Bezramic glazing attracts with airiness and simplicity of design ...

|

|

Until recently, we could not imagine what could be done with the ceiling ... |

It is no coincidence that part of the kitchen wall between the working surface consisting of a countertop, ... |

Do -it -yourself polystyrene foam installation: detailed instructions. How to install external insulation yourself

The question of whether to warm your housing often becomes relevant before the cold. Nowadays, the savings have become very popular, or it is caused by economic factors, or people just want to save somewhere, leaving an extra penny on vacation, but the fact remains. True, not only for the sake of saving, outdoor insulation is now being installed. This necessity is often caused by the technical characteristics of housing, where, for example, very thin walls are laid down in one brick, or severe blowing, when even metal -plastic windows do not save. How not to twist, insulation will always be beneficial.

Table of contents:

- Polistyle foam for external cladding

- DIY polystyrene insulation of walls: surface preparation

- How to insulate the walls with polystyrene foam: step -by -step instructions for mounting insulation

- Installation of polystyrene with your own hands video

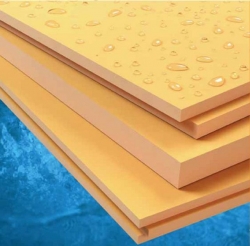

Polistyle foam for external cladding

Each owner, before taking up work on warming the house, finds out what materials are used for this case, what advantages have and decides to use one of them.

So, the following materials are most widely used for external cladding:

1. Foam polystyrene - stable granules filled with gas, soluble in the polymer mass (in the simple way foam).

2. Mineral wool - is formed after spraying molten glass by weaving such fibers.

3. Poliuretan foam - gas -filled plastamass, obtained by foaming and hardening (in a simple way - foam rubber).

4. Basalt slabs - fibers from molten rocks, plates are formed using a synthetic binder.

5. Pulp heater - based on paper, loose and fibrous material.

To date, the most common in external insulation is precisely polystyrene foam. It is used by both professionals and independent craftsmen. If for the pro it is clear why this material should be taken for work, then a person who decides to independently needs to familiarize himself with his advantages.

DIY peenproof wall insulation begins precisely from the study of the material that will be applied. Polostyrol foam, otherwise the foam has a number of features that distinguish it from the above materials - insulation:

- the cost is a very economical insulation, which gives him the right to be in the first place among insulation, because there are a lot of people who want to save a lot;

- during the cutting and installation - such an advantage also gives the right to a predoric purchase among other materials, because the walls of the walls with foam with your own hands, without the help of a pro, will be much easier if the material you work with is easy to use;

- reliable and durable - what is important for any building material, because I want to repair the repair as little as possible, not to spend interesting life moments on the construction.

DIY polystyrene insulation of walls: surface preparation

In order for all work to be completed successfully, you need to start them wisely. Familiarization with the material that will act the main during installation has already been made, its pluses and some disadvantages have been studied, it remains to prepare the surface and begin insulation.

Whatever installation option you choose: on glue, on the fasteners of fungi or using a frame, you must first clean the walls of various contaminants, previous cracked and partially soldered layers of plaster, different objects that may prevent the insulation. All this is combed, strangled, aligned.

There are times when the wall prepared for insulation requires more attention in preparation. These are those cases when it needs to be subsided in some places where the differences exceed 2-3 cm. Such gaps on the wall must be aligned, otherwise the insulation may be incorrectly attached, respectively, it will not be good enough to perform its function.

Important! Putty for external work is of different types, when buying it, you need to consult with the seller, be sure to indicate that it will be used for external work.

After these manipulations, it is necessary to primer the surface of the wall (do this after the plaster has completely dried). It is especially necessary to primer if you put up the wall, and if the glue mass is used in further work. The primer (necessary with the property of deep penetration) will provide the best adhesion between all layers during insulation.

For a more accurate fastening of the insulation, further plastering, and it is possible to fasten siding, you can do a whole system of beacons and plumb line. These manipulations are performed are not difficult, but they help to do everything efficiently, and facilitate installation, since the external edge of the insulation is visible on them.

On the upper edge of the wall, you need to attach an anchor, tie a strong thread or a special cord-twes to them, on which the loads will be attached to the floor. It is also important to make the threads located horizontally, then the grid will come out, with which it is realistic to lure when installing the insulation and frame blocks.

So, the preparation of the wall for the subsequent installation of foam requires the following materials and tools:

| Material/tool: | Application: |

| putty knife | With it, you get rid of excess old plaster, use it in the future and for putting the wall |

| putty | Building material for leveling the wall if necessary |

| primer | Building material is used for better adhesion of different layers during wall decoration |

| Roller | Construction tool, used to apply a primer |

| Anchor | Fastener, used to fix the threads for plumb line (cargo) on it |

| Cord-Obser | Special mounting and marking thread, with its help, marking is made for the long -range mounting of the insulation |

All materials should be at hand in order to quickly do preparatory work and start directly to insulation. But do not forget that the preparation of the surface is one of the most important stages, which should not be negligent.

