The destructive effect of moisture is subject to all structural elements of the building that ...

|

|

Blok House came to us from Europe. Thanks to the beautiful appearance and good ... |

A warm floor is a great option for heating of any home. There are many systems and ... |

Foundation made of missile stone: construction technology

A botum stone was used to build a foundation and base, and in some cases walls, from time immemorial. This was due to its strength, as well as accessibility along with such building materials of natural origin as clay and wood. Bout synonym not only reliability, but also aesthetics. The article will talk about how to make the foundation of a missile stone with your own hands.

Content:

The main positive moments found the foundation made of bottle stone:

- environmental cleanliness;

- high moisture resistance;

- durability (constructions from a boot will last for several centuries);

- resistance to sharp temperature fluctuations, as well as resistance to vertical and horizontal loads;

- inappropriateness of destruction by exposure to fungus, mold and insects;

- small financial investments, but taking into account the close location to the stone career;

- great appearance.

Boutor stone photo

Well, from the negative sides, it should be noted:

- the difficulty of fitting stones for more dense placement;

- high time costs, including the selection of a bottle of optimal shape, kneading and pouring concrete solution.

Ward stone

- But is a stone with uneven edges. It can be obtained both by natural destruction of rocks, and through explosive work in career areas. The rock of the stone can be absolutely any: dolomite, shell -to -cash, sandstone, etc.

- The most convenient stone for arranging the foundation and basement is botnet. Such material has a flat shape and has relatively even planes of opposite sides. A bedby type of boot reduces labor costs by reducing the fitting of the masonry element.

- When choosing a stone, a visual inspection should be carried out: cracks, stratification or other defects should not be visible on it. Quality can be determined by a strong hammer on the surface of the butt, a sonorous sound in tonality, as well as the absence of any damage indicates the strength of the material.

How to make a bottle foundation

Bouto stone masonry solution

- The solution is kneaded on the cement of the M300, M400 or M500. With the use of such brands, the mixture will turn out to be a more dense consistency. The sand should be clean with the minimum content of extraneous impurities, their presence will reduce the strength of concrete even when using a high -minor Portland cement.

- 3 parts of sand are taken for 1 part of the cement. If a botarous foundation is being built, then it makes sense to add 3 parts of the crushed stone of the fraction no larger than 5x20 mm. A portion of water should ensure the fluidity of the solution so that it can fill the voids between the stones.

- When kneading, it is important to observe the proportions. The mixture should not be too thick, otherwise air bubbles can form when filling, which will eventually lead to the destruction of the supporting structure. But at the same time, the solution should not spread without a residue between the masonry elements.

- For work, you can use the finished concrete mixture. However, it is delivered in concrete mixers in rather large batches, which is not very convenient. After all, the selection of stones of a suitable configuration takes a lot of time and it is very doubtful that the technique will wait for the next series of bottle masonry will be ready.

Basic moments

- The maximum strength of a bottle strip foundation is achieved through careful selection of material and compliance with masonry technology.

- In order to increase adhesion, a solution and a boot with a solution and a boot, the stone is cleaned and moistened immediately before masonry.

- The voids between the stones are minimized. In addition to the solution, they are additionally filled with small stones or gravel of various fractions (mainly 40x70 mm).

- The thickness of the layer of the solution should not exceed 15 mm, with a larger indicator there is a possibility of subsidence of the structure with subsequent destruction.

- For the initial and final layer, a large glass bot with the maximum flat planes is used. In the first case, the lower row will serve as a reliable support for the entire masonry, and the grillage will be installed on the upper.

- When laying, the dressing should be observed, as when using blocks or bricks.

- Particular attention is paid to the corners of the foundation. The material should have no cracks and heterogeneous intersperses, since they will be entrusted with a high load -bearing load.

- During the work, take care in advance about all technological holes (ventilation, outlets, sewage, etc.). Otherwise, after solidification, it will be very problematic to make them.

For work you will need:

- a sledgehammer, which is necessary for the plinths of large stones weighing up to 30 kg;

- a hammer. With its help, a chip of sharp corners is carried out, as well as a boot sediment in the masonry process;

- shovel for kneading the solution;

- master OK;

- building level for measuring operations;

- bchevka, plumb and roulette.

Training

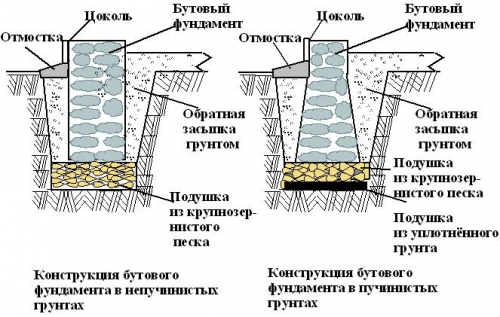

- Before work, geological surveys are carried out, on the basis of which the type of soil is determined. It is not recommended to use a boot for the foundation built on heaving, clay, peat and sand soils.

- First, clearing the site is carried out: garbage is removed, stump is uprooted. For the construction of light buildings, it is enough to remove the soft layer of soil (approximately at a depth of 5-10 cm). With the help of driven pegs and stretched twine, lines are marked for the future foundation.

