Polistyle foam is quite interesting material. The method of receipt was ...

|

|

The facade is the face of the house, and the windows, the most significant objects, his eyes. Here they are ... |

A monolithic foundation is one of the most expensive types of foundation for the house. But on some ... |

Do -it -yourself roof

Copper roof is called roof coating made of sheet copper. Such products have a thickness within 0.5-1 mm. The modern market offers several varieties of copper coating, but not all of them gained widespread, especially in the vastness of the Russian Federation. So, the most popular are the products with the folds (seam in the form of a groove), that is, the sheets of copper are fastened with each other through folding castles, which are reliably snap and hold the structure. You can also meet products in the form of copper tiles, various shapes, it is also called scales or checkers. The article will talk about the installation of a copper roof.

Content:

- The main characteristics of the copper roof for the cottage

- Types of material and installation of copper roof

- Assortment and prices for copper roof

The peculiarity of copper is that after time the material changes its color. Initially, the just laid roof has a reddish-golden tint, but under the influence of the environment (air and precipitation), copper is covered with an oxide film that gives it a dark color, first brown and then almost black.

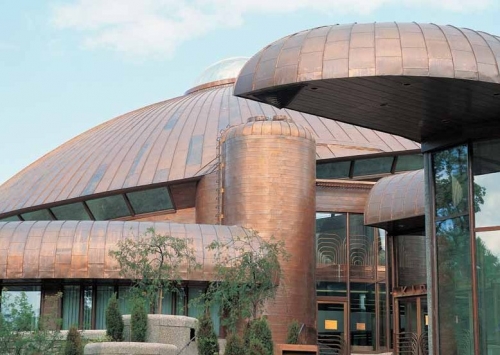

Copper roof photo

- This transformation occurs in the first years of operation. The process is called oxidation and it does not pass at the same time, that is, the shade of the coating will be heterogeneous. If there is a desire to immediately get the finished result and not wait for all metamorphoses, then it is better to purchase roofing material oxidized in the factory, which has an even brown color on the entire surface.

- Of course, copper is famous for a completely different, more noble shade. After 10-20 years (depending on the surrounding conditions), the roof covered with copper acquires a natural patina, that is, its shade changes to a green-malachite or turquoise-green color. This color is natural for copper products that are constantly outdoors. Manufacturers of copper roof also offer products subjected to the process of artificial aging (patination).

- The main advantage of copper coating is that such material does not require special care. This metal does not need to be painted or treated with anti -corrosion compounds, but at the same time it will calmly last 100 or more years. The proof of this is the roof of churches and castles in Europe, which have been in operation for nearly 700 years. Despite the apparent simplicity, this material can rightfully be called elite.

The main characteristics of the copper roof for the cottage

Copper belongs to a variety of non -ferrous metals, but the roof from this material is in an accessible price category, and if you take into account all the positive aspects of these products, it becomes clear why it does not lose relevance for many centuries. In Russia, back in the 18-19th century, roofs were covered with copper plates and many buildings still retained their roofs, which over time did not lose their attractiveness.

Perhaps copper can be called the metal that a person initially began to use for technical purposes. This was due to the fact that its nuggets are a common type of deposits, as well as the fact that the products made of copper were practical than the same gold.

The advantages of copper roof

Due to the fact that copper itself is distinguished by durability, strength and necessary hardness, then the products made from it have all the listed properties. In addition, this metal has bacteriological properties, which is also an equally important criterion in the modern world. And so, what are the advantages of copper roof?

- Easy processing. Due to the fact that this is a plastic metal that can be given almost any shape (using the methods of extract or flexion), modern roofing coatings have a variety of patterns themselves. But, despite any bends, products do not lose their strength properties. Also, the advantages of the material include the fact that mounting the coating is quite easy and simple, because the proportion of the copper sheet for the roof is relatively small (1m2 has a weight of approximately 5.5 kg).

- Safety and environmental friendliness. This is due to the fact that copper is natural material, and does not contain harmful chemical impurities. That is, even in the production of such a roof, it is not harmful to nature. It is no less important that this metal does not dissolve in the aquatic environment, which means that its use will not harm human health or the environment.

- Economy. This advantage, although not obvious at first glance, because the coating itself costs more, for example, the same bitumen tile, but thanks to a particularly long operation of operation, all expenses are covered in full. In addition, copper roofing practically does not require any care and maintenance, and this is an additional savings in the repair, which if the roof is needed, then no earlier than 10-15 years later.

- Corrosive stability. Due to the coating of copper with a special natural film, which is formed as a result of oxidation, the surface of the products is, as it were, sealing. This not only increases anti -corrosion properties, but also increases wear resistance. It is only important to prevent any extraneous objects on the roof (for example, foliage or pieces of plastic film), since they close air access and stop the process of natural oxidation.

