Laminated doors are a good alternative to expensive wooden or ...

|

|

Even if it seems that the air inside the house is very dry, and even specially purchased ... |

One of the advantages of wooden houses is their slight weight relative to brick ... |

How to build a cottage from panels

The desire to save as much time and finance as possible in the construction of suburban housing leads to the fact that construction technologies are increasingly being considered, allowing to transfer most of the structural details of the structure to factory conditions. Then directly on the site for development it will only be necessary to assemble the elements as a designer. A bright representative of such technologies is panel construction. The cottage from the panels is built quickly, easily and at any time of the year, and the so -called wet processes are minimized. At the moment, the most popular are SIP (SIP) panels, which are a three -layer structure, in the middle of which there is a thermal insulation material. A much less popular solution in low -rise construction is reinforced concrete panels, largely due to the negative experience of Soviet panel high -rise buildings of dull, monotonous boxes. All increasing interest makes you look for information on how to use panels in the construction of cottages.

Construction of cottages from panels

Panel construction suggests that the designs of walls, floors or ceilings will be made of factory -made panels. Panels of a standard size or manufactured for a specific project are imported to a construction site, where they are assembled as a constructor. This significantly reduces the costs and simplifies the task for the construction company, since the work itself takes no more than 2 months. After that, the house can be finished and entered into it immediately, without waiting for the shrinkage of a tree or the hardening of concrete.

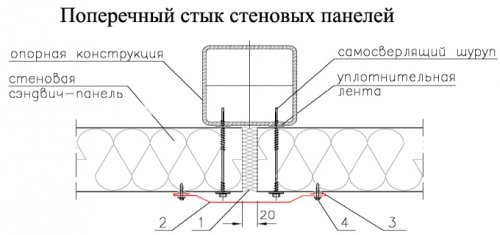

In the technology of panel construction itself, there is one significant lack of place of joints of the panels are not only cold bridges, but also the most unreliable in the entire building of the building. Any destruction due to mechanical exposure will occur precisely at the junction of the panels. Water can penetrate through the joints if the waterproofing layer is destroyed, and condensate accumulates inside. Despite the abundance of modern materials, allowing to close the joints as efficiently as possible, still the problems of joints are not completely solved, and over time they appear again, since the shelf life of the materials expires quickly.

Cottage from SIP panels

The assurances of advertisers and construction organizations are designed to convince us that the cottages from the SIP panels are the strongest, they are able to withstand strong hurricanes, the warmest, as they do not require additional insulation, quickly warm up and allow you to save on heating, and are also environmentally friendly and safe. Of course, all this needs to be divided into 48, since their task is to sell what is beneficial to them, and ours to build a comfortable house in which it will be convenient and safe to live. Therefore, first of all, let's figure out what are the advantages and disadvantages in the construction of cottages from SIP panels, as well as what are the features of such a technology.

Advantages and disadvantages of construction from SIP panels

Advantages of cottages from SIP panels:

- It is built in the shortest possible time, in about 2 3 weeks.

- There are no temperature restrictions during the construction process, you can perform all the work at any time of the year.

- They are not subject to shrinkage and deformations, so you can start finishing and you can call immediately after the construction of the box.

- SIP panels are easily transported and assembled in place.

- At the moment, one of the cheapest.

- Strong enough to withstand a hurricane wind.

- SIP panels are perfectly smooth, so they are easy to lay strictly vertically.

- The walls of the cottage from SIP panels are thin, due to this, the internal useful area increases.

- You can equip a light foundation.

- It has excellent heat -insulating properties, quickly warms up and holds heat for a long time.

- Economic in terms of heating.

- It has a good soundproofing effect.

Disadvantages of cottages from SIP panels:

- Absolutely tight. For such buildings, forced supply and exhaust ventilation must be designed and equipped. The cost of developing and introducing such ventilation more than overlaps the entire cheapness of the cottage from SIP panels.

- Absolutely non -ecological. All the assurances of sellers are that at home from SIP panels environmentally friendly housing are a frank lie. Polistyle foam used as the thermal insulation layer of the SIP panel is completely synthetic material. And in the process of manufacturing OSP plates, synthetic resins and additives are used. As a result, we get a box of absolutely synthetic materials that distinguish all kinds of unpleasant compounds. At the same time, the walls do not breathe, there is no flow of fresh air. In other words, thermos. Although if you build a house from a fixed formwork, the output result will be the same. And many build. So we will leave this to choose from the future owner of housing.

