The atmosphere in the apartment or house create details. In addition to furniture and finishing materials in ...

|

|

Modern landscape design often includes such a component as forged ... |

The desire to save as much time and finance as possible in the construction of a suburban ... |

DIY attic insulation

With an increase in energy prices, the need to improve thermal insulation of country households increases. Without high -quality work, arrangement and accommodation outside the city in the winter will not be comfortable. Comprehensive insulation of the attic in a private house with your own hands involves the study of all surfaces of the roof. This is a simple but multi -stage process where all operations should be performed in compliance with the styling technology in order to avoid errors that are difficult to correct during the operation of the structure. The attic is used in different ways, the degree of insulation from the inside and outside depends on this.

Table of contents:

- We are determined with the functionality of the attic

- Choose suitable materials and insulation

- Internal and outer insulation

- A little about safety precautions

- Preparation of the attic for insulation

- Warming technology

We are determined with the functionality of the attic

Full insulation of the attic of a wooden house or a small cottage is very important, and it is better not to delay this so that the formation of condensate does not cause dampness. It leads to a decrease in the life of the construction, the emergence of a favorable environment for fungi and mold. This happens over time both in the new house and in the old.

An unspleily attic is the whole house with a large heat loss, even if the boiler or stove works to the fullest. Due to the difference in temperatures, the cold penetrates the house into all the cracks and openings, and the unscheduled attic gives the bulk of the heat from the ceiling of residential premises. Therefore, after insulation of windows and floor, they proceed to thermal insulation of the attic.

When using the attic as a residential area on top of thermal insulation materials, a finish is needed. If this is a purely technical room, then you should not spend money on finishing materials. Perhaps over time, there will be a desire to use the attic as an attic, then and lay the floor and decorate the inner slopes of the roof as a wall. Before that, thermal insulation can be strengthened.

Tip: Experts recommend immediately doing full multilayer insulation with steam and waterproofing of attic floors. If the filler is stacked in a checkerboard pattern, closing the joints, then there will be no cold bridges.

When the attic is used for technical needs and general maintenance of the roof, it is worthwhile to warm up separately:

- floors;

- chimney;

- communications.

Choose suitable materials and insulation

In the recent past in rural houses, in order to reduce heat loss, in the attics lay out: they laid out:

- straw or hay;

- sawdust and chips;

- dry foliage or seaweed.

Mice often settled in natural materials, and the materials themselves could ignite when the chimney overheating. Later, attics began to be insulated:

- glassy;

- expanded clay;

- roofing material.

Today, specialized materials are used for insulation of the attic of the latest generation, in a convenient packaging that can be purchased at any construction store. They can be faced with all surfaces under the roof. The thickness of the insulating filler is selected in accordance with:

- with the functionality of the attic;

- technical characteristics of the material;

- climatic factors.

The main advantages of modern materials for complete thermal insulation:

- small specific gravity;

- low cost;

- simplicity of installation and operation;

- fire safety;

- they are not toxic;

- perfectly protect against moisture and temperature changes.

Among the most common materials for insulation of the attic in a private house with their own hands are used:

- mineral or basalt cotton wool (ecowata);

- polystyrene foam (polystyrene);

- expanded clay;

- polyurethane foam;

- fiberglass and others.

Before laying the main thermal insulation material, it is important to provide:

- condensate removal;

- vapor barrier of ceilings;

- roof waterproofing.

Tip: a windproof film, roller materials for waterproofing and a vapor barrier membrane, which will provide layers of the main insulation from condensate and get wet, will cope with this.

For high -quality insulation of the attic in a private house, you can use any last generation heater, which will be offered in a construction supermarket.

Attention: before buying, you should consult with specialists of the trading floor and read the instructions in order to have an idea of \u200b\u200bthe method of installation. Some materials pour, like snow, on inclined surfaces, others are laid using a crate, and expanded clay is covered with a layer on the lower surface.

When laying the layers for insulation of the attic with mineral wool and similar roller materials, it is important to exclude the divergence of the seam sutures. Thermal insulation should be tightly adjacent to all surfaces, enter the openings between the beams, forming a continuous cover. The seams between tile materials such as insulating foam can be filled with mounting foam.

When choosing materials, the defining factors remain:

- roof shape;

- the general condition of the attic and its functionality;

- a variety of roofing materials;

- the thickness of the pediments;

- pre -laid roll waterproofing or its absence.

