The ceiling insulation procedure is a very important process, especially when it comes to the bathhouse ...

|

|

The worthy design of the central entrance to the house sometimes creates a more favorable ... |

Before starting the heating season, the problem of good and high -quality ... |

Which foundation to choose for a wooden house

One of the advantages of wooden houses is their small weight relative to brick or concrete buildings. So, the foundation for them requires lighter and cheap. In addition, the need for pouring the base arises not only in the initial construction, but also in the reconstruction of old wooden houses. In the article, we will consider in detail the most popular types of foundations and ways to repair them.

Content:

- Column foundation for a wooden house

- Arrangement of a tape foundation of a wooden house

- Foundation repair of a wooden house

Before proceeding with the description and methods of erecting foundations suitable for wooden houses, it is worth talking about the principles of their choice based on the geodetic data of the site allotted for construction.

- It is not recommended to focus on numerous tables that are posted on the Internet, with the average data on freezing of soil in various regions and cities. This indicator depends on several factors, such as the thickness of the snow cover, the features of hydrogeology and the type of soil. In addition, the presence of an insulated foundation in a house under construction or a nearby communications with hot water may affect it.

- The most commonly encountered foundation for a wooden house is a strip with a pile of drilling piles below the level of seasonal freezing of the soil. For the middle band of Russia and the northwestern part, this parameter ranges from 1.5-2 m. Which means that the base is quite massive and expensive. But due to a large reserve of strength, which is almost 10 times the minimum acceptable, it turns out very costly. Therefore, future owners of mild wooden buildings (up to 3 floors) are looking for an alternative to him, cheaper, but not inferior in strength.

Column foundation for a wooden house

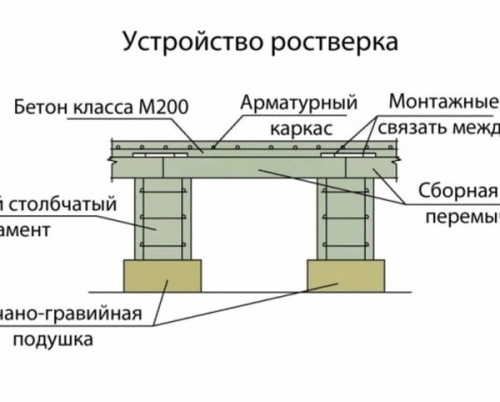

Most often, a column foundation for a wooden house is made of reinforced concrete. But for small wooden buildings, it can be mounted from brick or even wood. Pillars, as a rule, are connected by a grillage (reinforced reinforced concrete jumper). Sometimes it is replaced by a channel or even a wooden beam.

The advantages of the column foundation:

- yuevo cost value. If we proceed from the total estimate for the construction of the house, then its share does not exceed 15-20%, while the strip is almost twice as much;

- more simple and fast in execution;

- with a properly organized blind area and drainage system around the house, it is resistant to seasonal soil flowering.

Wooden column foundation

- Very often in the villages, old wooden houses have a wooden foundation. And if the log house itself can stand in excellent condition for more years, which requires only cosmetic repairs, then its base often needs to be changed. Often, new owners want to maintain the authenticity of such buildings or just comes to update it with minimal financial costs. For these purposes, larch is best suited, whose strength characteristics have been preserved for several decades. But it is also allowed to use oak.

- Such a foundation is wooden pillars with a diameter of 20 cm or more, buried in pits. Sand is poured onto the bottom, and on the supports themselves, to increase the bearing area, a cross is stuffed from the same material. During the reconstruction, it makes sense to make a concrete pillow and lower the pillars in the still -frozen solution so that they grab the most firmly with it.

- The number of wooden supports depends on the bearing capacity of the soil, on the area and weight of the building. But they are always placed in the corners and in places of intersection with load -bearing walls. Throughout the rest, they are located with a step of not more than 2.5 m.

Tip: To increase the service life, the use of modern impregnations is not as effective as a proven method of impregnation of tar. As an alternative, it is allowed to use modern oil -based impregnation with the addition of antiseptic components.

