Bathroom is a room with high humidity, so for wall decoration, ...

|

|

The wood is the most ancient, used for building material, and ... |

To protect your house from the penetration of groundwater, damp, capillary water, ... |

DIY wooden I -beams of wooden I -beams

If there is a reconstruction, the construction of a country house, cottage or baths, where a wooden overlap is provided, then for work beams are suitable for work. The material corresponds to the NNUP standards and can significantly reduce the construction time. The use of wooden beams has a number of undeniable advantages, which makes this material popular among developers. The design of the I -beam, the main purpose, calculation and installation technology are described in the article.

- Wooden I -beams: design and scope of application

- Types and technical characteristics of wooden lobes

- Requirements for inter -story ceilings

- Calculation of alleged loads

- Intelligence installation technology

- Using wooden overlapping beasts and SNiP

- Making wooden I -beams with your own hands

Wooden I -beams: design and scope of application

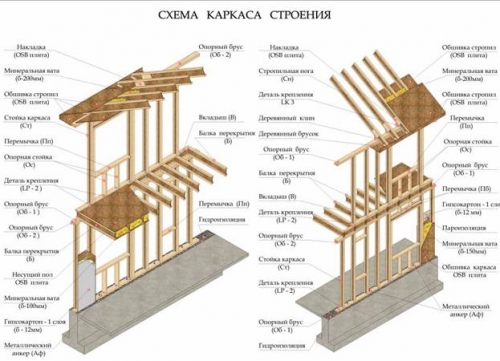

Disarmers made of wood are actively used in the field of construction for the installation of inter -story floors, as a supporting design of the rafter system, roofing and attic wall frames. In the context, the constructive material has a cross section in the form of the letter N. The side skids of the offspring are made of a dry glued beam, the jumper is made of OSB (oriented-brown plate). According to SNiP, the transverse jumper is impregnated with refractory, water -repellent glue.

A wooden I -beam is an excellent solution for private construction, ranging from the construction of a frame house to a wooden building from a log house. This constructive element is a worthy alternative to metal profiles, wooden boards and reinforced concrete slabs. Among the main advantages are:

- high strength and rigidity, which allows to withstand heavy loads;

- unlike traditional lumber, the beams do not bend and do not cause floor creaks;

- thanks to a relatively low weight, the installation of the floor is facilitated to do the work without involving special equipment; It is very difficult to execute an inter -story floor of concrete with your own hands;

- wooden I -beam beams, unlike metallic ones, are not corroded;

- the material does not dry out, does not deform, does not refer and is not subjected to shrinkage, twisting and bloating;

- in the shelves of an I -beam, there is an opportunity to lay communications;

- the use of wooden beams in different climatic conditions;

- the work is relatively clean - there is no such amount of dirt and dust, as when pouring an integrated ceiling with your own hands;

- reduction in the timing of construction and savings in labor costs;

- environmental friendliness and long service life.

The advantages of building materials determine the popularity of its application:

- Frame construction. The construction of the load -bearing elements, the support supports of the door and window openings, the rafter roofing structure.

- Arrangement of inter -story ceilings and attics. Especially relevant in the construction of aerated concrete houses, an attic.

- Reconstruction of the building. Wooden I -beam supports are used for restoration, replacement or strengthening of structural buildings.

Types and technical characteristics of wooden lobes

The series of impaired wood from wood is divided into several varieties. Classification according to SNiP:

- Series BP. Beams for the installation of ceilings on spans up to 9 m. The main dimensions of the elements:

- height 19-46 cm;

- side belts 4*9 cm;

- the thickness of the OSB-ducts 12 mm;

- the length of the beam is 12 m.

- BS series. The product is used for the rafter system. This group includes biases in sizes:

- support width 19-41 cm;

- belts 4*6 cm;

- transverse stand 9.5 mm;

- length up to 8.5 m.

- SS series. I -beams are used in the construction of houses according to Canadian technology, performing the function of the main rack in the construction of internal partitions and the facade wall. Parameters of products:

- beam height 13-25 cm;

- belt width 4-4.5 cm;

- the dimensions of the racks and length correspond to the models of the BS series.

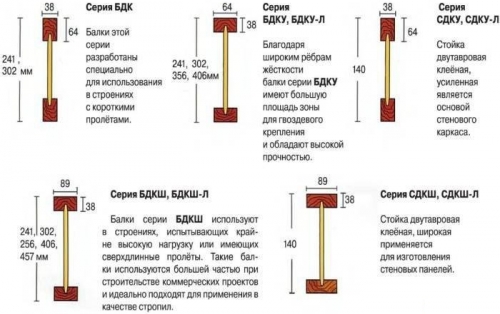

The nomenclature series of wooden I -beam includes a number of positions:

- BDK glued beams for the construction of structures with small spans;

- OBDCU/BDCU-L wide ribs of stiffness, providing high strength;

- SDKU/SDKU-L construction of the wall frame;

- BDKSH/BDKSh-L for the construction of structures subjected to high loads; optimal for the construction of commercial buildings;

- SDKSH, SDKSh-L wide stiffener ribs allow the use of beams in the construction of wall panels.