- In preparation, it is important to pay attention to the horizontal relief. If the height difference is minimal, then alignment is carried out by uneven removal of the soil layer. With significant irregularities, the body of the foundation under the horizon is adjusted during construction, by raising at the necessary points.

- If it is planned to build a solid house made of wood or brick, then the depth of the trench can be from 50 to 100 cm, this indicator depends more on the type of soil. The presence of weak soils implies a greater depth of the moat. If necessary, the formwork is equipped, which will prevent the sowing of the earthen walls. As for the width, it should exceed the actual width of the walls by 10-15 cm. On each side, but the minimum indicator is 35 cm.

- The compacting layer is a compacted sand, the height of the pillow should be at least 15 cm. The presence of waterproofing will be useful, here you can take ordinary sheets of roofing material that is laid overlapping. This material prevent moisture leakage from a poured concrete mixture.

Laying of bottled stone

- Ward material is laid in rows of the same height, while the presence of a large stone overlapping in a height of 2 rows is allowed. The work is carried out on the principle of brickwork, that is, the dressing must be observed. Of course, it is impossible to achieve ideal, but, nevertheless, the stones must be selected with special care in width and height.

- It is allowed to lay a boot alternately with a short and long side (poking and spoon). Then, later, spoon and vice versa are laid on the tech rows. If necessary, the crushed stone is filled with the resulting forms of germs of emptiness. Pebbles can be used as peculiar wedges, they are beaten with a hammer at the right point.

- The laying of each row begins with the installation of lighthouse and corner stones that will set the height of the entire strip. Tw offers are pulled along them, which serve for a guideline and observance of straightforwardness during masonry work.

- The lowest row is made of a bedstot. Large and relatively flat stones fit dry. The most flat side should be turned down. Voids are filled with gravel or torn stones.

- Stones fitting for a stable position in masonry are first carried out in dry, taking into account the standard height of the row (25-30 cm). After the joke, the boot rises and part of the solution is supplied. The material is seated in place with a sledgehammer or hammer. There should be so many sand and cement mixtures that when pressed on the material, he can fill in vertical seams. Thus, the foundation will gradually acquire the desired height.

- You can make the foundation more durable and reliable through a step design. For this, the trench is 2 times wider than the carrier wall. A bottle stone is laid according to the previous technology. The difference lies in the gradual narrowing of the bearing base. Concessions are performed at least than every 2 rows. Two or three steps are enough to increase the bearing capacity several times.

- Pantry are necessarily accompanied by regular measurements of horizontal and verticalness through a level or laser. Until the solution has been frozen, the location of individual elements is adjusted.

- At the end of the work, waterproofing the upper part of the foundation is performed and a blind area is built, which will protect the structure from the adverse effects of rains, dew and meltwater flowing from the roof. The drainage system is without fail, which will ensure the removal of excess moisture from the structure.

Button masonry

- This technology can significantly reduce both time and strength to build the foundation. It is worth noting that the method for filling is suitable only for non-set soils, under the buildings of the erected no higher than 2 floors. It is better to build the foundation in one breath, that is, avoiding breaks.

- The depth of the trench in this case must be increased with the calculation of the styling to the bottom of the sand pillow (10-15 cm) and the layer of crushed stone fraction of 20x40 mm (10-15 cm). A non -removable formwork is necessarily performed, the walls of which must be carefully strengthened and provided with spacers, especially in the corners.

- This technology allows you to additionally use the battle of brick, gravel and crushed stone of a large fraction. A distance of about 5 cm is left between the stones and walls of the formwork. This is necessary so that the material is seized with a concrete mixture, forming a monolithic structure.

- Despite all the simplicity of the process, you cannot throw stones into the trench and then pour a sandy-cement mixture. The chaotic location will reduce the strength of the structure, and therefore its bearing abilities.

- As in ordinary masonry, the boot is used only in clean and moistened form. A layer of solution is spilled onto the bottom of the trench, after its drying, a glass material is laid out, forming an almost even and stable base. The lower layer is covered with a sand and cement mixture, into which the next row of stones is pressed. The material laid should drown at least 2/3 of its height.

- Ideally, each layer is processed by vibration equipment. Pressing allows not only to compact a boot, but also to prevent the formation of air bubbles. If there is no way to use equipment, then work is performed manually. For this, the largest stones are slightly lifted by a bayonet with a shovel or crowbar. Each row is laid with wire, metal rods or reinforcing mesh.

- Although this method involves the use of stones of arbitrary shape of their width (diagonal) should not be more than 2/3 of the width of the structure under construction.

- If for some reason it is necessary to interrupt construction work, then it is recommended to fill out only vertical seams with a solution. When pouring a whole row after the resumption of work in the frozen mass, large notches are made, fragments and dust should be removed.

Foundation made of missile stone video

- The masonry is covered with a wooden flooring or any roller materials to protect against premature drying. This method is especially relevant in windy or sunny weather. If possible, the first few days, the unfinished foundation is moistened with water.

Popularity of the HAPP pipes

The popularity of the pipes of pipes is explained quite simply - despite the wide variety of modern polymeric materials, often their use is not possible.

Read more:

https://steel-pro.ru/trubi/truba-vodogazoprovodnaya/

Thanks for the useful

Thanks for the useful information