Today, fiberglass, foam glass and mineral wool are the most popular and reliable materials. But high -quality insulation of the attic at home with your own hands should begin with a full -fledged moisture protection and vapor barrier. And although these are additional expenses, it is worth taking care of this, even if it is a simple fiberglass or a special foil.

Heater used for processing the attic has a different degree of thermal conductivity. The heat conservation and the recommended number of layers for application, spraying or styling depend on this factor.

When choosing a material for warming the roof and the attic, it is important to consider the climatic zone. If the house is in the region with a warm climate, it is not recommended to buy rolls and sheets of maximum thickness. For a latch and long winter, volumetric materials are used. It makes sense to lay the insulation in 2-3 layers, use different types of thermal insulation on one surface. But remember that the volume of thermal insulation material does not always indicate the quality of the insulation and its maximum indicators. They can be applied according to the table.

1. Minvat of increased density Universal thermal insulation, which has a sufficient degree of protection against moisture accumulation. Under it, it is enough to lay a dense vapor barrier membrane. The basalt wool has several forms of release with slabs, rolls, a bulk mixture to use for surfaces of any type. It is also used as insulation and fire protection of chimneys and chimneys.

Attention: a small amount of formaldehydes is present in the mineral wool of some forms of packaging. Therefore, in working with it, a protective respirator and gloves are used, observing precautions.

2. Fiberglass excellent eco -materials with a high degree of fire safety, although some of its indicators are just below the analogues. It is produced in a convenient packaging for installation, it is easy to transport and store it directly in the attic. Laying fiberglass according to the instructions attached to the purchase, even a beginner in this matter will easily cope. Suitable for insulation of the cold attic. However, it is more often used for external roof insulation.

3. Experts of a great bulk insulation, which are poured onto the floor (lower horizontal surface) of the attic or attic. Since its weight is small, and thermal conductivity is low, the use of this bulk material makes it preferred. There is nothing easier to pour expanded clay on the floor or between the lags, aligning the layer required in height over a vapor -permeable membrane. The only drawback is difficult to use on an inclined surface. Also suitable for the main filling of the cement mixture. On expanded clay, fastened with cement-sand mixture, laminate or linoleum in the living room is laid.

4. Foam polystyrene resembles polystyrene, it is not subject to defeat with mold and fungus. It is quite fireproof, durable and environmentally friendly. It does not cause reaction even in allergy sufferers. It is laid using the crate with layers, but it is important to provide waterproofing with roll material before its installation.

5. The spraying with polyurethane foam resembles a layer of snow, and it is used where other heater is difficult to lay, for example, with a complex shape of a roof with many breaks. He is poured on a stacked vapor barrier membrane.

Tip: When warming the attic of a wooden house or cottage, you can combine several varieties of material, depending on the shape of the floor and the characteristics of the roof.

Attention: sometimes they use an additional wooden crate to eliminate the seams and bridges of the cold. But they should not add a significant weight of the design of the house, especially on problem soils!

The crate for the skin is made after the installation of waterproofing. The casing frame is made from the strips that were used for the crate for rolled and sheet insulation.

If it is supposed to use the attic as a dwelling, then after insulation they proceed to the lining of the finishing materials of the attic. For this purpose, they are suitable:

- drywall;

- oSB plates;

- plywood shields;

- leaf composite materials.

Internal and outer insulation

The building materials market offers a wide range of full -fledged insulation of the attic used as an additional living space. Today it is customary to combine the external method and waterproofing and insulation and interior decoration.