The impaired section acts as an amplifier of the design of the jumper strength increases many times. In terms of technical indicators, the material is in a row with the FUN and concrete ceilings.

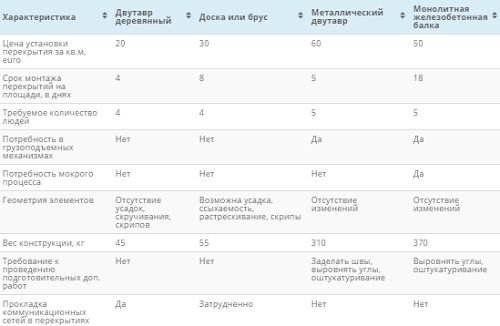

The comparative characteristics of the main parameters of a wooden I -beam, bars, metal and monolithic reinforced concrete support are displayed in the table. The indicators are designed for an area of \u200b\u200b200 sq.m.

Requirements for inter -story ceilings

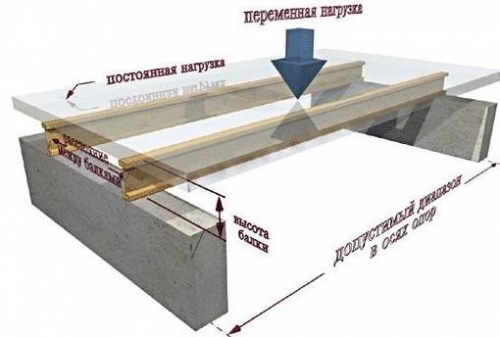

The arrangement of the overlap of the interference with hands is performed taking into account constant and variable loads. In addition to their weight, the beams should hold furniture, appliances and people. In addition, its value is necessarily laid on the purpose of the building, the number of storeys of the house, the material of the walls and other factors.

Important! When calculating, it is necessary to take into account the individual characteristics of the room. For example, cladding with natural stone, placing heavy simulators or installing a volumetric aquarium, significantly increase the load on the ceilings.

To reduce the load on the beam area, it is recommended to evenly place them perpendicular to the long walls.

The principle of the ceiling device depends on its purpose:

- Basement. The main requirement is high strength. I -beams are the base of the floor, so they are required to withstand a significant load. When arranging a basement or underground garage, the distance between the outlets must be reduced.

- Attic overlap. Perhaps independent or built -in in the rafter system placement. The first method increases the soundproofing of the room. In addition, independent installation allows you to repair the floor if necessary.

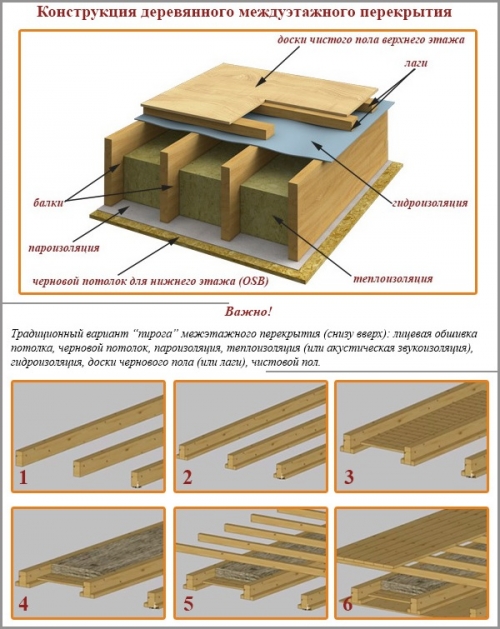

- Intersective design. On the one hand, the beams are a supporting construct for the ceiling, and on the other, they act in floor lags. The inter-story pie is filled with a sound and heat insulator using a vapor barrier layer.

Calculation of alleged loads

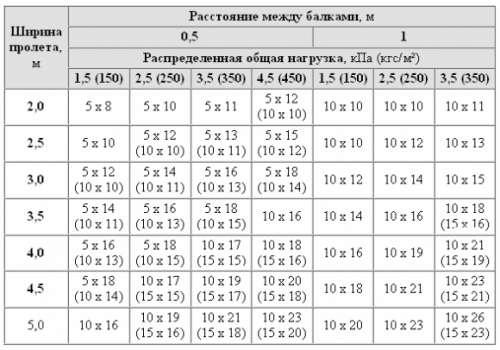

It is advisable to entrust a wooden overlap with a wooden floor. Properly made calculations and selection of materials guarantee high -quality installation and safe operation. To determine the type of support, its cross section and the installation step, the total load for the ceiling must be calculated, taking into account the specific mass of the ceiling and variable loads.

Previously, you should prepare a scheme of the inter-story floor, displaying on it the number and frequency of placement of wooden beams, a variety of hydro- and vapor barrier.

