Of course, the reliability of the concrete floor has been tested for years. The popularity of this option ...

|

|

An important stage in construction or repair work is the implementation of high -quality ... |

Parquet is a very beautiful and practical flooring that is made ... |

How to insulate the ceiling of the bathhouse

The ceiling insulation procedure is a very important process, especially if it concerns the bath. Since it is in this room that there is increased humidity that requires the use of special materials. We will talk about the features of insulation of the ceiling in the bath.

Table of contents:

- The main components of the ceiling in the bath

- How to insulate the ceiling in the bath: the principle of work

- Preparatory work on arranging vapor barrier of the bathhouse

- Ceiling insulation in the bath: functional purpose

- Choosing insulation for the ceiling in the bath

- We warm the ceiling of the bath with our own hands: Technology

- How to properly insulate the ceiling of the bath: thermal insulation of the steam room

- Technology of insulation of various ceilings in the bath

The main components of the ceiling in the bath

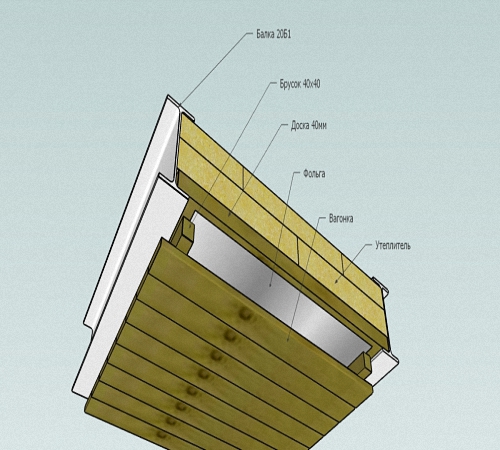

Any ceiling in the bath is based on the use of beams when constructing it. The beams are installed in such a way as to ensure uniform distribution of the load from the roof to all walls. The distance between the beams directly depends on their thickness.

Broughts are laid on the beams, which are supporting components of this design. It is on the rolling shields that the entire load from the ceiling lies, thermal insulation is installed on them, and then the main ceiling is attached.

When building a ceiling for a bathhouse in a brick building, you should take care of sealed the beams, since condensation begins to form with a stream of hot air. This process leads to the destruction of wood and damage to the ceiling.

As additional materials during the construction of the ceiling are:

- wooden boards;

- insulation in the form of mineral wool or other materials;

- Anchor details;

- skull bars;

- the ceiling of the main purpose;

- vapor barrier materials;

- waterproofing film;

- rolling shields.

Therefore, the beam, during installation, is plunged into the ceiling by at least 100 mm, and its end is made by oblique so that there is a gap of 2 cm between it and the wall.

How to insulate the ceiling in the bath: the principle of work

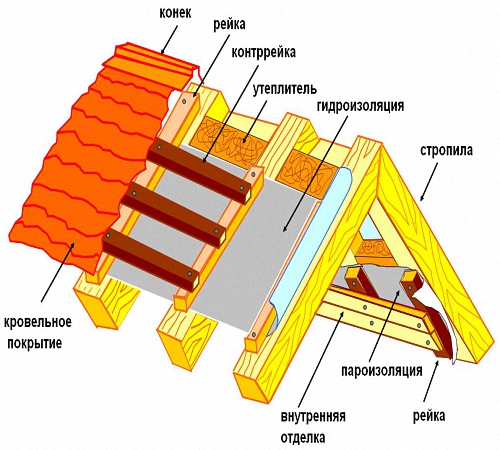

If we consider the roof of the bath in the relationship with its types, then two options for arranging the roof should be distinguished:

- with the presence of attic space;

- With its absence.

When arranging a bath with an attic, a more powerful ceiling will be required, since the flow of warm air will move to the attic space. This ceiling is equipped during the construction of the bath and its thermal insulation is carried out at this stage.

To fill in the undercarbon space, an air mass is used, which helps to reduce heat loss.

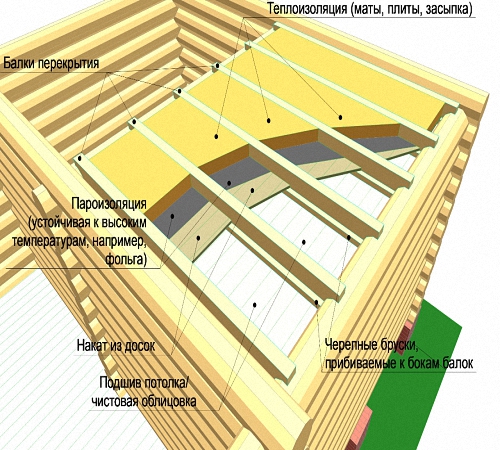

The roof with the attic space consists of such elements:

- vapor barrier layer;

- the lining of the main ceiling;

- upper strapping of walls;

- the attic floor beams;

- cornice boards;

- boards in the form of partitions;

- waterproofing layer;

- wood up;

- insulation.

