The appearance of water drops on the glass from the inside has a simple explanation ...

|

|

Lodge is the best option for continuing the apartment at the junction with open spaces ... |

In modern interiors of the rooms, the door from the glass appeared quite recently, and ... |

With your own hands

The facade is the face of the house, and the windows, the most significant objects, his eyes. So they demand an appropriate attitude to themselves. The decoration of windows with platbands pay close attention even with slight use of house threads, because it is the platbands that give a special type, completeness and attractiveness to the building. Thus, if we are talking about houses in the private sector, then, of course, you can’t do without platbands on the windows.

Content:

- The purpose of the window platband

- Material for window platbands

- Tools for the manufacture of platbands

- Choosing a pattern for the platband

- Production of carved platbands

- Connection of the parts of the platband

- Decorating a window platband

- Installation of platbands on the windows

The purpose of the window platband

The word platband is found in the description of houses in Russia, which dates from 15-18 centuries. Today, there are few about the platbands, but they still remain an integral element of the window from the facade and the entire extension, regardless of what material the house is built of, and which it has a decoration. An exception may be high -rise buildings of concrete or brick, the windows of which are drowned from the outside into the wall, as well as at home with glazing windows.

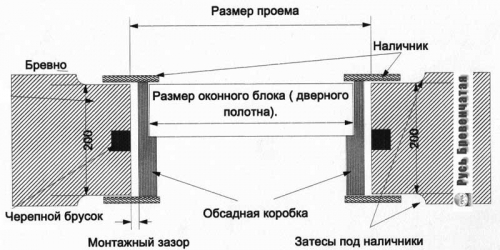

At its core, the platbands are a frame from a board 30 - 40 millimeters thick, which frames the window. However, platbands for windows are not just a decorative element of design: they are necessary to close the gap between the window box and the wall so that the heat does not go outside, and precipitation and dust do not fall into the house, as well as to reduce the level of noise coming from the street. If necessary, the platbands are a frame for the shutters.

If we classify window platbands in shape, then figured, flat and rounded platbands are distinguished, as well as platbands with a convex surface. The most inexpensive and simple in installation are flat platbands. The platbands that have a convex surface are made using special equipment, so the price of platbands for windows of this type is higher. And the most expensive carved platbands.

According to the installation method, two groups of platbands are distinguished: telescopic, which have special ledges, which are entering the grooves on the box, and the platbands are overhead plates. When choosing a platband profile, it is necessary to take the slope without fail, which is available in the upper part of the platband and allows the snow and rain at the top you can not accumulate, but drain down. The most popular in form are carved platbands, and according to the material made of plastic.

Material for window platbands

The design of the facade from the platband requires more than just aesthetic profile. The platband for the window should be resistant to changes in street temperature. If we talk about the climatic conditions of the middle band of our country, then the facade elements can heat up to a plus of 50 degrees in the summer, and cool to minus 35 in the winter. In total, the difference between the temperatures that these elements are subjected to the facade reaches 85 degrees. Therefore, the material from which the platbands are made should withstand such temperature fluctuations, as well as snow, wind and rain.

Remember that the material should not crack and crumble. In this case, MDF and Plywood become unpromising for the manufacture of facade elements. We all know that derivatives from wood, after installation on the facade, absorb water, crack, when moisture freezes inside, breaks down, then the paint is filled, and after a few years you have to change such platbands.

Therefore, platbands from MDF are used mainly inside the house or apartment. The material is characterized by the ease of processing and relative cheapness. In addition, you can make such a product in a short time. Well, if you decide to use such platbands for the facade, they need to be regularly treated with varnishes and adhesives to protect against moisture and preserve color.

The tree is considered the oldest material for the manufacture of carved window platbands. The best decor for the facade today is products made of oak and beech. Birch and pine platbands are less common. The tree is also inherent in hygroscopicity, like the MDF, and the repair of wooden platbands on the windows is too laborious and quite expensive. Therefore, in order to maintain the original form of products, regularly use all the same protective varnishes. There is also a need to update the initial color of the product, because the tree darkens over time.

Hygroscopicity, which is the absorption of water vapor from the air, is also a problem of gypsum decor for facades. The absorption of moisture provokes that moisture freezes when temperatures changes and thaws, which contributes to the gradual destruction of the material and the architectural window platband.

Heavy facade materials, glass -fiber concrete and polymer concrete, are spared the problem of hygroscopicity and have a small coefficient of linear expansion. Everything would be fine if it were not for the significant weight of architectural elements from such material. However, this is not a problem in our time for smart hosts. For each project of the window platband, it is recommended to simply calculate the possible loads on the facade so that the walls can withstand the weight of elements from heavy material.

Polyurethane window platbands, like any facade decor from this material, are additionally different in comparison with platbands from other materials. Polyurethane is a material from which thermal insulation is made, that is, insulation properties are inherent in it. This means that the platbands from polyurethane will well perform their main insulation function. Also, polyurethane is a light material, which is comparable by weight with wood, and polyurethane platbands are easily attached to the facade.

Tools for the manufacture of platbands

Before you make the platbands on the windows, it is recommended to stock up on the necessary tool. First of all, prepare a couple of knives and a set of chisels. It is not necessary to have a complete set of chisels: the most important for this are on the next list:

- Semicircular chisels that have a width of 5 - 25 millimeters (round, overcoming, medium);

- Flat, in size 7, 12 and 20 millimeters;

- Slicarse chisels (semicircular and curved in shape);

- Bricks-apples with the angle of bending of the blade are about 5 15 degrees;

- Chisels with a curved blade with an angle of bend from 50 to 70 degrees;

- Semicated chisels are semicircular in shape, which have a width of the blade of 2 - 5 millimeters, which have a bend in the lower part;

- Knife-cut with a wedge-shaped blade;

- A knife with a blade that is stood at an angle of 30 degrees and has the shape of a wedge.

At home, manual milling devices, electric lobe, drill are often used. Using a jigsaw, you can cut almost any patterns for decorating carved platbands. Sometimes a device is used to create a pattern, which is made of a lowering transformer and nichronome wire.

A tool is also needed, which is used to drink spikes. This device is very simple, and it is easy to make it with your own hands. Fix two blades from longitudinal hacksaw between 3 wooden rails that have small teeth. The principle of operation of this tool is as follows: one saw should be filled with spikes, and the other - the eyes of window platbands.

Choosing a pattern for the platband

The next stage in the creation of a window platband is the choice of the pattern that you will create, and the development of a drawing of platbands on the windows. If it comes to slotting carving, it is better to take wood of wood such as aspen, alder, linden and coniferous. The thickness of the board should be 5 - 50 millimeters. Not the best solution for the window is an abundance of small details, the image should be well read from a long distance and look a skilled addition to the general appearance of the house.

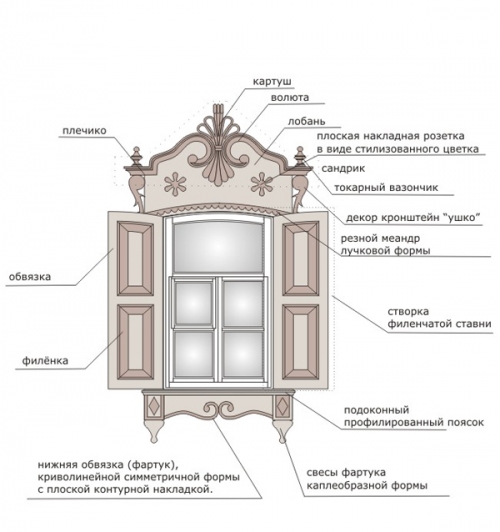

The upper part of the window platband is decorated with a kokoshnik, where it has long been customary to portray the sun. The upper part can be increased if necessary, connecting the composite parts with spikes. The bottom is called towels, it should have a water -roll bevel for water stack. The lower bar should have a thickness of 10 millimeters of the larger upper bar. The drawing of the lower part must stylistically coincide with the image on the kokoshnik.

To prevent cracking of thread over time, it is better to place the elements along wood fibers, this is relevant, first of all, for conifers. Thin endings and openwork bends are usually short -lived. The simplest slot is a round hole, which is drilled with a drill.

Therefore, it is preferable to choose patterns that contain many round holes. Most often, a pattern for a carved window platband is a whole ornament that includes repeating parts. Each similar repeating element consists of several round and semicircular holes, as well as cuts of complex shape.

Stretch the selected ornament along the entire length. To do this, draw a drawing in a 1: 1 ratio on paper, you can also print on a printer. Those areas where the slots have to be performed, mark in a separate color. Stick on a wooden workpiece. With the help of a drill, round holes are drilled, giving them the required diameter. Where you need work with a jigsaw, it is better to drill small holes.

