It is not difficult to build pillars for the fence with your own hands, here's an important ...

|

|

Powder painting doors is a technological process, as a result of which ... |

Behind the concept of the draft floor, not just poorly processed boards are hidden ... |

Installation of aerated concrete blocks with your own hands

Aerated concrete is a synthetic building material, which is a variety of cellular concrete, its mass does not exceed 0.5-1.2 t/ m3 (against the weight of brickwork of 2-2.5 t/ m3), that is, it is a light, porous substance produced On a mineral basis. Throughout the volume of aerated concrete products, small round pores up to 3 mm in diameter are evenly distributed, due to which the weight of the material occurs. The article will talk about the installation of walls from aerated concrete blocks.

Content:

- Malician production technology

- Advantages of aerated concrete blocks

- Technical characteristics of aerated concrete blocks

- Breeding a house from aerated concrete blocks

Ax concrete blocks are widely used in construction around the world, they are made in 50 countries at 250 factories and has high quality and strength. Products are used in the construction of walls of any type. Buildings built using this material are distinguished by high thermal insulation qualities that are achieved due to the verified geometry of the blocks, the composition and technology according to which they are produced, as well as due to their laying on an adhesive 3 mm layer, preventing the freezing of the seams.

Malician production technology

The mass for the manufacture of aerated concrete includes several mandatory components and some additional ones that may not be added, depending on the technology of production.

Mandatory elements:

- quartz sand;

- high -altitude cement;

- water;

- gasoling (pasta or suspension from finely dispersed metallic aluminum).

Additional additives:

- gypsum;

- lime;

- metallurgical slag;

- ash.

The components in dry form are thoroughly mixed with each other, and then knead with the addition of water. The resulting mass is laid out in metal-plastic forms, without filling them to the top. The process of foaming occurs as a result of interaction in the aquatic environment of the gas former and cement. After a short time, the mixture increases in volume and hardens, after which the monolithic plate is removed from the mold and cut into rectangular bricks of the required size.

- At the last stage of production, the workpieces are dried in an autoclave (the device allows you to process the material under pressure and at high temperature) or in drying chambers with an electric heating. It is according to the technology of final processing that aerated concrete is subdivided into autoclave and non -circular. For most types of construction work, it is recommended to use autoclave aerated concrete, which has improved technical characteristics. Due to steam processing, the structure of products acquires greater uniformity and strength.

- Non -autoclastic aerated concrete blocks, as a rule, are produced in small factories with manual manufacture, since with this technology special equipment is not required, the mixture hardens in the forms naturally. The finished material has less strength, and when erecting buildings, it is recommended to lay it in two rows, or the use of such products with an additional layer in multi -layer masonry.

Advantages of aerated concrete blocks

Estate blocks have many positive qualities:

- this is material with increased sound insulation and thermal protection;

- it is based on only mineral components;

- has high frost resistance;

- it has a small share of the standard block, in size 62.5x10x25 cm, does not exceed 10 kg;

- it has good resistance to fire, withstands an open flame for 3-4 hours;

- does not rot in a humid environment;

- it differs with a quick and easy installation, easily processed, sawn and cut without the use of special tools, so that the price of the installation of aerated concrete blocks is lower than for masonry made of brick;

- economical material, due to the low cost of the unit and lower expenses of cement during production as well as due to a decrease in the cost of transportation and the installation of the foundation, in addition, the installation of blocks can be carried out by one person without involving assistants;

- after time, the finished masonry made of aerated concrete gains even greater strength;

- differs in low natural radioactivity;

- environmentally friendly material;

- with low -rise construction (up to 3 floors), the use of blocks for the construction of supporting structures is allowed;

- reinforced aerated concrete products can be used as floor slabs.

Of course, like any other material, aerated concrete has its drawbacks. The main negative qualities include the presence of through pores, due to which the blocks need additional waterproofing, as well as such pores reduce mechanical strength.

Technical characteristics of aerated concrete blocks

Aerated concrete products are divided into two main types.

- Particular gas concrete blocks The thickness varies from 7.5 cm to 20 cm, the main purpose: the device of interior partitions and internal walls (unnecessary structures) can also be used as a warming layer for brickwork.

- Wall gas concrete blocks thickness from 25 cm, main purpose: the construction of the load -bearing walls. For the construction of buildings in cold climatic zones, it is recommended to use aerated concrete products with a thickness of 37 cm, in this case, there is enough plastering work from the outside of the structure for insulation.