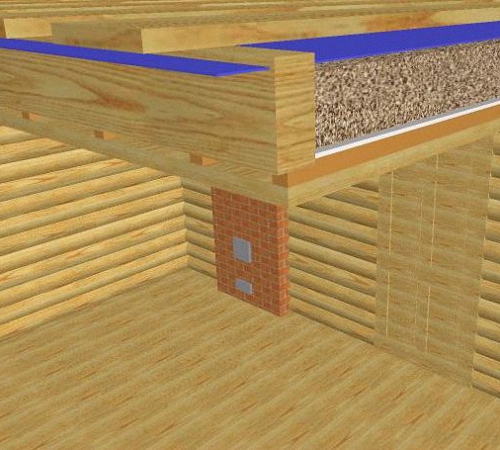

In the presence of a log -frequency overlap, when lining the ceiling on the bath side, the construction of the crate is required, and a vapor barrier is laid on the surface of the logs on which the sand pillow is covered with a thickness of at least 15 cm. Thus, the thermal insulation characteristics of the bath will improve.

Preparatory work on arranging vapor barrier of the bathhouse

In the process of arranging any type of bath, both with the attic and without it, it is necessary to equip a vapor barrier layer. This procedure precedes laying thermal insulation.

If vapor barrier is equipped in a bath without an attic, then it is enough to use materials such as aluminum foil, waxed paper or dense cardboard pre -treated with olifa. If the bathhouse has the attic space, it is preferable to equip vapor barrier in the form of a smeared three -centimeter layer of clay. Although it is quite possible to use the same materials as in the case of a bath without an attic.

There are options for vapor barrier of industrial production. Among them, they highlight:

- Polyethylene film - is low, as it creates a greenhouse effect. But still, when arranging, it requires a small gap that will help get rid of condensate accumulated inside the film;

- polyethylene vapor barrier film, on which there are villi that holds condensate;

- vapor barrier membranes.

Due to the presence of vapor barrier, condensate and wet evaporation do not settle on the surface of thermal insulation, thereby preventing its damage. A large amount of moisture accumulated in thermal insulation will lead to an increase in the weight of the ceiling itself and to its deformation.

Ceiling insulation in the bath: functional purpose

Since the bath is a room in which high temperature should be constantly maintained, heat loss should be minimized. If you follow physical laws, the higher the temperature requires, the more difficult it is to equip thermal insulation. Therefore, this issue should be given particularly close attention.

Before studying this issue, we propose to get acquainted with the most problematic places through which heat losses occur:

- gaps on the ceiling;

- the presence of cold objects taking heat from the room;

- Homogeneous obstacles that easily cross thermal waves.

The arrangement of the multilayer ceiling system and the installation of insulation precisely in its upper layer helps to prevent all of the above types of heat loss.

A properly equipped thermal insulation system helps to increase the service life of the entire bath and reduces the amount of fuel required for its heating.

In the process of installing a ceiling pie, each of its layers is laid perpendicular to the previous layer. Thus, the reliability of the entire structure increases, and the risk of ceiling deformation decreases.

Choosing insulation for the ceiling in the bath

Before proceeding with the direct process of insulation, you should take into account all the individual characteristics of the premises and materials used in its construction, and then select the appropriate type of insulation, which will provide reliable protection against heat loss.

We offer the most common options for insulation that are suitable for insulation of the ceiling in the bath:

1. The classic version is the use of mineral wool on the basalt -based. Thanks to its chaotic interweaving, heat is not able to penetrate through a layer of thermal insulation. The only drawback of this material is the loss of its functionality during getting wet. Therefore, with unreliable steam and waterproofing, it is better to refuse this option.

Tip: In the process of insulation of the ceiling of the bath, using mineral wool after a layer of insulation, a waterproofing layer is laid, which prevents moisture from entering the surface of the insulation, thereby extending the service life. In the space between waterproofing and a layer of mineral wool, it is necessary to provide a ventilation layer.

2. Thermal insulation materials based on super -light foamed polypropylene are also suitable for thermal insulation of the ceiling in the bath. This material is characterized by the presence of foil laminated coating, which helps to improve thermal insulation characteristics. It is this insulation that is an excellent tool for reducing heat loss in baths, saunas or steamers. With the help of a foil layer, heat is reflected and returned to the room, so the foil side must be turned into the room. This insulation reduces the cost of heating a bath at least twice.

3. The use of expanded clay is appropriate in large -sized bath designs. The minimum layer of its styling is 300 mm. Although the material is characterized by lightweight, it still increases the total weight of the ceiling. The porous structure of expanded clay is unstable before moisture, so its laying requires mandatory waterproofing.

4. Thermal insulation by a proven folk method involves the use of the first element in the form of a three -centimeter layer of clay lubricant. In the absence of clay, a solution of a solution of chernozem mixed with peat is possible. This option is of maximum environmental friendliness. This thermal insulation also performs the vapor barrier function. In addition, the option of using a solution is possible that includes a cement solution and wood sawdust, clay, sand and sawdust. After the layers of these layers, dry sawdust or oak leaves are placed, preferably from oak. At the end of this layer, dry earth is poured, about 18 cm thick.

5. The most modern insulation is a growing foam concrete. Under its arrangement, the construction of the simplest formwork is required. This version of the insulation is characterized by good heat -insulating properties and affordable cost. To install it, you will need a cylinder from which the material is supplied under pressure.

Among the advantages of the penoizol should be highlighted:

- good soundproofing characteristics;

- fire safety;

- excellent filling in all inaccessible places and cracks;

- improved thermal insulation properties;

- affordable cost;

- Lack of shrinkage.

We warm the ceiling of the bath with our own hands: Technology

Although the materials used in the thermal insulation process are different, the insulation technology begins with the arrangement of the overlap of the upper layer. As a supporting basis is the arrangement of the frame from the beams. They fit on the walls of timber, logs, bricks or panels. Before installing the beam, it is necessary to process it qualitatively with antiseptic solutions, which will significantly improve its life. If the tree was not processed before laying, then before installing thermal insulation it is required to apply an antiseptic on it. Pay special attention to the butt areas and angles.

On the inside of the ceiling, boards are installed, which are stuffed on the beams. Next, rolling shields that look in the form of two sites are formed, black boards are nailed on them.

Tip: In the process of amateur all the work related to thermal insulation, you should carry out certain calculations before installing the shields. Since the gap between the usual boards is at least 50 mm, and a minimum of 250 mm between the boards located near the chimney.

In the process of building multi -layer structures, it is necessary to prevent the occurrence of negative situations associated with complex operations. In order for all the wooden parts of the ceiling to serve for a long time, their antiseptic prevention should be carried out.

Draw the location of the boards and carefully calculate the distance between them. After their manufacture, numb the parts of the shields to install them correctly.

When arranging knocked out boxes, it is necessary to apply an antiseptic impregnation on them. On the internal walls of the shield using a stapler, waterproofing is attached.

Set the shields to the surface and fix them on the ceiling in the ratio with the previously numbered circuit. Next, a heater is installed, which is located in the space between the shield and the beam.

Further, the entire structure is sewn with boards that are located vertically in relation to the beams. In the process of this skin, both long and short boards are used, which alternate among themselves. A good alternative to the boards will be the use of wood-brown plates, homemade plates, which are based on a mixture of sawdust with cement. For processing the finished ceiling, antipyrers are used, and near the chimney are the sections sheathed with fireproof materials.

In order to save cash costs for the purchase of insulation, dry land is used: a chernozem with peat, which are covered on a layer of glass wool. In addition, for insulation of ceilings, slag, sawdust, expanded clay and a combination of the above materials are used in the bath.

The layer and type of insulation is calculated individually and depends on many factors, such as:

- the number of windows and doors and their size;

- wall thickness;

- the presence of the attic;

- type of roofing materials installed on the roof, etc.

How to properly insulate the ceiling of the bath: thermal insulation of the steam room

The arrangement of thermal insulation in the steam room is a more complex process that requires special attention. Since not only heat, but also steam should accumulate in this room. Therefore, when arranging a steam room, it is necessary to build two layers of vapor barrier and one layer of insulation, which has an increased thickness.

We offer to get acquainted with a special option for constructing thermal insulation in the steam room:

- For baking beams, riveted boards are used, 25 mm thick, they are covered with two or three layers as an Oliphi, so the material will become moisture resistant;

- Then a black board, low grade, the interval between its laying is 30 mm, is attached to the beams, it is equipped to ensure the ventilation clearance;

- The next layer involves the flooring of roofing material or polyethylene film, which provide complete waterproofing, an even better option is a reinforced foil flooring, which on the one hand will ensure waterproofing, and on the second it thermal insulates the room;

- Further, the entire structure is covered with a 20-centimeter sand pillow.

Technology of insulation of various ceilings in the bath

1. Thermal insulation of the ceiling of a flooring type is the easiest option. It involves laying thermal insulation material directly to the surface of the laid and knocked down ceiling boards. As a heater, in this case, mineral wool acts, the thickness of the layer of which depends on the individual characteristics of the bath. Next, vapor barrier is laid, which protects thermal insulation from water vapor and condensate.

To perform the upper layer of such a ceiling, a roofing material or a film made of polyethylene is used. This ceiling does not involve the use of the attic as a dwelling, since walking on such an overlap is impossible.

2. Warming of bearing ceilings - similar in the first option of insulation. A plastic film is installed on the ceiling beams with the help of a stapler, which forms a vapor barrier flooring. The option of installing foil or waterproofing membrane is possible.

Next, there is a stuffing of a black ceiling, on which a layer of insulation is installed in the form of mineral wool or expanded clay. To determine the thickness of the layer, all sources of heat loss that are present in the room should be taken into account.

Another layer of vapor barrier and boards, which will serve as a floor for the attic, is laid on top of the insulation.

3. The procedure for insulation of panel ceilings involves the use of two different technologies. The first of which is based on the presence of ceiling beams, and the second in their absence. To tighten the inside of each panel, vapor barrier is used, on top of which the insulation is mounted, sewn with boards. The arrangement of floors of this type is a rather time -consuming and complex process, which is extremely rare.

Insulate the ceiling in the bathhouse: