The double -glazed window is the most vulnerable window element. Modern wooden ...

|

|

From the sport of centuries, people equipped their house so that it was comfortable and warm ... |

The process of building a log house is preceded by the laying of the foundation that should be ... |

Roofing roof roofing. Do -it -yourself roof laying technology

The roof is the most important part of the house, on the quality of which the comfort of living in it depends. And if modern cottages are covered with expensive roofing materials, then for small country houses, garages and outbuildings, most owners still choose roofing material. This inexpensive material has successfully established itself for several decades. The article will talk about how to choose the right material and cover the roof with roof roofing so that one serves for many years without additional repair.

Content:

- Advantages of roofing material as roofing material

- Roofing from roofing roof

- Marking roofing material

- Independent coating of the roof roof roofing

- Roofing roof roof roofing material

- The cost of roofing roof roofing

Advantages of roofing material as roofing material

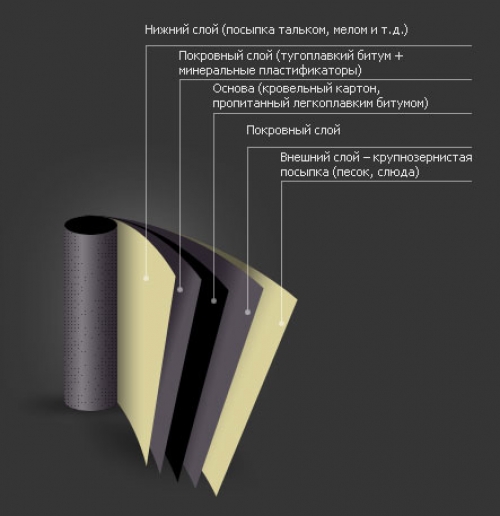

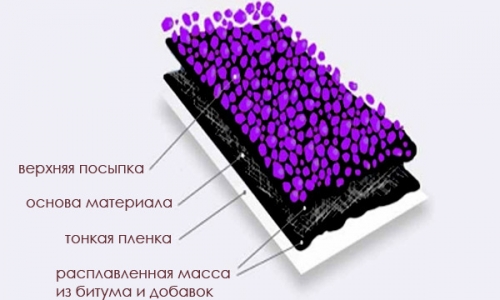

Ruberoid is inexpensive and widely accessible material. At its core, it is a construction cardboard, which is impregnated with oil bitumen and covered with refractory material. It goes on sale in the form of rolls of different lengths. In some cases, either a layer of asbestos or talcum is applied to the roofing material, depending on its purpose.

The main advantages of this roofing material are that it creates a very good waterproofing, and laying it with your own hands is not very difficult. The price of roofing roof roofing roof is also important, today it is the cheapest roofing material.

But besides the advantages, roofing material has disadvantages:

- this material can be easily ignited;

- it also has a rather low strength;

- the disadvantages include its appearance, for example, comparing it with slate or tiles.

Ruberoid is used as the final roofing, or simply as one of the layers of the roof pie. Its main task is to protect the construction from atmospheric precipitation. But besides this, roofing material is also used as waterproofing material in basement and storage facilities.

It should be said that it is used not only in construction work. There are some people who manage to heat the furnace roofing material, as well as fertilize the garden for them. Some more claim that he has soundproofing qualities, but this, of course, is not true. The sound insulation of this material is no better than that of linoleum.

The roofing material is made both on a cardboard basis and on a glass -wreck. Roofed material has not a very long service life, and low strength. That is why it is put in five, or even more layers. But the roofing material from the glasshold, without afraid to lay in two or even one layer, and this is enough.

Roofing from roofing roof

It is necessary to deploy rolls in advance and let the roofing rate be expanded for at least one day. This is done so that the roofing material is not twisted during operation. Another advice, before starting work, you need to see what the weather is currently. The day should be sunny, and the optimum air temperature is at least twenty degrees.

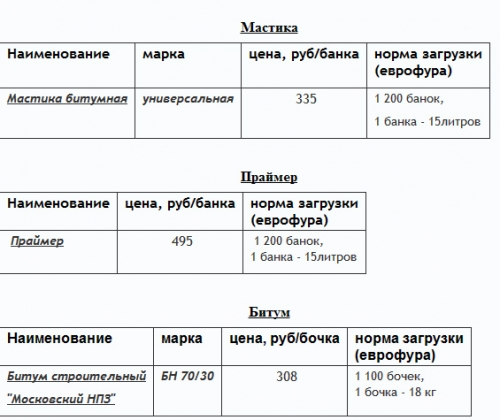

Initially, the surface is lubricated with a special mastic on a bitumen basis. There are a large number of types of mastic, and what will be chosen in a particular case depends on the type of roofing material. It is recommended to contact employees of a construction store who will help you decide on the material. To date, on sale there is a roofing material with a self -adhesive surface, which greatly facilitates and accelerates the laying process.

During installation, the sheets fit perfectly evenly and parallel to each other.

It is also worth paying special attention to the joints between the wall and the roofing material should not even remain there small gaps.

Summing up the above, we can conclude. With short terms and a modest budget, but having the need to create a reliable roof, and the priority is precisely the quality, and not the aesthetics of the roof, to opt for roofing material, it will be quite logical and justified.

Marking roofing material

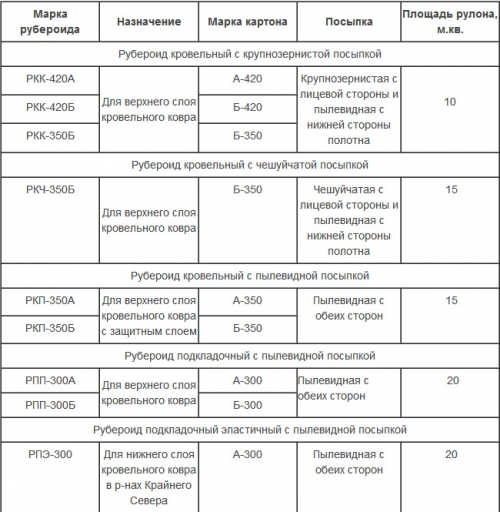

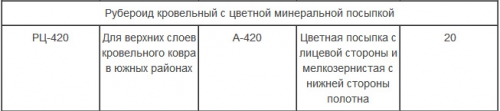

There are many types of roof roofing roofing, each of which has its own marking.

- First, the name P is the name P - which means roofing material.

- The second letter speaks of the method of applying the material: n lining and to roofing.

- The third letter is characterized by the type of sprinkle: M is fine -grained, scaly, to coarse -grained and Pusty -shaped.

- The numbers after the letter abbreviation mean the density of cardboard.

For example, decipher the brand of the RKK -420 roofing roof roofing roofing roofing roofing with coarse -grained sprinkling with a density of 420 g/m2.

Independent coating of the roof roof roofing

Before starting to lay roofing material, it is necessary to prepare bitumen mastic. In total, two types are distinguished - these are hot and cold mastic.

How to make bitumen mastic and primer with your own hands

For the manufacture of mastic, you will need:

- several pieces of bitumen without impurities;

- fillers (most often it is asbestos);

- plasticizer.

To obtain 5 kg of finished mastic, you will need 4.2 kg of bitumen, 0.5 kg of filler (asbestos, sawdust, peat, forest moss, rubber crumb or mineral wool), 0.25 kg of plasticizer, in the role of which produced oil acts.

For the preparation of mastic, thick -walled boilers with a lid are used. The thickness of the walls from 3 mm guarantee uniform distribution of heat, and as a result, uniform heating of bitumen.

Stages of cooking:

- the boiler is loaded with a maximum of 2/3, otherwise the mastic will begin to splash out when boiling;

- the boiler with bitumen is not located on the very fire, but in some distance from it. In this case, it is installed on a stable stand;

- in no case should there be overheating of bitumen, which can lead to the destruction of the structure. To obtain homogeneous mass without green-yellow bubbles, there should be no temperature changes;

- first, you will need to crush the largest pieces of bitumen and, if possible, remove dirt and sand from them;

- the fire should be adjusted so that the cooking process proceeds slowly. In total, it takes about 3 hours;

- regardless of which filler is used, before adding it to the boiler, it must be crushed and dried;

- the plasticizer and filler are added gradually, mixing them with a shovel and removing the resulting foam.

If during cooking something unexpectedly went wrong, then it is necessary to immediately close the boiler in which the mixture was prepared. The reason for this may be the incorrect distribution of ingredients, as well as overheating of the mixture. Such mastic is not recommended for work. If gray smoke comes from the boiler and hissing is heard, then the process goes correctly.

Such mastic is prepared immediately before the start of roofing, since its shelf life is not a field of day. When using, it should be constantly hot.

For better adhesion of bitumen mastic, the surface of the roof is initially primed.

The composition for such a primer is easy to do independently. For this, 3 parts of gasoline and 1 part of bitumen are taken. In the 76th gasoline, the bitumen warmed up to 700 degrees is gradually placed and is thoroughly stirred until it disappears completely in it. After cooling, the resulting mixture is filtered through a small grid.

How many layers of roofing material should be done?

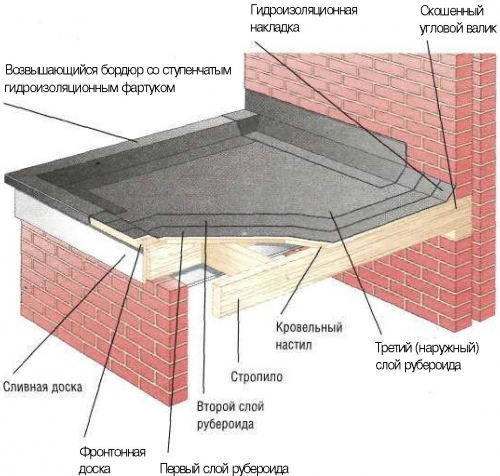

Depending on the slope of the roof on which the roofing material will be laid and the right number of layers depends. The smaller the slope of the roof slopes, the thicker the layer of material.

Coating in five layers

This maximum thickness is recommended for flat roofs. Together with a strong basis, a reliable roof is obtained, capable of withstanding snow loads even in the northern regions of the country.

Four -layer styling

It is used on roofs with a slope of 2-3 degrees (but only on unexplosive). For the main layer, RPP-350V and RPP-350V roofing material is selected. On top of it, the roofing material of the RKM-350V or RKM-350B brand is laid (which has fine-grained sprinkling).

Three -layer coating

Such a thickness of roofing material is enough with a roof slope from 3 to 10 degrees. In this case, it is best to apply the RKK-350 roofing roofing roofing roofing roofing room as the last layer. Often, when the roofs with an inclination of 15 degrees are also covered with only 3 layers. But then the material of the RKK-500A, S-RM or RKK-400A brand acts as the lower layer. The top is laid from the roofing material RK-500-2.

Roofs of two layers of roofing material

It is used when tilting the roof from 10 to 15 degrees. With a steeper inclination, the roofing material is recommended to be replaced with other roofing materials (slate, metal tiles, galvanized iron or corrugated board).

Ruberoid laying tool

The tool for roofing on the flooring of the roofing material depends on the chosen laying method. There are three ways in total how to do it:

- mechanical method. In this case, the roofing material is attached using the racks on nails or self -tapping screws. The sheets of the material are alternately rolled out and laid with an overlap at the edges of 15 cm. At the same time, the rails, located along the strips of the material, provide tight pressing it to the base of the roof. Accordingly, a hammer or a screwdriver, as well as special plastic or iron fungi, which will help prevent damage to roofing material;

- laying on mastic. It is necessary to have a metal container for melting mastic and a long brush for convenient application of hot mixture to roofing material. This method implies the smearing of roofing roofing rates throughout the area or only the joints (overlap). For work, you will need a roller for applying the composition and manual skating rink;

- using a gas roof burner. As the name is clear, a hand gas burner will be required. With its help, the lower layer of roofing material, which is pulled into a roll, and when smooth and heated, it is firmly glued to the surface of the roof. To exclude the formation of condensate due to the remaining air between the sheets, a manual roller is useful, which passes along the entire surface of the roof. This method is applicable only on flat surfaces.

Than cutting roofing material

Since the roofing material is sold in the form of rolls of a certain length, it is often required to shorten it. But it happens that you have to cut off along the sheets. In both cases, the cut should be even and high -quality. Cutting across will not be difficulties, this is done with the help of a household or boot knife. And the longitudinal incision is most correct to do without unwinding the roofing material, and cut the desired width from the roll on the tree with a saw with a saw. For ease of work, it is recommended to moisten the material with water.

Preparation of the base of the roof

Before laying, it is necessary to carefully prepare and check the surface of the roof. It should be cleaned of garbage, dust of other contaminants. And also do not have dents or significant changes in height.

Roofing roof roof roofing material

Most often, garages in cooperatives are equipped with flat roofs. In this case, the walls of the buildings are made of bricks and blocked by reinforced concrete slabs. Therefore, laying roofing material is not much difficult. It should be noted that this design has three weaknesses: the connection of the floor slabs between themselves and with the walls.

Stages of work

First of all, the surface is carefully cleaned of garbage, and if necessary, it is washed and dried until completely dry. In cloudy weather, this process can be accelerated using a soldering lamp.

When the surface is prepared, you can proceed to the warm -up of the bitumen mastic. Its consumption directly depends on the uneven surface of the roof. But on average, 2 buckets of the composition are spent on the roof area 6x10 m (60 m2). At this stage, a primer solution is also prepared according to the above recipe.

Important! In the manufacture of a primer (primer) with your own hands, it is the warm -up bitumen that is poured into gasoline, and not vice versa! Failure to comply with this rule can lead to ignition of the solution.

The primer fill all the cracks, detachment, cracks. It is recommended to smear the entire surface of the roof with bitumen mastic, but when laying by sailing, it is applied only along the edges of the roofing material sheets. In any case, the thickness of the mastic layer should not exceed 5 mm.

Now you can begin directly to laying the roofing material. The work is carried out from the bottom up (as a rule, a slight slope is still). When working with the burner, the rolls of the material are laid in such a way that they turn around, they fit into each other by about 15-20 cm.

Gradually promoting, roofing material is heated by a gas roof burner and pressed (with a manual roller or simply trampling with their feet). The life of the roof depends on how carefully this is done. This is due to the fact that in poorly pressed places, condensation is inevitably formed, which in a short time destroys the roofing material.

If the flooring is produced on mastic, then at first the entire area is covered with a thin layer of composition, and roofing material is laid on top of it.

Another thin layer of mastic is applied on top of the resulting coating and a second layer of material is laid. In the wallpaper of cases, the sheets should be located perpendicular to the previous layer. After laying the edges of the material, they are wrapped and attached to slate nails. And everything is repeated the right number of times.

Now the turn has come to lay the upper third layer. The roofing material for him has a rough powder that protects it from the influence of the external environment.

Lay it according to the principle of previous layers. It should also fit tightly, the joints have the necessary overlap, and the edges are securely fixed with nails. On this, roofing work ends. With high -quality performance, the service life of such a roof will be at least 10 years.

Roofing roof by roofing roof video

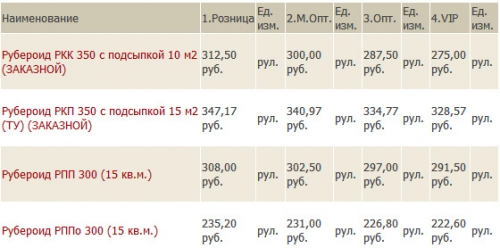

The cost of roofing roof roofing

For each roof, the amount of material is calculated individually and depends not only on the covered area, but also on the number of layers. But in any case, it is recommended to take a material with a margin of about ten percent, in case of incorrect laying of any site. Sale of roofing material is most often carried out in rolls from ten to fifteen meters. On average, a roll of 10 meters long and 1 meter wide costs from 300 to 400 rubles, depending on the manufacturer. The price of bitumen mastic also varies, but on average a twenty -liter canister costs within 500 rubles.

The use of roofing material is quite profitable, since the low cost of materials more than pays off a rather low operational period. That is why the roofing material is still in demand, despite the existence of more modern, high -tech and durable roofing materials.