The bathroom is a room with a high level of humidity, so it needs ...

|

|

The garage is not only a shelter for the car, but also acts as a second home ... |

During the operation of a wooden house, individual structural elements ... |

How to make a cement solution correctly

If you decide to build, you will definitely need a cement solution in the process. It is not enough to buy cement, because before starting construction, gray powder should turn into a real solution. Water, sand and cement are all components, but not everything is as simple as it seems at first glance. Let's figure out how to make a cement solution correctly.

Content:

- The history of cement

- Cement production process

- The use of cement in construction

- Making a cement mortar with your own hands

The history of cement

The cement is a well -known astringent building material, which is referred to as hydraulic binders used to fasten different surfaces of brick or railway blocks. Without cement, you can not make concrete or foundation. In addition to high viscosity, the material is characterized by excellent hydraulic properties, which allow you to create a stable connection with water and other liquids in the manufacture of the solution in the form of a plastic mass. After solidification of such a mass, a stone -like material is obtained, which has significant strength and rigidity.

Even in ancient times, astringent materials began to be used for building needs. The very first astringent material was natural, non -combustible clay. However, over time, she ceased to satisfy the builders due to low resistance of moisture and weak astringent properties.

For several millennia, air lime and gypsum remained the only astringent materials, but they had insufficient water resistance. And the rapid development in 17-18 centuries of navigation required the creation of new binders that are resistant to water for the construction of port structures.

In 1796, the Englishman Parker patented cement called Roman, who could harden in the air or in water. However, these qualities in our time have also lost practical importance. At the beginning of the 19th century, Academician V.M. Severgin described the astringent, which was received using the firing of Mergel with subsequent grinding. From the second half of the 19th century, Portland cement has firmly entered the construction practice of our camp.

Industrialization in the USSR and the violent pace of capital construction predetermined the growth of the development of cement industry. The USSR in 1962 for the release of cement took first place in the world. Today, about 30 varieties of cements are produced in our country. At the same time, its quality is growing and the prediction of the famous chemist Mendeleev, who argued that cement is the building material of the future.

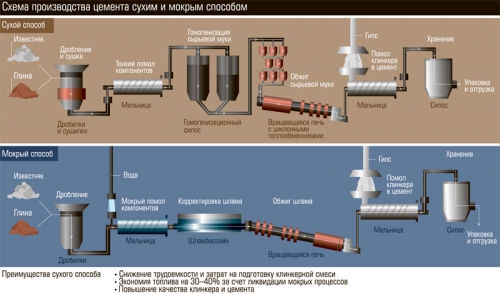

Cement production process

Natural cement is a mixture of limestone and clay, which forms high -strength stone -like material when solidifying, which most often turns out without odor, is a loose and has a gray color. The quality of cement is determined due to the presence of different substances in it - granular slag, magnesium oxide and sulfuric acid anhydrite. The cement brand depends on the ratio of these components. Also, the quality of cement, the time of setting, the strength during compression, and false grades will depend on the percentage of the substances.

As a raw material for the manufacture of Portland cement, a mass of limestone and clay is used, as was stipulated above. What are the cement made of? In rare cases, a rock is used called Mergel, which is precisely the natural mixture of clay and limestone in the ratio, which is necessary for obtaining Portland cement in the production process. Mergel was appreciated in the 19th century by the British Aspdin, who gathered on the road near the city of Portland Dust, made briquettes from her, which later are a glutton.

Cement plants, as a rule, have their careers of the necessary material - clay and limestone. This allows you to withstand the necessary chemical composition of the charge with a high accuracy of 0.1 percent, which is of great importance. They burn the shiht in rotating furnaces, which have a diameter of 3.6 - 7 meters and a length of 100,150 meters. The temperature in the sintering zone is maintained at the level of plus 1450 degrees Celsius.

The sintering product is the clinker, which is rounded granules, the diameter of which reaches 5 - 100 millimeters. The clinker is waved in ball mills to a specific surface of 3,000 square centimeters per 1 gram. Without fail, 5% of the two -water gypsum is added with a paraple, which plays the role of the setting time regulator. Without a gypsum, the so-called cement-bastard is formed, which instantly grasps, and from which the dough cannot be prepared. All clinker minerals are able to interact with water and form new compounds - hydrates. Hydrates form a spatial structure creating a cement stone.

The use of cement in construction

Cement is used to build a foundation and manufacture a solution for laying bricks, filling the screed in the installation of floor, creating paths and blinding. It is used for prefabricated and monolithic concrete, which serves as raw materials for reinforced concrete, asbestos -cement products, various artificial materials, solutions, fastening individual parts of structures, and anti -insulation. Large consumers of cement are the gas and oil industry.

Cement and building materials that are obtained on its basis are able to successfully replace in construction a scarce tree, lime, brick and other traditional materials. A little later we will talk about how to make cement with your own hands and a cement solution. The use of cement in different construction sectors is closely related to its technical characteristics. Let us consider this connection in detail.

Frost resistance is a property that characterizes the ability of the material repeatedly freezed and thaw for a long period. Pure cement does not have this ability, it receives this characteristic thanks to various modification additives. If you live in the cold lane of the country, and for you it matters high frost resistance of the structure, then you should choose hydrophobic cement 500.

Corrosion resistance determines the ability of cement to withstand almost any aggressive factor of the external environment. Increased corrosion resistance is characterized by pocolane cement, which is intended for the construction of underwater and underground structures.

Sulfate resistance is the property of the powder, which allows the construction mixture to be stable in the aquatic environment that contains sulfate ions. This property was embodied in sulfate cement, which is used for the construction of hydraulic fires that are subject to salt water.

Water resistance as a characteristic of cement has found application in a waterproof expanding cement. Cement is capable of increasing in volume when hardened, the setting process is performed quickly enough in about 10 minutes. Waterproof expanding cement is required to seal joints and seams in concrete structures that are located in water.

The thinness of the grinding is attributed to the characteristic that affects the time of grasping, hardening and concrete strength. The greater the thinness of the grinding clinker, the higher the strength of hardened cement will be. It should be remembered that too thin grinding provokes excessive water consumption and decrease in concrete strength instead of excellent characteristics.

Making a cement mortar with your own hands

If you want to minimize the costs of repair work or construction, you should forget about ready -made mixtures, the price of which is much higher than the cost of cement and sand, which are necessary to obtain an equal volume of cement mortar. First of all, for the preparation of the solution, you need high -quality cement. We have already talked about the right choice of this material in the previous article. Let's talk about how to make cement and its solution at home.

Cement at home

The production of cement at home allows you to get this irreplaceable material in construction when using the minimum number of resources and endow it with the desired characteristics. We offer to get acquainted with the popular methods of independent manufacture of cement.

The putty for the sealing of cracks and cracks in the flooring is made in this way: mix lime with coal ash and dilute with water until the consistency of oily sour cream is formed. For the manufacture of a cement designed for putting iron utensils, wells, steam boilers and holes in metal products, take forty parts of baritic white, thirty parts of graphite dust, fifteen parts of lime and mix the resulting mixture to the required density in linen oil with the addition of varnish.

For attaching iron in the stone, make cement with your own hands from the following components: sand (20 parts), kaolin (2 parts), grinding chalk (4 parts), fierce lime (3 parts), liquid glass (15 parts), mix everything until homogeneous Test -shaped mass. For ceramics, you will need the following preparation cement: rub 2 parts of bastard lime with 5 egg proteins, dilute the mixture with 2 parts of water, rub with 10 parts of the gypsum.

For the preparation of cement for stone, it is recommended to mix with each other 10 parts of sulfur and bitumen 1 part of bee wax. Melt the mass, then add 2 parts of brick powder. Immediately before applying the solution, dry the stone and lubricate with olifa. For pipes, mix in a heated mortar 15 parts of olifa or linseed oil and 85 lead oxide until a plastic mixture is obtained.

For the production of glycerin cement, you need a lead glue, which should be diligently rubbed into powder and dried at high temperature. Mix the dust with glycerin. The technological characteristics of cement made according to this recipe are several times more than the characteristics of the factory Portland cement. Such material is characterized by high density and the level of resistance to negative influences of the external environment.

Home glycerin cement is absolutely not afraid of high temperatures: it is able to withstand the increase in temperature even to plus 300 degrees Celsius. Another important practical characteristic of glycerin cement is the ability to firmly glue objects of porcelain and faience. It is safe to say that this material is a real perfect cement.

Europeans have recently invented a new way of producing cement, which has unique characteristics. A similar Chinese cement is able to glue the skin, gypsum, marble, porcelain, faience and other materials. For the preparation of cement, the following components are needed: flashed lime (54 parts), quartz (6 parts), fresh blood! (40 parts). The resulting mixture must be thoroughly grind until a homogeneous mixture is formed.

Preparation of materials

The first stage in the manufacture of cement mortar preparation. Choose a container in which you will breed cement. The volume of the container must necessarily correspond to the volume that is planned to be made. If the dishes are less than the planned volume, then you will probably select the solution from the ground. If the container turns out to be too large, then you will not be able to create a uniform mass that will not get into lumps.

