Roofing with roofing iron is a rather complicated process. Finite...

|

|

Despite the abundance of finishing materials, pasting the walls with wallpaper remains the most ... |

An excellent place for storing conservation and vegetables will be a cellar. When to equip ... |

How to make slopes with your own hands?

Not all firms involved in the installation of plastic windows include the installation of slopes in the list of services provided. For the arrangement of slopes, sometimes they require an unreasonably high fee. In the presence of appropriate equipment, materials and basic knowledge, this task can be performed with your own hands.

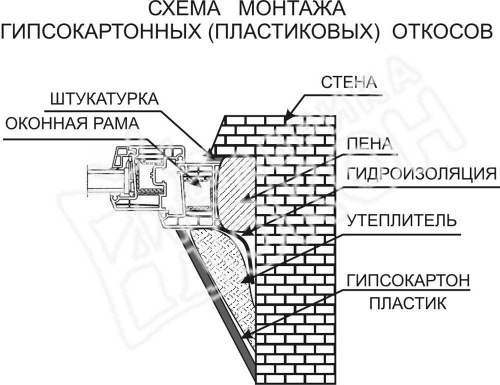

The slopes protect the seams from moisture and provide thermal insulation. There are several ways to install slopes: plastering, installation of drywall sheets or PVC.

Content:

- Installation of plaster slopes

- Installation of lighthouses

- Plassing of the slope

- Slopes made of drywall

- Laying slopes from drywall to the frame

- Handwheel method for installing slopes

- Plastic slopes

- Types of plastic slopes

- Plastic sandwich panels

- Slopes from foamed PVC

Installation of plastering slopes (sloping plaster)

Do -it -yourself installation of plaster slopes will require a lot of time to perform. This method is usually chosen for the restoration of existing slopes during major repairs. To create slopes in the process of fluid cosmetic repair, it is better to choose other materials. Indeed, when performing plaster and putty, the wallpaper covering around the window opening will inevitably deteriorate. If during the dismantling of the old surface the rib of the slope was showered, then it is necessary to install a metal corner.

Installation of lighthouses

Professionals carry out plaster on lighthouses with wooden or metal devices. If you need to increase a small layer, then you can do with the marks from the mixture with the addition of gypsum. It is better for beginners to purchase ready -made plaster beacons. The first lighthouse is placed at the very window or door block so that the plaster layer lies on the frame at least 50 mm. During the installation of lighthouses, all distances are verified by the construction level or laser leveling. The second lighthouse is laid in the corners of the box. The distances between the first and second lighthouses should be the same around the entire perimeter of the window opening.

Plassing of the slope

For plastering slopes indoors, plaster plaster can be used indoors. Such a solution refers to rapidly drying, knead it better using a construction mixer. This type of plaster can be applied with a thicker layer than cement-sand, which is important if you have to cover deep potholes in old slopes.

Sand is added to the cement mixture if you need to apply a layer of plaster more than 3 centimeters. So the layer hardens faster. Before adding sand to the solution, it is better to sift it. External slopes on the windows are treated with a cement mixture or facade starting putty in combination with water -repellent additives. If the house has plastic windows, then the thermal insulation will also need to be carried out before plastering. Otherwise, in the cold season, glass will sweat strongly.

The plaster is applied to several layers, each of which requires drying. First, spray is carried out, then soil is produced in 1-2 layers. The last is the finish layer. The next layer of the mixture is applied only after the previous one has completely dried. After that, the surface is putty, thus getting rid of smaller irregularities. It is impossible to put their putty with a thick layer. If you need to apply another layer of putty, then the previous one is necessarily primed. The last layer is finished, finishing putty. When drying, it becomes lighter. The next stage is grinding, which is performed by a grinder.

Small gaps in the places where putty and window or door block joints are covered with sealant that can be painted. The junction of the joint is cut into 2-3 mm with a clerical knife at an angle of 450. The resulting recess is primed. With the help of a pistol, the surface is covered with sealant so that the groove is completely filled. A strip of sealant should be as even as possible. To do this, apply a masking tape. The sealant is locked with a small rubber spatula, after which the painting tape is removed.

The surface of the slope must be primed with a wide brush in order to prevent cracking and prepared for subsequent painting. You can paint with solvent -based enamel. But recently, acrylic paint has been increasingly used. The finish of the slopes takes place in two layers. The second layer is applied after the first dries completely. So the base will not be visible through the layer of paint. Performing all stages will take about a week.

Slopes made of drywall

One of the advantages of drywall slopes over plastic is their practicality. In case of minor damage or pollution of the upper layer, drywall, unlike plastic, is subject to repair. To return the slope of the initial aesthetic properties, it is enough to plunge it again, stoop and stain. To perform slopes from drywall, the presence of special skills is not required, but there will be a lot of time for their manufacture. Installation takes place in several stages: creating a frame (with a frame method), laying drywall, putty, primer, and painting. Such slopes are durable and practical. However, they have a significant minus absorb moisture. Therefore, for rooms with high humidity and outdoor decoration, they are not suitable.

Laying slopes from drywall to the frame

The package of high -quality metal -plastic windows always includes a profile for the installation of slopes from drywall. The presence of the profile must be clarified directly by the manufacturer or the supplier. In case of its absence, you can apply a galvanized profile. To lay drywall on the slopes of doorways, a metal profile is also used. Before installing the window block, the profile is mounted in the groove provided for this purpose.

Usually the slopes are installed the next day after the installation of windows. Then the surface is treated with mounting foam.