Ass concrete products have the following options:

- density: 350-1700 kg/m3 (marking D, the lower the brand, the warmer the material);

- compression density: 1-7.5 MPa;

- length: 60 cm, 62.5 cm;

- width: 7.5 50 cm;

- height: 20 cm, 25 cm;

- frost resistance: up to 75 cycles (marking F);

- environmental friendliness coefficient: 2.0;

- water absorption: less than 20 %;

- thermal conductivity: 0.16-0.81 W/m3;

- sanding when drying: 0.5 mm/m.

Breeding a house from aerated concrete blocks

Calculation of aerated concrete blocks

- Before starting construction, you should calculate the required material. As an example, you can take a house, the dimensions of which are 15x13 m, at a height of 3 m. To calculate the area of \u200b\u200bthe walls around the perimeter, it is necessary to fold the width of all four walls and multiply by height: (15+15+13+13) x3 \u003d 168 m2.

- If several walls have the same sizes (as in our example), then you can do as follows: 15x2x3+13x2x3 \u003d 168 m2.

- To find out how much cubic meters of aerated concrete blocks you need the result should be multiplied by the thickness of one block (for example, 0.3 m): 168x0.3 \u003d 50.4 m3. This number of blocks is necessary for the construction of the external walls of the building (blocks are sold in pallets and measured in M3). According to the same scheme, the internal walls and partitions are calculated.

- If it is required to calculate the piece of products in 1 m3, then the volume of one block used should be calculated, for this the lengths of all its sides are changed. For example, you can take a product with a standard size: length 60 cm, height 20 cm and thickness 30 cm. First of all, it is necessary to transfer centimeters or millimeters into meters. As a result, the following formula and the result will be obtained: 0.2x0.3x0.6 \u003d 0.036 m3. Next, it remains to divide 1 cubic meter into the resulting volume of blocks: 1/0.036 \u003d 27.7. It turns out that for the construction of one cubic meter of masonry it is necessary to purchase 28 blocks of the installed size, and for a house at 168 m2 it will require approximately 1,400 blocks.

Based on the calculations, you can calculate the approximate cost of the entire construction.

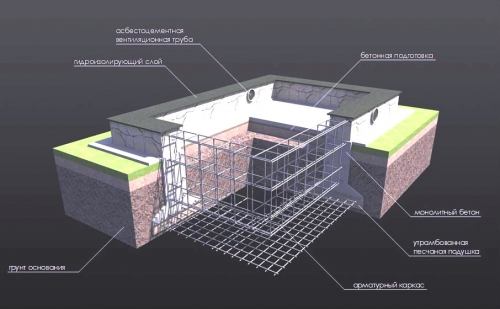

House foundation from aerated concrete blocks

Having calculated the required amount of material, you can proceed to the construction of the foundation. For construction from aerated concrete, the foundation of several types is used:

- columnar;

- monolithic strip;

- monolithic tile.

A specific species is selected based on a number of parameters, such as the project of the house, the characteristic of the soil, the depth of groundwater, etc.

Tip: Experts recommend pouring a monolithic-lental foundation. If substances for accelerated hardening were not added to the foundation solution, then it will be necessary to leave the foundation for a month for complete hardening and a set of strength.

Whatever the base for the house is chosen, it should be carefully insulated and waterproof. This can be done using 1-2 layers of roller material, for example, roofing material. The base for laying walls should be leveled in a horizontal plane.

Estate blocks installation tools

Before laying aerated concrete blocks, you need to prepare the necessary tools and materials for work:

- aerated concrete blocks;

- adhesive solution;

- tough and straight spatula;

- building level;

- shirt or grinding board;

- manual hacksaw or electric strip saw;

- brush.

To prevent cold bridges that are formed in a cement-sand solution, a special adhesive composition based on Portland cement, quartz sand and additives (mineral, polymer) is used when laying blocks. The mixture is shut in clean water, the temperature of which is not more than 30 degrees.

The indicated norms for adding water to the composition should not be violated, since too liquid glue will have reduced strength characteristics. It is recommended to apply glue with a layer not exceeding 3 mm using a gear spatula. The prepared solution cannot be stored for a long time, and the location of the blocks can be adjusted for 3-4 minutes.

The Xella company has been producing various tools for several years, the main purpose of which is to increase the quality and speed of the installation of aerated concrete. A professional tool is developed taking into account the technical characteristics of individual blocks, their size and geometry are taken into account.

