The roof of the building is one of its main protective systems from bad weather, ...

|

|

Buildings and crafts made of wood occupy an important place in national culture, here ... |

The plastic window consists of several parts, and each of them should be taken care of ... |

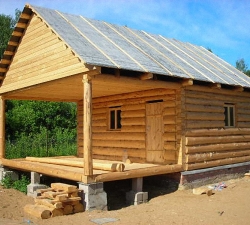

Foundation for log house: instructions for arrangement

The process of the construction of the log house is preceded by the laying of the foundation, which should become a strong base that protects the building from adverse environmental factors. About which foundation for a log house to choose and how to build it we will consider further.

Table of contents:

- Foundation for log house: varieties and features

- Foundation for a log house: marking

- Earthwork on the manufacture of the foundation for the log house

Foundation for log house: varieties and features

The main and most important part of any building is the foundation. Therefore, before building a log house, it is important to choose the right type of foundation that will contribute to the long -term operation of the building. The main characteristics when choosing the type of foundation is the type of soil and the load of the building itself.

We offer to get acquainted with the main types of foundations that will help in the future construction of a strong and reliable log house.

1. The foundation of the tape type - is a building base, buried in the ground. There are two types of strip foundation:

- deeply buried;

- surface.

The use of the first option is connected in the construction of a log house with a heavy structure or in the presence of an underground room. The depth of laying such a foundation is from twenty to thirty centimeters from the lower point of freezing of the soil. This foundation is very time -consuming and expensive, it is used in the construction of multi -storey buildings made of concrete, brick or stone.

The strip foundation of a surface type is used in the process of building a bar of a bath. In this case, its height is from fifty to seventy centimeters.

2. The foundation of the columnar type is the lowest -budget and simple in execution. It is used in the construction process of non -wealthy buildings of wooden or frame performance. When equipping such a foundation, pillars are installed in the ground, which help withstand the load and contribute to its uniform distribution. Pillars are installed along the perimeter and in the center of the building, necessarily in the corner areas, at the points of intersection of walls or the largest load. This type of foundation is not suitable for all types of soil, therefore, before its construction it is necessary to attribute the soil on which the log house will be built in a specialized laboratory where its properties will be determined. Pillars are installed to a depth of 150 to 200 cm. If you plan to build a log house on the foundation of this type, it is recommended to use a profiled or adhesive beam. With this material, the construction will become more attractive and colorful. If the massiveness of the log house is quite high, and the building is powerful, it is appropriate to use a galinder log adapted to withstanding large loads.

If we compare the consumption of materials for the construction of the foundation of these two types, then for arranging a strip it will take 2-5 times less building materials than for a columnar. In most cases, the use of a columnar foundation is appropriate in the construction of a log -shaped or frame type log house. During the construction of a bath, there is no need for equipment equipment, therefore, in this case, a columnar foundation is a good option.

There are several types of column foundations in relation to the material:

- reinforced concrete piles;

- steel pipes;

- asbestos pipes;

- screw;

- Plastic pipes.

The most common and often used type of column foundation is a screw. Its cost, ease of installation and the duration of operation make it popular. Installation of such a foundation involves deepening the screw piles using screwing. The main components of the screw pile are the trunk and blade. Among the main advantages of this type, they highlight:

- quick process of installing the foundation;

- the ability to install swampy type on the soil or on a soil with a high level of groundwater;

- lack of need to equalize the foundation;

- It is not required to expect a certain time after installing the piles;

- performance of work at any time of the year;

- High level of maintenance.

The most optimal type of foundation in the price and qualitative sense is the strip foundation of surface laying. Its construction does not need as much money as a deeply buried foundation for a strip, but its quality will not be as low as when arranging a columnar foundation. When equipping a log house, a depth of 45 to 75 cm will be quite enough. Even if small progress occurs, they are permissible for a building from a log house. The foundation for the log house of the bath allows you to reduce the depth of the laying to forty centimeters. When using the foundation of this type, it is necessary to insulate the surface of the soil, to reduce the risk of freezing. The main advantage of arranging the foundation of small deepening, in comparison with the column -type foundation, is the lack of need to arrange thermal insulation of the floor.

