To build a building from a cinder block yourself is quite real even an inexperienced newcomer ...

|

|

The parapet of the balcony is an integral part of the architectural structure of the house. Fencing ... |

Sooner or later, each of us is faced with the need to build or repair ... |

How to care for roofs from corrugated board

Breeding - a popular material in the roof decoration. But, in order for the roof from the corrugated board to have an attractive look and last longer, preventive work on caring for the roof should be carried out. We will talk about how to care for the roof from the corrugated board.

Table of contents:

- Features of the roof from corrugated board

- Advantages of using corrugated board for roof decoration

- Variety of roofs from corrugated board

- Checking the roof from corrugated board

- Annual maintenance and repair of roofs from corrugated board

- Staining roofs from corrugated board

- Roof insulation from corrugated board

Features of the roof from corrugated board

Corrugated board is a material for the manufacture of which simple galvanized steel or steel with the presence of polymer coating is used. To increase the stiffness of the structure, profiling is used - to give the form a galvanized sheet.

For decoration of the roof, corrugated board with labeling n, NS is used.

The service life of the corrugated board depends on such qualities as:

- The thickness of the zinc coating,

- The quality of the polymers used,

- The thickness of the polymer coating.

As a polymer coating, they use:

- polyester coating,

- acrylates,

- polyvinyl chloride coating,

- polyvinylenfooride,

- polyurethane.

Depending on the number of layers, they distinguish:

- steel corrugated board with the absence of a protective layer,

- Steel sheets of hot -valked type,

- hot -valked corrugated board with a protective layer,

- corporates of a special perforated type.

Roofing corrugated board, differs from other species, the presence of a special deepening, which is designed to remove moisture from the surface of the roof. The height of the corrugation corrugated corrugated corpus delicti is from 2 to 6 cm.

The thickness of the sheet of roofing corrugated board depends on factors such as:

- The power of the wind,

- climatic conditions,

- operational loads,

- The angle of inclination of the slope.

The cost of roofing corrugated board depends on:

- the heights of the corrugation and the thickness of the material,

- the availability of a galvanized steel coating,

- the purpose of the material,

- protective coating,

- colors,

- the quality of the polymer coating,

- The length of the material.

Roal from corrugated board photo:

Advantages of using corrugated board for roof decoration

- corrugated board is a fairly easy material that does not require additional efforts to install;

- strength and durability;

- A variety of colors and varieties of corrugated board allows you to choose the material, according to the type of building and the design of the facade;

- corrugated board - universal material that is used in different climatic zones;

- installation of corrugated board - does not depend on climatic conditions and temperature regime;

- Installation of corrugated board does not take much time;

- It is possible to install corrugated board on the old roof, without preliminary dismantling;

- Repair and care for the corrugated board does not require greater efforts and is carried out easily and quickly;

- corrugated board is characterized by low cost, compared with alternative roof decoration options;

- corrugated board is an environmentally friendly material that does not distinguish harmful substances.

Among the large number of advantages of this material, we highlight several shortcomings of the corrugated board:

- corrugated board is characterized by increased noise, during the rain;

- In case of violation of the protective layer, corrosion appears;

- corrugated board - a material that requires additional thermal insulation and waterproofing.

Variety of roofs from corrugated board

Depending on the marking and features of the corrugated board, they distinguish:

1. N corrugated board, which is the supporting. This is the strongest type of this material used to arrange roofing surfaces. Such corrugated board has the largest thickness, additional grooves and high corrugation. Such a structure provides additional rigidity of the structure. Scope of use:

- installation of formwork non -removable type,

- Equipment of a powerful ceiling,

- arrangement of hangars,

- manufacturing of heavy -loaded containers,

- overlapping garages, warehouses,

- wall sheathing,

- arrangement of gates and fences.

The most popular type of corrugated board is C8, indicating the thickness of the sheet 0.4-0.8 mm.

2. NS - corrugated board used to arrange non -prophet structures. The corrugated board of the NS is distinguished by the average indicators of the thickness and height of the sheet. Used to arrange wall and roofing structures.

3. C - marking of corrugated board, which denotes the use of this material in wall decoration with preliminary insulation.

Checking the roof from corrugated board

The galvanized steel, and, accordingly, such factors as:

- ultraviolet radiation,

- climatic conditions,

- wind load,

- atmospheric precipitation that provoke the appearance of mineral salts,

- temperature changes.

These factors, during prolonged operation of corrugated board, affect the integrity of the protective polymer layer. Therefore, it is recommended to conduct a roof check from corrugated board for damage twice a year, in autumn and spring time.

Cleaning the roof from corrugated board consists in regular cleaning of the roof of small particles of garbage and leaves. Since the rains do not always wash away the leaves from the surface of the roof, the roof should be cleaned independently.

For these purposes, use a soft brush. Sharp tools should not be used in order to avoid mechanical damage. Pay attention to the joints of the roof and cleansing the gutters.

Pollution is washed off using a jet of cold water and a soft brush. In the presence of additional mud, use the help of special detergents.

Use a soft rag to clean very contaminated surfaces.

Snow removal from the surface of a flat roof from corrugated board is carried out using a wooden shovel. Remove the snow in small layers, leave a small layer of snow, which will protect the corrugated board from damage.

Annual maintenance and repair of roofs from corrugated board

During operation, such damage to the roofs as dents, scratches or small detachments appear.

Such defects arise from improper use of the tool, mechanical damage to the roof, improper transportation or low -quality installation of the material on the surface.

Damaged surfaces accumulate dirt and lead to corrosion.

Therefore, in order for the roof from the corrugated board to last longer, these defects should be eliminated as it is detected.

Defects of the overhabitation or fragmentation provoke the effect of ultravioletus or an unfavorable climate. To eliminate these defects, use cleaning, painting or processing corrugated board with special means.

The formation of cracks on the surface of the corrugated board causes improper use of building tools, incorrect transportation or mechanical impact on corrugated board. For these purposes, it is necessary to use anti -corrosion impregnations.

The process of the development of corrosion on the surface of the sections or specialized edges provokes the poor quality of corrugated board or failure to comply with the technical requirements for installation. To avoid damage data, use special solutions and paint.

To prevent freezing of the drainage system, it is necessary to clean the roof from the garbage daily.

In case of violation of the rules for the installation of corrugated board or when using unsuitable screws, a leak of the roof occurs. It is necessary to replace the fasteners to eliminate this defect. Use larger screws than were installed in advance.

Staining roofs from corrugated board

There are several methods of staining the roof from corrugated board. Consider the main ones:

1. Coloring with paint with powder, which contains a coloring pigment and rubber. Such paint does not require additional solvents, is characterized by a high level of environmental friendliness, fire safety and does not contain harmful components. After staining, the corrugated board becomes more durable, shock -resistant, durable. The paint withstands sharp temperature differences, a high level of humidity, is distinguished by anti -corrosion. Powder paint is glossy and matte. It is not recommended to use glossy if the roof is on the sunny side. Such paint is applied to corrugated board in production using special coloring furnaces.

2. Combined staining involves the presence of complex equipment that supplies paint under high pressure.

3. Early staining - the use of special sockets, which provide high staining performance.

4. The pneumatic method of staining is carried out at home, and involves staining corrugated board using aerosol or spray gun. Before painting, corrugated board should be cleaned of dirt and wash with an alkaline solution. After the surface dries, apply paint with a spray gun in several layers. The consumption of paint, using this method, increases, but additional use of special equipment is not required.

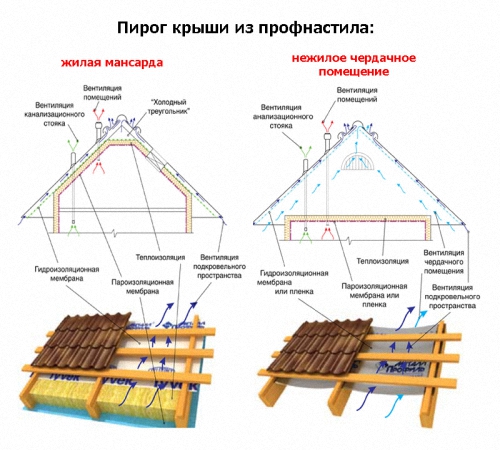

Roof insulation from corrugated board

For work, the availability of:

- rolled insulation,

- mineral wool or glass wool,

- waterproofing material,

- construction knife,

- Stapler,

- connecting tape,

- screwdriver,

- self -tapping screws,

- wooden bars,

- Lining.

Advantages of roof insulation from corrugated board:

- prevention of roof leakage,

- lack of the formation of condensate masses,

- lack of heat loss,

- noise insulation that hides the noise defects of corrugated board, during the rain,

- Prevention of the development of fungus, mold.

First you should build a frame on which the insulation will be attached. The frame consists of lag and boards. The gaps between the boards are about 5-8 cm.

When using the attic space as an attic, the insulation layer should be increased.

A waterproofing film with gaps of 3-4 cm is laid in the rafter system. Do not allow sagging waterproofing. Lay the waterproofing overlap. In the subchank region, in the absence of an air cushion, a cold triangle should be built, which will provide ventilation of the roofing room.

Under the waterproofing film, lay the insulation: glass or mineral wool. For the attic, the insulation layer is about 10 cm. It is possible to lay the insulation with several layers. The thickness of the insulation depends on the climatic conditions of the region.

After a layer of insulation, another layer of waterproofing should be laid - a string. This layer is installed from the inside of the roof and is fixed using a stapler.

The final stage is the installation of wood casing on the inside of the roof. As this layer, a lining, wood, plywood or other finishing materials are used.