- Fire safety. Copper is able to withstand a sufficiently high temperature, and, therefore, the roof made of this metal is distinguished by heat resistance, in addition, the material does not burn, does not support burning and does not emit hazardous substances under the influence of fire.

- Great heat transfer. Leaf copper on the roof is easily capable of heat, but when heated, it does not lose its basic properties (as well as during freezing). Another plus is that when arranging a warm roof (with a heating system), you can forget about the winter cleaning of the coating from snow and ice. After all, it is not recommended to carry out roof cleaning independently due to a high risk to health, and hiring specialists is an expensive service.

- Frost resistance. The material withstands the temperature of up to -700 degrees, which means that the mounted roof does not threaten to suffer from frosts. Also, metal is capable of steadily tolerate sharp temperature fluctuations.

- Strength. The roof of copper is resistant to almost all external influences, even without special processing or painting. After copper plates are covered with a special plaque (patina), this occurs as a result of natural oxidation of the metal or in the process of factory patination, the product receives additional protection. The plates do not rust, they are subject to microorganisms, and any pollution is removed from them without a trace, and for this it is not necessary to specially wash the roof, it can be cleaned naturally after the rain.

- Durability. The guaranteed service life of such products exceeds 100 years. You can still find many confirmations of their long life. Especially a lot of buildings with copper roofs in Europe, since it was there that this type of coating was quite popular in the 18th century.

- External attractiveness. This factor for many homeowners is often in the first place. Indeed, thanks to special properties, the metal over time not only does not lose beauty, but even vice versa, it becomes more noble and aesthetic. When choosing a copper coating, you can favorably emphasize the exterior of the whole house.

Disadvantages of copper roof

Like any material, copper products for the roof have their weaknesses.

- First of all, it is a high price, which, although it pays off, is still not available to all categories of citizens. The cost of the roof is also increased by the fact that its additional elements should be made of the same metal.

- The next drawback also follows their advantages to the material, we are talking about thermal conductivity. Copper roof heats up very quickly, which is not very comfortable in the summer heat, and quickly cools in the cold. That is why, when arranging the roof, an additional layer of thermal insulation should be laid.

- Another disadvantage of copper flooring can be high noise, any extraneous objects that fall on the surface of copper will create an additional sound background, especially rain drops. Of course, it is also easy to get rid of this problem, it is enough to lay a noise -absorbing layer.

Types of material and installation of copper roof

Varieties of roofing copper

The roof of copper can be two main types:

- soft copper roof;

- falts copper roof.

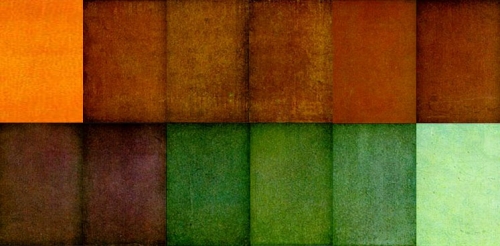

Any type of product looks great on the roof, differ among themselves by fixing and shape. Copper is a material that over time changes its color, manufacturers offer not to wait a long time, but immediately acquire the shade that seems most attractive.

There are 5 main types of copper roofing according to the degree of processing:

- classicalhas a brilliant coating of yellow, that is, copper was not subjected to additional effects, such products change the color during operation first on brown (process of oxidation), and then on malachite (patination process);

- artificially oxidized, the surface of the material is covered with an oxide film in the factory, initially the product has brown color and after the expiration of time gradually acquire a beautiful emerald color;

- artificially patchedIn this case, the manufacturer accelerates the process of patina formation, exposing copper to the effects of various chemical reagents, the peculiarity of such copper in that throughout the entire operational period it does not change its shade;

- varnished, a special protective layer of polyurethane is applied to the plates, it gives the material a light shade and gloss;

- pooped type of coating, means that the product made of copper was subject to pudding, that is, the manufacturer additionally applied a tin layer on the products, the color of such a roofing will be gray, with a matte surface and will not change over time.

Copper tile

- This material in the form of separate fragments, outwardly resembles traditional tiles. The peculiarity of such products is that they can imitate stone or wooden surfaces, or look like scales. When the material is laid on the roof, it is done in two layers, as if with an overlap, that is, the upper layer closes the joints of the lower. This installation method helps to avoid leaks, and the roof is completely tight.

- One of the varieties of copper tile is considered copper checker. These are also products in the form of separate plates, only they have a square, rhomboid or trapezoidal shape. Copper checker and scales are very similar in their functionality, their appearance will be a significant difference. So, checkers are straight elements with a flat surface, and scales have a slightly curved shape.