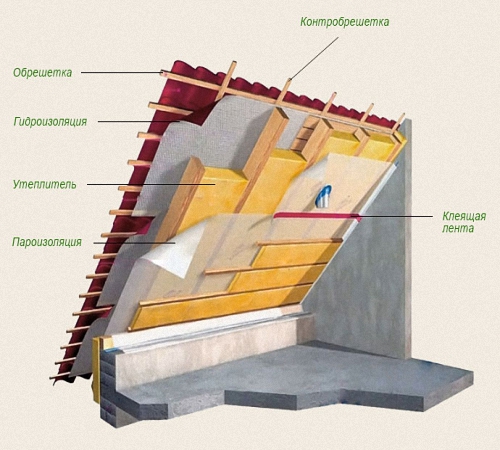

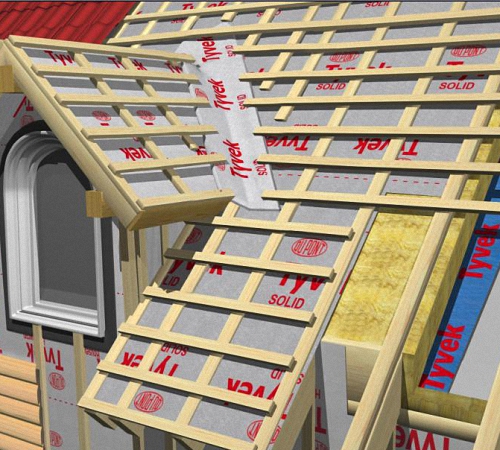

When choosing an external insulation method of a gable or hip roof, how its slopes and roofing materials will be insulated. The insulation is mounted between rafters, beams and crate. For example, they combine roller materials and a solid insulation, for example, basalt wool, a special membrane or foil bearing with layers. The difference between external and internal insulation in the method of laying on ceilings or by beams.

For internal work, they begin by laying a layer of vapor barrier and waterproofing, and then mount 1-2 layers of insulation, for example, mineral wool. It is not closed with anything so that excess moisture from condensate can easily evaporate.

Polyuertan foam does not require additional skin at all, it is light, sprayed from a two -component mixture with special equipment. Upon completion of application on the inner surface of the roof slopes, a durable material is formed in the form of dense flakes. He does not form condensate and cold bridges, even if we spray directly to the frame and roofing iron. It can also be used as insulation of pipes of the attic and chimney.

A little about safety precautions

A loose insulation has the ability to crumble, dust or evaporate volatile substances. Therefore, experts recommend working in a mask and clothing that protects the skin and respiratory organs from stimuli and allergens. It is equally important to secure your eyes with protective glasses.

All work is carried out in working gloves, regardless of air temperature and installation conditions. In external works on roof insulation, you can use insurance and equipment for climbers. It is important to check the reliability of the stairs in advance, including the roof moved along the skate. All work is done with an assistant or a person responsible for insurance.

Preparation of the attic for insulation

The attic is often filled with various household rubbish, which is rarely used, for example, equipment for winter fishing and summer picnics. Before starting insulation work, all this must be removed from the attic, especially when processing with spraying.

Wooden details, such as beams, rafters and a crate, is important to pre -treat the protective composition from decay and the formation of the fungus. Metal surfaces are treated with an anti -corrosion composition or primer for metal. All rust is cleaned with a special metal brush. There is a washing in the use of moisture repellent compositions.

From the cracks, the old seal is removed, which was used for a long time. Old felt, foam, foam, sawdust and rags expire and lose their properties over time. After cleaning the old materials used fragmented, sometimes small cracks appear, which can be treated with mounting foam.

Thereafter:

- provide access to all processed surfaces;

- prepare the working area and all tools;

- prepare materials for insulation and work clothes;

- we provide ventilation after completion of insulation work.

Before laying, the mineral wool as a heater of the attic make a wooden crate from fixing strips, which should hold the layers of the material. This can be done from ordinary installation rails that will cost inexpensively. Under the decorative decoration of the walls of the attic used as an attic room, styling can be done without a crate, placing between the ceiling and shields of finishing materials.

Warming technology

1. After the initial inspection, all overlap defects should be found, all the rotten parts must be replaced or duplicated. Wood is treated with fungicides and antiseptics.

2. Equip or correct the waterproofing layer to get a full -fledged water -barrier. In unstable places, membrane materials can be packed with a mounting tape.

3. Between the rafters of the gaps is filled with a layer of thermal insulation material. If you need to lay in 2 layers, but the seams of the boards must be blocked. Rolled materials are overlapping.

4. The adjacency of the overlapping structures to the walls should be insulated especially carefully, without gaps. The insulation is laid without jams and failures.

5. It is important to carefully fit the insulation at the joints, at the ventilation window, near communications and chimney. In some places, it is advisable to fill the bulk mineral wool, which to fill the voids, besides, it does not ignite even in hot places in chimneys.

6. A layer of vapor barrier is fixed on top of the thermal insulation layer, while the canvases are laid with a small drop, fixing with mounting tape.

7. The insulation of communications is the next stage, since without insulation of the ventilation shaft, chimney and pipes, the work will not be integrated. This can be desired by special corrugation and insulating pads, perlite and basalt wool are suitable.

8. After checking the tightness of the installation of attic insulation, the floor is processed. It is done after building garbage is cleaned after installing fillers for insulation. Specially laid lags are best held by a layer of bulk expanded clay. It can be filled with sawdust or clay, and lay a moisture -resistant plywood on top. More clearly insulation of the attic, video: