When asked which house is the most durable, the answer is obvious monolithic. And if earlier ...

|

|

Despite the rapid development of the construction sphere and the emergence of the latest methods ... |

Everyone who decided to build a sauna on his country site is early or ... |

DIY parquet restoration

Parquet is a very beautiful and practical flooring, which is made of natural wood of solid breed. If you choose a parquet for your home, then get ready for its periodic repairs. The first thing that is recommended to do before making the final decision on the appropriateness of repairs is to examine its condition. Sometimes it is enough just to restore the parquet, say, when he stopped shining, lost his color and began to creak.

Content:

- The need to restore parquet

- Getting rid of chewing gum

- Small defects

- Narrow cracks

- Wide cracks

- Parqueters are staggering

- Cosmetic putty

- Imitation of joints

- Manual cycles

- Grinding your legs

- Parquet varnishing

The need to restore parquet

Of course, you can choose a cheaper laminate in the parquet instead of parquet if you are scared of repairs. But remember that not in all cases it is required to carry out repairs, you can do with recovery. And do not confuse these two concepts! The repair consists in bringing the coating to working condition, and the restoration in the return of the pristine type of parquet and maintaining its cultural value. Let us first consider the situations when the parking of the parquet is required.

- Falling flooring. The parquet floor, which is varnished, periodically needs an update. This is customary to do once every few years. Many factors play the no small importance in this: the tree from which the parquet is made, the purpose of the room, and care for such a floor. Prevention of damage to the varnish coating preventing blows with various heavy objects, replacing plastic wheels for heavy inpatient furniture with rubber.

- Oil coating defects. To preserve the primordial natural parquet structure, it is customary to cover it with special opaque paint, the basis of which consists of oil and wax. The wood that is covered with this substance is resistant to household chemicals and moisture. Over time, damage to the oil coating on the parquet is observed.

- Local damage to the parquet. This can happen as a result of a slight fire, flooding with water, rupture of the parquet field during the dismantling of the partitions. Parquet can be very worn out, groomed and trampled with visible wave -like cracks in the dicks and hollows.

- Slots in the parquet. Slits appear in the floor covering, since the process of drying the parquet is observed. The cracks, depending on the time of year, can disappear and appear again. To avoid the appearance of cracks, it is recommended to maintain the temperature in the range of 20 degrees indoors. Air humidity should be no more than 60%. This is especially important in the cold autumn-winter season, when the heating system works, so you need to use the household humidifier of air.

- Sliding parquet. Unpleasant sounds of various kinds arise if you made a mistake when creating a black floor, or there is a loose fixation of the parquet board to the base. Writing parquet dies are best replaced.

- Parquet with water. It is no secret that wood is able to absorb water perfectly and tighten strongly at the same time. And, if the neighbors or you yourself fill your parquet with water, then you will increase your work. The recovery of the parquet after the bay is carried out depending on the area of \u200b\u200bthe bay and the styling methodology, since the coating is missed in different ways.

- Mold and rot. A sure sign of the development of the fungus swollen parquet. The dies are darkened, the tree becomes loose, the awl with light presses goes into wood by 5 millimeters or more. The reproduction of mold is closely connected with the bay of the parquetin with water or other liquid.

Getting rid of chewing gum

If parquet work you have timed to repair the entire room, they should be performed last. To carry out minor repair and restoration of parquet, you should only master several technological techniques, such as removing defects, manufacturing tinted putty, imitation of joints, cycles of manual cycles, foot grinding and varnishing of parquet.

It is impossible to wash the gum or remove it with a solvent: a spot will remain on the floor after such manipulations. Go as follows. Prepare a plastic non -plastic bag with ice cubes and put on pollution. After 20 minutes, the chewing gum will rise with the bag, then it can be easily chipped without a trace.

Small defects

To eliminate minor defects (chips, potholes, scratches, damage to the corners of the dies) without the removal of the furniture, you need to remove the old varnish first cycle, and then the skin to clean wood and close the defect using a cosmetic putty on a cardboard stencil. Previously, you need to clean chips from garbage, sometimes deepen with the help of a corresponding tool.

After the putty froze, draw a skin to an even effect, until the composition gains strength, falsehood should be scratched. At least two layers are applied from above, each subsequent after the previous one is completely dry. Single chips and scratches can be removed with the help of universally sold sets, including wax pencil.

Narrow cracks

It is customary to close the narrow single cracks with putty in this way as potholes with scratches: carrying out peel, putty, creation of falsehood and varnishing. The cracks that are located near the skirting boards are the most unpleasant. It is customary to start with the fact that the skirting board should be removed. A bursting wedge should usually be present between the extreme board and the wall.

If the bursting wedge is shattered, you just need to strengthen it. If you find a foam instead of a bursting wedge, you should squeeze the bar from the wall and install a suitable wedge in the formed space.

Wide cracks

But sometimes we are faced with the widespread formation of cracks in the floor coating made of natural wood. The sealing of multiple cracks and cracks, which is wider than 5 millimeters, is somewhat more complicated. Too wide gaps do not make sense to putty, they still crack over time. Fighting such recesses should be against the nasty.

Several parallel parquets, if laying was carried out not by a Christmas tree, you need to warm up for 10-20 minutes by a household hairdryer. A sure sign that the flooring is warm enough is considered the occurrence of the smell of mastic or putty. With a rubber hammer and a bag of heating designed for a laminate, the dicks are pulled to each other so that only one wide gap remains.

In it you need to tightly lay a wooden rivet flush with parquet on putty. Upon solidification of putty, put the repaired area, put it, draw falsehood, rush with a skin and sink. On the parquet, which is laid by a Christmas tree, it is customary to close the wide cracks individually, instead of rivets using chips.

Parqueters are staggering

If several separate dies are scattered, they must be attached to the 45 degrees adjacent to the neighboring angles of 45 degrees. Nails must be driven on the long sides of the strips 15-20 millimeters from the corners. Drive the hats of the nails into the tree with a metal rod-product or hammer. Holes with hats need to be trapped, without peeling.

After the putty hardening, you should go with a skin and apply a drop of varnish once. If they play foci, then you need to fix them with a bamboo. On the cut of the bamboo it is clear that its fibers are located not like a tree. After it sets a little humidity from the air, it will swell more than wood.

The process of driving the playing parquet using bamboo is done in this way: drill on the long sides of 15-20 millimeters from the corners at the joints vertical holes, which have a diameter of 4-6 millimeters. Round bamboo blocks must be driven into the holes tightly as possible. The remainder that acts is necessary to cut off a sharpened chisel. Find the renovated section of the cycle after a week, put the gaps, draw falsehood, sand and cover with varnish.

Cosmetic putty

Having discovered cracks and cracks on the surface of the coating, the thickness of which is no more than one and a half millimeters, you need to be close with special putty. In the process of restoring the parquet with your own hands, you can do without making home -made putty, because there are all kinds of restoration pastes for the parquet floor of various shades on sale.

When choosing a putty, take into account the type of wood from which the laid parquet is made. Before putty, carefully clean the gap and dust, using a vacuum cleaner with a plastic nozzle. You should not use sticks, screwdrivers and other similar objects to remove garbage from cracks, because the thickness of the damage can increase. In this case, the garbage will be clogged even deeper, preventing the reliable setting of putty with the base.

If old parquet was lying in your pantry, the same as on the floor, you can prepare a grout for seams and potholes that will be perfectly approaching the floor. To do this, drink more appropriate tools and mix them with parquet varnish until the consistency of sour cream is formed. You can also add aiper filler in an epoxy varnish in a ratio of up to 4: 1, it turns out as a result of something like plasticine. If you do not have exactly such wood samples, it is easier to purchase ready -made paste or putty of a suitable shade.

After preparatory work, you need to put the putty with a knife or a spatula to the crack, trying to fill the space as tightly as possible. The excesses that performed substances are removed from the surface of the parquet, after which they give time to the material for drying. Next, they clean the restored place with a skin until a perfectly smooth surface appears.

You should not waste time sealing large cracks, because still the putty will go from the edges, the whole will come out to the surface of the parquet, and the price of recovery of the parquet will increase significantly. In such cases, it is customary to use other techniques for restoring natural parquet.

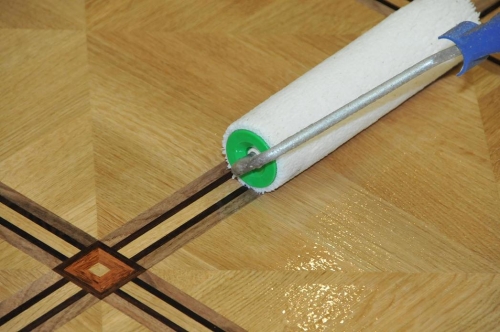

Imitation of joints

Imitation of the joints of parquets on the plucked surface of the coating is made by ordinary awl and a metal line made of metal. Wait for the gelatinization of putty so that the substance is no longer taken, but it was still soft. In urekut and alkyd varnishes, gelatinization occurs a few minutes after application and lasts about a minute, so you will have to work very quickly.

After that, it is necessary to carry out direct falsehood with an awl along the ruler. To make curved falsehoods, you need to use the rib ruler with a little pressure. According to frozen putty, the falsehood, if necessary, is scratched with an awl according to the template or line from the galvanizing.

Manual cycles

Small sections of the parquet are customary to cycle manually manual. In any instrumental store you can buy a cycl. But you can also make such an apparatus with your own hands from a piece of iron for a shirt: release its blade, crocheted it and harden it again. When working, it is necessary to strictly adhere to safety and technology for the performance of work.

If the thickness of the parquet board is 15 millimeters, then it can be manually treated 5 times, thin 8-mm parquets no more than 3 times. First, it is necessary to carefully examine the coating for the presence of garbage and the item of protruding nails that can damage the grinding tape. The first stage of the cycle is a rough grinding of the coating.

For rough grinding, it is customary to use a flat -grinding machine or drum -type apparatus. At the first stage, the largest abrasive No. 40 is filled into the drum, then the engine is launched and the machine is driven along the wall. Having passed the first strip, about 20 centimeters wide, which is identical to the width of the abrasive tape fixed on the drum, you should shift about 10 centimeters.

It is customary to remove the upper layer of varnish and old wood from the parquet, leveling the surface of the floor. In this case, the chips will be removed thick, which reaches 3 millimeters, strictly along the wood fibers. To make the result as high as possible, the grinding machine must be kept at an acute angle of 45 degrees to even walls of the room.

Remember that the rotating drum of the machine should not linger in one place. If there is a need to stop processing, the drum should be raised above the floor. Using at the initial stage a rough abrasive tape, you can align the floor, remove the accumulated dirt and the old darkened varnish.

In order for the cycle on the entire surface to pass evenly, follow the wear of the abrasive and periodically change it. In hard -to -reach places, for example, in walls or under the heating battery, the floor is treated using a disk corner machine. Continue to work until the entire area of \u200b\u200bthe coating becomes perfectly smooth and even, which does not even have the smallest changes.

After the grinding process is completed, the parquet using a rough abrasive on the coating occurs scratches and other defects, from which a fine -grained ribbon will help you get rid of. With its help, process the entire area of \u200b\u200bthe room. If there are large defects on the boards, they should be covered with putty. It also needs to be treated with a grinding machine after completely drying out.

After that, install a tape with the smallest abrasive on the drum and finally polish the entire floor. If you can’t cycle old parquet, then darkened parts are recommended to be treated with large sandpaper to a light layer. To remove small particles of varnish, wipe the treated surfaces with acetone, then open the BF-6 with glue and treat again with acetone.

Grinding your legs

To make a sandpaper with a skin of local plots of parquet, you can use old shoes that have a flat sole: sneakers, Chinese summer shoes. Stick on one sole by 88th glue a rough skin number 40, on the other skin thinner number 80, for the primary and final grinding procedure.

It is also tiring to scream with your feet, but it is much more difficult to rub the parquet with your hands, bent or kneeling. In addition, the skin on elastic soles will work more accurately than fixed on the skirmish.

Parquet varnishing

Traditionally, the restoration of the old parquet is completed by the varnishing procedure. Before the procedure itself, you should consider which materials for this will be required. To create a protective coating on the parquet and fitting the replaced planks to match the fact that there are already, you need parquet varnish.

Alkyd varnishes are non -toxic, are inexpensive and dry quickly: you can populate the room after applying the substance an hour later. But the durability of such a layer does not exceed 10 years, after this time it is required to carry out a full cycle and overlapping.

Ural varnish will cost you a little more, but it is also more durable than alkyd. It is recommended to use this substance around the perimeter of the room or to create a temporary coating for several years before major repairs.

Epoxy varnishes are able to provide high durability with proper care, which is not limited to 30-40 years, but are expensive. When such a composition is cured, highly toxic volatile substances are released, so you should work in a respirator, glasses and rubber gloves, tightly closing the door to the room and opening the window wide. You can settled into the room a week after the varnish: varnish, which seems completely frozen, will be gained for a long time.

Acrylic varnishes are similar to epoxy, before using the hardening of the hardener and the base. This composition is little toxic, but very expensive. The durability of acrylic varnish with proper care is up to 50 or more.

Water -based varnishes are a fine suspension of the polymer, for example, PVA, in water. Cheap, non -toxic, matures in a day. A similar substance penetrates the mass of wood, which gives it strength for decades. The service life will depend on the quality of wood. The parquet that is debugged with water varnish is not so sensitive to grains of sand.

The application of the varnish composition may be accompanied by the process of raising the pile on wooden strips, to prevent this, after grinding, slightly moisten the floor and let it dry. After that, polish again. Apply a primer with greater viscosity to the prepared surface. That is why it is able to fill the microcracks well and glue the pile.

Pour a primer on the floor, then quickly distribute with a wide steel spatula along the surface. The primer will dry quickly for 20-60 minutes. After the first layer dries, the surface must be sanded again. Then apply the second and third layer, withstanding the interval in 20-40 minutes. After that, you can proceed to the varnishing procedure.

Before repairing and restoring parquet, any varnish must be mixed well and leave for several minutes to remove air bubbles. The varnish is applied with a wide brush with a soft and thick pile, a foam roller or a varnish brush. Do not press the tool very much on the tool, too noticeable connections must also be avoided. To obtain a beautiful and high -strength surface, the varnish must be applied in several layers.

Thus, not in all situations it is advisable to thoroughly repair the parquet. If you carefully take care of the floor covering and make sure that the parquet remains their original appearance, you can do with simple manipulations to restore parquet. The main thing is to timely detect problem areas and identify damage.