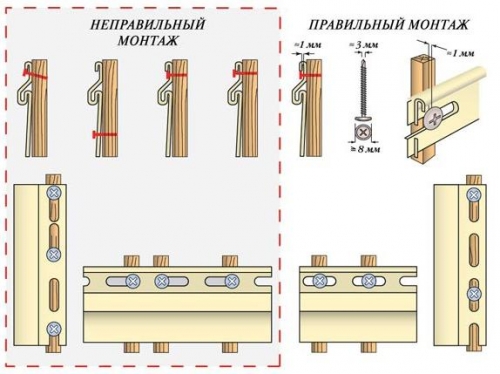

- the sheets have a high coefficient of thermal linear expansion, so strict fixation of the products to the facade is prohibited. The gap should remain between the hats of metizes and the strip itself;

- low strength. A garden car that has not been inscribed in a turn or flying tennis ball will leave a dent on the surface of such a facade.

Tips for buying vinyl siding

- Before purchasing, it is recommended to pay attention to the uniformity of the painting of the product, otherwise there is a kalra saving by the manufacturer or a violation of manufacturing technology.

- The sheet should have the same thickness along the entire length, the presence of differences signals a decrease in its strength characteristics.

- There should not be any damage, chips, abrasions on the surface.

- The quality of the products will help to determine the packaging, the fact is that serious manufacturers pack the panels in boxes of dense cardboard, where each is marked with a barcode.

- An indicator of quality is the even edges of the mounting holes.

- You should know that if stores are offered in stores of joint production, for example, Russian-American, then you know, in front of you is a fake.

Leading manufacturers of vinyl siding

Eminent companies carefully monitor the compliance of all standards of products. Therefore, the probability of purchasing a poor -quality product is reduced to almost zero. Foreign and domestic manufacturers are widely represented in the building materials market. The variety of products will satisfy a person with the most demanding taste. Where the choice of panels is more based only on aesthetic preferences of the buyer.

MarkD.öcke Awarded the Honorary Awards Narodnaya Mark 2007. Although the production of panels is carried out on the territory of Russia, all the equipment, raw materials and applied technologies are brought from Germany.

- It was this company that first proposed a two -tone version of facade facing, where panels and additional elements are ideally selected in shades. Which makes it possible not to suffer with an independent selection of a suitable combination.

- A distinctive feature of the panels is an additional rib of stiffness in the castle part, which gives the product greater resistance to wind loads.

MarkFineber Production Russia. The sheets are made on Canadian equipment by the coecrose method. By the same method, components corresponding to panels in texture, mounting sizes and shades are also available.

- Recently, the production of panels for a log was established, which allows a simple structure to give the form of a thorough log house.

- According to the manufacturer, vinyl siding Fineber will last at least 50 years.

MarkTecos From the Belgian factory, represented in a huge color diversity. The products of this venerable manufacturer have accurate geometry and a dense lock. Installation holes allow you to perform the fasteners of the methyse to the stop, and the improved locking design makes the connection more reliable.

- First -grade raw materials and innovative technology allow you to produce products in accordance with all international quality standards.

MarkMitten It belongs to the Canadian manufacturer, who was one of the first to release vinyl siding. The presence of rich experience (more than half a century), worked out technology and constant control at all stages of manufacture gives the right to argue that the manufactured product meets all standards.

- Vinyl sheets Mitten They are available only with a matte surface, which is one of the indicators of quality, since the gloss attracts the sun's rays, and as a result, the panel quickly burns out and can deform.

It is worth noting that German companies are famous for the high quality of the panels, Canadian are based on their rich experience, but domestic indicate the stability of the products to the harsh conditions of the country.

Calculation of the amount of material

- The calculation of the required number of sheets for lining the house with vinyl siding is quite simple. For convenience, a drawing of the structure is performed on paper. Visual division of the house into simple geometric shapes will greatly facilitate the calculations, especially if it has complex architectural forms.