But, nevertheless, the main factors that determine the type of foundation used in the construction of the log house are:

- type of soil;

- ground water level;

- The load and the type of building being built.

In order to accurately determine the type, the necessary foundation, it is better to entrust this issue to specialists, they will determine the height of the foundation in the ground with an accuracy of a centimeter.

Foundation for a log house: marking

The most important process in the construction of the foundation is the marking. If the marking is done incorrectly, then the foundation will be remade, and this will affect the quality of the log house.

The main requirement for the site on which the foundation will be located is its absolute evenness and a slight slope in one of the sides. The slope is necessary so that the water, in rainy spring weather, drains, and not settled and does not destroy the foundation.

To mark under the foundation, you should use ordinary reinforcement rods and a fishing line or rope. It is better to give preference to fishing line, since it does not stretch, does not sag and stable before exposure to temperature, gravity or moisture.

First, start by fixing the fishing line on reinforcing bars, and then, using the level, select the line, which will become the starting point of the foundation. Set the foundation beam, which consists of two pegs driven into the ground that form the width of the foundation pit. The place of fastening of the outskirts from the facade section of the house is 150-200 cm.

In accordance with regulatory documents, the minimum distance between the house and neighboring buildings is 300 cm. The interval between the facade part of the house and the other building is at least 500 cm.

When the necessary boundaries are observed, proceed to create markings. First of all, remove the vegetation layer and completely level the site. After that, based on the preliminary design of the log house or bath, apply the contour parts of the foundation. The design of the walls affects the width of the foundation. The minimum width of the foundation is the width of the wall of 10 centimens.

Mark around the perimeter and forget the reinforcing bars in the corners. Check the evenness of the marking. To check the corners, use laser levels or roulette. All corners of the building should be straight. When the corners are exhibited, pull the fishing line on reinforcing bars.

Now proceed to mark the internal boundaries of the foundation. This process is simpler, since the corners are already leveled, and it remains only to measure the desired distance of the width, set the pegs and pull the fishing line. Next, you should check the evenness of the entire structure and move to the next stage - the equipment of the pit.

Earthwork on the manufacture of the foundation for the log house

There are two options for arranging the foundation:

- trench;

- pit.

The first option is several times cheaper and less costly in relation to the amount of work. The construction of the pit involves finding the basement in the log house. If the basement in the log house is absent, the trench is the most optimal option.

Based on the minor slopes of the site for the construction of a log house, you should use a water level that will help calculate the lowest and high-grade places. The depth of the founded pit depends on the highest point of the site. It is on the basis of it that the depth of both the pit and trenches should be determined.

The average depth of the trench is forty -centimeter for a log house, while the size of the sand pillow is not taken into account, which is from ten to fifteen centimeters. The total depth of the foundation for the log house is 55-65 cm.

Using the water level, when building a pit or trench, it is necessary to align their bottom in accordance with the level of the horizon. In order to determine the cubic membrane of the land performed during the construction of the foundation, the size of the pit's length to the average depth should be multiplied.

To reduce the load on the foundation during the spring swelling of the soil, it is necessary to pre -lay the pillow of sand. At the same time, sand is poured, which is gradually compacted and aligned. To make the process of building a sand pillow fast, you should pull the fishing line so that its height corresponds to the height of the sand cushion. The following is the process of backfilling the pit or trenches and ramers using special equipment.

Tip: When installing a sand pillow, it is recommended to moisturize the sand with water in order to ensure its high -quality compact.

To calculate the right amount of sand, it is necessary to multiply the perimeter of the trench by the thickness of the sand layer.

After the trench is dug, and the pillow is compacted, the process of installing wooden formwork follows. The main function of the formwork is to give the necessary shape of the concrete surface. There are two types of formwork:

- removable;

- non -removable.

The construction of the formwork is the most time -consuming and important process when arranging the foundation. For the manufacture of shields, the formwork is used a finished board, which, although more expensive than ordinary boards, differs from them near the advantages, including:

- smooth and even surface;

- cheaper costs for finishing the basement, since its quality during formwork with a trimming board is much higher than when installing formwork from ordinary boards;

- the presence of specific measurements of the wiped board allows you to monitor the height of the formwork of the future foundation;

- The possibility of repeated use of such formwork.

