An important stage in the installation of plastic windows design of window openings. Slopes for ...

|

|

The use of glass -fruits is associated primarily with internal and external ... |

With the help of a ceiling cornice, it is possible to divide the space between the wall and the ceiling ... |

DIY roofing film

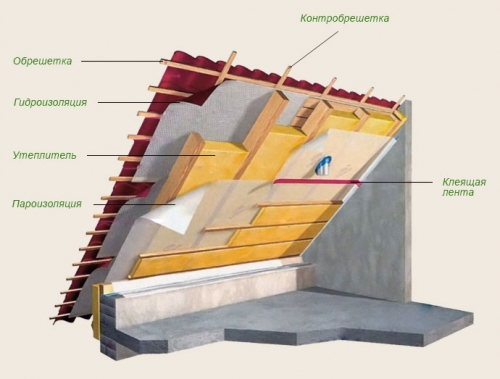

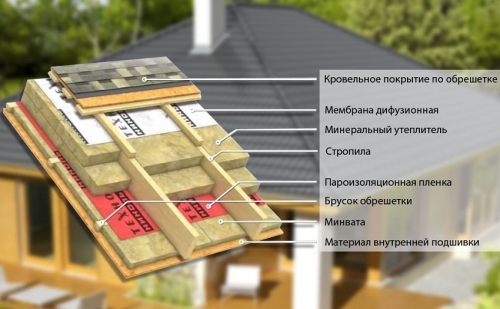

In order to reliably protect the residential building from moisture, thereby extending its operational period, it is important not only to produce competent installation of a roof pie, but also to choose the right hydro- and vapor barrier materials. The relevance of this issue is not in doubt, since any roof is under the adverse effects of precipitation, however, the pitched roofs suffer more, for the installation of which metal tiles, profilelist or ondulin, which do not form a continuous surface are used. In this regard, the question arises: how to protect the roofing surface from the destructive effects of melt and rainwater, which leads to the wetting of the insulation and the formation of condensate? In order to prevent the rolls of rafters, crate and insulation, leading to icing the crate, the appearance of mold and damage to the interior decoration, it is necessary to use membranes, as well as steam and waterproofing films, the characteristics and installation methods of which will be considered in this article.

Content

- Using the roof film: the relevance of the issue

- What needs to be taken into account in the process of arranging roof waterproofing?

- What is a vapor barrier for a roof?

- Varieties of hydraulic and vapor barrier materials for the roof

- Installation of waterproofing films: fundamental rules and norms

- Installation of waterproofing polyethylene film: step -by -step instructions

- Installation of an anti -condensate film: step -by -step instructions

- Storage and transportation of waterproofing material

Using the roof film: the relevance of the issue

The main function of the roofing of the roofing of the roof from atmospheric precipitation, and even its slight mechanical damage can lead to a significant decrease in the effectiveness of the entire structure. To avoid this, it is necessary to use the roof waterproofing roofing, protecting the structure from the effects of atmospheric precipitation. In addition to moisture, which enters the surface of the roof outside, an internal condensate that forms indoors is also a threat to a roof pie. The reason for this is the difference in temperature in the insulated underwear space and outside. Regardless of the materials used by the developer, the condensate will fall out in any case, and to protect the roofing pie from damage, experts recommend using roll waterproofing for the roof, which will additionally protect the roof from moisture.

In addition, the dew point can form inside the thermal insulation fiber and on the wooden elements of the roof, and therefore, its design should assume the presence of a ventilation system through which steam particles will evaporate before the formation of condensation will occur. In the process of arranging the ventilation system, waterproofing materials are also used.

In other words, in accordance with the laws of physics, pairs of warm air strive up and accumulate under the ceiling. Thus, he seeks to go beyond the heated room and, encountering an obstacle in the form of unprotected thermal insulation, penetrates the structure of the insulation, which leads to its destruction. In winter, low temperatures on the outside of the roof will stop the movement of steam and turn it into hoarfrost, and subsequently into an ice crust, which will cause the insulation and destruction of the insulation. In the spring, accumulated ice will melt and flow, which will lead to erosion of the interior decoration. All this will be unusable used thermal insulation material.

What needs to be taken into account in the process of arranging roof waterproofing?

