A screw foundation in the military and industrial sphere has been used for more than a hundred years, in ...

|

|

Make a aesthetic ceiling in the bathroom with the help of painting is easy, but much depends on ... |

In recent years, polycarbonate has received great distribution and popularity. Greenhouses ... |

Basal wool insulation: step -by -step instructions

Sooner or later, each of us is faced with the need to build or repair, one of the current issues of which is thermal insulation. Its relevance is due to exponentially growing electricity and heating costs and associated thoughts about energy saving, as well as excessive concern of environmental safety issues of building materials used, due to the outlined growth of oncological incidence. Despite the fact that the construction market offers the consumer a wide variety of insulation characterized by certain advantages, considering the features of materials from this diversity in the process of choosing the insulation, often give preference to basalt cotton wool, the features of which will be considered in this article.

Content

- Internal or external insulation: what to prefer?

- The scope of basalt wool: the main provisions

- Operational and technical characteristics of basalt wool

- Advantages of basalt wool

- Disadvantages of basalt wool and methods of their leveling

- Basalt wool: the choice of the manufacturer depending on the operating conditions of the structure

- How to insulate basalt wool: basic recommendations

- We insulate the house with basalt cotton wool: step -by -step guide

Internal or external insulation: what to prefer?

As already mentioned, sooner or later the question arises acutely about saving energy resources. How to save on heating a house or apartment? In civilized countries, an answer to this question has long been found, the solution of which is to insulate houses, cottages, apartments and other buildings. In addition, the feasibility of this method of insulation is quite proven, which is confirmed by a wide consumption of this building material, which is in third place among building materials in the process of analysis of costs during the construction of buildings.

Important!You can talk about the appropriateness of insulation in two cases: if you have purchased a new house that needs improvements that guarantee comfortable accommodation, or are engaged in the design of a new house from scratch.

Speaking about the feasibility of various types of insulation, it should be noted that the opinions of specialists in this case are split. Some stubbornly confirm the feasibility of internal insulation, others, on the contrary, believe that the structure, first of all, should be subjected to external insulation, since the internal is a rather complex process, the question of the appropriateness of which is solved in each particular case.

Important! Beginners in the field of insulation often rely on the opinion of specialists or tips on the relevant forums and prefer internal insulation, which is later the reason for the appearance of condensation and mold on the walls of the house. The reason for this is the use of cotton wool or dense foam, which, in case of installation on the internal walls, prevent the drying of the walls that always remain moist.

Disadvantages of internal insulation:

- Strength and low thermal conductivity of insulation in combination with high soundproofing characteristics, which cannot be compensated even by the high cost of the material;

- The presence of seams in the places of connection of the insulation reduces the performance of the material, making it not tight enough;

- In the process of working with this thermal insulation material, small pieces are abandoned from it, contributing to the raising the pillar of the smallest basalt dust and causing the need to use respirators or covering the surface of the insulation with a layer of waterproofing membrane;

- The high vapor permeability of the material contributes to the inappropriateness of the use of insulation in some cases, such as insulation of the foundation or basement, when basalt wool can be replaced with polystyrene foam.

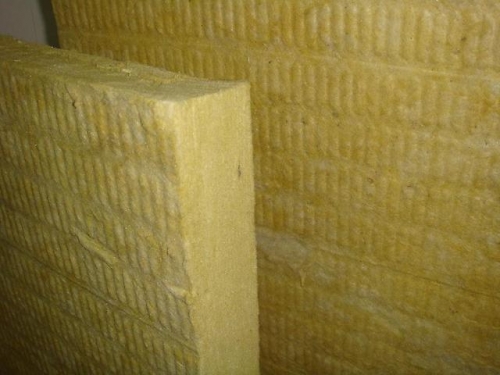

Basalt wool photo

The scope of basalt wool: the main provisions

The use of basalt insulation is relevant in the process of erecting and subsequent insulation of almost any building structures. It can be used for isolation of both roofs of any shape and walls, partitions and ceilings. In addition, the use of basalt wool can be relevant where the feasibility of using another insulation is minimal. To make sure of this, consider the main areas of use of basalt wool:

- Insulation of rooms characterized by high humidity (for example, baths or saunas);

- Use in the process of mounting hinged facades of a ventilated type, as well as wet facades;

- The use of walls built from sandwich panels and made on the principle of layered masonry as a heater;

- Insulation of cabins of ships and other ship structures;

- Use for insulation of pipelines, the surface temperature of which varies from -120 to +1000 degrees;

- Basalt wool as a fireproof insulation prevents the fire of ventilation pipes and other building structures.