Production of carved platbands

Naturally, all the windows of a residential building should be decorated with the same platbands. The sizes, shape and patterns should match. The platbands on the windows of a wooden house are made in the form of a whole frame consisting of several well -interconnected parts. When processing is not required special care, but reliable protection against atmospheric phenomena is needed. To do this, process the wood with different impregnations and paint with a composition designed for outdoor operation.

If the window will open out, the platband should be placed 30 millimeters higher than its wings. Consider the manufacture of platbands that they should not prevent the opening of windows at an angle of at least 90 degrees. The remaining parameters will depend on the size of the windows themselves.

It is recommended to make platbands like this. It is necessary to strict dry boards that have a thickness of up to 30 millimeters and a width of 75150 millimeters, from all sides. The window platbands should be wider than the box for 2550 millimeters. On the back of the platband, you need to select a groove or gap, which has a depth of no more than 2 millimeters, which should not reach the edges by about 1015 millimeters. In this case, the platbands will fit the walls and boxes denser.

In working with an electric tool, you should not help him, that is, it is not recommended to make great efforts in the hope that the matter will go faster. Excessive pressure on the saw provokes its overheating and creates a risk of breakdown. If the wood is difficult to cut, perhaps the reason lies in the gaping of the edge. In this case, you need to replace the file. To create even long cuts, it is better to use a wide canvas. If you have to work with plastic or metal, you should stock up on machine oil or at least water so that there is something to lubricate the file.

Connection of the parts of the platband

In the process of manufacturing a window platband, the connecting of parts is carried out using a single dull or through spike. It is preferable to use a deaf spike, in this situation it is not necessary to close the connection of the parts of the parts with a decorative element. There is no need to buy a special machine for making spikes, you can manually do it with an electric drill, chisels and hacksaws.

To get a nest for spikes, drill several holes, which have a depth that exceeds the length of the spike itself by a couple of millimeters, and then remove the partitions. The holes must be made by drill for wood, and remove the partitions with a drill on metal. You can work out the edges with a sharp knife or chisel. According to the scores on the window, the spike should enter the nest tightly, but without much effort.

The spikes are fixed with the help of bastards, which are made of dry wood of solid breed (birch or larch). It is not advisable to use glue to connect the parts of the window platband for several reasons, one of them is a significant drop in air temperatures, the effect of chemicals and moisture contained in the atmosphere. No glue can withstand such a load. In addition, on the frame of the platband, which is rigidly fixed to the window block, side loads do not affect.

Decorating a window platband

On the front side of the window platbands, you need to select strokes of a certain size and shape. Having built the appropriate workpiece, it is necessary to cut it into pieces. In order for the platband of the irregularity of the wall completely, on both sides, you need to nail rails, the thickness of which is equal to the width of the gap.

It is recommended to complete the manufacture of platbands on the windows with your own hands with processing cut elements. It is customary to treat the edges with a sandpaper. The platbands are painted or covered with varnish. Separate elements must be attached to the base with glue or nails. To highlight certain patterns, you can contrast them contrast to the rest of the color.

Carved platbands are an element of decor in itself, but in addition to the thread you can decorate them with painting. But remember, it should be combined with carved patterns, emphasize them. Furning wood is also used: beautiful tanks look very impressive. This will be done by using a burner on gas or a soldering lamp.

On the other hand, the decor on the platband should coincide with the general design of the facade of the house, harmonize with other elements of the finish. Woodlor window platforms can be complemented by shutters that are decorated in this way.

Installation of platbands on the windows

The platbands are put in place without glue, on the nails. They use nails, which have a length of 75 millimeters, drive after about 400,500 millimeters from each other, hollowing a hat into the wood. The window platbands are customary to be attached close to the front side of the window box, or retreating 520 millimeters from it, depending on where the wings are opened.

At window openings, platbands should be adjacent close to the window sill. This will put the nightstands - thick segments of the boards that are smoothly lined up, without kalevo. The nightstand is necessary to protect the bottom of the platbands from rapid wear.

After installing the platband, the wood must be treated with a special composition, which protects the material from sunlight and moisture. In addition, they need to be covered with paint or varnish for external use. Periodically update such a coating, then the platbands will serve for a long time, and the facade look original!

Hello. And I ordered in

Hello. And I ordered in the carpentry workshop according to my sketch and windows and carved platbands on them. They coped with my order just perfectly. By the way, I was given a 30% discount. Here is a site if anyone is interested.

http://nalicniki.ru/