The bulk roof is usually used in the construction of household and industrial ...

|

|

Plastic windows firmly take a leading position. They are distinguished by a high level ... |

Like any ceiling coating, drywall ceiling is required over time ... |

Geotextiles: characteristics, application, styling

The modern world is very demanding on the characteristics of materials. Everyone is trying to choose something better, innovative, reliable and natural. That is why manufacturers are increasingly moving away from synthetic products, or offer excellent substitutes for natural substances. This applies to almost all spheres of life, from households, everyday life, and ending with construction products. Geotextiles became one of such modern materials that combined the properties of natural products and high technology. Its main purpose is water filtration and the separation of soils. It is not replaced when working with any kind of soil, perfectly retains and strengthens the slopes, and is also used in the construction of dams. The article will talk about the use of geotextiles.

Content:

- Geotextile canvas, types and characteristics

- Advantages and characteristics of geotextiles

- Laying geotextiles

- Geotextile assortment and prices

Geotextiles are considered the best choice in cases where it is necessary to mount any hermetic underground structures and not worry that sharp stones will be able to break through the protective layer. The product is used in the construction of buildings and houses, roads, landfills or other underground storage facilities, as well as various other structures.

There are several types of geotextiles by the manufacturing method. It is worthwhile to analyze in more detail the classification of this material and its basic properties.

Geotextile canvas, types and characteristics

A non -woven canvas of synthetic fibers, which outwardly very reminiscent of fabric, is commonly called geotextiles. It is produced in large rolls, and is produced from polypropylene or polyester fibers, which are pressed, forming a single structure. The product differs in a small cost, but at the same time, excellent performance characteristics and a long service life.

The scope of the material is quite extensive, it is used in construction and in the furniture industry, in gardening and in the household. The geotextile canvas can be divided by the scope of use.

- Drainage geotextiles- is used for the device of the drainage system or for winding drainage pipes;

- Furniture geotextiles used for internal upholstery of upholstered furniture and in the production of mattresses, as well as a protective layer during transportation of furniture sets;

- Garden geotextile In this capacity, it is used to create greenhouses, as it perfectly protects against frost, as well as from direct sunlight, in addition, it is often covered by the Earth around cultivated plants to reduce the number of weeds;

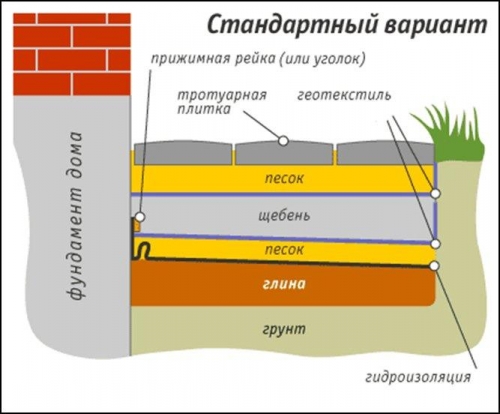

- Construction geotextiles Such a variety is used for construction purposes, for waterproofing the foundation or basement of the house, paving slabs are laid on it, and also used in road construction;

- Packaging geotextiles- It is used as a packaging material for equipment, shoes, clothes and other substances and elements.

This classification does not give an idea of \u200b\u200bwhat geotextiles are created from. So, according to the manufacturing method, modern manufacturers offer several main types of geotextile material:

- needle -punched geotextilethat can be reinforced with geosets or duplicated with a geomata;

- thermaced geotextiles;

- woven geotextiles.

In Russia, most construction companies, and ordinary consumers prefer to use thermaced geotextiles, while abroad prefer to most often use the needle -punched one. This is due to the fact that thermacious material, although it has high breakdown, but in fact, this characteristic does not guarantee long operation.

- The thing is that such a canvas is not able to efficiently filter water from the soil containing clay or small sand. Particles clog the structure of the product, and the water does not pass inside, but erodes the upper layers of the soil. The acupuncture geotextile has more elastic pores through which the liquid passes freely, even if the material is used on clay soil.

- This means that the thermos -fast geotextile can only be used in cases where the soil does not have finely dispersed particles, that is, as a drainage system, as well as to strengthen slopes. While acupuncture geotextiles are more universal material, especially in cases of enhancing geogrids.

- Geotextiles made of polypropylene, which is the most durable, reliable and resistant to chemical effects, are also distinguished. And made of polyester, which is considered not so resistant to chemical reagents.

And another species that deserves attention can be called geotextile mixed with the addition of recyclables (wool, cotton fiber, viscose), has a low cost, but, however, is not very reliable. This is one of the most natural and environmentally friendly geotextile materials, which, unfortunately, quickly fails during operation, as natural fibers rot from contact with water.

Needle -punched geomaterial

- It can consist of both polypropylene fibers and polyester fibers, they are interconnected by an needle -resistant method. That is, the canvas is obtained by pulling the fibers with the help of jagged needles through layers of special material. Thanks to this technology, the product perfectly misses liquids, but only along and down.