- Short -lived. The service life is not more than 30 years. Although the stated terms of 50,100 years, in practice, everything is far from so rosy.

- Not vandal -resistant. The strength of the cottage from SIP panels is very relative, since it will not be difficult to cut a hole in the wall with an ax.

- SIP panels burn. And it’s not so scary that they burn, as the fact that during a strong fire, the polystyrene foam will go into a liquid state and simply pour on top like rain, distinguishing all muck. The fire hazard of SIP panels also affects the fact that all communications can only be open.

- If you do not equip forced ventilation or incorrectly operate the building, performing the finish without taking into account the vapor permeability of the materials, then mold and fungus will appear in the walls.

As you can see, the shortcomings of construction from SIP panels speak for themselves. Nevertheless, many choose this technology to build a country cottage of seasonal residence, due to its cheapness. Although there are those who want to build a cottage from panels for permanent residence. So choose you.

SIP panel: design and features

SIP (Structural Insulated Panel) is actually transformed into Russian into Russian (structural-the-insulating panel), but for some reason the name SIP or Sanwich Panel was fixed firmly and most likely for a long time.

SIP panel consists of 3 layers that glue among themselves under high pressure. Two outer layers They are made of durable sheet material. Most often, slabs are used for private housing construction OSP (focusing and steering plates) Or OSB (Oriented Strand Board). Such plates are made of wood chips, which is laid in three layers perpendicular to each other. After adding the resin, the material is pressed. As a result, the OSP plate is durable to bends and elastic, and its surface is waterproof. Magnesite, wood -fiber (fiberboard) stoves or just wooden boards are used much less often for the outer layers of SIP panels.

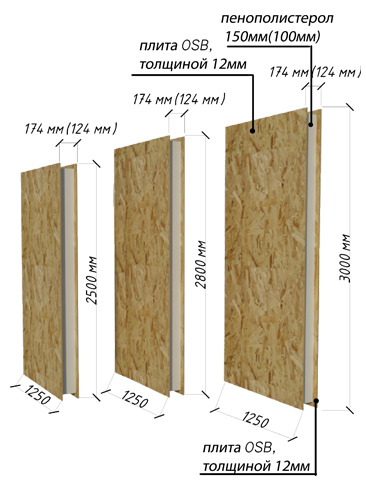

The thickness of the sheet material of the outer layers can be 9 mm or 12 mm. The most common OSB-3 option is 12 mm thick.

Core or middle layer of SIP panel It is made of thermal insulation material. Most often this foam polystyrene (PSB-25 or PSB-S-25 density 25 kg/m3), due to its cheapness and small weight. Less commonly used polyurethane foam, even less often mineral or basalt wool, since the panel with mineral wool is heavier and more expensive than a panel with polystyrene foam 2 times.

The thickness of the insulation depends on the needs and can be from 50 to 250 mm. The most common in the CIS are SIP panels with a thickness of 124 mm, 174 mm, 224 mm (where the outer layers are 12 mm). The height and width of the panel largely impose certain restrictions on the project, in our market several standard sip panels are presented:

Projects of cottages from SIP panels

Typically, panel construction does not differ in a design relation, unlike frame or monolithic buildings, where any angles and radius elements are possible. But the field for choosing a cottage project from SIP panels is really great. Moreover, any project you like can be redone or modified according to the needs or taste of the customer.

The height of the first and second floor of the cottage in some ways dictates the dimensions of the panels themselves, which are 2500x1250 mm and 2800x1250 mm. On the other hand, the height of the floors can be done by any one, but then you will have to surplus the panels, and the general view will be unaesthetic, and the design is less durable.

You can order a cottage project from SIP panels in the same construction organization in which it is planned to order the manufacture of housekeeping from panels. All elements of the house kit will be numbered and signed, so that on the construction site itself it will only be necessary to collect them.

Do not forget about ventilation also. Its project and calculations must be done at the stage of designing the cottage in order to provide for everything you need during the installation process.