The main set of specialized auxiliary tools:

- kelma is the width of the width of the blocks, provides the thickness of the applied layer from 1 to 3 mm, the dignity is that when applied, the solution does not flow down the sides, but is precisely distributed on the surface of the block, as a result of which the masonry remains clean;

- the carriage with a dispenser also corresponds to the width of the blocks in size and is used for the highest possible application of the adhesive mixture, has a maximum width of 500 mm;

- a rubber hammer that prevents damage to cellular concrete (you should not replace this product with a simple metal or wooden hammer, since their use leads to damage to the blocks of aerated concrete);

- stroborer helps to cut grooves in aerated concrete manually;

- a hand saw or cutter is used for a neat cut of blocks, have carbide attacks;

- rubanok helps to change the shape of the block and level large irregularities in the masonry;

- a grinding board eliminates minor irregularities and defects in erected aerated concrete structures;

- the corner fixes the block and helps to make even cuts on it.

In addition to a specialized tool, the German company Xella produces the Ytong gas concrete blocks themselves, as well as adhesive compositions and winter mixtures.

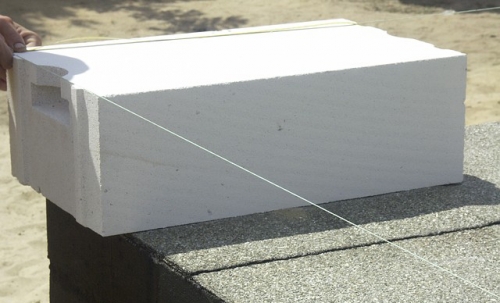

Laying aerated concrete blocks

- The strength of the entire structure depends on how qualitatively the first row is laid. Masonry made of aerated concrete blocks differs from brick, since aerated concrete is a relatively light material that does not squeeze an excess solution from the seams during installation. In addition, walls from it can be erected without technological pauses.

- To build external walls by building codes, it is recommended to use blocks, the thickness of which is at least 37-40 cm, for external walls there are enough blocks with a thickness of 25 cm, and decorative walls and partitions are allowed to be erected from aerated concrete with a thickness of 10 cm.

- So, before starting the construction of the first row of masonry, the base should be carefully prepared. First of all, this applies to laying waterproofing materials. Any roll bitumen or polymer material (for example, roofing material) or a special waterproofing solution based on polymer -cement components can be used as waterproofing.

- A layer of a cement mortar of 2-3 cm is applied on top of the waterproofing material (approximate composition: 1 part of cement, 3 parts of sand), which will help compensate for the irregularities of the foundation. Horizontal is necessarily checked using the construction level. The first row is laid along a stretched thread starting from the corner.

- The adhesive mass is applied with a thin layer on the blocks and the first row is laid out. Each laid block is checked in level in a horizontal and vertical plane, if necessary, the blocks are knocked out by a special rubber clay.

- If, when laying blocks in a row between them, the space remains less than the standard length, then a pretequisite element should be made. To do this, using a manual or electric saw, cut off the required length from an aerated concrete unit and trim the sawing a grinding board or a shirt.

Tip: It is important when installing such an element to smear with adhesive composition and its ends, adjacent to the main row. This should be remembered at any stage of the construction of the wall, if the block has slices, it is necessary to treat it with glue from all sides in order to add the strength of the constructed structure.

- The second and subsequent rows are laid from the corner with a displacement for half a block to the right or left (at least 8-10 cm). For a more reliable masonry, before proceeding with the installation of the second row, you should wait 2-3 hours to solidify the cement mortar of the first row. With the help of the brush, all small particles and dust swing. In cases of the appearance of excess solution, such smudges are cleaned, but do not grin.

- In order to achieve optimal evenness of the rows, it is recommended to install wooden structures for the entire row or in corners. The leveling of the horizon and verticals is made after each row. If even small differences remain, then this can lead to the appearance of voltage in separate areas, and subsequently to the formation of cracks.

- You should refrain from unpacking all the products of their aerated concrete at the same way, since the material can reduce its technical parameters from the effects of precipitation and various atmospheric phenomena. If it begins to rain during the construction, then the unfinished masonry must be covered with a film, and when stopping work for the winter period, it is necessary to carefully insulate the structure from moisture. On hot days, the installed aerated concrete blocks are recommended to be wetted with water.

- Upon completion of the construction of a building from aerated concrete, it is best to leave the structure for some time for shrinkage. As a rule, buildings made of cellular concrete do not give a large shrinkage and after 1-2 months you can begin to interior decoration.

- The finish inside the building is made earlier than the decoration of the facade, since moisture formed from the filling of floors and painting should be out. When installing windows, doors or other elements, special dowels should be used without using a shock drill for drilling.

Glue solution for laying aerated concrete blocks

- It is worth saying separately about the adhesive composition used in the process of erecting aerated concrete structures. Until now, many for these purposes use cement-sand mortar in attempts to save. In fact, this is only the appearance of savings, since the cost of special glue, although it exceeds the cost of sand and cement by about 2-3 times, but at the same time, the flow of adhesive composition is much less, about 6 times.