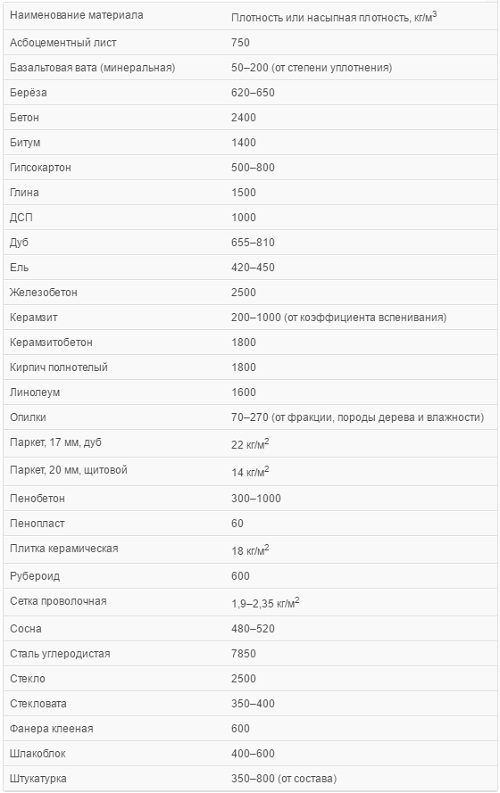

The mass of each component is calculated as a product of the volume of the material and its density. The volume is determined based on the area of \u200b\u200bthe floor, and the density value is taken from the reference book.

The density of building materials and finishes

Important! The weight of interior partitions and walls based on the floor is calculated as a stable load. The nominal specific weight of structural elements is 50 kg/sq.m.

A variable load (the weight of people, items of furniture, animals, etc.) according to SNiP for residential buildings is 150 kg/sq.m. The total load is determined based on the reliability coefficient:

- 1.2 if constant and variable mass within 200 kg/sq.m.;

- 1.3 If the amount of calculated loads is over 200 kg/sq.m.

Based on the obtained value and the recommended maximum loads on wooden I -beams, the optimal type of support and the distance between the beams are selected.

Intelligence installation technology

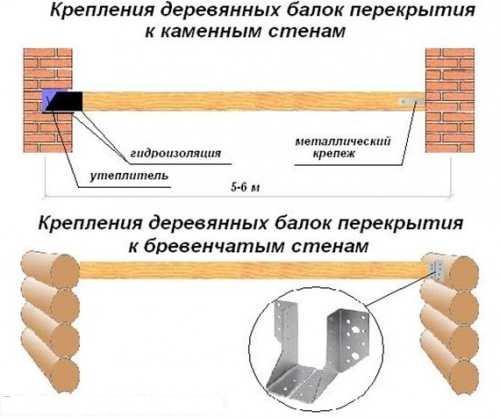

Balks fastening options

A wooden inter -story overlapping with hands is equipped with one of the following methods:

- Fixation in the supporting structure. The beam is fried to a depth of 15-20 cm. The ends of the wooden support are cut at an angle of 60, cleaned and covered with a water-repellent layer, for example, roofing material. The wall is placed in the wall and a gap of 2-2.5 cm is left to ensure normal air exchange.

- The suspension method is used, as a rule, when erecting an integration ceiling of a wooden house with your own hands. The fixation of the beams is carried out by means of metal fasteners, corners and brackets. With this installation, supporting structures take over the weight of the beam of the I -beam and the rest of the load.

Important! The extreme beams of the ceiling should not be placed close to the parallel wall. The minimum permissible distance of 10 cm can not be set a beam near the chimney.

Wooden beams

The floor of the wooden I -toe is carried out according to the following scheme:

- On top of the beams, fix the ceiling coating. As a black floor can be used: plywood, chipboard, boards or other material.

- Put a vapor barrier film. It is advisable to attach the material to the breakfast brackets so that it does not shift in the process.

- Put the thermal insulation material (mineral wool) into the space between the doubles. It is important to control the insulation tightly adjoins the wooden elements.

It is worth remembering that the ceiling from the lower floor will be a ceiling, and from the side of the upper floor. The top is sheathed with a laminate with a laminate with a laminate with a downshole board. The laying of carpet or linoleum is suitable. For finishing the ceiling, drywall, wooden lamellas, lining, plastic panels or suspension systems are used.

Using wooden overlapping beasts and SNiP

The use of wooden losers in construction is regulated by state standards and standards. Before work, you need to get acquainted with the main documents:

- SNiP 2.01.07-85 loads and exposure;

- SNiP II-25-80 wooden structures;

- GOST 8486-86E Pilomaterials of coniferous breeds. Technical conditions;

- SNiP 2.08.01-89 residential buildings;

- GOST 30244-94 materials and construction products. Flame test methods. Carrying and enclosing structures.

Making wooden I -beams with your own hands

To create an I -beam, the following tools and materials will be needed:

- a circular saw;

- grinder;

- clamps and a channel;

- roulette, glue for wooden products;

- glued beam and OSP.

Processing procedure for beams:

- Cross glued beams into equal parts and cut the grooves of the desired depth in them. This will be the base of the beam.

- Prepare the rib of stiffness. There should be no irregularities on this element, all defects must be fucked.

- Fix a jumper from the OSP in the grooves of the bars using special glue.

- Leave the beam until the adhesive composition is completely dried.