One of the most difficult stages of repair is rightfully considered to be filled with screed. Really...

|

|

To protect the internal space of the room from moisture is used ... |

The parquet floor wears out over time and requires a capital or ... |

DIY wood boiler

Despite the widespread gasification, firewood boilers continue to be widely used in country houses. To equip a heating system based on a solid fuel boiler is quite real on your own. It is enough to understand the principle of operation of the equipment, follow the manufacturing technology and adhere to all fire safety standards.

- Wood heating: advantages and disadvantages

- Varieties of boilers on wood

- Fire boiler device

- DIY wood boiler

- Installation and commissioning

Wood heating: advantages and disadvantages

Solid fuel boilers is a popular way to ensure autonomous heating of a private house, cottage, garage, warehouses and industrial facilities. Drew boilers have a number of significant advantages compared to devices operating on special fuel:

- The material used for the furnace has an acceptable cost and reduces energy costs.

- Firewood is environmentally friendly fuel that does not cause allergic reactions and other diseases.

- The boiler on wood is easy to operate.

- The high speed of heating the room after turning on the boiler Thermal effect occurs within a few minutes.

- Solid fuel boilers on wood are independent. Their work does not require the connection of the gas system/electric industrial system.

- The firebox with wood is aesthetic, so such boilers are often installed in both small summer houses and elite cottages.

- In addition to heating, stoves/wood boilers can provide a house with hot water without additional costs. The boiler will heat a boiler with water, which will simultaneously play the role of a water radiator of heating.

Homemade boiler on wood: photo

The disadvantages of such devices include:

- The susceptibility of the metal body of the boiler to corrosion processes.

- The need for regular cleaning of equipment from fuel combustion products (ash).

- A short period of combustion and heating from one load.

Varieties of boilers on wood

Boilers on wood wood depending on the supply method are divided into two types: automatic and manual. The first view includes boilers on pellets. The fuel is laid in special bunkers and from there is supplied for burning. The device can function in automatic mode for a long time.

You can connect electrical equipment to the wood boiler, this will reduce the frequency of human participation in the heating process. The devices operate in parallel, and the electric boiler supports the minimum temperature regime of water.

An alternative way to reduce the participation of a person is the use of a battery tank. The system operates in automatic mode per day in the tank accumulates heat, and energy is consumed at night.

Firewood boilers with manual loading can be divided into three types:

- Traditional boilers. The device has a standard design of the firebox chamber is located below. Such boilers labor consumption in maintenance.

- Pyrolysis boilers. The equipment operates on the principle of fuel separation into solid and gaseous components. Advantages of pyrolysis devices: high efficiency, slight formation of ash and soot. However, such boilers require the use of dry wood with a moisture content of not more than 20%.

- In boilers on wood firewood, the upper layer of fuel burns, and the remaining part smokes slowly. A distinctive feature of the boilers is a high level of efficiency and the ability to regulate the power consumption. The device can be served once a day.

Fire boiler device

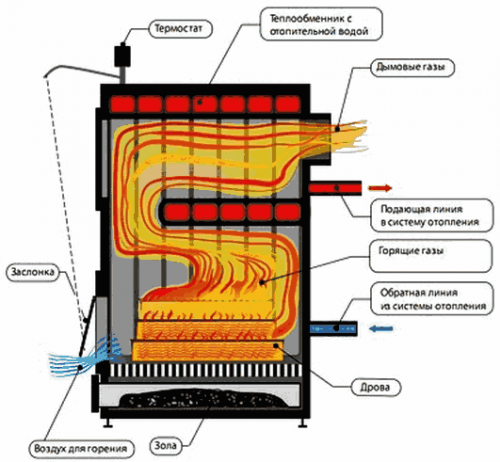

The wood boiler is made of heat -resistant material resistant to high temperatures. The main elements of the boiler are:

- combustion chamber;

- ash chamber;

- the chimney of the air output pipe outward, passing through a container with water/steam.

The ash chamber and combustion chamber are separated by grates. Both cameras are closed with special barriers and doors.

DIY wood boiler

Drawing boiler drawing

A simple wood boiler can be made independently without the use of complex technological equipment. The main essence of the technology is the transformation of the process of combustion of firewood into processing process.