Now the window block should stand. After a day, plastic or wooden spacers are removed, and excess foam is cut off.

In the groove along the perimeter of the opening, they are placed, and then, along the line of docking the drywall with a window block, the guide profile is screwed with self -tapping screws. The frame is installed before insulation of the slope of mineral wool. The insulation is laid in the voids between the profiles. The slope angle is set at 950. A drywall is mounted to the frame.

Regardless of the method of installation of slopes, drywall is polished. The gaps between the sheets are spit. Only after that they start a primer and painting. So that the corners are not relaxed, a metal galvanized corner is mounted around the perimeter.

As with the plastering of the slopes, in the places of connection of the window frame and slop (in this case, drywall), a deepening is made at an angle of 450, glued with a painting ribbon and treated with an acrylic -based putty. Acryl will completely freeze after 12 hours. After that, the slopes are painted.

Handwheel method for installing slopes

Unscarled technology is rational to use when you need to lay drywall on old slopes. To do this, clean the surface of previous finishing and construction materials and produces a primer.

When performing slopes along the existing sheet of drywall, it is attached to the guide profile with self -tapping screws and pointedly glued to the base of the mixture of perfillics. The glue prepared from this mixture is grasped very quickly. Therefore, drywall must be cut in advance.

For better fixation, drywall is pressed with a wooden bar, according to which it is shaken by a hammer made of rubber. To maintain the upper horizontal slope in the desired position during the gluing time, sprinkles from the window sill are used. The minimum time during which it is necessary to fix the surface for an hour. The slopes are left for 2-3 days until complete drying. At this time, the outer edge of the slope (the place of the conjunction of drywall and the walls) is left open. So glue will dry much faster. After the glue dries, the edges of the slopes are covered with acrylic. Next, the surface must be finished with finish putty.

Plastic slopes

The easiest way to complete the installation of a window block is plastic slopes. They are easy to install, do not require special care, durable and moisture resistant. Depending on the style of the room and the color scheme of the windows, you can choose the necessary tone. For heat and sound insulation you will need mineral wool or foam. Plastic slopes can be installed both from zero and on an old wooden or plastered surface.

Types of plastic slopes

Plastic slopes are suitable for external and interior decoration. They can be installed on the day of installation of the double -glazed window. There are several types of PVC slopes: from foam plastic, plastic plastic coating and sandwich slopes.

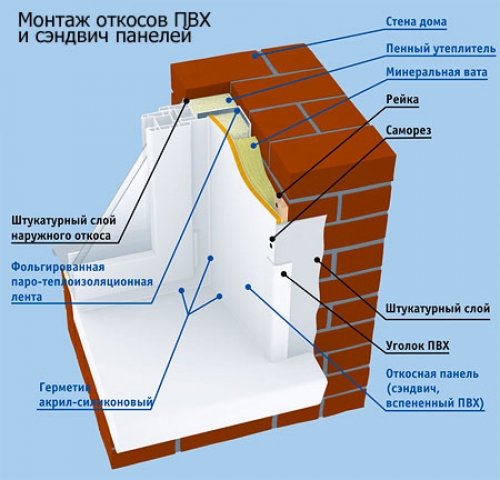

Plastic sandwich panels

Recently, slopes from sandwich panels are often installed. Their cost is small, they are not at all afraid of moisture, they can be matte, glossy or with imitation of wood. The structure of this material resembles a sponge, so the slopes better retain heat. After installing such slopes, the appearance of condensate on the glass is rare. The reason for fogging the windows in this case lies in the incorrectly equipped ventilation system. In the production of sandwich-fluids, panels 1 cm thick are used.

Along the perimeter of the outer edge of the window opening with self -tapping screws, we strengthen the wood rail, the level determining its location. Reika will take on the load of the slope. Therefore, it is necessary to fix it reliably.

The start profile is installed in the grooves. The slope itself is attached to the profile, after which the insulation is performed (the insulation is laid for plastic). The outer edge of the slopes is mounted to the wall with self -tapping screws, dowels or brackets. The first method is the easiest. Do not worry that the hats of the screws will be visible. Self -tapping screws are screwed as deeply into the panel and hid in plugs.

Installation of slopes using brackets is as follows: the first bracket with a double -sided mounting tape is attached to the wall, and the second to the slope. The brackets are attached to each other with self -tapping screws. The side slopes are fixed to the windowsill of the glue, then they glue with the neighboring ones. The cracks are treated with sealant.

Slopes from foamed PVC

The slopes of integral polyvinyl chloride have a rather smooth upper layer, easily cut by a grinder. In order to bend the PVC at an angle, small cuts are carried out in the places of fold. If you need to perform a slope in the form of a semicircle, then it is better to find the material than foamed polyvinyl chloride. For the formation of the necessary arc, frequent incisions are made. However, it should be remembered that the furrows should not exceed one third of the thickness of the slope. The cuts are certainly processed with glue.

In pre -prepared furrows in the mounting foam, apply glue and put the panel. As with the installation of previously described methods, we fasten the metal profile to the box and fix the plastic in it. The space between the PVC and the wall is blown by a strip of foam, leaving a small space for its swelling. Next, proceed to fasten the profile to the outer corner. The docking places are treated with silicone, smoothing its surface with a rubber spatula or a damp cloth. Installation of slopes made of drywall with PVC opening is carried out in the same way as from plastic.

Installing slopes with your own hands is a great way to acquire new skills and at the same time save. A correctly completed finish will help to hide some of the shortcomings of construction and repair work and minor errors made during the installation of PVC windows.