To reduce thermal conductivity of various structures and save in rooms ...

|

|

Not all firms involved in the installation of plastic windows include the installation of slopes ... |

Have you started repairs and dream of completely changing your bathroom? The best option... |

Forged gazebos for giving: disadvantages and advantages of this structure

Modern landscape design often includes such a component as a forged gazebo. Skillfully executed, it will certainly become a real decoration of the site. It looks especially harmonious in combination with a fence, grates on the windows of a house or garden furniture made in the same appliances. The article will talk not only about the advantages and disadvantages of forged arbors, but also about how to cook a simple metal gazebo yourself.

Content:

- Advantages of forged arbors

- Disadvantages of forged arbors

- Elite forged gazebos

- Materials for the manufacture of metal and forged arbors

- DIY metal gazebos

- An example of building a gazebo with your own hands

- Forged gazebos photo

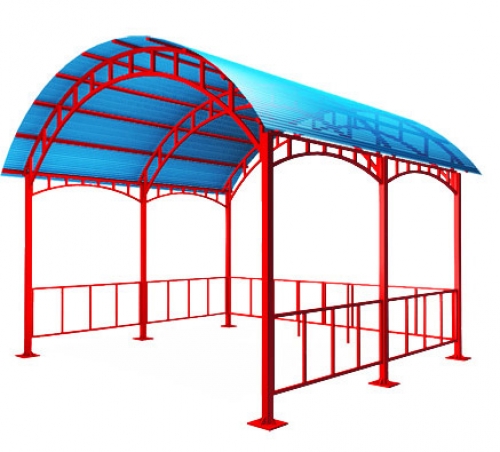

Forged gazebos for cottages can be a massive closed structure on a solid foundation and a light openwork structure. The first species is great in order to spend time even in the cold season. In them, as a rule, a barbecue is installed, and sometimes a fireplace. Such arbors are more reminiscent of pavilions with elegant artistic forging on the windows and colored roofs made of polycarbonate or any roofing material.

- Light designs are unable to protect from heavy rain, but will be tired of the scorching sun on a summer day.

- They are distinguished by an exquisite appearance, especially if these are elite arbors made by the masters of their craft in a single copy that can rightfully be called real works of art.

Advantages of forged arbors

Forged gazebos are rightfully a luxurious decoration for any site.

- They are used not only as a place for family vacations, but also as a background for solemn events, for example, wedding ceremonies;

- they look great against the background of the landscape of the garden, among the trees, and against the background of the facade of the house;

- a metal arbor goes well with elements made of other materials of stone, wood, plastic or metal;

- have not only an attractive appearance, but also more durable than wooden;

- less commonly, repairs are required, which, as a rule, consists in annual painting;

- you can choose an option for any wallet from expensive elite arbors, to quite economical welded options from reinforcing bars or even cheaper using a lattice for a natural fence;

- no matter what price category the forged gazebo is included in, it is installed on almost any surface, whether it is a lawn, a concrete platform or gravel embankment. Often, embedded parts on concrete supports are used as a mount, but there are gazebos that simply buried in the ground, or mounted on top of it.

- easily stained with any alkyd paints, including compositions imitating gilding or platinum. They will not only give structures a beautiful view, but also protect the metal from atmospheric influences;

- for lovers of cooking various dishes on the grill on the site, forged arbors will be an ideal option. Indeed, in comparison with wooden analogues, which are still leading in popularity, they are not afraid of fire. Therefore, you can without fear of installing a barbecue inside them and cooking your favorite dishes even in rainy weather.

Disadvantages of forged arbors

Naturally, any constructions have not only advantages, but also disadvantages and forged gazebos are no exception.

- It is believed that because of the properties of the metal to heat up in the sun, it will be very hot in the gazebo. To avoid this, you need to choose the model as openwork as possible and plant trees near it that will create the necessary shadow;

- the metal rusts. But this drawback is also easy to eliminate if you cover the surface of the arbor with coloring compositions, especially since modern dyes include excellent metal protection, they are more durable, which allows coloring once every few years. In addition, they can be applied to a metal surface even without preliminary processing, which is greatly simplified by the work.

Elite forged gazebos

The uniqueness and originality of the main features of elite forged arbors. They are made according to an individual sketch, and therefore are called exclusive. Despite the fact that they most often look like thin, lace constructions, in fact are extremely durable, due to the fact that the metal itself is very hard and elastic material.