- In Russia, a similar method is made such a material as Dornit. Its polypropylene is based on it. It is resistant to mechanical exposure and large loads, is not deformed during operation and has excellent strength. Most often used in road construction, landscape design and to strengthen slopes.

Thermo -fixed geomaterial (non -woven geotextiles)

- It turns out by fastening the fibers at high temperature. That is, the resulting canvas has increased strength, but can pass water in only one direction of the transverse. As a result, it is not recommended to be used for drainage device or in the road sphere, but optimally used to protect against weeds and for laying paving slabs.

- In Russia, geotextiles are produced by Technonikol. The material is made mechanically, and fastened with heat treatment. The company positions its products as reliable and strong and offers to use to strengthen the foundation, during the construction of pipelines, roads, to improve the drainage and as waterproofing.

Weaved geotextiles

- Otherwise, they are also called knitting and flashing, also consists of fibers of polyester or propylene, which in this version are stitched with threads. This is the least persistent type of product, as there is a risk of breaking the material. As a result, the canvas becomes worthless, as it ceases to cope with the main functions.

Advantages and characteristics of geotextiles

Geotextile material has many positive qualities:

- universal in application;

- resistant to decay;

- has high strength;

- resistant to chemical reagents, both acids and alkalis;

- has a long operational period and increases the service life of construction facilities;

- suppresses the growth of weeds;

- prevents the development of soil erosion;

- has filtering properties;

- accelerates water drainage;

- it has high resistance to ruptures (capable of lengthening to 45 %)

- has high elasticity;

- reinforces building structures;

- does not decompose and refers to environmentally friendly materials);

- has a low cost;

- reduces the consumption of materials during installation of structures;

- it is easy to use and styling.

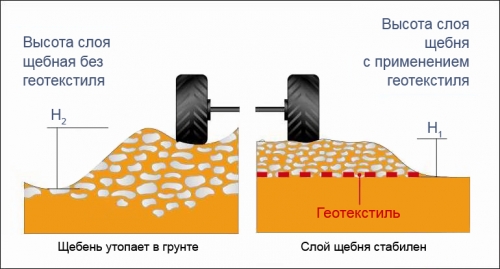

When using geotextiles, the cost of maintenance of structures is significantly reduced. Roads erected on grounds such as peat, clay or other soils with high humidity may not survive one season, if they do not previously reinforce them. Crushed stone used in construction, due to the use of the geotextile canvas, is not mixed with weak bases and reliably holds the motorway from destruction and deformation.

Geotextile materials are resistant to many external factors, including:

- to punctures (you can not be afraid to lay the canvas even in the presence of a large accumulation of sharp stones);

- to alkalis and acids (not susceptible to soils with any pH level);

- to ultraviolet radiation (which is especially important in cases of the device of roofing systems);

- to bioorganisms (fungi, bacteria and others);

- to soil waters.

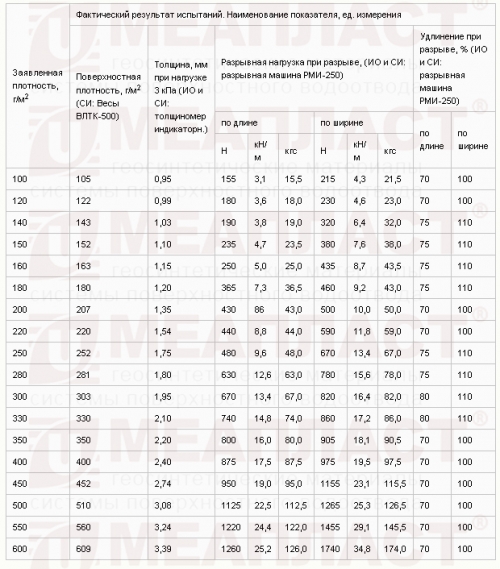

When purchasing a product, you should pay attention to such parameters as:

- density;

- compound;

- operational period.

So, the most popular material is considered completely made of polypropylene. The life of geopoloten can reach 100 years, no other similar material can compete with such durability.

Laying geotextiles

For the correct laying of the geotextile canvas, a certain sequence should be observed.

- So, the first step will be the preparation of the base. That is, the surface is aligned, if necessary, the upper layer of the soil is removed by several centimeters, and the opened soil is compacted. If it is impossible to achieve even the existing layer, then it is recommended to fall asleep the even layer of the sand and carefully compact it.

- The next step will be the flooring of geomaterial on an even and clean surface. The rolls are rolled up on the base with an overlap at least 25-35 cm. Such a measure is necessary that the material qualitatively copes with its main task. If it is not possible to achieve perfect smoothness of the base, then the overlap is made from 40 cm or more.

- Next, it is necessary to connect the canvases qualitatively. To do this, special brackets of plastic or metal are used, you can also use the cold welding method. The brackets require more time, so if you need quick installation, it is better to use just welding.

- In order to qualitatively connect the material into a single canvas, the edges of the tape are heated by a special burner, and then, a second sheet of geotextiles is applied from above and the seam is crushed to a short gap. This is enough to securely fix the product.

- The next step is to cover the geopolitan with the soil of the thickness that is required for each specific case. The soil rolls, but not too heavy. Next, the remaining materials are laid or appropriate designs are being built, according to the required technologies.

It is not difficult to lay geotextiles, it is important to choose the right material for a specific situation.

Geotextile assortment and prices

Geotextiles geotex

- Geotex 150 price from 214.87 rubles.;

- Geotex 200 price from 19.35 rubles.;

- Geotex 250 Price from 223.31 rubles.;

- Geotex 300 price from 227.97 rubles.;

- Geotex 350 Price from 32.63 rubles.;

- Geotex 400 price from 37.29 rubles.;

- Geotex 500 Price from 46.61 rubles.

Geotextiles Canland

- Canland 150 Price from 22.42 rubles.;

- Canland 200 Price from 29.90 rubles.;

- Canland 250 Price from 37.38 rubles.;

- Canland 300 Price from 44.85 rubles.;

- Canland 350 Price from 52.32 rubles.;

- Canland 400 Price from 59.80 rubles.;

- Canland 450 Price from 67.27 rubles.;

- Cannland 500 Price from 74.75 rubles.

Geotextile AVANTEX

- Avtex 100 Price from 12.50 rubles.;

- Avtex 150 Price from 14.70 rubles.;

- Avtex 200 price from 20.25 rubles.;

- Avtex 250 Price from 23.30 rubles.;

- Avtex 300 Price from 27.95 rubles.;

- AVANTEX 110 Price from 10.80 rubles.;

- AVANTEX 120 Price from 11.80 rubles.;

- AVANTEX 130 Price from 12.75 rubles.;

- AVANTEX 140 Price from 13.75 rubles.;

- AVANTEX 160 Price from 14.90 rubles.;

- AVANTEX 180 Price from 16.80 rubles.;

- AVANTEX 200 Price from 18.65 rubles.;

- AVANTEX 220 Price from 20.50 rubles.;

- AVANTEX 330 Price from 30.75 rubles.;

- AVANTEX 350 Price from 32.60 rubles.;

- AVANTEX 400 Price from 37.25 rubles.;

- AVANTEX 500 Price from 46.55 rubles.;

- AVANTEX 600 Price from 55.90 rubles.;

- Ecotex 200 price from 18.12 rubles.;

- Ecotex 250 price from 22.23 rubles.;

- Ecotex 300 price from 26.33 rubles.;

- Ecotex 350 price from 31.08 rubles.;

- Ecotex 400 price from 34.92 rubles.;

- Ecotex 450 price from 39.51 rubles.;

- Ecotex 500 Price from 43.60 rubles.

Geotextile geospan

- Geospan TN 100 Price from 2 207.75 rubles.

Geotextile Technohaut

- Technohaut GEO 60 Price from 700.00 rubles.;

- Technohaut GEO 100 Price from 1,148.00 rub.;

- Technohaut GEO 130 Price from 1,484.00 rub.;

Geotextiles Dorn

- Dornit 200 3x100 m price from 19.30 rubles.;

- Dornit 250 Price from 21.00 rubles.;

- Dornit 300 3x50 m price from 28.05 rubles.;

- Dornit 300 6x50 m price from 28.40 rubles.;

- Dorn 350 price from 33.60 rubles.;

- Dornit 400 6x50 m price from 37.45 rubles.;

- Dornit 400 3x50 m price from 37.70 rubles.;

- Dornit 500 6x50 m price from 46.50 rubles.;

- Dornit 550 3x50 m price from 49.50 rubles.

Before buying geotextiles, you should remember that it is different. Woven (obtained by weaving threads at a right angle), non -woven (obtained from polyester or propylene by needle -knitting and thermal fastening of threads) and even knitted (the so -called geographic flow, made by loop weaving). The canvas has high strength and durability.

The material is used in many areas, especially where the separation of soils, reinforcement, filtering or as drainage is required. It is used in medicine, in road construction, in agriculture, in the construction of houses, in the production of furniture and for packing various substances.

- The main properties include the fact that the product does not rot, does not change its qualities, even being in aggressive conditions, persistently to chemical reagents. The material perfectly misses water, but does not light up and not clogged with particles of soils. It retains reliability even at minus temperatures (up to -60 degrees) and with high (up to +100 degrees). Geotextiles are laid quite simple, and stripes can be fixed with each other both using special brackets and cold welding.

- Russian manufacturers offer their own version of the material, which is called Dornit. It is produced in rolls, the width of which is 150 cm and up to 5.3 m, and from 50 m long and to 150 m. The density of the product is different and varies from 90 and to 800 g/m2. You can use the canvases in many objects, when installing embankments, in landscape design, for drainage systems, in the construction of houses and roads. In terms of cost, it is Russian material that is the most profitable for consumers.

GC Meataplast

GC Meetaplast http://meaplast.ru/geotekstil-doronit/ produces an needle-punched geotextile with a width of 100 mm. This size is very convenient for work and ideal for landscaping.