Reinforced concrete column foundation for a wooden house with your own hands

- The work begins with the preparation of the site for construction (this is not only the perimeter of the foundation, but also three meters of indentations on each side for the blind area and the ability to drive up construction equipment). They consist in harvesting large garbage and relative alignment of the site.

- Next, make markings for future pillars. To do this, their location is transferred from the construction plan to the terrain. First, pegs are clogged in the corners of the structure, checking the correctness of their location diagonally (it must coincide). Between them tightly pulled a rope, which will become a guide for the mark of wall supports around the perimeter. After using the roulette, measure the distance of the load -bearing walls and also marked with twine. Depending on the calculated load of the house, the pillars are placed in steps from 1.5 to 2.5 m from each other.

- Pits under the foundation are digging with a margin, since the formwork of a board 5 cm wide will be mounted on the sides, and a drainage pillow of sand or crushed stone is equipped at the bottom. The depth and width of all pits should match.

- In the case when the column foundation for a wooden house is made of asbestos pipes, the wells for it are digging with a drill with blades of the corresponding diameter.

- Often they save on the sole, simply falling asleep with a sand of 15-20 cm. This is enough, for a light wooden building, such as a barn or a bathhouse. But for the construction of a residential building, it is recommended to observe all the technology. The first layer is laid by a dense geotextile that prevents sand in the ground. Then, crushed stone or sand is poured with a layer of 15 cm and rammed or spilled with water. Sometimes experts recommend pouring a concrete pillow up to 20 cm thick without reinforcement over a concrete pillow.

- The formwork is assembled from boards or wooden shields and is attached to self -tapping screws. Also, OSP, moisture -resistant plywood with a thickness of 1 cm, is suitable for these purposes. At the end of the work, it will be dismantled.

- But there are a case in which soil characteristics are so dense (for example, clay soils) that they allow you to do without formwork over the entire height of the support, but only stick it for the aboveground part. In this version, the walls of the pit are dug as evenly as possible and with a verification of the vertical level, then they are covered with roofing material with overlap, which, in the future, will play the role of waterproofing.

- A tied reinforcing cage of 4 vertical rods with a diameter of 10 mm is placed in the finished formwork. Both metal and fiberglass are suitable. It should be located with an indent from the walls a few cm. To firmly stand, the concrete is poured into the bottom and the reinforcement is immersed in the liquid mixture.

- The level of pouring all pillars should be the same, regardless of the slope of the area. For complete setting a concrete solution, a week is required.

- When the formwork is removed, the pillars are coated with a liquid waterproofing composition in two layers. You can wrap them with roofing material or apply a layer of liquid glass.

- Next, burrow the free space around the pillars. Most often, the soil selected earlier from there is used for this, but it is better to use crushed stone or CPS.

- The turn has come to connect all the separate pillars into a single foundation design. For this, a grillage is made. It can be made in several ways, and again, each of them depends on the calculated load of the future house. The reinforced concrete is considered the most durable. For him, the formwork is built from three sides, laid the reinforcement and poured with concrete. This is an expensive and laborious way, but for a wooden two -story building it is most acceptable.

- For a light frame house or one -story log house, it is enough to make a strand from a thick beam.

Tip: for the necessary ventilation of the underground, which will save the wooden lags of the ceiling of the first floor, the distance between the Earth and the grillage should not be less than 0.5 m.

Wooden foundation at home video

Arrangement of a tape foundation of a wooden house

- The depth of the strip foundation for a wooden house depends on the characteristics of the soil. This parameter is calculated individually for each developer.

- Then, the location of the house is determined on the site and its first corner is noted. A peg is clogged in this place. Then the desired distance is measured and the second angle is also marked with the peel, the twine is pulled between them. When all 4 corners are measured, their correct location is checked by the diagonal, and if necessary, adjusted. The procedure is repeated under all the supporting walls of the house.

- The bottom of the digested trench should be at the same level, regardless of the slope of the built -up site. This is checked using the construction level.

- If you want to save money or due to the impossibility of entering construction equipment, land work is carried out manually.

