The most original solution for creating a non -repeated atmosphere in your house is ...

|

|

Despite the popularity of suspended ceilings or multi -level, complex structures, ... |

To improve the setting of the attic, it is recommended to make it comfortable and bright ... |

House finishing block house: step -by -step instructions

Blok House came to us from Europe. Thanks to the beautiful appearance and good technical characteristics, I gained popularity. The building material is made of wood or materials copying natural wood.

Consider the design features of the facade finished by the block with a house, and describe the sequence of the line of the house with wood panels.

- Siding Block House: Design features

- Advantages and disadvantages of different types of House block

- How to choose a material for finishing the house block house

- Rules for the installation of lamellas Block House

- Facade of the House Blok House: Phased Stage

- Finishing block house inside the house

- Processing and care for panels of the House block

Siding Block House: Design features

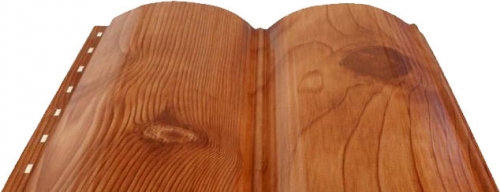

Block House Popular building material used in the external and interior decoration of the walls of the house. The surface that is sheathed by the block with a house resembles a wall trimmed with a natural tree. The elements are made of wood or galvanized steel covered with a polymer film, the shape of the elements - double or single logs.

Boards for the skin have a convex front wall and flat rear. On the ribs there are spikes and grooves for docking elements.

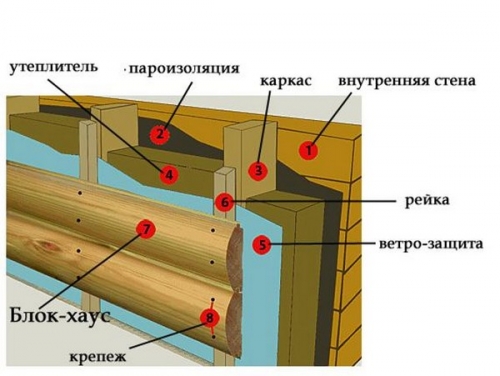

Before proceeding with the arrangement of the house from the House block, it is necessary to understand the device of the ventilated facade of this type. The design includes mandatory elements:

- Democration - protects the insulation from humidity vapor. The vapor barrier misses steam in the direction of the wall, preventing him from penetrating to the insulation.

- The crate creates a cavity between the wall of the house and the block of house, serves as the basis for fastening the rails. The crate is made of a wooden beam with a cross section of 100*40 mm or 50*40 mm (depending on the type of thermal insulation material). This structural element acts as a frame for attaching the House block.

- A layer of thermal insulation foam, mineral wool, etc. The thickness of the insulation should be at least 10 cm.

- The windblastic is mounted on the bar of the crate and additionally protects the insulation from the humidity contained in the air.

- The counterpart provides the space between the windmill of the wind protection and the block house. The counterpart is made of a small cross -section bars - 20*40 mm. If you neglect this element of the facade structure, then the wooden lamellas of the House block will quickly rot.

- External sheathing Block House.

The device of the line of the house Block House: photo

Advantages and disadvantages of different types of House block

The main criterion for the classification of the House block material is made. For finishing work, wooden, metal and vinyl panels are often used.

In the production of a wooden block of House, coniferous and deciduous woods are used (cedar, pine, Siberian larch and spruce). Such types of wood are resistant to decay and last a long time.

Wooden lamellas are made using this technology:

- The logs are sawn the square in a circle. The result is four blanks.

- The blanks are placed in a drying chamber.

- Drying lasts about 2 weeks. If you dry the wood in a natural way, you need about 6 months.

Block House made of wood has several advantages:

- strength surface of the panels withstands high mechanical/physical influences, without losing its original appearance;

- the damaged element of the finish can be restored or replaced;

- the material has a slight weight;

- ease of installation;

- environmentally friendly material;

- the walls sheathed with a wooden block with a house breathe - a favorable microclimate of the room is created;

- block House additionally insulates the house;

- high decorativeness and attractiveness of the wooden facade.

Block House made of wood needs regular cleaning and varnish processing these measures increase the moisture resistance of the material and extend the life of the sheathing

The facade is often finished by metal sheets of the House block, which have some features:

- the building material is made of steel with a thickness of at least 0.5 mm;

- the steel case of the element is covered with zinc;

- from the inside, the metal plate is processed with a primer and paint, and a pattern imitating natural wood is applied to the front side of the House block;

- the main advantages of the metal facade are durability and high strength; The House type block withstands temperature fluctuations, resistant to moisture and does not change its characteristics under the influence of adverse climatic conditions;

- the House metal block has different shapes in one or two logs.

The composition of the vinyl panels includes protective strengthening components and additional plasticizers. The House vinyl unit has many advantages of wooden panels, but it is stronger, cheaper and is produced in a wide range.

How to choose a material for finishing the house block house

The choice of the House block is not easy. Boards differ among themselves not only in manufacturing, but also in other parameters. When buying lamellas, it is advisable to be guided by the following advice of specialists:

- For facade work, it is necessary to use boards with a width of at least 15 cm, it is desirable that all the lamellas have the same size.

- It is better to choose long boards this will reduce the number of joints. The standard lamella length is 6 m.

- An external siding perform a block with a house made of coniferous wood. The ideal option is larch.

- Boards from the northern regions more dense property improves other characteristics of the material. The density of wood can be checked by annual rings. The closer they are to each other, the denser the material.