- To make such a coating, separate sheets of copper with a thickness of 0.6-0.8 mm are used, and then the required fragments are cut out of them. It is quite easy to mount a roof of checkers, each part is equipped with a castle system. The plates are laid in one layer, firmly interconnected.

- It was the copper checker that was used to cover traditional Russian tower, as well as Orthodox churches. Today, this type of product is used both for residential buildings and for commercial structures.

- The device of the roof of tiles in the form of checkers is quite a laborious process. In addition, it is such roofing that is considered the most expensive coating. The main advantage of the products is that if any element is damaged, it is enough to replace it only without the dismantling of the rest of the surface, while the repair site will be almost invisible, and over time the difference will be completely hidden (the color is level).

- The checker is a great option for installation on flat roofs, that is, for structures that have an angle of inclination to 12 degrees. But this is far from the only configuration, it is allowed to lay it on round, oval, elliptical, dome -shaped and other complex shapes.

- Each plate is equipped with a special connecting element, which are located as follows: a straight lock is installed in the lower part of the product, and the opposite is installed in the upper part. Monting the elements, they are interconnected, starting the upper mount of one plate for the lower mount of the neighboring one, and then special rivets are additionally installed. So it turns out a single roofing.

- The standard dimensions for the tiles are tiles with sides 22 cm or 27 cm. The material can be broken both in place and in the factory. When covering structures of a non -standard shape, many waste remains. But still, it is copper tiles that can give the structure a unique design and a light plaque of noble antiquity.

- A type of copper roof is also considered a bitumen tile, the upper layer of which is covered with copper. This is a compromise between quality and price. Such tiles are available in various variations both in form and in thickness. The combination of reliable and durable copper with a flexible bitumen base creates excellent material, with a beautiful appearance and relatively inexpensive.

Installation of copper folding roof

This type of product is made of roll copper, the thickness of which is in the range of 0.8 mm. In general, the Falz is a peculiar type of bend (seam), which looks like a groove connection. It is thanks to this fastening of the sheets to each other that the flooring on the roof is a single canvas. Falts roofs belong to the most reliable type of coatings.

There are several types of compounds in total:

- single;

- double;

- corner;

- lying;

- standing.

The most widespread facks are double -standing, because such a combination minimizes the number of joints, but at the same time provides efficient tightness.

The process of installing a copper roof involves the use of a large number of tools and auxiliary elements (a total of about 30, these are Klyammers, various metizes, rivets, additional elements, seating machines and other building tools).

To lay copper sheets, a number of main stages should be performed:

- a rafter system device;

- ventilation devices;

- installation of the crate;

- laying of the insulation layer;

- installation of copper roof;

- installation of roofing elements.

- The rafter system is a bearing frame of a roofing cake. Experts recommend making it from coniferous wood. For this purpose, strong, high -quality beams and logs are used. Do not forget that the life of copper is large enough, therefore, all its elements should have durability.

Important! During the construction of residential buildings, all wooden elements are necessarily treated with hydrophobisators, anti -piren, antiseptics and other protective drugs.

- The rafters should be strong and capable of withstanding a large load, only in this case you can build a high -quality roof. In addition, it is imperative to observe the evenness of the rafter system, because due to the fact that copper elements are flexible and thin, they can very easily be damaged from the skew of the roof skeleton.

- A layer of waterproofing is laid on top of the rafters, which can be used by a diffusion membrane. Its advantage is that in addition to protecting the thermal insulation from moisture, it is able to divert the resulting condensate by the cornice. Strips of waterproofing material are overlapping and fastened with bilateral tape. This layer should not have sagging, otherwise it will lose its functionality, so when laying it is optimal to slightly pull it.

- By laying the heat -insulating materials in the design of the copper roof, it is imperative to protect them with a vapor barrier layer. For installation of the crate, you can use plywood, a torn board or a beam. The frame for copper sheets is continuous. These elements are also treated with protective drugs. Do not forget about the holes for ventilation, attic windows and chimneys.

- A lining sealing material is laid on top of the crate. It can be in the form of rolls that are covered on a crate overlair at least 10 cm. It is recommended to spread the litter in parallel to the skate, from the lower edge of the roof. After the flooring of the second insulating layer, you can proceed to the direct installation of copper plates (they are also called paintings).

- Copper roofing blanks are laid out on the roof, and then are already connected by the folding method. Two falses on fragments, they are located on the sides. A small fold that has a height of 2.5 cm is installed from one side, and there is a large fold, 3.5 cm high from the second side.