Important! The use of hard mats made of basalt wool is especially relevant where the exposure to both installation and operational loads exceeds permissible values. If you intend to insulate the ventilated facade, experts recommend using basalt cotton wool consisting of two layers, each of which is characterized by various density. In this case, the layer with a more loose structure is located on the inside of the thermal insulation layer and is in contact with the surface of the wall, and the second, characterized by a denser texture, should be located outside, from the ventilation side.

Operational and technical characteristics of basalt wool

For the manufacture of basalt wool, basalt and some related mineral breeds of the basalt group and close to it are used. In order to ensure a large fluidity of thin basalt fibers, the manufacturer includes from 10 to 35 % of limestone or shiht in the melt, which helps to transform the fiber structure and weaken its exposure to the influence of aggressive environmental factors, including high temperatures. In connection with the inclusion of third -party components in such fiber, it is incorrectly called basalt, and it is called basalt mineral wool. This fiber is called the basalt super -tick fiber (BCTI). It is thinner and short (thickness 1-3 micron, length 50 mm).

Technical characteristics of mineral basalt wool:

- Thermal insulation material, based on the use of BDST, is characterized by resistance to vibration. In the process of basalt wool production, it undergoes vibermic treatment at a temperature of 900 degrees, after which the loss in its mass remains minimal and does not exceed 0.35 %, which, first of all, is due to long -fiber. In this regard, experts came to the conclusion that the qualitative and operational characteristics of basalt wool directly depend on the length of its fibers. An equally important parameter is the degree and nature of crystallization, which helps to preserve the optimal level of elasticity and strength characteristics.

- Basalt wool based on basalt thin fibers (BTV) is characterized by less vibration resistance. In the process of vibration for 3 hours at a temperature of 600 degrees, the loss of mass from the initial state is at least 2 %, however, when a temperature of 900 degrees reaches the loss of mass, increase to 12 %. In this regard, the conclusion suggests itself that cotton wool based on short fibers is less vibration resistant.

- Having studied the technical characteristics of basalt wool, one cannot fail to note the absolute non -combustibility of the material. Under the influence of high temperatures, there is no destruction of the fibers of basalt wool, which remain associated and demonstrate high strength.

- Thermal conductivity and hydrophobization of basalt wool. Due to the fact that the basalt wool fibers do not delay moisture, it always remains dry and retains its thermal insulation characteristics. Hydrophobization is a natural obstacle to moisture accumulation, and therefore, there is no increase in the total weight of the structure. This, in turn, prevents mechanical damage.

Important!Despite the hydrophobization, the features of the chemical composition of the basalt wool determine its insignificant hygroscopicity, the presence of which guarantees the stability of thermophysical characteristics of the material, even despite the duration of its use.

Advantages of basalt wool

According to experts, basalt wool has many advantages compared to other thermal insulation materials. Consider what they are.

- One -component basalt woolOne of its main advantages, implying the use of only one basalt breed in the process of its production. However, modern production technologies involve the inclusion of a shiht or limestone in its composition, which helps to increase the fluidity of the fibers. Despite this, experts admit that these features of its production can negatively affect the stability of thermal insulation material to the effects of high temperatures. It is important to know that basalt wool is a qualitatively new material, the production features of which allow its use as the main heat insulator for residential and administrative buildings, as well as pipelines and refrigerators;

- High heat and sound insulation qualities, due to the low thermal conductivity of the material, which contributes to a significant reduction in the financial costs of heating of the room. The sound permeability of the material is due to its fibrous structure, which reduces the speed of distribution and subsequently extinguishes sound and vibration waves, turning them into thermal energy;