Card of boiler on firewood

Between the two casing (internal and external) is a layer of air. Cold air enters from below, heats up from the walls of the inner casing and moves up through the hole in the outer body. Hot air heats the room.

Preparation of tools and materials

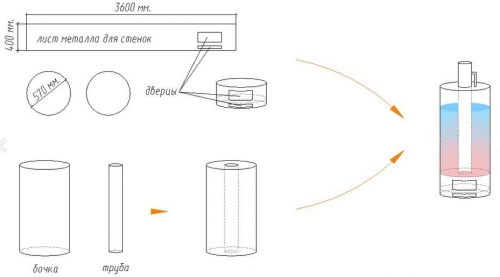

A wood boiler can be made from the following materials:

- metal sheets with a thickness of 4-5 mm (sheet metal can be replaced by a barrel with 200 liters or a case from an old stove);

- thick -walled pipes;

- metal corners and reinforcement;

- fasteners.

Work tools:

- welding machine;

- drill;

- bulgarian;

- electrodes;

- a hammer and a chisel.

Assembly guide

We will analyze the step -by -step how to make a boiler on firewood:

- Making air supply device:

- take a thick -walled pipe, the length of which is equal to the height of the furnace;

- to weld the bolt to the pipe;

- cut a circle from a sheet of metal; The diameter of the circle should be slightly larger than the diameter of the pipe;

- drill a hole for the bolt in the circle;

- connect the air duct and bolt, fasten the nut (the duct should be freely closed with a metal sheet, changing the size of the lumen and regulating the combustion intensity).

- In the air duct, make vertical cuts (width 1 cm) with a grinder. Air will flow through these holes into the firebox chamber.

- Cut the circle of sheet metal. The diameter of the circle should be slightly smaller than the diameter of the furnace.

- Inside the circle, make a hole under the duct of the duct.

- Insert the duct with a blower into the hole (retreat 20-30 cm from the edge of the pipe) and weld.

- Production of the boiler housing:

- if the old gas cylinder is used, then it is necessary to cut its upper part;

- using the thick -walled sheets of metal, they are twisted into the shape of the cylinder, fastened and welded the bottom.

- Production of the chimney:

- make a hole in the cylinder (upper side);

- procate the pipe (diameter at least 10 cm) in the made hole.

- Install the air tube in the body of the boiler. To do this, make a hole in the bottom of the furnace chamber and install a duct in it. The blown should hang outside the boiler. The air supply pipe must end below the location of the chimney.

- The next stage is the creation of a heating disk. From a metal sheet (thickness of 10 mm), cut a pancake. The diameter of the disk is slightly smaller than the size of the case. Build a handle from reinforcement or steel wire and attach it to the heat -reparaceum disk.

- Fastening the convection casing to the furnace:

- The roof for the case of the stove. As a roof, the rest of the gas cylinder or a barrel cover is suitable. For ease of use to the lid, you need to weld a home -made handle.

Installation and commissioning

For sufficient air circulation, the boiler must be set above the floor level by 20-30 cm. The legs of steel elements should be welded to the base of the boiler. It is advisable to lay a fireproof foundation under the boiler.

Work on connecting the boiler to the heating system takes place in two stages:

- The pipes of feed and return of the heating system are cut into the boiler housing using special pipes.

- In a water tank, cut a smoke pipe.

Before connecting the boiler, it is necessary to take care of fulfilling the safety condition. Around the boiler, build a brick screen with a height of about 1 m with a wall will increase the efficiency of heating and protect from careless touch to hot metal. There should be a distance of about 30 cm between the heating installation and the brick screen.

Order of the boiler water into operation:

- Remove the lid and a heat -disable disk from the installation.

- Open the air damper on the air -moving pipe.

- Put the firewood tightly in the furnace no higher than the chimney level. Pour slightly small chips on top of firewood.

- Drink firewood with a small amount of ignition fluid. Melt the stove.

- Cover the boiler with a heating disk and close the lid.

- When the fuel is flared up, the damper can be covered.

Homemade boiler on wood: video