- Next, the area of \u200b\u200bwalls (individual figures) is calculated. All results are summarized. The total area of \u200b\u200bthe surface of the area of \u200b\u200bthe siding area. In order to find out how many siding panels you need, you need to divide the area of \u200b\u200bthe walls into an area of \u200b\u200bone strip.

Here you should take into account the presence of windows and doors:

- the total area of \u200b\u200bthe openings is deducted from the total area of \u200b\u200bthe walls and 5-7% of the material for stock is necessarily added. This calculation is recommended to be carried out in the presence of a large number of doorways and the extensive area of \u200b\u200bglazing;

- in other cases, the number of panels is calculated on the basis of the main area of \u200b\u200bthe walls, and the windows and doors participate in the calculations. Then you do not need to add a spare coefficient.

Proper storage of vinyl siding

- In order for the siding sheets to serve for a long time and delight not only with an aesthetic look, but also do not lose their original qualities, then transportation, storage and installation should be carried out in accordance with the rules:

- When transporting and storing packaging with panels, they should lie on a flat horizontal surface with support along the entire length.

- Highly storage of packages of more than 15 pieces in a stack is not allowed.

- You can not leave products under direct sunlight or completely cover it with plastic film, it is better to store them under a canopy, not forgetting about ventilation.

- If installation is planned to be carried out in winter, then the air temperature should not exceed -15C. In such conditions, the material becomes fragile, so pruning and installation work are carried out with extreme accuracy. In this case, sheets should adapt to the conditions, that is, to lay down for a couple of hours at street temperature.

Vinyl siding installation technology

A serious manufacturer to the product attaches instructions for the installation of vinyl siding, where recommendations are given, typical solutions of structural nodes are shown. Therefore, there will be no difficulties in independent work.

Installation of siding begins with the leveling of walls, sealing the cracks and other similar works. You can get rid of large irregularities with the help of a crate by laying wooden sheets under the profile of the required thickness.

Chatter

- The crate is needed not only on old buildings, but also on new ones. The design forms a ventilation facade, which does not allow condensate to accumulate, leading to the formation of dampness. In addition, the distance between the bars or profile allows you to perform additional thermal insulation of the house.

- The most economical material for the crate is the tree, but the financial costs of acquiring impregnating funds will minimize such savings. In addition, its quality must be approached very carefully, if the beam is raw, then after a certain time it will lead it.

- This will negatively affect the aesthetic form of the house, but will also lead to a decrease in all operational characteristics of vinyl siding as a whole. Therefore, more often the choice is stopped on a conventional metal profile. Of course, it will cost more, but it will last much longer.

- With vertical laying of the strips, the crate is mounted horizontally, and, accordingly, vice versa. The step between the profile should be 30-40 cm.

- Fasteners are carried out depending on the material of the walls. If this is a wooden surface, then self -tapping screws act as metizes, if brick dowels. Remember, it is not recommended to fix the crate with nails.

- The installation of the crate should be carried out by observing the level in all planes. Otherwise, the correct geometry of the sheet will show all the made mistakes, and the house will look slightly skewed.

- In principle, the technology for installing the profile for siding is no different from installing the structure for drywall sheets. Here, the distance from the surface of the wall to the vertical support is also exhibited by means of the P-shaped ears.

- In places of installation of additional elements, for example, lighting devices, an additional profile is mounted. Particular attention is paid to door and window openings.

- If the base protrudes from the wall to a certain distance, then a separate frame is mounted for it. To do this, at the corners of the house is the lowest level, from which the first row of wall panels will go. A nail or dowel is driven into the marked point and the twine is pulled. It will serve as a dividing line between the basement and wall sheets.

- You can perform the same angle of inclination for the tilt panel around the entire perimeter of the house by means of a template. It is easy to make it from improvised material (from a piece of drywall or sheet of fiberboard, chipboard), where one of the sides is cut at the right angle.