The shield set along the length of the foundation should be a little shorter, on the thickness of the board installed in width. The inner part of the formwork is broken by nails that connect all its parts. After assembling the shields, you should proceed to the installation of formwork on the trench.

The assembly of the end parts of the formwork is carried out using self -tapping screws. This process allows you to ensure a tight fit of the shields to each other and reduces the risk of staging the solution through the cracks. The lateral and upper parts of the formwork require strengthening using spacers. The reliability of the formwork constructed depends on the number of spacers. The concrete solution greatly loads the structure, so the formwork should be durable. To avoid the solution of the solution on the boards and absorbing it, as well as in order to make the walls of the foundation perfectly even, pergium or roofing coating should be installed on the internal walls of the formwork. Make sure that the formwork height is greater than the height of the foundation itself.

To determine the cost of the formwork, which is based on a trimming board, it is necessary to divide the length of the total perimeter by 600 cm, the length of one of the boards, and the formwork height is divided into 15 cm - the height of the board. Thus, we get the right number of boards that will help to build formwork for the foundation. The amount of Pergamine depends on the required formwork height. This material is in a roll state, the width of one roll is a maximum of forty centimeters. To fix Pergamine, a construction stapler with brackets will be required. When the formwork is ready, you need to start the next process, which includes reinforcing and strengthening the walls of the foundation.

In order to increase the mechanical strength of the concrete foundation, as well as to increase its mechanical strength, the reinforcement process is necessary. The reinforcement is a kind of skeleton that holds the entire load and increases the durability of the foundation. The distance between the edges of the foundation and the reinforcing grate is 30-50 mm. To reinforce concrete, it is necessary to have a reinforcement, the cross section of which is 1.2 cm. The fittings are laid on a brick, previously laid in two rows. To increase the strength of the foundation, you need to use whole reinforcement, and avoid a large number of compounds. Using a knitting wire with an interval of 40 cm, you need to tie the jumpers. Vertical rods are installed on the corner parts of the reinforced structure. To make the connections as strong as possible - use the welding machine.

Then, also install the upper and lower row of the designs with jumpers in forty centimeters. To determine the cost of reinforcement, the number of jumpers required for reinforcement should be determined.

When the reinforcement is performed, proceed to the installation of ventilation of the basement of the foundation. To do this, you will need a pipe from asbest cement or plastic, the diameter of which is 10 cm. So that in the process of filling the concrete does not get into the pipe, you need to first close it with sand or rags.

Tip: the pipe should be installed with a slope that leads to the street so that water or condensate that accumulated in it is easily drained to the ground.

When pouring the foundation, the mandatory component is the presence of a concrete mixer or automyxer, which will provide a homogeneous structure of concrete. And the vibrator - will help make the structure of the foundation homogeneous, get rid of excess air in the solution and increase the adhesion between concrete and reinforcement.

The process of preparation of the solution includes the use of a cement of two hundred, three hundred or four hundred brands. The choice of a certain brand depends on the individual characteristics of the object and the season in which work is carried out. To prepare the solution, you will need cement, sand, aggregate in the form of crushed stone and water, in a ratio of 3x3x1, and water is calculated in accordance with the required viscosity of the solution.

Concrete pouring concrete gradually in order to avoid the formation of air accumulation. Each of the layers requires the use of a vibrator that compacts it. For a good fit of concrete to the formwork, it is necessary to carry out periodic tapping, which will help distribute the load from the solution evenly.

In order to avoid stratification of the mixture, it is necessary to very quickly fill one of the layers. To avoid cracking with make the foundation as strong as possible, after pouring it, water it with water, during the entire period of drying.

In rainy and gloomy weather, as well as in winter, it is recommended to cover the foundation with polyethylene, in order to avoid washing off the upper layer. After at least three weeks, the formwork is removed and the construction of the log house begins. This type of foundation is suitable both for the construction of an ordinary log house, and as a foundation for a log house.