The microclimatic parameters of any room contribute to the formation of water vapors, in accordance with physical laws, striving up to the subcutaneous pie, where they penetrate the insulation, reducing its operational characteristics. In accordance with SNiP, to prevent wetting of insulation, the waterproofing layer is equipped with vapor barrier. When equipping a vapor barrier, it is necessary to take into account the steam -permeability of the film, on which its density, measured in grams per square meter, depends.

Another parameter, which must be taken into account in the process of arranging vapor barrier, the degree of resistance of vapor barrier material for the gap. This can be especially clearly traced in cases where:

The elasticity of the insulation layer is reduced. This happens when the weight of the rafter system is transferred to a vapor barrier material, which should withstand additional load;

In the case of mechanical deformation of the roof pie, a vapor barrier film is an element responsible for the integrity of the steam barrier.

What is a vapor barrier for a roof?

A hydro- and vapor barrier film for the roof, in fact, is a material similar to a polymer film, which is used for wind protection of window openings and shelters of greenhouses. Unlike a traditional polymer film, the thickness of which does not exceed the tenth fractions of a millimeter, the roofing is characterized by a thickness of 1 to 2 mm, high mechanical strength and frost resistance, as well as resistance to ultraviolet radiation.

In view of the listed characteristics, roofing hydro and vapor barrier films are integral material during the construction of a multilayer roof. In the structure of the roof pie, which forms the basis of the multilayer roof, the construction film performs the function of both the steam -barrier and the waterproofer, without releasing a pair of warm air out and not letting atmospheric precipitation inside.

In modern construction, a vapor barrier roof film receives a lot of opportunities to implement its direct purpose. It is used in the following areas:

In the process of arranging the roof, where it performs the function of a material that protects not only the roof frame, but also the thermal insulation layer represented by mineral wool, for which losses of up to 30 % of thermal inertia are characterized in case of humidity even by 1 %;

In the process of building foundations where it is used to isolate horizontal and vertical surfaces located above and below the zero level;

For the installation of attic, inter -story and basement ceilings, where it helps to increase the moisture resistance of formwork and the formation of internal protection in rooms with high humidity, such as bathrooms, baths, etc.

Varieties of hydraulic and vapor barrier materials for the roof

Currently, when arranging a hydro and vapor barrier of the roof, three types of materials are used:

- Polyethylene films A universal material that can be used for both hydraulic and vapor barrier. In view of their insufficient strength, they are reinforced with a special fabric or reinforcing mesh, which allows you to significantly increase their strength characteristics. There are two types of polyethylene films: perforated and non -certified.

Important! Perforated films are used for waterproofing, while non -certified for vapor barrier.

- In addition to traditional reinforced films, the modern construction market offers a plastic film for roofing, one side of which is laminated by reflecting aluminum foil. This significantly increases their vapor barrier properties, which determines the scope of their use - they are used to arrange vapor barrier in wet and hot rooms, such as saunas, baths and pools;

- Polypropylene films, unlike polyethylene, are characterized by greater strength. They are woven material, which on both sides laminated by polypropylene. The indicated features of the structure of polypropylene films make them as strong and resistant to ultraviolet radiation. There are more modern modifications of polypropylene films, which involve the application of the material of the anti-condensate layer on one of the sides, which is a viscose-cellulum fiber.

They function as follows: one way or another on the surface of the film facing the thermal insulation material, moisture is formed, which is absorbed into the layer of viscose-cellulum fiber, thereby not in contact with the insulation. After the causes of condensate formation are eliminated, the moisture will gradually dry due to the continuous air exchange occurring due to the presence of a ventilation clearance. In this way, the system will remove the resulting water vapors outside the roof. Thanks to the above features, the anti -condensate waterproofing film is able to retain moisture, which is formed on the inside of roofing materials such as metal tiles, galvanizing and a profiled sheet.

Important! Experts drew attention to this and concluded that during the installation of roofing and facade systems, the anti -condensate film must be laid between the insulation and roofing material. A striking example of a high -quality anti -condensate roofing of the Yutakon film, which can be used not only as a waterproofing material, but also as a temporary shelter for a roof located at the construction stage.

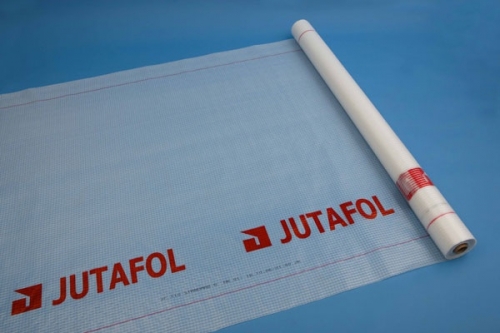

- Roof membrane Quality new material for waterproofing. Unlike the traditional waterproofing film, the roofing diffusion membrane is a breathing material, which is characterized by high vapor permeability and at the same time remains waterproof. Roofing membranes coating characterized by a more complex structure, which allows the material to produce moisture outward, but do not pass the liquid or steam particles inside. In its structure, the membrane resembles human skin, which can breathe, stretch and covers the entire surface that needs protection.

Important!The only drawback of roofing membranes is the need to arrange an air gap between thermal insulation material and diffusion membrane. Otherwise, the membranes will block the pores of the membrane, which will lead to a violation of its vapor permeability. In the case of all the rules and installation standards compliance with a diffusion membrane with a size of 100 x 100 cm, it will pass from 400 g to 1 liter of a liquid in the form of steam particles, which will be quite enough to carry out full -fledged natural air exchange.

- SuperDifous membrane A more modern and perfect type of roof membranes, devoid of the above deficiency, which is characteristic of ordinary diffusion membranes. SuperDiffusion membranes can be laid directly on the insulation or glued directly to the surface that needs a ventilation gap in the case of using a superdiffusion membrane.

There are single and bilateral superdiffusion membranes. The laying of unilateral membranes must be carried out taking into account the direction of vapor permeability of the surface of such membranes into the external (facing the wall or finishing layer), and internal (directed to insulation). Bilateral membranes can be laid without taking into account the direction of vapor permeability.

An example of superdiffusion membranes is a two -way film Utafol, the styling of which can be done by any side. The vapor permeability of such membranes is up to 1 liter of liquid per 1 sq. m, due to which, based on such membranes, it is possible to equip systems of natural supply and exhaust ventilation.

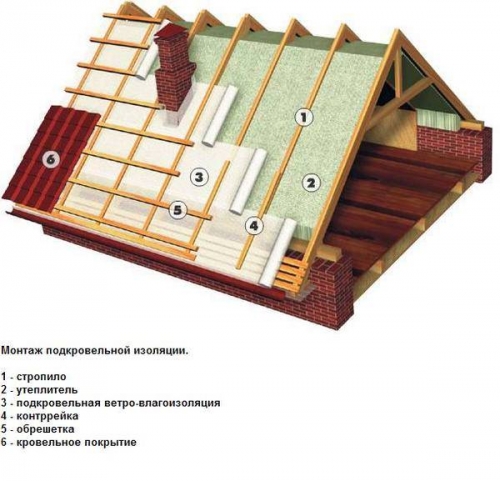

Installation of waterproofing films: fundamental rules and norms

In order to equip the roofing cake as efficiently as possible, during the installation of a waterproofing and vapor barrier film, it is necessary to take into account the norms recommended by the manufacturer of waterproofing materials.

In most cases, they come down to the following:

- In the process of laying the superdiffusion film, there is no need to leave an air gap, they fit directly on the insulation. Installation of diffusion films provides for the presence of a ventilation gap - they are laid on a controlled box, which, in turn, is laid on the insulation. And the one and the other material to the crate are attached with roofing nails with a wide hat, while the joints of the rolls are laid with a vertex of at least 10 cm;

- As for polypropylene anti -condensate films, they are mounted only in dry weather, which is due to their high absorption ability. In this case, their adsorbing surface should be facing the inspection. Like the diffusion membrane, the polypropylene film is mounted on the counter, since a ventilation gap should remain between the waterproofing material and the insulation. After laying the anti -condensate coating, another counterparty is mounted on it, on which roofing material is subsequently laid. To fix the anti -condensate film, galvanized nails will be required;

- During the installation of a vapor barrier film, it is laid under the insulation, and then fixed with a tape or special glue. If you prefer adhesive tape, it is necessary to protect both ventilation outputs and surfaces adjacent to window openings and other problem areas that need protection. At the same time, the joints of the material must be overlapsed with overwhelming up to 10 cm.