- Applying the workpiece to the profile, the tilt of the vertical part of the tint for the tide is checked. The same manipulations are carried out when installing window plums. It is worth noting that a metal profile allows you to easily make such adjustments, which can not be said about wooden rails.

Vinilov siding rules

- External and internal corners are mounted on a completely ready -made dozen structure. The initial and final planks are attached around the entire perimeter of the structure. In the same way, window and doorways are equipped.

- For convenience, it is recommended to use the corresponding parts (profiles), which will significantly accelerate the installation work and reduce their complexity.

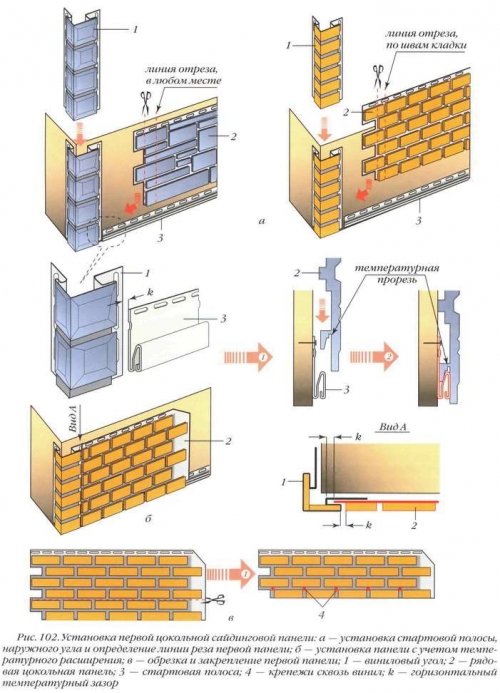

- First of all, basement panels are mounted, work is carried out from right to left. During installation, a gap is necessarily left between the details, which will serve as a compensator with a linear expansion of vinyl siding.

- With the protruding part of the foundation, the drain panel will act as the initial bar for the wall strips, as it has an appropriate lock. Otherwise, after the base sheets are mounted on top of them, the initial bar for vertical facade cladding is mounted on top of them.

Important! The fasteners of any elements are carried out in the center of the working holes. You should always leave technological gaps of 1.5-2 mm the distance between the Hy of the Metiz and the vinyl details of any appointments. Loosely screwed screws and not completely clogged dowels prevent deformation and fragility of panels.

Installation of wall panels

- Installation work is an assembly of the designer, where one part of the panels enters the other by means of a lock connection. The first panel is inserted into the initial bar, its upper part is attached to the crate.

- Fixation with meters is carried out from the middle to the edges of the product. The next strip is inserted into the return part of the castle of the previous sheet. Similarly, all sheets of siding are installed from the bottom up.

Each cut -out part should be 6 mm less than the actual size .

Vinyl siding video

- The transverse section is carried out using metal scissors, a saw with small teeth or a cutting disk, a longitudinal with a construction knife, here it is necessary to walk along the intended line several times and bend this part of the panel until it breaks down.

- As a rule, the last strip under the cornice turns out to be cut, it is simultaneously inserted into the castle of the lower leaf and into the finish bar.

Caring for siding

The maintenance of the facade, sheathed with vinyl panels, consists in simple manipulations using the minimum amount of detergent. In order for the building for a long time to rejoice in its impeccable look, you should adhere to several rules/

- In most cases, bring the facade to the proper appearance with simple washing with water from the hose. If the panels are very contaminated or their profile has a concentrated look, which favors the accumulation of dust, then you need to use a soft rag.

- You can get rid of soapy water (powder or liquid for washing dishes diluted with water). The mold will easily retire 5-6% vinegar.

- For cleaning, you cannot use brushes with hard bristles, as well as abrasive cleaning agents, liquids containing clean chlorine, solvents.

With the help of such a simple and unpretentious material, you can radically change the facade of even the oldest structure in a short time, giving it a more respectable look.