Features of the foundation for a cottage from SIP panels

Due to the fact that the buildings from SIP panels are very light (not more than 50 kg/m2 of walls), they do not perform heavy buried foundations under them. Panel cottage can be put on the strip, fine -trimmed foundation, pile, pile-rod, the strip-tower, slate or column foundation. Which one is more suitable in one case or another depends on the weather conditions in the construction region and the structure of the soil, as well as on the wishes of the customer. To deepen the foundation for a cottage from SIP panels below the depth of freezing of the soil is not necessary. But it is extremely important to fulfill the foundation efficiently so that its surface is perfectly even and is in the same plane, otherwise the structure will turn out to be a curve.

Before making a cottage from the panels, the surface of the foundation should be waterproof to protect the tree from moisture rising from concrete.

Bill of a cottage from SIP panels

First of all, the foundation is laid and fixed embedded beam 240x150 mm. The beam is laid in the middle of the foundation, in the corners it is connected in a chisel in the half -term and fastened with a wooden embroidery. To the foundation, the beam is attached to 350 mm with a length of 10 12 mm thick with a step of 1.5 m.

After the embedded timber is laid broadcasting board, it is also called sill. The sizes of the mortgage boards depend on the thickness of the SIP panels. For example, for panels of 174 mm, a board 50x150 mm is suitable, for panels 224 mm board 50x200 or 100x200 mm.

The lying is laid on a embedded beam with an indent from the outer edge of 10 12 mm and fixed with self -tapping screws with a step of 400 mm. Be sure to check and control the strict horizontal board.

Installation of SIP panels begins from the corner. The bottom of the first panel is discouraged with mounting foam and dressed on the head, the panel is installed evenly. Then, a board is inserted into the side groove of the second corner panel to fill the empty space, the bottom is also foam and dressed on the lynch so that the panels of steel are on. Before finally fixed the corner panels, it is necessary to check their location vertically.

Important! The simplicity and correctness of the installation of panels depend on the correct installation of the first corner SIP panels.

The panels are fixed to 3,2x35 mm screws with screws every 150 mm. They are screwed to each other with 12x220 mm screws at a distance of 500 mm.

SIP panels are designed so that they have a groove 25 mm deep (at this depth, a layer of polystyrene foam begins). To connect the panels with each other, boards are used with a thickness of 50 mm, and width depending on the thickness of the panel: 150 mm or 200 mm.

The rest of the SIP panels are installed as follows: the side groove of the installed panel is foam, the board is inserted and pressed into it. Then the groove of the installed panel is launched, and it is put on the board sticking out of the panel. The design is tightly compressed and fastened with 12x220 mm screws, and 35 mm to a layer.

When all the panels of the first floor are installed, it is laid on top of them binding boardaccording to the same principle as a lying. The upper groove of all panels is damped, a strapping board is inserted into it and fixed with screws.

Installation on top of the second, etc. The floor is made by analogy. Window and doorways are cut either on the construction site or even at the manufacturer.

Floor arrangement, ceilings and roofs from SIP panels

Paul in a cottage from SIP panels can be made in two ways: common wooden floor on the lags or paul from SIP panels. The first option is more reliable and easy to operate, in the case of urgent repair it is easier to disassemble and redo it. The same algorithm is suitable for the manufacture of the floor from SIP panels as for connecting the panels between themselves, and the clamping boards will be the floor lags and rely on the embedded beam or foundation.

The overlaps from the beams are fixed standardly: using trubki, corners or brackets, you can choose any convenient option.

The roof of the cottage with an unheated attic is performed using a standard rafter structure, crate and roofing material. But if the attic is planned, then the roof can also be made from SIP panels, although this method is more laborious.

Cottage of reinforced concrete panels

Low -rise construction of concrete panels is not popular for various reasons. This is a limited layout, and a small selection of simple design solutions, and the need for heavy equipment that will import, unload the panels, and then also a crane to install them. So this is not the case when the house can be built with your own hands.

Advantages and disadvantages of construction from reinforced concrete panels

Advantages of concrete panels cottages:

- The structure is very durable and strong, able to withstand not only a hurricane, but also a small shock wave after the explosion.

- Full fire safety.

- The walls are even and smooth, only aesthetic finish is required.

- Cottages made of concrete panels are not blown.

- Great vandal resistance.

- They are quickly built.

- Reliable and durable (more than 100 years).

Disadvantages of concrete panels:

- Tough requirements for room planning.

- The seams between the panels are weak.

- High thermal conductivity of concrete. The building requires additional insulation.

- Low soundproofing audibility as in a communal apartment.

