Along with rising energy prices, the issue of thermal insulation of housing is becoming more and more ...

|

|

In the modern world of design, a lot of attention is paid to stretch ceilings with a beautiful ... |

To date, all the owners of the premises, from residential to warehouse and office, ... |

Masonry of a brick chimney: step -by -step instructions

The choice as a chimney for a stove is a brick device is due primarily to its excellent thrust and presentable external species. In addition, such a chimney will serve its owner much longer than analogues of metal or pipes. The arrangement of a brick chimney requires compliance with the finest technological nuances associated with masonry. We will consider how to lay out a chimney from a brick further.

Table of contents:

- Brick chimney: requirements, size, configuration

- Masonry of a chimney pipe made of brick

- What brick for the chimney should you use

- How to make a brick chimney: design features of the chimney

- The phased construction of a brick chimney with your own hands

Brick chimney: requirements, size, configuration

The chimney is the most important part of the heating system, because the correct functioning of all equipment depends on its quality. The main function of a high -quality chimney is the removal of products that were formed in the process of combustion and providing high traction that promotes fuel combustion.

The brick chimney differs primarily with cheapness, strength and good performance. Brick tolerates both low and high temperatures well.

It is the correct calculation of the chimney that provides comfortable conditions for people who live in the building. A high -quality chimney is able to reduce the fuel level, which is necessary for heating the stove, in addition, fire safety and the quality of the air in the room depends on it.

Each equipment connected to the chimney must meet the following requirements:

- Providing protection against fire - the chimney should differ in a high level of fire safety, the minimum distance between the chimney and the wall should be at least 38 cm, in addition, in areas where the chimney passes through the ceilings, it is necessary to build special extensions;

- The value of the height significantly affects the thrust, the correctly defined chimney height significantly improves the thrust and the combustion procedure passes with high productivity, the minimum chimney height is 500 cm;

- The thickness of the chimney is a parameter that provides fire safety in the room, the thicker the chimney, the less it heats up, the optimal parameter of the chimney thickness is 100 mm;

- In the ratio with the internal cross -section of the chimney, it must be laid out in such a way that the differences do not turn out, by internal size.

Keep in mind that each chimney is individual, its calculations are made in relation to the individual characteristics of the room, but still each chimney made of brick should be sealed and have a smooth inner surface.

Smoke moves inside the chimney with a spiral, so most often the chimney has a round shape. Although, the brick does not allow to build a chimney in this form. Most often, a chimney made of brick has the shape of a rectangle or square.

Although, the corner areas of the chimney are places that prevent the normal movement of smoke in the system. Using a plaster mixture, aligning value, it is possible to smooth out the surface of the chimney so that it turns out to be round inside.

Keep in mind that the quality of work should be at the highest level, since plaster, due to the temperature difference, is prone to shedding. The size of the chimney is significantly reflected in the quality of the thrust. In addition, the chimney should be in harmony with the general exterior of the room. On a small house, too large in size, the chimney will look ugly.

The chimney size 26x13 cm is considered optimal, this design is built when laying each row of five bricks. Although the option of making a chimney and larger diameter is possible, but for this, you will need to spend more effort.

Masonry of a chimney pipe made of brick

It is necessary to start masonry on top of the stove, before that, a nozzle pipe is installed on its surface. For its construction, it will be necessary to comply with the dressing between the rows.

The brick is laid in the same way as during the construction of the wall. But, nevertheless, there are certain features of laying a chimney made of brick:

1. Follow the horizontalness of each of the rows, regularly check it for evenness. In addition, it is necessary to monitor the verticality of the entire structure.

2. To ensure durable adhesion between bricks, it is recommended to use the composition of clay, cement and sand as a solution. The ratio of sand with cement is two to five, and clay is necessary part.

3. The solution is applied to a brick with a thickness of five to ten millimeters. If the layer of the solution is too thick, then the structure will be less durable, since temperature drops will lead to its crime.

4. Another important aspect is the correct sealing of joints between bricks. If you neglect this procedure, then sparks from the chimney will fall into the room.

5. In the process of masonry, use only whole bricks, if you need to install a certain part of the brick, then the layer of the solution for its laying should be minimal.

What brick for the chimney should you use

To build a chimney made of brick, the presence of only two main materials in the form of brick and solution will be required. We offer to familiarize yourself with recommendations for the choice of materials for the construction of the chimney:

1. The choice of brick should be carried out with special seriousness. The material should be refractory and high -quality. The minimum value of the brand 200. In appearance, the brick should have even edges, a clear rectangular shape, good firing and be strong enough. The optimal size of the brick for the arrangement of the chimney is 25x12x6.5 cm.

2. The next moment is the manufacture of the solution. To build a strong chimney, a solution is required, which contains water, sand, clay and cement. A high -quality solution contains a fine fraction with small grains. Otherwise, the thickness of the solution layer increases, and the quality and strength of the chimney decreases. Particular attention should be paid to clay, it should not contain extraneous impurities, and water for the preparation of the solution should be clean and have softness.

The stove roof adjoins the chimney using a special material that waterproof this section. In order to protect the premises from moisture and atmospheric precipitation from the outside of the chimney, a thickening is made, called otter.

If there is no otter, then the material is used in the form of galvanized iron, which is mounted on the roof in a special way.

If you follow the previously given tips and recommendations, then the chimney made of brick is high -quality and durable. However, there are certain points in which inexperienced builders most often allow oversights, and we will talk about them further.

The first and most common mistake is a small pipe. It leads to the fact that there is no traction in the stove or other heating device. Such a chimney is not able to function normally. Therefore, before carrying out work on the arrangement of a brick chimney, you should carefully study the recommendations for determining the optimal length of the chimney pipe, which is able to provide good traction.

Not compliance with the proportions for the preparation of the solution leads to the fact that cleaning the chimney is darkened, and the solution crumbles over time. The more uniformly the inner channel of the chimney, the better the smoke and all combustion products are removed from it. If the channel is made poorly, then the smoke penetrates the room, and this threatens the residents of the house with poisoning.

Try to provide maximum vertical of the chimney, avoid too long horizontal areas. If it is planned to arrange a chimney deviation, then on the site up to 100 cm, the chimney should deviate by no more than thirty degrees.

How to make a brick chimney: design features of the chimney

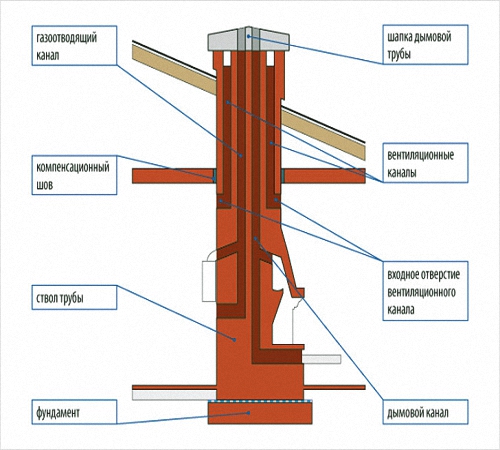

Before the manufacture of a brick chimney, it should be carefully studied by its design. The first element of the chimney is the pipe installed on the shoulders. She has a valve. Bricks should be bandaged to lay out the pipe.

If you count from the ceiling 5-6 rows of brick, then at this stage you should equip a cervix. This element is a kind of bruise, hot, in diameter inside, it is the same as a chimney. The diameter of the outer part of this element decreases by 30-35 cm.

The chimney located in the attic is called a riser, this area passes already to the roofing. The next cutting element is the otter, it expands on each side by at least 100 mm. It is this fragment of the chimney that prevents the entry of atmospheric precipitation into the room.

After the otter, the arrangement of the neck follows, the size of which is a gathering with the section of the chimney. The final fragment of the chimney is the arrangement of the heading on which the part is installed in the form of a deflector or a metal cap. Thus, the chimney receives protection from snow, rain or wind. In addition, these elements significantly improve traction.

The phased construction of a brick chimney with your own hands

We offer to divide the work on laying a chimney made of brick into several stages:

1. Preparatory stage.

To begin with, you should consider the chimneys made of brick and select the best option that is suitable for individual parameters of the room and heating equipment. In the presence of a conventional wood stove, it will be necessary to carefully develop each of the rows of masonry. And if the furnace is gas, then inside the chimney you need to install a metal pipe.

Before starting the masonry of the chimney, the installation of a rectangular foundation should be installed. It will require a full -colored brick or concrete with the presence of metal reinforcement. The minimum foundation height is 300 mm, and the width is 150 mm larger than the chimney itself.

2. The next stage involves direct work on laying a brick chimney with your own hands.

For these works, a special scheme will be required, according to which each brick is masonry. To lay out the chimney, red or refractory brick should be used. If the temperature in the chimney is too high, then to connect bricks, it is recommended to use special fire -resistant solutions. Otherwise, the use of a solution of cement with lime or cement with clay is enough.

In order to cut off a certain part of the brick, you should use a grinding machine, and the marks are applied using a marker. The strength of the chimney directly depends on the thickness of the layer, the thinner it is, the stronger and more reliable the chimney.

To form a detachment or other sections of this purpose, there is enough use of metal rods, which are mounted according to the structure of the structure. Keep in mind that rods should not be in the diameter of the chimney, since they will become an obstacle to the bunches of the removal of combustion products. In addition, it should be taken into account the moment that the chimney is high and width depends on the thickness of the solution, which is applied to the brick.

In addition, in the process of manufacturing a chimney made of brick for the boiler, special holes should be made that will simplify the procedure for cleaning it. The wall, inside the chimney should be particularly even. For this, they must be finished with plaster. Thus, soot will not be collected on the walls, which negatively affects the quality of the chimney.

3. The final stage of manufacturing chimneys for brick furnaces.

If the construction of the chimney is carried out directly in the proximity to the wall, then to increase its stability, it should be fixed on it using steel anchors with an interval of 25 cm. In places of connection of the chimney, ceiling and roof, fabric based on asbestos or fiberglass should be laid. Although the heating of the brick is carried out quite slowly, it is still necessary to reduce the possible fire. Another important point is the fact that the minimum value of the height of the chimney towering above the roof is 300 mm.

To increase the attractiveness of the brick chimney outside the building, it is necessary to thermal insulation and finish. Choose thermal insulation materials that are of good stability before high temperatures and moisture. Thermal insulation, will help to avoid accumulation of condensate in the chimney due to the temperature difference. As a finish, it is recommended to use facing bricks or special roofing materials.

Brick chimneys video:

Bla-blah blah and no

Blah blah blah and no specifics