- In a dug trench, waterproofing is laid with such a margin that it is enough over the entire height of the blind area. It can be a classic roofing material or any modern rolled material.

- The basis of the strip foundation for a wooden house will be a sand pillow. The recommended thickness of its layer is 20-25 cm. After filling, the sand is leveled and rammed with a vibro-fuel or spilled with water from the hose.

- Then the formwork is chipped. Thanks to the slight weight of wooden houses, it is not so wide as for brick. A blind area of \u200b\u200bboards, thick plywood or any other durable leaf material is performed. It is most convenient to assemble the shields in advance and exhibit in the trench in advance and ready sections. Outside, pegs are clogged, to which fastening is carried out. To enhance the strength, sprouts are placed with a step of 1.5-2m.

- As a rule, the formwork is higher than the ground level at the highest point by 30 cm. Next, the foundation is laid out by red brick.

- It is convenient to use fiberglass rods with a diameter of 0.81 cm as reinforcement. They are binded by wire. The reinforcing cage should not reach the walls of the formwork by 2-3 cm.

- Pouring should be carried out in one stage. Often you can meet that private developers, in order to save money, independently knead and pour concrete. As a result, a non -low -rise structure with a large number of seams is obtained. When the solution is completely poured, it is recommended to knock on the formwork to remove air bubbles.

Given that a light wooden house is being built, work on its construction can be started after 7-10 days.

Foundation repair of a wooden house

- Often, the foundation of wooden houses begins to settle, more often this happens with old buildings, but sometimes, due to violations during construction, and new houses are subjected to this problem. The reasons may be somewhat natural changes in the physical and mechanical indicators of the soil, and groundwater, which negatively affect the bearing capacity of the soil. It is possible that too close the dug pit of the neighboring house or other vast earthen works could lead to such deplorable consequences. In any case, the foundation requires immediate repair or replacement to avoid destruction of the house.

- Repair of the base of a wooden house can be divided into several types:

- cosmetic. This is the simplest and cheapest way, which consists in replacing individual rotten areas, which are replaced by elements of the desired size. As a rule, this is used for old buildings, whose base was immediately laid out of logs without brickwork. But, despite the tempting lightness, in such works the integrity of the house will inevitably be broken. Therefore, it is not recommended to use it for the repair of residential buildings, but only for small summer houses;

- analysis of all wooden walls. This method will make quality repairs, but will require a lot of physical efforts and financial costs from the performers. It will be necessary to gradually disassemble all the logs, up to the lower injured crown. After its full replacement, the walls are being built again;

- replacing logs using a jack. This is the most popular way that allows you to perform work quickly and efficiently. With their help, without analyzing the walls, it is easy to repair the foundation and put the house itself smoothly.

- Depending on the chosen method of replacing the foundation of a wooden house, various tools will be required. So, if only cosmetic repairs are made, then it is quite possible to do with a hacksaw on wood, sledgehammer and chisel. But when disassembling the walls, you will have to dismantle the roof, which means you need to stock up on a whole list of manual and power tools.

- You also need to take care of temporary supports during the repair of the foundation in advance. When raising the house with jacks, their number will depend on the length of the walls. So, for a small country house, 2 jacks on the wall are quite enough.

- The foundation is the basis of the house, its reliability and durability. Therefore, if you have the need to replace it, you need to carefully consider everything and prepare everything, so that in the future it serves as long as possible without additional repair. First, they are determined with the type of base whether it will be columnar, brownish, tape or pile-screw.

- The most popular for wooden houses in dachas and gardens is a column foundation. Despite the apparent fragility of the structure and simplicity in execution, it will become a reliable support for many decades for a frame, log or a timber house.

The foundation for the old wooden house with your own hands

- It is most convenient to fill the foundation under the old wooden house, when the distance between the earth and the first row of a wooden log house allows a person to fit freely in a lying position. Outside around the perimeter of the house, a shallow trench is dug up (approximately on a shovel bayonet), its width should correspond to the size of temporary supports. Strong wooden pillars or concrete blocks are suitable for them.

