Ready -made greenhouses from ideal aluminum profiles and cellular polycarbonate, undoubtedly ...

|

|

What do you think about to make repairs? That it is already scary to enter the apartment ... |

The choice of the finish coating for the room is the final step in the repair. Decor... |

Roof waterproofing: materials, requirements, installation

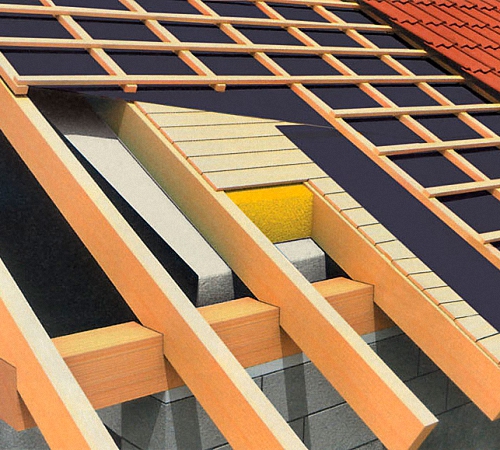

High -quality laying of roofing materials provides for insulation and waterproofing to protect the structure from the negative effects of atmospheric precipitation and external environment. The lack of waterproofing of the roof leads not only to moisture penetration, but also violates the integrity of the overall roof structure. This leads to the appearance of dampness and adverse microflora in the attic, and also reduces the life of the entire roof.

Table of contents:

- Varieties of roof

- Typology of modern waterproofing roofing materials

- Basic requirements for roof waterproofing

- The selection of materials for waterproofing roofs of various types

- Main recommendations for choosing

Varieties of roof

Considering the features of the installation of the roof and its reliable waterproofing, it is important to figure out what types of roof and varieties of roofing materials are. The solution to moisture is largely dependent on these features.

On the constructive features of the roof there are:

- non -shaped (not ventilated, ventilated and partially ventilated);

- attic type (broken, with a living room inside, single -level and two -level, with a remote console, etc.);

- attic type (insulated and cold).

Attention: waterproofing of a cold roof or insulated varies in choosing materials and the number of layers! It is better to entrust the warm roof to professionals. In cold cottage roof, waterproofing can be done independently.

In private low -rise construction, the most commonly used gable and hull four -sided roof types. Today, architects also often offer other types of roof. In general, they are classified into:

- hollow -sloping (flat);

- single -sided;

- gable;

- four -sided fake (2 trapezes and 2 triangles I go to them);

- semi -vapor;

- tent;

- pyramidal;

- multi -plot (yend, with several angles);

- broken;

- dome;

- conical.

There are significant differences in the installation of a gable, complex shape of the roof and flat roof:

- according to the method of general arrangement;

- at the choice of roofing materials and protection against weather factors. All work on the waterproofing of the roof must be carried out according to the instructions attached when buying the material. 5 main types of building materials for waterproofing are distinguished by varieties of the waterproof layer;

- film polymer membranes;

- rolled;

- mastic (viscous);

- leaf;

- piece (type).

Attention: the choice of materials and the quality of waterproofing laying affects protection against negative external influences and whether the condensate will accumulate in the under -wrapping space. Therefore, it is also important to take care of the ventilation of the roof!

Typology of modern waterproofing roofing materials

Waterproofing materials are divided into subspecies relative to the shape and release and installation methods:

- hydrophilic (water -repellent) leaf rubber;

- a hydrogen-barrier film (perforated);

- anti -condensate film membranes;

- other polymer superdiffusion and spike -shaped membranes from PVC and EPDM;

- sprayed waterproofing (two -component acrylate composition, liquid rubber, polymochevin);

- 1- and 2-component coating mastics;

- injection and waterproof emulsions and resins;

- penetrating or penetrating emulsions.

1. Membrane coatings are widely used in the arrangement of roofs of public buildings, warehouses, workshops and industrial buildings on a solid base with a small slope. This is a film made of elastic polymer material resembling thin tires. It has high strength even with high stretching and resists with various contacts and punctures. An important advantage of simplicity and installation speed, which explains the demand for membrane packages for waterproofing work on the roof. It is convenient to transport them and raise them to the roof during installation. In place they are unfolded, laid on the base, and their edges are joined with special self -vulcanizing stripes during closing. Such a roof can last at least 35 years.

2. All types of roller roof are available on the basis of polymer or bitumen materials on a dense basis. A cardboard, synthetic substrate or film substrate acts as a reinforcing basis. Since ancient times, the most popular types of waterproofing remain:

- ruberoid,

- permamin,

- only.

