In modern society, construction and repair are in demand, and ...

|

|

Any design of the building should effectively perform the main functions, including protection ... |

The double -glazed window is the most fragile part of the window structure, it is very easy ... |

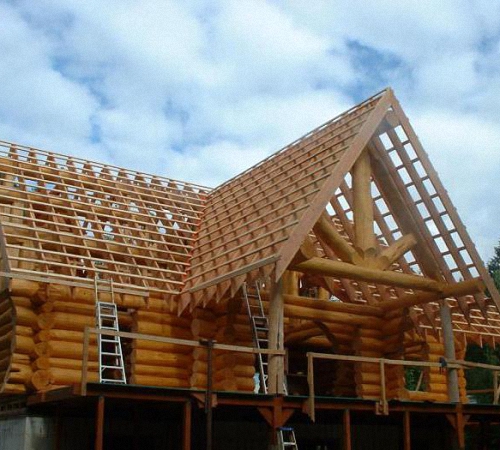

Installation of wooden roof

The modern market for building materials offers a huge assortment of various kinds of roofing coatings. The roof of wood is not particularly popular, although it has a large number of advantages. First of all, we note the environmental friendliness of the wooden coating and its safety both for human health and the environment. We will consider further about the features of the installation of a wooden roof.

Table of contents:

- Wooden roof: advantages and disadvantages

- Varieties and a wooden roof device

- Calculation and estimate on a wooden roof

- Wooden roofing technology: styling features

Wooden roof: advantages and disadvantages

If the roof is covered with a tile of wood, then it will take quite a lot of time to install it. Since the fixation of each element is carried out manually. However, wood roof is characterized by good soundproofing characteristics. In addition, the tree has excellent thermal insulation characteristics and is a regulator of a healthy atmosphere in the room, that is, if the room is high humidity, then the tree absorbs moisture, if the air in the room is dry, then the tree gradually gives moisture.

The roof made of wood has an attractive appearance, since wood is a natural material that fits well into the surrounding area. The cost of buying a wooden roof is average compared to alternative roof options, however, if you make such a roof yourself, then much less material investments will be required.

The principle of the functioning of a roof made of wood is that when getting wet, it increases in volume and creates a holistic structure. At a time, when the weather is dry on the street, the tree decreases, and through the cracks between it the air circulates, ventilating the space. That is, wood is the so -called waterproofer and fan that provides these functions naturally. Therefore, in the process of installing a wooden roof there is no need for laying layers of steam and waterproofing nature. Thus, the cost of the roof is reduced.

The roof of wood differs primarily with functionality. With the help of wood, you can equip all kinds of roofs in houses, arbors, canopies, sheds, etc. Wooden roofs are resistant to wind, snow, high and low temperatures. The duration of the operation of the roof made of wood is more than fifty years, with proper care and processing of wood. A special kind of impregnation makes a tree resistant to moisture, fire and all kinds of negative influences.

Also, wood roof has excellent thermal insulation characteristics, it does not accumulate on the surface of condensate, so it does not need thermal insulation and waterproofing.

Therefore, highlighting the advantages of a wooden roof, we note:

- aesthetic appearance of the coating;

- the economy of the roof made of wood;

- environmental safety;

- Universality of application and multifunctionality.

Varieties and a wooden roof device

The roof of wood has a fairly wide area of \u200b\u200bapplication. In the ratio with the place of its installation, the type of roof, its functions and design is determined. In addition, wood roof is factory production or is made independently at home. For additional decoration of the roof, an artistic thread is performed in its lower areas. In relation to the configuration features of the roof made of wood, they happen:

1. Raid.

The racing is called individual sections of the roof, in the form of stab or sawn plates, which have a cut of rectangular, trapezoidal shape. Each of the boards lends itself to a kind of shopound. Their connection is carried out using spikes and grooves and additional fixation on the surface of the crate. If the wooden structures of the roof are made of unlawed -type materials, then fixation on the surface of the crate and is carried out exclusively with nails or self -tapping screws. Fasteners are installed on the surface of two plates and entered in the lattice by two centimeters.

In order to calculate the required amount of material for the honde roof, you should initially determine the circuit of a wooden roof. To determine the step of the crate, it should be divided into the number of layers, two or three, depending on the design features of the roof.

Keep in mind that sawed materials are distinguished by lower operational properties and technical quality, since when they saw them, the natural structure of wood fibers is destroyed, so the tree becomes unstable to moisture, ultraviolet and other external irritants.

Wooden roofing photo:

2. A wooden roof in the form of a fight or wood chips.

These roof options are more simplified, they differ in size and thickness. Each line of the roof has a length of about forty centimeters. In order to make a wooden roof with your own hands, you should split the chocks into plain -type planks. Keep in mind that logs should differ in impressive dimensions, and at the same time should not contain moisture in their composition. The optimal level of wood humidity is 17%. With lower humidity, the tree will crack in the process of Kolki. The inside of the logs is not used for the manufacture of the roof, since it has low operational characteristics.

Each element of the roof of the fights or wood chips should not contain a zabrinka or knot in its composition. It is best to make a roof of coniferous materials or alder. The installation of wooden roofs of the fight is carried out in a checkerboard pattern, in several layers, with the mandatory observance of overlaps, both in vertical and horizontal position.

Keep in mind that in order for the side planks to fit each other tightly, you should remove the chamfer from them, at an angle of forty -five degrees. In addition, the appearance of the roofing will improve.

3. The roof made of wood is Shindel.

This version of the roof has the shape of a tile, which is installed with a small overlap, which does not have a clear chess order, but a little displaced. Fixation of the elements of a wooden roof is carried out with a small gap. In the process of getting wet, the tiles increase in size and forms a continuous flooring that prevents moisture from entering the room. In the process of manufacturing this kind of roof, the location of wood fibers should be taken into account. Otherwise, there is a risk of roof deformation.

4. The roof of a lemhah type.

This type of roof has long been used to decorate the roof in churches and mansions of the boyars. Each particle of the roof is a work of art created manually. In order to build this version of the roof, the presence of aspen and manual tools will be required. Time for the harvesting of a tree is the middle or end of spring. In this period, the tree contains a large amount of juice. The cost of a roof of a lemhah type is quite high, due to the difficulties arising in the process of its manufacture.

5. The teddy version of the roof.

This roof consists of boards made of coniferous wood, which are installed in the longitudinal or transverse direction. The installation of boards with a transverse cornice is more practical. In the central part of the roof, the gutter is mounted along which water flows. Roof installation is carried out in two layers, in compliance with or without gaps. To fix the boards on the surface, solely nails are used. The core of the tree is installed on the outer part. The inner layer is installed by the core to the bottom. If the installation is made in the longitudinal direction, then you should initially install a sheathing board on which the roof will be attached. Each board is installed on the previous one with an overlap of 50 mm.

To build a fight or wood chips, a small experience with a carpentry tool is enough. At the same time, the cost of the roof is significantly reduced. Keep in mind that the wood should have a low level of humidity, and the process of ripening logs, after cutting them, is at least three years. If you cut the logs into small chocks, then their workpieces are reduced several times. The process of Kolka of a already dried tree is quite laborious, but only in this case it is possible to get a reliable and strong coating.

Calculation and estimate on a wooden roof

In order to prevent problems with a lack of roofing materials in the process of laying them, the required amount of wood for the roof should be calculated. In order to determine the amount of factory production material, it is enough to use special tables and schemes from the manufacturer. With their help, knowing the total area of \u200b\u200bthe roof, it will be possible to calculate the amount of material quite quickly and with high accuracy. In this case, it is enough to purchase 5-6% more material for the reserve. Since there is a risk of wood marriage, for example, incorrectly clogged with a nail.

The size of the roof determines its steepness. In order to independently calculate the amount of material, determine the flow rate of the tree per square meter of the roof.

Keep in mind that the material in the form of fights and wood chips is quite light, so under them the crate is equipped with witty thin poles. The number of layers of the roof laying and the interval or the overlap between the tiles depends on the step of the crate. In the process of laying shocks in three layers, then the overlap is two -thirds of the total size of the material. If the number of layers increases to four, then the material should be laid in three fourth.

The overlap in the process of laying wooden elements is carried out both vertically and horizontally. Keep in mind that the maximum steepness of the roof made of wood is no more than 75 degrees. The duration of operation of the roofing depends on increasing the steepness of the roof. The slope of the roof of 12-19 degrees is critical. The number of materials used in the process of its arrangement depends on the height of the slope.

If the size of the log used in the process of making a fight is four meters, then it is divided into ten parts, each of which is about forty centimeters. One chock is used for the manufacture of no more than four boards, the width of which is 150 mm. Elements do not need accurate calibration. In the longitudinal direction, about seven plates are laid per meter of roof. The number of roof layers determines the amount of material necessary for its arrangement. Most often, three -layer laying of the material is used.

If the roof is intended for a bath, arbors, outbuildings or a barn, then it is enough to lay it in two layers. In this case, only fourteen plates will be required to form one meter of roof. For decoration of the pediment or cladding of the roof facade, races are used. Please note that in the front row, the length of the plates is much smaller than the subsequent ones.

Wooden roofing technology: styling features

Depending on the weight, the wooden roof is the average in weight of the material. Therefore, it does not need to arrange a powerful rafter system. The arrangement of the crate directly depends on the fixation step of each of the elements. Before making a crate, you should create a project in which all the nuances of the roof fastening will indicate.

According to the recommendations of experienced craftsmen, the crate should be built without gaps in the form of continuous flooring. It is allowed to install a crate with gaps from 20 to 30 cm. Keep in mind that in order to calculate the step of installing the crate on a roof built from three layers, the length of the elements by three should be divided. Cut to the smaller side.

In order to fix the plates on the surface of the roof, nails made of galvanized steel are used. In addition, the option of using wood screws or special screw -shaped nails is possible. Fasteners are installed in the upper part of the roofing elements in the corners. At the same time, the indentation from the hem of the edge is at least 20 mm.

Note! If the roof is mounted with previously installed thermal insulation materials, then the gont should in no case contact the waterproofing directly. Between them, the space in the form of a ventilation clearance is equipped. For these purposes, a hint is mounted. In the case of use as a waterproofing of a superdiffusion membrane, there is no need to arrange a crate.

The technological principle of arranging the roof nodes is the same in all its areas. However, in the places of installation of the chimney, a apron made of tin and hermetically fixed on the roof should be equipped. To lay out the yendova, a fan scheme is used. To decorate the ridge zone, two coasted long boards, with a small overlap, should be laid. It is possible to lay a whole log on the riding area, inside which there is a longitudinal groove.