Vinyl tile is incredible today. It is bought for ...

|

|

With rising energy prices, the need to improve thermal insulation is increasing ... |

In order to fulfill linoleum alignment, can... |

Keramoplast: reviews, advantages, disadvantages, installation features

The assortment of building materials every year increases by more than a dozen new species, which are intended not only for the construction of the structure, but also the installation of the roof. The operational characteristics of each type allow them to be used in certain conditions, which determines in turn the priority of the choice. Relatively recently, a new, universal roofing material has appeared, which combines aesthetic attractiveness, environmental friendliness, reliability and durability. These are the key characteristics of the compositional material of the keramoplast, which is based on natural mineral components and synthetic additives. It was the optimal connection of the above components that made it possible to distinguish this roofing material among analogues. The article will talk about pormoplastic roof.

Content:

- Features of production and technical characteristics of keramoplast

- Advantages of keramoplast

- Disadvantages of roofing material

- The main directions of the use of keramoplast

- Installation of roofing porcelast

- Additional opportunities

Modern production technologies contribute to the fact that the material has a high strength of strength, which allows to withstand the serious loads of natural extreme conditions, which can be accompanied not only by strong gusts of wind, but even by storms and hurricanes. The perfectly selected composition of the components gives the roofing material a high level of sound and thermal insulation.

The production process involves the color of the keramoplast sheet for the entire thickness, which in the event of any mechanical damage does not affect the external attractiveness of the roof. Decorativeness is not even lost from exposure to various acids and alkalis, as well as other aggressive substances. In addition, such a roof is not threatened by mold, nor decay, nor the formation of fungi.

Poramoplast photo

Features of production and technical characteristics of keramoplast

- A unique combination of source materials made it possible to create a wave roof of unified sizes. Despite the fairly lightweight, the material has serious advantages of technical characteristics. The structure of the external coating eliminates the likelihood of an avalanche slipping. And the classic sizes of sheets provide the opportunity to carry out the installation of the roof or the replacement of the damaged segment without any problems.

- A large spectrum of color shades of the sheet allows you to experiment with a palette and choose exactly the color that is as suitable as possible to the eternal appearance of the structure itself and will give a special charm and originality to the house. Sheets are packaged in special transport pallets, on which a certain batch of goods to the customer is transported.

- The thickness of the sheet can vary from 3 mm to 5 mm and is produced by geometric dimensions of 2000x900 mm. The depth of the wave can be very different. At the same time, it is possible to purchase sheets with both a perfectly smooth surface and with a certain texture. You can also find specimens in which a steel grid frame is added, which gives greater strength to the sheet.

- Production capacities and modern equipment allows you to produce not only sheets, but also tiles of porcelast. This opens up unlimited possibilities for creating architectural masterpieces.

- When heating the material to a certain temperature, you can get a sheet of the desired configuration. The composition of porcelast includes components that do not harm human health, as evidenced by the relevant certificates. The minimum service life is about 30 years.

Advantages of keramoplast

Despite the fact that he appeared on the market relatively recently, Kramoplast has already managed to win positive reviews thanks to a number of properties, which determined its advantages:

- resistance to natural precipitation (rain, snow, hail, etc.) indicates the water resistance of the material;

- it has resistance to frost;

- does not accumulate statistical electricity;

- when rain drops hit the noise, no noise is heard;

- has a long service life;

- able to withstand heavy loads;

- due to the presence of a surface made of a special alloy of elements, dirt is not delayed, and during the rain, the resulting pollution is easily washed off;

- the unique property of withstand a wide range of temperatures (from +55 to +800C) provides the opportunity to use this type of roofing material in almost any region with various climatic conditions.

Disadvantages of roofing material

In the presence of a sufficiently large number of positive properties, the keramoplast has some disadvantages:

- fire hazard has a high flammability. This determined that there is a need with special care and close attention to think through the structural features of chimneys;

- despite the painting of the sheet throughout the thickness, as a result of very intense radiation of sunlight, the burnout of the material becomes noticeable, sometimes even in the first year of operation;

- to fix the keramoplast, it is necessary to use a special system of fasteners and caps, which are often on sale with a slight marriage, which becomes destructive in a short period of time;

- sometimes in the batch of sheets there are specimens that have an uneven thickness. This is reflected not only on the convenience of installation, but also on the attractiveness of the final result.

However, the main drawback can still be considered the likelihood of a fake of this material, which during operation shows simply terrifying results, which can cause not quite flattering reviews. When making a purchase of keramoplast, it is important to pay attention to the manufacturer. This will save not only money, but also nerves.

If necessary, the sheet can be cut or sawed by any tool, giving the desired size and configuration. In the process of its installation, the overlap is made in only one wave and it is enough to use 10 nails for fasteners.

The main directions of the use of keramoplast

- This type of roofing material is referred to universal, since it can be used not only for the installation of the roof, but also of surfaces, the construction of fences. Keramoplast found application not only on an industrial scale, but also in private.

- Thanks to the property, withstand heavy loads, it is allowed to use it as a floor in the attic. It is the increased strength in this case that plays a decisive role in the process of choosing the flooring.

Installation of roofing porcelast

In order to perform the fastening of this roofing material, it is not necessary to be a professional and have some skills in this matter. Everything is extremely simple and the whole process will not take much time. In addition to attaching entire sheets, the material can be easily amenable to such manipulations as cutting, drilling, and if necessary, it is allowed to even bend.