- As for high thermal insulation characteristics, they are achieved due to the air that is located between the fibers and is characterized by a low coefficient of thermal conductivity;

- No less significant advantage of basalt wool is its long operational periodwhich, according to experts, is from 30 to 40 years, but in practice it demonstrates even higher indicators;

- Resistance to chemically aggressive substances (organic oils, acids, alkalis and solvents);

- The water resistance of the material, which is achieved due to the inclusion of specialized hydrophobic additives in its composition. Low moisture content in the structure of the material, in turn, helps to increase the thermal insulation characteristics of the material;

- Resistance to the defeat of mold and fungal microorganisms one of the important qualities that are relevant for insulation of residential premises;

- High density of basalt wool plates Allows them to withstand increased mechanical loads, and also makes it possible to decorate the material with protective compounds;

- Resistance to atmospheric influencesimplying the preservation of the initial operational characteristics under the influence of temperature changes and humidity;

- Low specific gravitydue to the fibrous structure of the material;

- Convenience of masonry, achieved due to large square plates, immediately covering large areas.

Disadvantages of basalt wool and methods of their leveling

Despite all the above advantages, basalt wool is characterized by certain disadvantages that, under certain conditions, can be minimized. Consider what they are.

- The structural features of the material contribute to excessive absorption of moisture, which helps to reduce thermal insulation characteristics of the material. How to deal with this drawback? Experts believe that the most optimal solution to this issue is foil or lining of an additional vapor barrier in the installation process. However, the latter option is less preferable, since the glue that is used for this reduces the fire resistance of the material. Another way out, during the implementation of which the operational characteristics of the material are not reduced, is the acquisition of firm basalt mats;

- In the process of choosing a variety of basalt wool, it is necessary to focus on the conditions in which its operation will be carried out. If you plan to insulate the house with basalt wool, which is located in conditions of high humidity, experts recommend preference to basalt cotton wool with aluminum coating. If at the same time it is necessary to ensure the stability of the coating to elevated temperatures, then the foil used for this should not be glued to the base, but stitched by a galvanized wire. Hydrophobidity indicators are much higher and in products, in the manufacturing process of which foamed rubber was used.

Given the foregoing, we can conclude that, despite the presence of certain deficiencies in this material, they are easily eliminated under certain conditions.

Basalt wool: the choice of the manufacturer depending on the operating conditions of the structure

- TechnonikolOne of the largest Russian corporations, which occupies the production and supply of heat and waterproofing materials. For the first time, Technonikol products appeared on the Russian market in 1992 and today there are at least 40 production sites throughout Russia, the countries of the former USSR, as well as some countries of the European Union;

- RockwoolThe company, the main office of which is located in Denmark, and 23 production sites in 15 countries of the world. The main direction of the corporation is the presentation of its products not only as thermal insulation materials. But also a comprehensive system, which is a reliable solution even in the most difficult issues of thermal insulation;

- ISOVER One of the famous French brands engaged in the production of stone wool and insulating materials based on fiberglass. As for Russia, it is one of the largest sites for the sale of goods of the company, where the development of this brand is carried out in two areas technical isolation and private construction.

- Unconditional leadership in the Russian market of basalt wool belongs to Technonikol and Rockwool companies. The German-Austrian corporation iso short, for the production of products of which is used by the highest quality fiber, does not plan to concede them. In this connection, it is characterized by low thermal conductivity.

- The Kharkov company thermolaif, whose products are not inferior to other well -known brands, also works with a fiber of similar quality.

Important!It should be noted that basalt wool production is carried out in accordance with GOST and technical conditions developed by each individual enterprise for the production of its unique products. Moreover, in this case, the generally accepted rule acting for food products does not work, in accordance with which the highest quality products are produced according to GOST. In the case of heat -insulating materials, the situation is different, since modern plates of a particular brand are produced in accordance with the rules developed by the manufacturer and are the latest development of the company.

- For insulation of unloaded structures, such as attic, attics, partitions and internal walls, it is recommended to use plates of the aforementioned brands: technolaite, isolaite, isolaite luxury, thermolife Light and others;

- The rather popular products produced by the Technonikol Corporation are the slabs of the Rochelite and Rolons of Technoroll. They are characterized by a density of 30 kg/ m3 and are used mainly for unloaded horizontal structures.