How to insulate the walls with polystyrene foam: step -by -step instructions for mounting insulation

As already stipulated, the fastening of polystyrene foam can occur in various ways: on special glue, on fungi or using the frame. We will consider the option that is the most reasonable and worthy attention. Fastening with glue, but also using the second method, fastening with fungi, verified by professionals and many years of using such technology. Each owner will be able to make such installation without special costs, because the double reinsurance will cost only a couple of packages of fasteners in the form of fungi, and they are inexpensive, especially in comparison with the scale of the entire insulation of the dwelling.

When the purchase of foam is made, you need to take into account the features of your home and buy material of the correct thickness. After all, when external insulation with a foam with your own hands is performed, this moment is the most common error that entails the inefficiency of work, or the consequences in the form of a fungus and collecting moisture in the room.

In practice, it is known that the required sheet thickness for a private house should be at least 50 mm, then the insulation will be really effective. Another best solution would be to install two sheets of 50 mm overlap, which together will give 100 mm. Such installation will be ideal both in thickness and thermal insulation, because in this way all the bridges of the cold in the joints are eliminated.

The work will require not only the foam of a certain thickness, but also other building materials: starting profile, building glue, dowels called fungi (their length varies depending on the thickness of the foam and type of wall, from 90 to 120 mm), a metal perforated corner, mesh, grid An external, metal profile with a grid for slopes, plaster, paint or siding, depending on the decision on the final decoration of the facade.

1. The first thing that is necessary is to install a perforated metal profile below the perimeter of the wall, which will subsequently serve as a kind of shelf in order to smoothly exhibit the first layer of sheets of polystyrene foam. The width of the corner must correspond to the width of the foam sheet.

2. After fastening the perforated corner, you need to dilute a special glue with water in accordance with the instructions. There is a more modern and easy -to -use glue in the form of foam, it goes in cylinders as a mounting one, it is already applied ready. The glue should be bought in advance, and be specially designed for such work. The first option, diluted with water, is more common in practice and is many times cheaper.

3. The third stage is the application of glue. This must be done with great caution, first laying the foam block onto the flat surface, so that more than one edge is not on weight, otherwise the material can break off under the heaviness of glue, because the foam is air building material, and very fragile. It is also necessary to apply glue correctly: not with stripes or blots, but on the entire surface of the docking with a wall. Of course, it is not necessary to smear the entire block, but to do this with a gear spatula, with wave -like movements. If the wall is not perfectly flat, then the method of applying glue is used along the edges and blots along the rest of the perimeter.

4. How to put polystyrene on the wall - it would seem that the question is, but it is not necessary to rush with it, because the fragile material is with a large load - glue on the surface, because it is important to even just pick it up, it is better if two will do it man. For installation of polystyrene, select the farthest wall to practice in the mount, and start from the lower corner. To help, the marking made in the preparation of the surface will be performed in the preparation of the surface. Subsequent rows are laid with a displacement (according to the type of laying of tiles, bricks).

5. After the additional mount is used using fungi. Their number on each foam block is five to four in each corner and in the middle. This is one of the options, some builders mount differently, fixing fungi along the edges of the sheet.

When installing dowels, they should not perform, but rather delve into a sheet of foam. Later, the joints of the joints and the mounting location of the dowels are sealed with glue with a spatula.

6. External insulation with foaming with your own hands requires an attentive approach to all the nuances, so the next step is the pruning of the protruding parts of the foam sheets in the corners, grinding the surface of the sheets with a special grater. In the case when a more crescent has passed since the foam fastening, the upper layer of foam around the perimeter will have to be washed with grinding, since it is damaged by weather effects.

7. The corners of the house made of foam with your own hands must be provided with a meal perforated corner with a net. Moreover, it will not work perfectly at the junction of the foam, and with the help of the corner it will be possible to remove a beautiful angle. It is necessary to fix the corner using the same glue as the sheets of foam. It is advisable to control with the help of the level how smoothly it turned out to glue such a corner, because so far the glue has not dried - everything can be adjusted.

8. At the previous stage, the mounting of the insulation and the main finish were completed. But the important finish line remains. At this stage, it will be necessary to cut off the reinforced mesh of the desired size, apply glue to the upper part of the wall and gradually lay the net with glue. With such manipulation, the main thing is that the net is slightly overwhelmed with the subsequent stripes, and does not suse, creating irregularities, they are unacceptable. If such already arose, while the glue is not dry, it should be fixed with a spatula or manually, so as not to make even worse. Next, the reinforcing mesh is covered with two layers of putty, which are applied after the previous layers dry out. They need to be applied with a spatula, drawing in even lines without leaving divorces.

After the above work, there should not be a single clearance of foam, all areas should be carefully worked out by plaster. After that, everyone decides for himself, or use the most affordable option for decorating the facade is the usual painting for plaster, or to run to a more expensive, but certainly chic siding in appearance.

Installation of polystyrene with your own hands video

Sometimes it’s better to see once than to hear a hundred times, and for such cases we offer to watch a video on this topic:

I was building a house and I had to buy

I was building a house and it was necessary to buy a stainless corner at a low price. Friends advised the company "Steel- pro" http://www.steel-pro.ru/metalloprokat/ugolok/nerzhaveyuschiy/. I accurately decided on the dimensions, after which I called the manager, left the order. The corner was delivered exactly in the time, cut as ordered.