Since ancient times, the tree has been considered popular building material thanks to its ...

|

|

Daching and suburban life always has one significant advantage ... |

The modern market of building materials offers a huge assortment of various kinds ... |

DIY monolithic construction of a cottage

When asked which house is the most durable, the answer is obvious monolithic. And if earlier the technology of monolithic construction was used only for the construction of high -rise buildings or industrial facilities, today you can increasingly find a monolithic cottage or private house. Such technologies are able to realize even the most amazing design ideas into life, not limiting straightforward constructions. In addition to the amazing strength, which is enough to withstand a slight earthquake, such cottages are also popular because they are quickly and easily erected, do not require expensive materials and labor costs, and are also reliable and durable. The walls of monolithic cottages can be finished with any materials without restrictions, and the technology of non -removable formwork allows you not to equip additional wall insulation.

- Monolithic construction of cottages: advantages and disadvantages

- Technologies for the construction of monolithic cottages

- Types of formwork for monolithic construction

- Types of concrete solutions for monolithic construction

- DIY monolithic construction of a cottage

Monolithic construction of cottages: advantages and disadvantages

Construction on monolithic technology is carried out completely at the construction site by pouring concrete into formwork. Due to this feature, this technology has its advantages and disadvantages.

To date, such vaunted praises are sung to monolithic construction that it seems that there are no shortcomings at all, and there can be nothing better to be a monolith. Let's figure it out there are really many advantages:

- Due to the integrity of the monolithic structure, the mechanical strength of the entire building increases, it is resistant to destruction caused by soil shifts, promoons and earthquakes.

- The absence of seams in the building of the building makes the cottage warmer, since there are no so -called cold bridges.

- Work on the construction of a monolithic cottage can be done at any time of the year, on any soils.

- Fast construction.

- Low financial costs.

- The possibility of curved construction, projects of monolithic cottages can be arbitrarily intricate.

- Subject to the use of insulated concrete solutions with additives: expanded clay, perlite, sawdust, slag, etc. The design becomes light enough so that you can not equip a heavy buried foundation.

- The walls of a monolithic cottage can be insulated and finished with various materials.

- When using non -removable formwork, additional insulation is not required, and the total wall thickness will decrease. The walls will also have exceptional sound insulation.

- The possibility of arranging any inter -story floor: slab, from monolithic concrete, wooden.

- Uniform shrinkage of the building, which excludes the appearance of cracks.

But also does not do without a spoonful of tar, disadvantages of monolithic construction:

- To fill the concrete mixture at the height requires concrete pump (solutions). This is not a problem at all if you order construction in the company, and it is an invoice if you perform it yourself.

- When pouring a monolithic floor slab, labor costs increase many times, special forests will be required.

- A monolithic cottage with a fixed formwork, which is simultaneously thermal insulation, is not able to breathe walls, and the arrangement of supply and exhaust ventilation will be required. High humidity in the house.

- Foamy polystyrene, which is used in non -removable formwork, is a non -ecological material, which, although it has a COURE CLASS, which means that it fades within 2 minutes, but in the process of decay, distinguishes extremely toxic substances, so the mandatory requirement is plastering walls from non -removable formwork.

- Temporary costs for the manufacture of formwork, taking into account the features of the project.

- Mandatory grounding for the entire cottage is required, as the walls are reinforced concrete with metallic reinforcement.

Considering what prices and all their advantages are on monolithic cottages, many neglect the disadvantages associated with the non -electricality of polystyrene foam. It is understandable cheaply, quickly, beautifully, durable, firmly, who will think about their health there? Although it should be noted that if you do not use non -removable formwork, but build walls from warm concrete, and then insulate it with more environmentally friendly materials, then the cottage will turn out not only cheap and warm, but also quite comfortable.

Technologies for the construction of monolithic cottages

In total, there are two technologies through which monolithic cottages can be built. They differ only in that in one case the formwork is removed after the concrete hardening, and in the other the formwork is fixed. Both technologies have their own characteristics and nuances in construction and operation.

Construction of a monolithic cottage with removable formwork

The removable formwork is made individually for each cottage project, as it should exactly repeat its bends and features. Most often, wood, plywood, plastic or iron are used.

The width of the empty space between the walls of the formwork should be equal to the width of the future wall, which is calculated taking into account the thermal conductivity of the concrete mixture and the construction region. Formwork shields are fastened with washers, studs, nuts. So that after pouring concrete, the formwork can be easily removed, it is necessary to put on corrugated tubes on threaded studs, protecting them from contact with concrete.

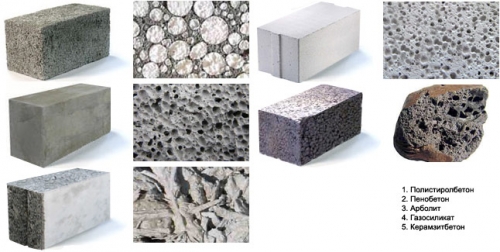

The technology for the construction of a monolithic cottage with removable formwork suggests that you can fill not only ordinary concrete, but also mixtures that have much less thermal conductivity, for example, expanded concrete, perlitone concrete, slag concrete, foam concrete, foam concrete, aerated concrete, arbolite and others. The walls will be much warmer and vapor permeable, but will not be able to withstand too much loads.

Also, an important moment is the reinforcement of the concrete wall. To do this, you can use reinforcing mesh, plastic or steel, and for greater strength a frame of reinforcement is binded.

Important! The wall reinforced with a reinforcement with a reinforcement of 8 18 mm will be quite cold, since the metal parts of the frame will be cold bridges.

In one pass, it is allowed to fill in no more than 50 cm of concrete. Only after it grabs can you continue to fill. Concrete concrete in the formwork is carried out using deep vibrators, special attention must be paid to the corners.

After the concrete hardens, the formwork is removed and rearranged above. So, until the whole cottage is flooded.

In order for the concrete to take maximum strength, it is necessary to let it survive at least 4 5 weeks. After that, you can start insulation and decoration.

Monolithic walls can be insulated with polystyrene foam, extruded polystyrene foam, mineral wool, warm plaster. At the same time, use the technologies of the ventilated or wet facade.

The option of the well facade is also possible, when an indent is made outside the concrete wall, then it is covered with facade bricks or tiles, and free space is covered with insulation: expanded clay, ecowide, etc.

An indisputable advantage of this technology is that the house can be made as breathing and environmentally friendly as possible, although you will have to tinker with the assembly and disassembly of the formwork.

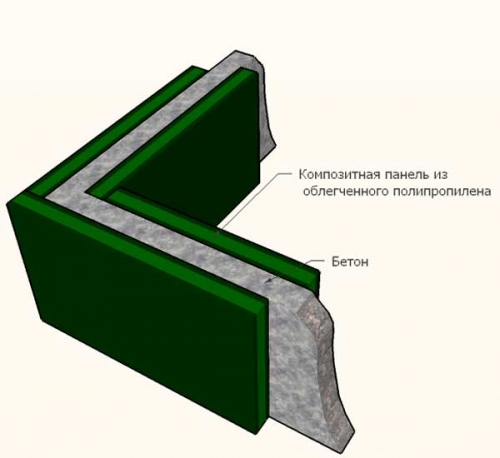

Construction of a monolithic cottage with a fixed formwork

The use of fixed formwork is advertised with enviable constancy and perseverance. Indeed, according to this technology, the formwork is not just not removed after pouring concrete, it is also a layer of thermal insulation. When using this technology for monolithic construction of cottages, the price is the lowest, since labor costs are maximally reduced.

After the arrangement and waterproofing of the foundation, a formwork is installed on it, which is a form of polystyrene foam, fastened with special profiles. These forms have a spike-paz mounting system, which allows you to connect so tightly and without gaps that the leakage of concrete or its influx in the compounds of formwork shapes is absolutely excluded.

The width of the formwork of polystyrene foam can be different, in the case of a large order, at the factory they can make blocks of any required thickness. A block is considered standard, in which the empty space for concrete is 150 mm wide and on both sides of the polystyrene foam with a layer of 5 7.5 cm. This is enough for the house to be warm in winter and cool in summer, heating will only have to be turned on when the temperature drops below + 5 S.

After installing the formwork inside, concrete is poured with a layer of 50 cm and is compacted by the deep vibrator.