Important! When choosing a material with certain operational characteristics, a general rule applies: for horizontally located unloaded structures, stone cotton wool with any density indicators can be used, while for vertical unloaded structures it is recommended to use the material with a density of at least 35 kg/m3.

- If you choose a material for the arrangement of the average thermal insulation layer of layered masonry, it is recommended to use the material in the name of which the words of Kaviti and the Blok are used: technologists Standard, thermolife Kaviti. In this case, the density of the material should be not lower than 45 kg/m3.

- For insulation of hinged ventilated facades, it is recommended to use technology heater, thermolife facade, isofas.

How to insulate basalt wool: basic recommendations

The technology for installing basalt wool is quite simple, and therefore, insulation of the house using this material is likely not to cause difficulties. When warming the house, it is recommended to use basalt cotton wool in the form of a rectangular or wedge -shaped slabs, since they are easiest to be combined with each other during installation.

Before insulation with basalt wool, prepare the following materials and tools:

- Basalt cotton wool in the form of plates;

- Wooden rails;

- Permamine;

- Knife and construction nails;

- Mounting foam;

- Hammer and grinding grater.

Before proceeding with the work, remove all cracks and defects from the surface using mounting foam, which can be replaced with packley or felt.

Next, the layer of vapor barrier is carried out, enclosing the insulation from the negative effects of moisture, which can be condensed on the inner surface of the roof. To preserve the performance of the material, it is necessary to organize effective ventilation. If you are warming the roof on the inside to prevent the accumulation of moisture in thermal insulation material, organize a vapor barrier between cotton and roofing material, which is a special film that creates a gap between the roof and the insulation and prevents the water accumulation. As a vapor barrier layer, it is recommended to use foil, polyethylene film or permamine, which is attached using a construction stapler or bilateral adhesive tape, which creates additional tightness in the process of laying thermal insulation.

Important! The laying of the waterproofing layer is carried out directly under the roof. The waterproofing material performs the function of a kind of barrier, which prevents the penetration of moisture not only to the heat insulator, but also with wooden structural elements. As a waterproofing, a plastic film is used, the stripes of which are mounted. In this case, the lower strips are first fixed, and the upper ones are laid so that they overlap the lower ones.

If the thickness of the thermal insulation material is 50 mm, it is attached to the rafters using a construction stapler. At the same time, a crate from wooden rails is fixed under the plates of basalt wool. If the thickness of the thermal insulation material is 100 mm, it is laid in the strut between the rafters. At the same time, screws, glue and mastic are used.

We insulate the house with basalt cotton wool: step -by -step guide

The insulation of the frame house begins with the installation of the cornice made of metal. It is attached to the wall with dowels in the area of \u200b\u200bthe base. The cornice is designed to facilitate the laying of insulation and protect the material from the negative effects of rodents;

Next, thermal insulation slabs are fixed using polymer -cement glue, which provides reliable fastening of the plates to a wall base. The glue is distributed evenly on the surface of the stove, after which it is pressed to the wall structure. The insulation is mounted in the direction from the bottom up and from right to left. First of all, whole plates are fixed, and after covering large areas, the insulation is mounted in small areas in small areas, for which the slabs must be cut;

In conclusion, the surface is aligned with a grinding grater, which is necessary in order to further carry out effective installation of the ventilated facade.

Installation of basalt wool video

Correct Russian

Correct Russian

Crossed the floors in the country in

He crossed the floors at the cottage this year and at the same time the attic ceiling decided to react, everything is already chilly there. A neighbor in the site advised to take the stroke of super warm, this is mineral wool. I went looked and did not understand at first, she was in the stoves and I thought that the roll would go better. The plates are usually hemorrhoids and break a little that. But then he touched - and they are flexible as foam, only denser and harder. It turned out to be a very cool thing, due to their elasticity, they can be placed denser. With your hands, press right on the sides to a centimeter and insert it. That is, even after a while you will not eat anything and will not crawl out. I am going to re-get the facades next year, so I think I'll take the same.