- First of all, it is necessary to mount a crate from wooden beams with a pitch of 380 mm. A similar design is also used for attaching a classic asbest cement slate. At the same time, it does not matter what angle of inclination will be at the roof. Today you can even buy sets that allow you to assemble the construction of a sub -seal space quickly.

- Do not forget that wooden elements must be treated with a special solution, which to prevent premature aging of the crate. In addition, neither fungus, nor mold, nor various microorganisms will be able to damage the structure.

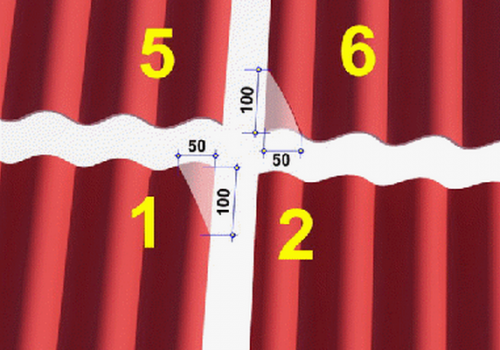

- Having completed the calculation of the right amount of material, it is extremely simple. In this case, all lateral and end overlars (approximately 50-100 mm) should be taken into account. Having familiarized themselves with the reviews of people who have already tried the keramoplast in practice and claim that its use is much more economical than other roofing options.

Roof installation is carried out in two ways, the choice of which everyone carries out for himself.

- The displacement relative to the rows, which is carried out by half of the sheet. This method involves a mandatory joint of sheets in the middle of the next row. Has another name zigzag.The use of this method eliminates the likelihood of overgrown with four sheets at once.

- Chess order - A more classic option, which involves not a displacement, but an overlap of 4 thicknesses. However, there is a probability of excessive formation of overlap. In order to avoid this, the corners of two sheets located in the middle must be cut a little.

Since the keramoplast belongs to that category of materials, the operational characteristics of which are impeccable, they cover even very large areas. First of all, the lower row along the entire perimeter should be laid, after which it will be much easier to mount the side rows. The fastening of sheets at right angles relative to the first row is quite simple and completely simple.

Immediately fix the sheet to the crate is not worth it. Previously, you can slightly make the material with several screws. After the installation of a certain section of the roof, all the overlaps are carefully checked and only then they carry out the final fixation of the sheets to the crate.

There are some nuances of fastening of keramoplast

- For example, it is recommended to use a rope to correctly perform sheet fasteners in the center of the board. In addition, a keramoplast located in the lower row must be fixed with a large number of elements for a higher structure stiffness.

- The installation of the ridge is extremely carefully performed, where the mount should not be pulled too much. If this moment is not taken into account, then the leaf deformation may take place in the case of sudden changes in the temperature regime.

- It is best to drill holes at a distance of a little wider than usual. In addition, it is recommended to use shurns for fastening sheets, not nails, since in the process of the hammer there is a possibility of damaging the roof.

- The final stage of roofing is installing the skate. This procedure is carried out only after the final laying and fastening of all sheets of keramoplast. In the event that the bending angle of the skate is smaller than necessary, it is enough to just use the soldering lamp and heat the inner surface. As a result, the material will heat up to the desired temperature and will be easily deformed.

Additional opportunities

- A beautiful alternative to leaf pormoplastic is a tile made of the same material. This product is able to withstand any weather conditions and a fairly long period of time to delight owners with their attractiveness and originality.

- Tiled masonry is one of the simplest measures related to the improvement of the roof. Special tools and a certain education are not required. Only ordinary shchuvuruvo, with the help of which fastening will be enough.

- Numerous positive reviews left from construction companies and ordinary owners of private property indicate that the popularity of keramoplast is gaining more and more speed every year. This type of roof is worthy of more expensive materials, but at the same time it is in no way inferior in quality and presentability of the appearance.

Today to look stylish does not mean making large capital investments. Everyone can allow themselves to acquire a papricoplast, regardless of the situation in society and financial viability. The light weight of the sheets largely facilitates the load of the roof structure on the entire structure. And light scratches on the surface can be removed independently, heating defective zones with a soldering lamp, which can even be performed by a beginner of the construction business.

pi building *** Lies in a year

pi Building *** Lies in a year tears with his hands without much effort !!!

Keramoplast stood for 4 years

Keramoplast stood for 4 years and began to crumble all the outcast

nonsense. Two years later from

nonsense. Two years later, from dark brown became some kind of pink

Uncle for Komeni

Uncle for Komeni

Shittylast. Grown for the second

Shittylast. Burned for the second summer

5 years worth it. Not for strength

5 years worth it. I did not check for strength. Do not hunt the roof to spoil. The sheets are strong. The waste breaks like chocolate in their hands. Without a good open flame, it does not burn. The fact that over time will accept the color of the old chocolate (initially dark brown) were warned, but if desired, it passes a slightly burner and everything is restored. Not noisy. In the cold they say fragile, but I'm not going to climb onto the roof without need. Until the roof flows.

Shit, breaks like cookies,

Shit, breaks like cookies, the whole roof flows.

Stronged 5 years for the 6th year

He stood for 5 years for the 6th year. Presumably at the site of fastening with self -tapping screws. In winter, ice from the roof tore off all the caps, and apparently it caused a leak. The first snow made itself felt.

5 years later he began to crumble,

After 5 years, he began to crumble, in the seventh year, the roof on the southern slope - a sieve! Ultraviolet does not bear.