They are known for accessibility and practicality, but belong to the category of short-lived materials due to a cardboard basis. However, they were universally used for laying slate and sheet roofing iron. But they have low frost resistance and strength strength, but they are lined where the use of other materials is inappropriate. Rolled materials can be laid in 2-4 layers and glued.

Bitumen-polymer waterproofing materials of later generation, based on fiberglass or industrial polyester. They differ in greater frost resistance, are not susceptible to temperature differences and are distinguished by the best indicators for heat resistance relative to the felts and roofing material. They do not have stratification and cracks, respectively, the service life is longer. They can be fused on a concrete or metallic base or glued with mastic for the waterproofing of the roof.

3. Mastic waterproofing belongs to the existing type of surfaces, which are formed by processing by the composition of a solid base. These are bitumen, polyurethane, acrylic, silicone and rubber mastics, which are effective for obtaining a continuous rubber -like elastic film on the horizontal surface. It is most convenient to use liquid waterproofing of the roof on adjacent surfaces in areas with an unfavorable climate. It withstands the temperature amplitude from 40C to +100C and remains strong and elastic. A small specific gravity makes it indispensable on the roof, where a large load is undesirable.

Pouring waterproofing is a two -component or one -component viscous mixture, which is poured onto the surface with a small slope, on a flat roof or to where the mixture should go around the streamlined roof plane. This kind of mixtures are known for high adhesion relative to metal, concrete, asphalt and bitumen materials. Liquid waterproofing is resistant to intensive temperature loads, aggressive environments, does not respond to oxidation and other chemical reagents.

Basic requirements for roof waterproofing

If for any reason, work on the waterproofing of the roof was not qualitatively performed, this must be done at the first opportunity in the warm period or during a forced roof repair. The more carefully this work is done, the longer the roof will last without the penetration of moisture into the building. Properly completed work, although it involves certain expenses, but subsequently this will make it possible to save on the repair of the entire building.

The choice of materials for waterproofing the roof depends on different factors, including the type of roof, but they must provide the roof:

- strength,

- water resistance,

- moisture resistance,

- resistance to temperature drops,

- air circulation,

- heat saving,

- protection of the integrity of the structure.

The waterproofing of the roof should reliably protect the structure:

- with a strong gust of wind,

- with a long shower,

- from the snow cap melting on the roof,

- when a large city is falling out, followed by active melting, and other adverse atmospheric phenomena.

The construction market today offers a large list of quality materials for competent and quick installation of roof waterproofing. However, you should not wait for such adverse factors to think about waterproofing how well you have done these works will show any watering. Particularly important is the waterproofing of a flat roof and the provision of sanitation, as an important indicator of its arrangement. The more reliably all these works are done, the less often you have to correct the roof, no one wants to carry out roofing work annually or after each leak of the ceilings.

The selection of materials for waterproofing roofs of various types

Bitumen materials today are very common in the modern construction market, and the bitumen waterproofing of the roof is also very in demand, especially for the arrangement of flat roofs. Morally obsolete roofing material and only fade into the background, but are used by some masters. The materials of the new generation, such as polymer-bitumen coatings, have much more advantages. Modern bulk and melted materials have:

- reliable base and chemical formula,

- indicators of high strength and elasticity,

- protection against stratification and decay,

- long service life.

1. The wave slate is considered relatively durable material, since it is made on the basis of Portland cement and asbestos. Sometimes it is painted, that is, it is covered with a special composition not only for decorativeness, but also to extend the service life. This layer reduces water absorption, which makes it possible to save on the number of waterproofing materials for it any roller varieties are suitable.

2. Gapling or steel roofing sheet can be smooth and corrugated refers to the most durable materials. Under ordinary environmental conditions, at least half a century will last, that is, enough for a whole generation of living in the house. Roof metal is also painted to increase the service life, and the folding connection itself protects quite well from moisture, so here it is worth taking care of ventilation of the waterproofing layer.

3. Euro-shifer (Ondulin, Akvalin and other firman names) are bitumen-cartoon sheets with a special pigmented polymer with a decorative protective layer. Fragments are laid out on a layer of membrane waterproofing, and the elasticity of the material allows you to form a broken slope. However, it is less durable with all its advantages, and the ease and ease of styling makes it as combined with any rolled waterproofing.

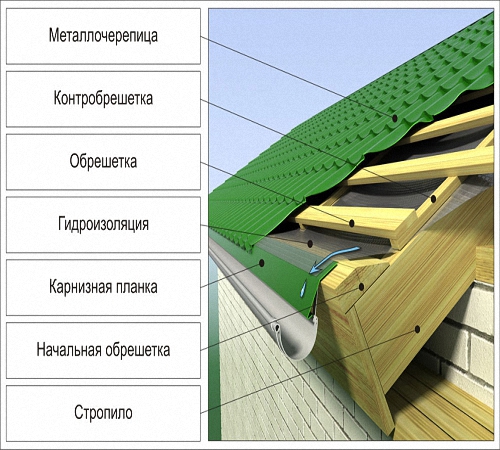

4. The metal tile is not related to ordinary ceramic tiles, but the small size of the roof sheet gave this name to steel galvanized sheets with a colored polymer coating. This highly decorative coating often imitates natural tiles, but has a slightly different type of laying and waterproofing. The material itself is well protected from the effects of moisture on the roof, but it creates an additional noise during a rain, hail and snow movement. In addition to the simplest waterproofing, it requires sound insulation, so it is undesirable to use on an irreplaceable roof.

5. Other piece roofing materials (porcelain, Tes, Tes, Dranka, Clanet, Gont, Soft Tiles) belong to environmentally friendly materials and have a lot of advantages. Such a roof has high aesthetic properties, but it costs an order of magnitude more expensive. The shale roof is quite elastic, but heavy, so it has not been widely distributed, but it is indispensable for the roofs of a complex streamlined shape. For piece materials, it is imperative to make reliable continuous waterproofing.

Today, waterproofing roofing with mastics and roller materials are effective on all types of roofs. The choice of material and the number of waterproofing layers depend on the slope of the roof. They are applied to solid grounds:

- wood,

- concrete,

- metal,

- old coating.

Main recommendations for choosing

1. Polymer membranes relate to new technologies in the building materials market, this is:

- diffuse membranes (there are superdiffuase, anti -condensate, with perforation),

- PVC membranes,

- PDM membranes.

Modern membranes have microperforation, which ensures thermal insulation and counteracting the formation of condensate.

Tip: Use superdiffusion membranes for waterproofing a warm attic or attic, for example, under a metal tile or other piece roofing materials.

2. Crystal waterproofing as a rule, based on bitumen, these are polymer rubber -like mixtures. The materials over time lose their elasticity slightly, but this is noticeable only with mechanical exposure. Such mastic for waterproofing the roof is applied with a layer of 5 mm to 5 cm. According to the application method, they are divided into heated or hot and cold mastics. The mixture is poured on a flat roof or on a surface with a small slope. The viscous medium adhes well with a solid base, forming a seamless coating resembling rubber.

Tip: bulk waterproofing is one of the most progressive types of roof arrangement.

3. Penetrating waterproofing is indispensable for working with porous materials such as foam concrete, limestone blocks, etc. This impregnation fills the voids and small pores well, preventing water from the help of:

- liquid polymers,

- molten bitumen,

- liquid glass,

- synthetic resins.

They are applied with a spray on a low -fat and well -purified surface of building materials. The resulting structure repels water and fastens the crumbling surfaces.

4. Rolled adhesive waterproofing is one of the first methods where the layers of roofing material, or Tolya were soldered with each other. Today, the basis is made of polyethylene, isoplast, viniplast, polyhlorvinil, ecoflex and isoelast are most in demand. After cleaning and leveling, the surface is opened with a layer of bitumen primer and the material is glued. This requires accuracy so that the rolls do not disperse to the sides. Upon completion of the work, it is recommended to sprinkle the upper layer with granite chips.

Tip: the waterproofing of the roof with your own hands in a country house or a country house is easiest to do in this way, especially under the slate, on a dry surface. Therefore, such a work should be planned in hot weather without rains.

5. Coloring waterproofing method for applying special protective varnish emulsions using a construction spray gun or roller. Usually this is done not in 2 layers for uniformity and strength. It is also recommended to disperse the sand on top of such isolation to compact the layer.

Tip: If there is no ability to make waterproofing in any other way, then use this technique.

6. Waterproofing film The simplest type of insulation used for pitched roofs for piece materials. This is a great choice for the pitched roof, an insulated attic and attic rooms. It is laid in the direction of the skate from the cornice. With a small angle, an overlap is an overlap between the canvases of the waterproofing film.

Tip: Follow the styling so that the membrane does not pull excessively and sagging slightly.

All waterproofing roofing materials are laid according to the attached instructions, an example of a video.