Installation of waterproofing polyethylene film: step -by -step instructions

- During the installation of the first row of waterproofing material, the film is spread along the roofing cornice, while ensuring the sagging of the film between the rafters up to 1-2 cm. Do not forget that the step between the rafters should not be more than 1.2 m. Between the film and thermal insulation material should be maintained air gap to 40 mm;

- The film is laid horizontally, in the direction from the cornice to the ridge, providing the overlap between the paintings of the film up to 10-15 cm. At the same time, the films between the rafters should be at least 20 mm. To ensure sealing the waterproofing layer, the joints of the materials are glued with adhesive tape;

- To fix the waterproofing film, a mechanical stapler or galvanized nails with a wide hat are used;

- The subsequent rows of waterproofing material are laid with an overlap 10-20 cm, while the size of the overlap is determined by the angle of the roof slope (see table)

- On top of the fixed film, the bars of the counterparts are nailed, the cross section of which should be at least 40 x 25 mm. The step between the bars should be 10-15 cm;

- After that it mounts the crate;

- At the level of the ridge between its axis and a waterproofing film, it is necessary to leave a gap called the skate blow, the size of which should be 50 mm. The skate is blowing is a kind of rupture of the film under the skate of the roof necessary to ensure ventilation of the undercarbon space;

- In those places where on the roof it is necessary to mount antennas, pipes or other structural elements, the film must be cut and its edges to the closest arcas of the crate using tape or bilateral self -adhesive tape must be glued. In the presence of attic windows, in the process of device a waterproofing film, adhere to the recommendations of the window manufacturer;

Important!To ensure free air passing through the horse, it is necessary to leave a ventilation gap of 40-50 mm.

Important! Laying a perforated film should be carried out so that perforation is oriented out. Otherwise, the action of the film will be directly opposite to the originally conceived film to pass moisture into the roof and not let steam from the inside. The roof will begin to flow and rot.

Installation of an anti -condensate film: step -by -step instructions

- Laying a polypropylene film can only be carried out in dry weather after the installation of the rafter system is completed and the insulation is laid;

- The distance between the rafters, as in the previous case, should be no more than 1.2 m;

- The laying of a polypropylene film is carried out so that its absorption surface is facing downward, towards the insulation. In this case, its lower surface should not in contact with it;

- The anti -condensate film is also fixed using a mechanical stapler or galvanized nails with a wide hat;

- Installation of the anti -condensate film is carried out from the cornice to the ridge of the roof. In this case, the film is laid with horizontal stripes. According to vertical, the material is laid with an overlap of 15 cm, vertically at least 20 cm;

- Film joints should be at the level of rafters and fastened with adhesive tape;

- During the installation of the waterproofing layer, it is important to ensure that the film is stretched evenly so that there are no folds and nozzles. In the central part of the interspolary space, there should be sagging up to 1-2 cm, which is necessary in order to take moisture from the wooden structural elements;

- In the process of laying the film between it and the insulation, it is necessary to leave a gap of at least 40-60 mm;

- The lower edge of the film in the ideal version should ensure the removal of draining moisture, which enters the drainage groove;

- After you have completed the installation of the film coating, fix it using a 3 x 5 cm sizes, which must be beaten on top along the rafters with galvanized nails. A crate is installed on top of the rails, which is selected taking into account the characteristics of a particular roofing system.

What needs to be taken into account in the process of installing an anti -condensate film?

- In the process of installing a waterproofing film, it is important to exclude the possibility of running moisture from the upper surface of the film to the insulation;

- Try to thoroughly isolate the intersection of the film with penetrating structural elements, such as ventilation boxes, antennas racks, stoves and fireplaces, etc. In places of intersection of the film with the indicated elements in the film, an incision in the form of a trapezoid is made. In this case, the upper and lower valves are removed and fixed on the nearest horizontal element of the crate or penetrating part using the sealing tape. The side valves are similarly fixed on the penetrating element.

Storage and transportation of waterproofing material

- Answering the question: how to store a roof waterproofing film?, It should be noted that this is carried out at a temperature of -40 to +80, in other words, the range of temperatures comfortable for material is quite high;

- The laying and connection of the waterproofing film using a waterproofing tape should be carried out at a temperature above +5 degrees;

- The warehouse where the material is stored should be protected from ultraviolet rays;

- In the process of unloading and loading the material, it is important to ensure that the packaging does not occur, since in this case the risk of rupture of the film itself increases.