In addition, you need a fairly stable container. Pay attention to how strong the walls of the container are. It is also not recommended to take a container with low thin walls, because they do not allow to mix high -quality solution. The best solution at home will be the old cast -iron bath.

In addition to dishes for the resulting mass, you will need a special tool for the most convenient creation of the solution. It is usually customary to use a special construction mixer, however, our skillful compatriots adapt the usual drill with nozzles for this purpose.

Preparation of components

If a bag of cement has been stored in your garage for many years, it should be abandoned. To obtain a quality solution, the technical characteristics of sand homogeneity, purity and lack of impurities are also important. The best option is washed career sand.

Before work, place all the necessary tools and materials in maximum proximity so as not to be in an uncomfortable situation when you need to run after the components of the solution. Next, it is necessary to sift a powder for the manufacture of a cement solution in order to avoid the formation of lumps and getting into a mass of garbage, which significantly worsens its astringent properties and quality. When preparing a cement solution for plastering, you need to use a sieve with cells of 5 by 5 millimeters, for stone - with cells of 10 by 10 millimeters.

After that, the ratio in the composition of the solution of each element should be determined. At this stage, it must be remembered that the admixture of sand when using high -quality cement should be insignificant or nominal. Also, remember the classic ratio that builders are used for a long time: 1 part of the cement is customary to mix with 3 parts of sand. All incoming components are usually measured using certain dishes or scales.

During construction, it is often necessary to prepare cement not according to the traditional recipe, which is adopted at all world construction sites in the world. Non -standard mixtures are obtained thanks to various impurities. They are able to change the properties of a cement solution, for example, change the speed of solidification of the substance or slow down the speed for prolonged work with the solution, improve the characteristics of the viscosity of the mass so that it turns out to be plastic and more supple to work in complex areas.

There are such varieties of cement solutions: normal, fat and skinny. A fat cement mortar is a mixture that contains too many connecting components. This solution is able to harden quickly, but after use it dries and forms cracks, therefore it is short -lived.

A normal cement solution is a mass where the proportions of the elements are observed correctly. A similar solution does not freeze too quickly, but cracks are not formed in it, it is strong and durable. The skinny cement mortar is a mass in which the binder is not enough, such a solution will not be taken if you do not decide how to dilute the cement.

Regardless of the recipe for the preparation of a solution of cement, such a mixture is considered to be qualitative, which does not spread in the process of work and is characterized by a high or average viscosity level. At the same time, the mixture should not be too dry with this, as this provokes the loss of fixing qualities of a cement mortar, masonry in this case does not hold.

Preparation of the solution

So, pour a layer of cement into the container, then a layer of sand, then again cement and then sand again. The number of such layers should be at least six, this will make it possible to mix the components. Cement and sand are poured in layers in the form of a bed to a total height of about 200-300 millimeters.

First, mix sand with cement correctly. Shift this bed several times with shovels until smooth. When mixing, do not forget about the concept of intensity. Without a specific technological procedure for mixing, you cannot get a quality solution. It is recommended to sift the mixture through a frequent sieve, which has cells size 3 by 3 millimeters, but no less. The uniformity of the mixture should be close to the absolute.

You can not add water and other liquids when you mixed dry components. Adding a liquid to the resulting mixture should be carried out gradually and very carefully. Pour in the water slowly so that the mass receives the desired consistency. If you have more water than required, then it is gradual infusion that will allow you to stop on time.

Remember that the fluid temperature should not be too high or extremely low. Take the water of the optimal temperature regime, that the environment. Masonry requires the preparation of a more thick solution, and the filling process is more liquid. Do not knead a lot of cement solution at once, especially if you used wet sand. Now you know how to make a solution of cement at home.

And finally, remember that a cement solution is a material that cannot be stored. This is due to the high properties of the viscosity of cement, so the solution is able to freeze quickly and turn into unsuitable for use for construction work. The composition that you received after proper mixing is available for another hour when using wet sand and up to three hours, if you are dry dry sand.

An article about cement is simply

An article about cement is just decayed. I neighed heartily. "Mix the slaughter lime with this and that and that and that and that and that ..." Even the slagged lime is simply impossible to buy now. And about the addition of freshly living blood to the components of the English method, this is not treated. When will fools translate on the Internet?

To begin with competently

"First, mix the sand with cement correctly." And then "you can not add water and other liquids when you mixed dry components." Mix or not?