- After installing the blocks, the trench for the foundation is dug under the house and on its inner side. A sand pillow is poured onto the bottom with a layer of 15-20 cm and, if possible, compacted. Then they make the formwork, as in the construction of a new house. That is, the shields are built from the boards and they are nailed to wedges, clogged at a distance of 1.5-2 m from each other. If the height of the underground allows, then it is advisable to make several spacers of wooden bars, scored in the ground at an angle to the formwork.

Tip: If the strip foundation is poured under an old wooden house in which there is no basement or underground, then from one of the outside sides you need to leave a small hole, so that later it is possible to climb inside to dismantle the blind area and waterproofing the base. In the future, it can be decorated, making the door with a warm foam and sheathe it with a basement facing material.

- For reinforcement, it is best to buy special reinforcing rods, whose diameter will correspond to the calculated data of the load of the house. But any scraps of thick wire, steel grilles or suitable trimming of old reinforcement are suitable.

- Concrete filling is made from the outside. It is convenient if the concrete car is equipped with a special hose. Otherwise, the solution is poured with buckets or using a construction car. Drink it immediately, stirring with a shovel.

- After hardening the composition, temporary supports are dismantled. In their place, in some cases, the formwork is mounted and similarly poured with concrete solution. Sometimes these places are left by closing and then hearing with facing material along with the entire base.

Replacing the foundation of an old wooden house with screw piles

- The method of reconstruction of the foundation under an old wooden house with screw piles is very popular. This is facilitated by the quick terms for the work and the ability to immediately continue the operation of the building, without the need to wait until the concrete solution gains strength. In addition, it does not require large -scale land work, structures of blind area and waterproofing, which is especially important when working in such constrained conditions.

- Screw piles are hollow pipes made of durable steel with screw blades and a sharp tip. They are twisted directly under the supporting walls of the house to the required depth.

- In order for their twist to become possible, you will need to alternately lift the sides and corners of the house with jacks. For greater strength, concrete is poured inside the screw pile, filling the entire cavity to the top.

- If the house is small, for example, a wooden country house, then it is enough to tighten the piles only along the outer perimeter with a step of 2.5 m and in the corners.

Tip: on sale there are cheaper screw piles made by a handicraft with a welded tip. When reconstructing the house, it is better to abandon them, since the integrity of the design is not enough and the probability of rust formation is high. The best option is cast copies.

Foundation for a wooden house video

Replacing the foundation of a wooden house using jacks

Next, consider the simplest and most convenient way to reconstruct the base using jacks.

- The main value of the jacks is the uniform rise of the house. To work with a log wooden house, this is especially important, since during a distortion there is a high probability of the deflection of the lower binding and further fault or separation of logs. Therefore, the gold rule when installing jacks to look for places where the wood is the most durable and was not deceived.

- Before raising, gaskets are installed to the jack of jack to wood in the form of steel plates 0.5 cm thick. This will evenly convey the force when lifting.

- Then the house is synchronously raised by all jacks to the required height. Having fixed, remove all rotten wood and foundation elements that interfere with repair. A beam or bricks are laid as temporary supports.

- Now they begin to equip the base, depending on the chosen type. For a strip, a shallow ditch is digging (a fertile layer is removed), pour a layer of crushed stone or sand and mount the formwork.

- The reinforcement is laid in it and everything is poured with concrete. When he grabs, the temporary supports are removed, and the house carefully lowers to a new foundation. Thus, it turns out that the segment of the foundation that has become unusable to be unusable.

- When a wooden house is built or the repair of the old foundation is required, when choosing the base, they are based on two important factors. The first is geodetic features and weight of the structure. The second is the prices for the foundation for a wooden house. And only having evaluated all the nuances, you will be able to make the right choice.

If I built a house itself, then

If I built the house itself, it would have been longing out for more than one year, the sea of \u200b\u200btime will take for one foundation ... I decided to turn to professional builders, here in this company order http://www.home-projects.ru/proekty_domov/ Derevjannye-Doma/.