Important! Please note that you can only use concrete to fill the fixed formwork and you can not use warm mixtures. This is due to the fact that the vapor permeability of polystyrene foam is negligible and equal to 0.05 mg/(m*h*PA), and the vapor permeability of warm mixtures above 0.09 mg/(m*h*PA). If you squeeze warm concrete between layers of polystyrene foam, condensation will accumulate in it, as a result, mold and fungus will appear over time.

After the construction of the walls, they do not need to be insulated, it is enough just to plastered with decorative plaster or sheathed with siding.

The advantage of the technology of non -removable formwork is ease of construction, cheapness and lack of need for additional insulation. But at the same time, such a cottage is a thermos that is not able to breathe.

Types of formwork for monolithic construction

In the area of \u200b\u200bapplication, several types of formwork are distinguished: wall formwork, foundation, floors, tunnel formwork, ring walls with a changed radius. Thanks to this variety, you can use a monolithic fill for any construction element of the building.

Various formwork elements are installed in different ways. The formwork of the foundation is installed on struts and horizontal supports. Wall formwork with racks, brackets and connecting locks. The formwork for ceilings is laid on a design of telescopic or voluminous retaining racks.

Removable formwork is made of these materials: steel, aluminum, wood, plastic. Depending on the material of execution, it has different properties. If you use plywood for formwork, then it must be cut with a saw with small teeth so as not to damage the veneer and lamination. It is necessary to drill holes for pipes and cables in the formwork on both sides, for the same reason. Store plywood formwork in a dry place.

Before use, removable formwork is treated with a special solution so that it can be easily removed.

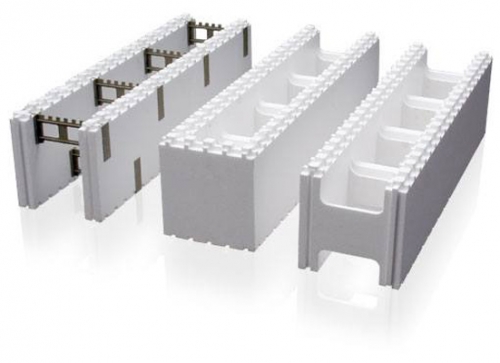

The fixed formwork, as already mentioned above, consists of polystyrene foam, does not require additional processing. Its forms are different: corner, longitudinal, podon, must -end and others. In fact, the arrangement of removable formwork resembles the connection of the figures of the Lego designer.

Types of concrete solutions for monolithic construction

An indisputable advantage of monolithic construction is the ability to fill in the formwork solutions with various thermal conductivity and vapor permeability.

Concrete The easiest option and, unfortunately, the only acceptable when pouring non -removable formwork. The cottage made of monolithic concrete will be very cold, since its thermal conductivity is 1.51 W/(m*C), and vapor permeability 0.03 mg/(m*h*PA). Walls of concrete should be carefully insulated.

Reinforced concrete Even colder than concrete, since iron reinforcement is cold bridges. A cottage made of monolithic reinforced concrete requires insulation with polystyrene foam, extruded by polystyrene foam or mineral wool.

Keramziton It has thermal conductivity of 0.66 0.14 W/(m*C) and vapor permeability of 0.09 0.3 mg/(m*h*PA). The indicators depend on the density of the mixture, the larger the porosity of expanded clay, the warmer and vapor permissive the wall. The wall thickness for the region of the Moscow region is 50 cm.

Slag concrete The same as expanded clay concrete, only instead of expanded clay slag. It is less durable, so the thickness of the walls should be 55 60 cm.

Opilc concrete A mixture of cement, sand, sawdust (needles) and water. The walls are warm, fireproof and environmentally friendly, only from the outside they must be protected by waterproofing material.

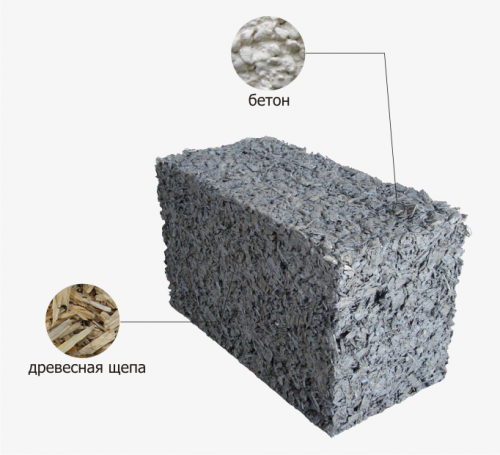

Arbolit A mixture of cement, water and wood chips 40x10x5 mm. The chips are pre -ventilated or treated with lime. The walls of arbolite are warmer and stronger than from opilcoo concrete.