- In addition, making the inter -block seam of the minimum size, you can achieve a significant decrease in heat plant, and this is possible only using special glue.

- By laying blocks on a cement-sand mortar, it is impossible to obtain their maximum density in relation to each other, so it will not be possible to avoid the appearance of cold bridges. As a result, the interior decoration will also suffer, since condensate will accumulate on the outer part of the wall and eventually this will lead to the formation of bacteria, mold and fungi. Also, a cement -based solution significantly reduces the strength of the compression structure and is quite difficult to achieve acceptable evenness of the entire masonry.

- Preparing an adhesive solution is not difficult. The mixture is sold in the form of dry powder, which is added to the water before use according to the instructions. The resulting mass is mixed until smooth by the construction mixer or with the help of a special nozzle on the drill. The resulting solution has an average consistency resembling thick sour cream. You can apply it both with a trowel and using a special carriage or bucket with a bent edge. Then, the applied layer is leveled with a spatula with a gear comb.

- The carrier seams should be filled out completely regardless of the shape of aerated concrete products. Interlock joints with a groove connection are filled with the mixture partially. In winter, it is recommended to use glue solutions with special frost -resistant additives.

Internal and external decoration of gas concrete structures

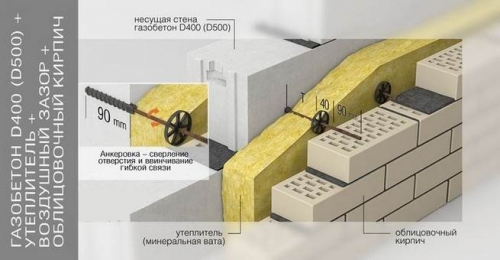

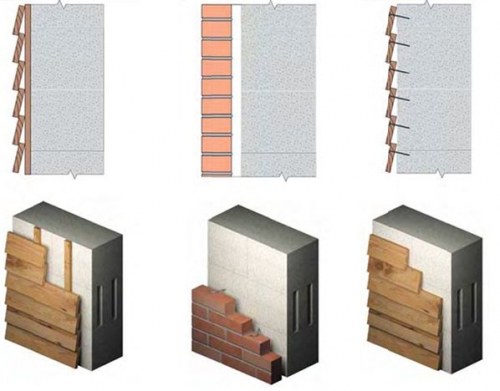

Thermal insulation

- Aerated concrete products perfectly maintain heat. Most often, a significant part of the heat loss occurs due to the presence of cold bridges in the interlock seams, as well as through other elements of the window structure, roof, foundation, and so on. Therefore, erecting a house from cellular concrete, you should take care of increased thermal insulation of these elements. If there is a need for an additional insulation layer for walls, then you can use products based on mineral wool, and then use plastering or ventilated facades.

Finishing

- When choosing materials for finishing the house, it is necessary to take into account the fact that aerated concrete is a porous material that can absorb water. This process should not be afraid, since moisture does not penetrate deeply the material, but only slightly moistening its surface. At the same time, the formation of dark spots or subtexts is possible, which very strongly spoil the appearance.

- The interior decoration can be performed using vapor -permeable materials, while the building will lose natural ventilation, but the external decoration of the facade, especially with the help of plaster, will last much longer. It is also possible to perform cladding and vapor -permeable material, forces for such a finish will be required a little more, but at the same time comfortable living conditions will remain in the house.

- Starting to the interior decoration, you should wipe all the irregularities available on the walls, filling them with an adhesive composition or a mixture of cement and sand. First of all, the masonry must be treated with a special primer (for hygroscopic materials). To do this, the surface is exhausted and abundantly covered with a primer. Next, withstand 3-4 hours and proceed to plastering.

- For residential rooms, it is best to use inexhaustible compositions, the same rooms where there is increased humidity (corridor, bath, kitchen), it is worth additionally treated with waterproofing mixtures, and then linen with moisture resistant plaster. After primary processing, you can proceed to the decoration process. It is recommended to use paints for aerated concrete for these purposes.

- For decoration of facades, it is best not to use foam glass or foamed plastic products, it is also worth refraining from painting steam and air-resistant compounds or using polymer plasters. It is optimal for external wall cladding to arrange various ventilated structures from siding, rails or decorative plates. If you want a plastered facade, then only special compositions designed for aerated concrete can be used, since ordinary plaster will begin to lag and peel off over time.

Masonry from aerated concrete blocks is not destroyed under the influence of the environment even without the use of additional external decoration. In general, cladding is carried out only to increase the aesthetic qualities of the exterior. Properly mounted roof, a reliable drainage system, as well as elements as visors and window sills, will help maintain the erected structure in its original form for many years.