The process of manufacturing such arbors is quite laborious and long -term in time. It begins with a sketch, which is either performed by a professional designer, taking into account the wishes of the customer, or is selected among ready -made options available in the company manufacturing forged products.

When the sketch is ready, it acts as a designer creating a project. In it, he calculates all the necessary parameters of supporting structures to ensure complete safety from the consequences of possible loads. After that, the printed project enters the anger workshop, and then along the conveyor in the assembly workshop. At the finish stage, he finds himself in the painting workshop. When all these stages have been passed, the manufactured gazebo is sent to the customer, which is most often installed by the mounting team.

It is worth noting that during forging, the proportion of manual labor is quite large, because the machine can not make any element and part. Also, the assembly of individual parts of the structure occurs manually, which is why forged arbors retain the heat of the wizard's hands.

Distinguish between cold and hot forging. Cold forging is called metal at room temperature, which is below the temperature of the recrystallization of the metal. In the work, iron and soft varieties of steel are used. The process can be described as cutting blanks or called stamping.

Ready -made elements with cold forging are collected using welding. The gazebos made using this technology have a lower cost than made with hot forging, but the result is less spectacular.

Materials for the manufacture of metal and forged arbors

For the production of forged products, it is used:

- iron;

- copper;

- steel.

Soft varieties are more suitable, which include up to 13% carbon. With an increase in its shared content, the metal becomes rigid, hard and the tendency to hardening increases, which complicates art forging and prevents mining, which is often used in blacksmithing.

For machine forging, it is used:

- round or square profile;

- sheet metal;

- stamping.

For manual, everything is also, with the exception of the latter. As a rule, the gazebo combes both the elements of the machine tool and the elements of manual forging.

As for the specific terms of manufacture, they will vary depending on the characteristics of the order whether the gazebo is first performed, or has already been performed according to a similar sketch.

At the end of the work, it will be quite difficult to make some cardinal changes, since the product is a full-fledged, completed work. The revision will subsequently reduce, as already noted, to coating with coloring compositions.

The cost of their products is a manufacturing company or an individual master usually set on their own, based on the difficulty of work. As a rule, the price of a forged gazebo varies from 8 thousand rubles. and may exceed 1 million rubles.

DIY metal gazebos

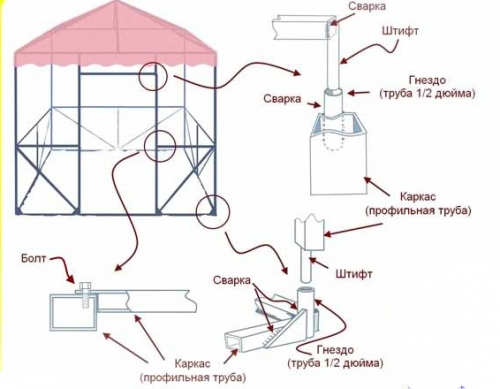

In order to create a complex design of an elite forged gazebo, whether the technology of cold forging or hot, certain skills in working with metal, as well as the availability of special equipment, are needed. But if desired, you can always find an alternative, for example, a simple metal gazebo from profile pipes with welding joints.

The most rational option is considered to be a metal frame of the gazebo, made of a profile pipe of a rectangular or square section with a wall thickness of at least 2 mm. Welded structures from such pipes will look more neat than when using round pipes and a channel. For partitions, you can use a metal corner.

To date, a wide variety of drawings and metal arbors is presented on the Internet. But in most cases, they require finalization for themselves. But in any case, this is a good way to save on ordering an individual project.

An example of building a gazebo with your own hands

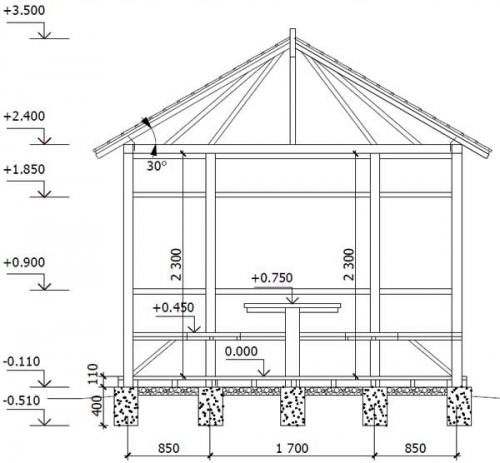

The size of the gazebo is 3x5.4m.

Roof

For the manufacture of the roof, a 20x40 mm pipe is required, which will need to be cut according to certain sizes.

- For a roof slope, you need a 20x40 mm pipe 2 m 12 m 12 pieces;

- the crossbar of the pipe 20x40 mm 3 m long;

- for central supports, a pipe 20x40 mm 40 cm long 6 pieces.

All these pipes will need to be connected to triangles using welding, for which you will need a welding inverter and electrodes of 3 mm.

Work should be done on a good flat surface. To set the right angle between the central support of the vault and the cross, you need to use a square. First, it is necessary to weld the support of the vault to the middle of the cross -member, and then weld both the vaults to the support and separately each of the arches to the crossbar. At the same time, a vault of 20 cm is made.

The roof is half ready. Now you can proceed to the workpiece of other elements for which you will need:

- pipe racks 40x40 mm 3 m long 10 pieces;

- binding transverse pipe 40x40 mm long 3 m 2 pieces;

- binding longitudinal pipe 20x40 mm long 5.4m 2 pieces.

Square

On the selected site for a future gazebo, it is necessary to mark the places for installing the pillars. First, marks are set for installing posts at the 4th corners according to the specified parameters of 5.4x3M, the distance between the corners is necessarily checked by the diagonals, it should be the same. Next, the short side must be divided in half, respectively, put a label by 1.5 m. The back wall of the gazebo should be divided into 3 equal parts, putting the tags every 1.8 meters. For the front wall, you need to set the marks, taking into account that the entrance will be located here. As an option 2.3 m 1 m 2.3 m (from the corner from left to right). In this case, the entrance will turn out in the middle.

Installation of pillars

After the marking is made, you need to start preparing pits for installing the pillars, for convenience in work you can pull the ropes. Pits should be dug to a depth of about 40 cm, respectively of a square shape.

In the resulting wells, it is necessary to install the pillars and drive them into the ground to a depth of about 80 cm (for this it is best to use a sledgehammer). During installation, the level is necessarily used to withstand the size more accurately.

The next stage is welded to the pillars

Roof installation

First of all, you should weld in level 2 of the extreme pre -prepared triangle. For the convenience of installing the remaining, already mounted triangles are fastened on top of a 20x40 mm pipe 6 meters long. After that, the roof slopes are installed without much difficulty.

Next, the remaining transverse profile pipes of the roof slopes are welded.

Storing structure

At this stage, the color of the roof slopes should be performed, because after the roof is covered, it is quite difficult to do this qualitatively.

The most durable is considered to be powder, but in this way the gazebo can be painted exclusively in the conditions of production. With independent staining of the elements, a primer is first applied, and then covered with a resistant to various external influences nitroemal. Or the so -called hammer paints are used, which are applied without preliminary primer (they are allowed to even apply them to the parts touched by rust).

Setting the floor

Before laying out the tile, the surface of the site must be leveled using the level. To do this, the soil in the elevated areas is cut off and poured in lower. Then, so that the tile is easier to lay, we sprinkle the site with a layer of sand. This type of work is performed at the very beginning of construction.

The next step is the laying of the tiles. At the same time, it is important to arrange a surface with a small slope from the middle to the edges, which is necessary for water drainage. Such a measure will exclude the formation of a puddle in the middle of the gazebo. It is convenient to use a rubber hammer for alignment of tiles.

The second way to equip the floor in the gazebo equipment of wooden flooring. This is a cheaper and simple option. The main thing is to treat the wood with a protective drug.

Now you should do the roof. It can be covered with a galvanized profile or boards. First lies one side, then the second, after which the horse is installed.

The gazebo is ready. It remains to attach castings, install a barbecue, lay out the path to the gazebo, and so on, which will turn it into a place for a comfortable rest.

Forged gazebos photo

Buying a forged or metal gazebo for a summer residence is not difficult now. The market is full of various offers, from an economy class in the form of a metal frame with a polycarbanate canopy, to elite with manual forging. Next, a selection of photos of arbors for any wallet is presented.