Foam concrete Concrete, foamed in chemically, warmer material than ordinary concrete. Its thermal conductivity is 0.29 0.08 W/(m*C), and vapor permeability 0.11 0.26 mg/(m*h*PA).

DIY monolithic construction of a cottage

Typically, the construction of a monolithic cottage is ordered in a construction company. This is due to the fact that the work will need formwork, concrete pump, forests for the floor slab and other inventory, which is in any construction organization, and buying it for once unprofitable.

But for those who do not like simple ways and agree to spend money on the solutions, and make an overlap with wooden or order a slab of ceilings and install it with a tap, the construction of a monolithic cottage with your own hands will be possible.

The project of a monolithic cottage can be performed independently, downloaded on the Internet or ordering in a design organization, in the latter case you will be made all the necessary calculations: the strength of the load -bearing walls and the load on them, the necessary thickness of the filling and insulation.

When the project is ready, equip the foundation. If the house is with a basement, then the base of the basement can be made by a monolithic slab, and the foundation with tape. Usually they build a pile-and-lent foundation and carefully waterproof it.

How to build a monolithic cottage with removable formwork

The formwork is made of wooden boards with a thickness of 30 50 mm. If the temperature in the region decreases to -30 s, the thickness of the walls is made 55 60 cm. We tightly connect them with each other and drive them 80x80 mm racks, at a distance of 1 1.5 m from each other. The length of such shields should be 2 4 m, and the height is 60 80 cm.

At the bottom, we install metal screeds with bolts so that the shields do not burst when concrete flows into them. At the top, the shields are fixed with wooden overlays or the same screeds.

We insert a reinforcing mesh or frame into the formwork depending on the project.

For the manufacture of opilco concrete, we take: 8 parts of dry sawdust, 1 part of the cement M400 M500, 3 parts of lime, 2 parts of sand.

Important! Sawdles should be released in the open air for at least a year.

First, mix the cement with sand, separately lime with sawdust, then connect both mixtures and thoroughly knead, adding water a little. As a result, there should be so much water so that it does not flow from the solution.

Pour the layer of 20 cm into the formwork with the resulting solution. We seal with vibrators and pierce the rods to carefully compact the solution. Then fill in the next layer. And so on until the formwork is practically filled (for convenience we leave 5 10 cm on top empty).

You can rearrange the formwork higher only after 3 5 days. All this time, concrete should be covered from the sun and precipitation with a film or roofing material.

After completing the construction of the walls, we give concrete to gain strength within a month, then equip the ceiling and roof. The floor should go to the walls of 15,100 cm minimum.

After the opilc concrete dries completely, you can insulate the walls on the outside as necessary. To do this, you can use warm plaster, which can be applied with a layer of up to 50 mm. It is an excellent waterproofer, a heat insulator and at the same time easily releases steam outward.

How to build a monolithic cottage with a fixed formwork

The construction of a monolithic cottage with a fixed formwork is an extremely simple task. First you need to stock up on formwork elements. They are wall, corner and radius. It is necessary to calculate the number of each type of elements according to the developed project.

We install a fixed formwork on the foundation, collecting it as a Lego designer, connecting the locks of the blocks. To begin with, the first row will be enough.

We carry out all the necessary sewer, water and ventilation pipes. Then, if reinforcing is required, we insert a reinforcing mesh. We prepare a concrete solution of cement M500, sand, crushed stone and water. We build up the formwork and pour 50 cm layer, compact with deep vibrators.

Per day can be increased in a height of not more than 50 70 cm.

After completing the construction of the walls, they do not need insulation, and as a finish, you can perform the so -called wet facade with decorative plaster along a fiberglass grid.

The construction of a monolithic cottage with your own hands is greatly simplified if you call a couple of partners to help. Indeed, after overcoming a certain height in the construction of walls to fill the concrete, the use of concrete pump will be needed. And agreed actions will be able to reduce time and organize the right work.

Quite often, special equipment is used during construction. A large selection of spare parts for road-building equipment of leading manufacturers, such as spare parts for Komatsu bulldozers, are presented on the website of the company Aimashineri.