- The consolidation of the sheets is as follows: a large fold bends over the small one, and then they bend again, but already together. The height of the finished bend is approximately 2-3 cm. To combine the elements in such a lock, use a special frame.

- It is important to consider that the mount can expand under the influence of temperatures, which means that it is necessary to provide a small gap, about 3-4 mm. If this is not done, then during operation there is a chance of deformation of the entire roof.

- Connecting elements can be created directly on the construction site. For this, special rolling machines are used. It was due to this method that it became possible to get perfectly fitted roof elements. After all, the roof does not always have clear standard forms, and if you make castle connections in the factory, they may simply not coincide with the existing surface configuration.

- Of course, this applies only to the sheets themselves, the additional roofing elements are delivered in the finished form, the main thing is to correctly install and fix them. If there is no way to use special tools, then you can buy self -recluses. In such cases, it is quite simple to press on the castle mechanism, and it reliably fasten the sheets among themselves.

- Roof installation begins with the installation of cornice overhangs and drainage systems. Next, move to the fastening of the apron and fixing the valleys. When the main additional elements are mounted, proceed to marking under copper paintings.

- The first plate should go 30 mm over the edge of the apron, after fixing the sheet, the protruding part simply bends behind the bar. Lay copper from both the corner and from the center. If installation is made from the center, then you can arrange the elements more symmetrically, this will increase external aesthetics, this fact will not affect functionality in any way.

- To the crate, copper products are fixed to the Klyammers - plates with a curved clip. Each latch is inserted into the fold between two paintings. Thus, the brackets are completely hidden under the sheets and reliably hold them in the desired position. The optimal option is the use of 4 Kounds for 1m2. In cases of fixing the elements along the cornice, it is better to add one more additional latch (that is, make the distance between them 35 cm).

- Experts recommend using a ventilated horse when arranging a copper roof, since this type of coating is demanding on ventilation. If you do not take care of blowing the undercarbon space, then very soon mold and fungus will begin to appear on the elements.

It is important to remember one rule! When installing a copper roof, all the elements that are in contact with it should also be made of copper (in extreme cases, from stainless steel).

Assortment and prices for copper roof

Depending on the type of copper used, the price of copper folding roof may vary significantly. For example:

- classic copper, with a brilliant reddish golden surface will cost about 1600 rubles/m2;

- the product for bronze, that is, the alloy of tin and copper is about 2200 rubles/m2;

- oxidized copper will cost 2500 rubles/m2;

- the price of patinated products is in the range of 3500-3700 p./m2;

- copper under brass (alloy with zinc) and under gold (alloy with aluminum) stand 4000 rubles/m2;

- the most expensive is tin copper (tinned), its price is 4100-4300 p./m2.

If you take only the classic version of the product and see how the price changes depending on the form, then the picture will be approximately as follows:

- bitumen copper tiles - 1600 p./m2;

- falts roof 2000 p./m2;

- twola tiles - 2200 p./m2;

- the tile of the dune (domestic or imported production) is 2500-2700 p./m2;

- tagmano tiles (Russian production) - 4300 p./m2;

- in the form of scales 4400 p./m2;

- in the form of checkers or rhombuses - 4600 p./m2;

- tiles of Metrotyil - 5500 p./m2.

The most famous manufacturers copper roof:

- Aurubis - a German manufacturer, is considered a leader among enterprises involved in the sale of copper and alloys, mainly supplies products to US and European markets;

- Kme Tecu is a concern founded at the end of the 19th century and is still a major manufacturer for the production of copper products;

- VBS - a Serbian factory producing a roof tape made of copper, products have European quality certificates and are produced on high -tech equipment;

- GZOTSM - the Russian Factory Plant, is located in the Orenburg region, this is the oldest domestic enterprise at which a copper roof is produced;

- UMMC - also a Russian manufacturer, the Ural Mining and Metallurgical Company, is the second largest domestic copper manufacturer.

The special difference between the manufacturers is practically not noticed, both as products and in its price. Only the forms of the product and their color schemes can differ.

Roofs covered with copper material are considered the most reliable and durable type of roofing. But this fully corresponds to the truth only on condition that the coating was mounted in compliance with all the necessary rules and norms. And only in this case, the roof will really serve for many years, will remain airtight and will not require permanent maintenance.

there are several comments on

there are several comments on the article:

1. First you write that copper is available, and then - that dear;

2. The weight of 1 m2 of copper depends on its thickness (as far as I remember, with a thickness of 0.6 mm, the weight is 5.37 kg);

3. Metrotyil does not supply copper roof, it is engaged in composite tiles;

4. "Roof installation begins with the installation of cornice overhangs and the drainage system" - debatable.