- Do not buy wooden boards if they have defects: cracks, rotten knots, mold plane or cyanotic spots.

- The breakup should be small: in a width of about 8 mm, in a depth of 3 mm.

- The permissible level of moisture in wooden boards is 20%. This value should be displayed in the certificate for building material.

- The packaging of the House block should be holistic, without damage.

Rules for the installation of lamellas Block House

DIY House Blok House should be carried out in compliance with a number of rules:

- Installation is performed along the guides, and not directly to the wall.

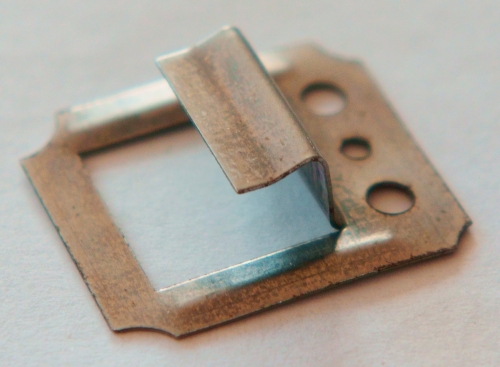

- The fixation of the House block is preferably performed using clamers or metal brackets. For fastening thick boards, the House block is better to use self -corrosion screws.

- Before starting installation, it is advisable to hold wooden boards in the room for several days. This will reduce the moisture content of the material.

- During fastening, the panel is located so that the groove is below, and the spike is from above. This method reduces the risk of dust/dirt accumulation in the groove and increases the life of the skin.

- Between the floor/ceiling surface and the skin, the gap for natural ventilation should be left.

- A small gap should be between the boards. This measure will prevent deformation of the material in the event of moisture and temperature differences.

Facade of the House Blok House: Phased Stage

Consider how to properly sheathe the house of Blok House. The installation process we will consider on the example of wooden panels.

Tools and materials

In addition to the House block itself, other materials will be needed for work:

- windproof film/membrane;

- rolled insulation;

- vapor barrier film;

- primer;

- antiseptic;

- components for creating a crate of the bars;

- klyimers or screws for fastening panels (Kleaymers' consumption: 10 sq.m. casing about 200 pcs.).

Important! It is better not to use foam as a heater. This heat insulator goes well with wood, as it has low vapor permeability and supports combustion

Necessary tools:

- level;

- brush;

- hammer;

- sandpaper or grinder;

- saw;

- electric drill;

- squad.

Preparatory events

Before proceeding with the decoration of a wooden house, the block of house needs to be held preparatory measures.

- Pill the wooden elements with an antiseptic. In addition, it is advisable to treat the boards with antipyrene, this will increase the stability of the tree to fire and mold.

- Attach vapor barrier to the walls of the house. The film is fixed with an overlap of 10-15 cm. It is convenient to perform the work with a construction stapler with brackets.

- Attach the crate. This design must be done horizontal. Brus fixation is performed with self -tapping screws or nails. In the case of casing of brick/panel walls, it is better to use dowels frame. The step of attaching the crate depends on the width of the thermal insulation material.

- In the cells of the crate, put the insulation.

- Attach an additional vertical layer of the crate to the main frame. The bars are fixed with a level check. The House block is mounted on this crate.

Blok House

Installation of the boards begins from the lower corner, the mounting of the panels is horizontal. Fixation of the House block with the help of Climers:

- Attach the cowls to the crate with self -tapping screws.

- In the paws of fasteners, insert the first panel. The location of the board with a groove is down.

- Put the next panel on the spike located below the installed element of the crate.

- The work on the cladding continues until the entire wall is lined with panels of the House block.

If the basters are replaced with self -tapping screws, then before installing the boards you need to prepare recesses for fasteners. Fixation occurs with a step of 40 cm. Self -tapping screws are screwed at an angle of 45.

In order for the decoration to have an aesthetic type of self -tapping screws must be disguised. For this, the remains of wooden panels, ready plugs or a wooden pasta are suitable.

For decorating the internal corners, boats are suitable, special skirting boards or a strugan beam 5*5 cm are applied to the outer corners. Experts recommend fixing the beam before starting the skin this will make it possible to fix the panels of the House block to the beam and make the finish as attractive as possible.

Door and window openings are decorated with platbands. The main function of the platbands is hidden by cracks and protection against the penetration of cold air, precipitation and garbage.

You can choose decorative platbands with interesting carved patterns and unusual ornaments. In shape, platbands can be flat, rounded or curly. The choice depends on the style and the common facade of the house

Finishing block house inside the house

Installation of the House block inside the house practically does not differ from the external sheathing, but has some nuances:

- for work, use boards of small width;

- external and internal corners are fixed at the end of the installation of a block house.

Important! The wooden panels of the House block are best not used for decorating the internal walls of wet rooms. Otherwise, the material must be covered with a layer of varnish

Processing and care for panels of the House block

To ensure prolonged operation of the finish, wooden houses Block House must be treated with protective coatings: stain, antiseptic, varnish, paint and mastic.

Processing sequence:

- The surface of the House block is primed.

- Apply a layer of varnish or colorless paint.

- Every 5-7 years, the protective coating must be updated. It is preferably to apply the same varnish or paint, otherwise the previous layer will have to be removed with a grinder.

Important! In order to avoid the appearance of white stripes with a drying of wooden panels, the spike of the House block must be treated with varnish before installation

Blok House House Lorination: Video