- Low vapor permeability and breathability.

- Ventilation is required.

- The walls are so durable that it is difficult to lay communications and hang shelves/furniture.

- For construction, heavy equipment and a crane are needed.

- The relative cheapness of the material is leveled by the cost of hiring equipment and workers.

If we summarize what has already been said, it turns out that it is only beneficial to build a cottage of their reinforced concrete panels in two cases: if there are old Soviet panels after disassembling a high -rise building for a catchy price, or if you immediately build a whole quarter of cottages (i.e. is profitable for the organization). Otherwise, such a cottage is essentially the same apartment in a panel house, only a covered with a personal roof.

Wall reinforced concrete panels

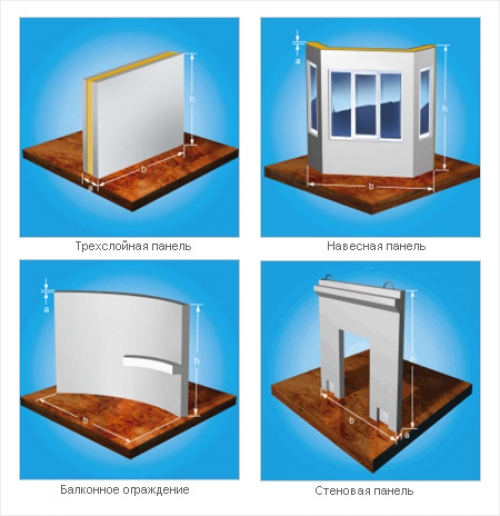

Concrete wall panels are carrying, self -supporting and hinged. At the same time, it is worth considering that in the cottage from such panels, not the external walls, as we are used to, are, but internal ones. External walls are usually made of light panels using heat -insulating concrete (aerated concrete, arbolite, etc.).

The panels are also divided into single -layer and multilayer (two and three -layer).

Single -layer concrete panels They are made of light cellular or other thermal insulation concrete. The panels are reinforced with a net or a welded frame. The thickness of the product depends on the features of the climatic zone 240 320 mm, and the concrete strength class from the loads that are designed to maintain the walls. Most often used concrete with a density of 600 700 kg/m3. These panels are used for external self -supporting walls.

Two -layer concrete panels It is made of heavy concrete with a density of more than 1000 kg/m3 with a thickness of at least 60 mm and a heat -insulating layer, which can be made of light warm concrete (cellular) or tilts of hard insulation material. For example, as a second layer, you can use polystyrene polystyrene, extruded polystyrene foam, and strict boots of basalt wool. The outer thermal insulation layer is protected by a decorative concrete with a thickness of 15 20 mm.

Three -layer concrete panels There are two load -bearing layers with a thickness of 50 mm, performed by their heavy concrete, and a layer of thermal insulation, the thickness of which is calculated in heat engineering calculations (most often at least 80 mm). In such panels, the middle layer is made of mineral slabs, cement fibrilite, fiberglass mats, foam glass, mineral traffic jams and other materials. The outer layers are interconnected by reinforcement.

Reinforced concrete panels cottage projects

If you do not look for architectural delights, but be pleased to be a simple box of concrete, then you can safely look for a suitable project. The variety of cottages from reinforced concrete panels do not differ. Rooms should be strict in shape: rectangular or square, certain sizes that can allow the size of the plates.

Features of the construction of a cottage from reinforced concrete panels

Before you build a cottage from the panels, you need to take care of a reliable foundation. The structure of reinforced concrete is very heavy, so saving on the foundation will not work. It is allowed only wheeled strip foundation and slate. The depth of the laying should be lower than the level of freezing of the soil.

The construction of walls from reinforced concrete is carried out using a crane, since the weight of panels is from 250 kg/m2. The panels are installed VSTOK, and the reinforcement sticking out of them is welded. Then the seam is covered with a solution. In general, the technology of performing seams between the plates is a serious constructive task. After all, joints are elastic and hard-monolithic. So it is better to entrust this work to professionals.

Paul and floors are most often made of concrete plates, although nothing prevents the floors on the lags.

Cottages from panels belong to the rapid buildings. But, nevertheless, everything is determined in practice, not on paper. Construction can be delayed due to the impossibility of passing heavy equipment, and the cost of construction will increase significantly due to the arrangement of forced ventilation.