The wooden house is fashionable, beautiful, environmentally friendly, safe. That's why...

|

|

Drying wood is an important stage in the preparation of lumber for work, as a result ... |

Almost every interior element in the house lends itself to renewal. Of course, inhale ... |

DIY chimney for a boiler

There is nothing easier than the arrangement of autonomous heating through solid fuel or gas boilers. However, they can not always be installed independently. But, in order to reduce the cost of work, it is quite affordable to install the boiler chimney with your own hands. There are subtleties in the construction of brick and coaxial chimneys, as well as when installing and warming the chimney made of stainless steel. Each method has long been thought out to the smallest detail, so nothing needs to be invented easier to use ready -made advice from specialists.

Table of contents:

- Features of the construction of the chimney

- Purpose and device of the chimney

- Chimneys for boilers of different types

- Varieties of chimneys according to the type of materials

- Installation of a coaxial chimney

Features of the construction of the chimney

It is no secret that competent chimney sweeps, stovers and fireplaces of the master have always been appreciated. There are many historical curioses associated with the arrangement of chimneys. For example, the case of one despotive lady, from which the peasants wanted to get rid of or somehow avenge, persuading the stovenik, to whom she turned to insulate the estate. Everyone knew that the landowner was afraid of the devils that threatened her peasants tormented by her. The ingenuous stove -shaped mounted a bottle of special shape into the chimney, which howled in the wind with great thrust. Major did not find a place at night from horror until she finally went crazy and drowned in the well, fleeing from the devils. So that curioses and troubles do not happen in your house, make a chimney according to all the rules.

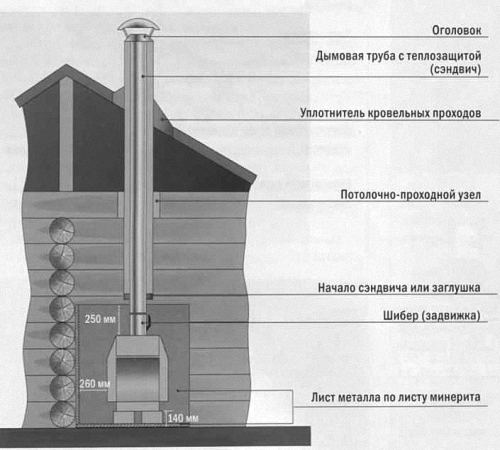

Installing a chimney for the boiler is a simple process, but it is important to understand the specifics of the combustion process and the removal of decay products. All these nuances are based on elementary knowledge from the field of physics. They are thought out and taken into account by technologists to the smallest detail, with one purpose to make the process of heating the dwelling the most safe. Everyone knows that due to incorrect operation or use of the chimney valve, carbon monoxide poisoning occurs with severe consequences. Therefore, these physical laws cannot be ignored, and refer to the recommendations of specialists. This is especially true for equipping a solid fuel boiler, since it requires an appropriate chimney. Modern chimneys for boilers photo:

Attention: it is strictly forbidden to remove 2 sources of heating into a common chimney with a fireplace and from the boiler so that the difference in rarefied and dense air does not create a reverse craving and throwing smoke gases!

The productivity of the boiler falls with low thrust and with increased. The upper level of the chimney pipe should be 20 cm (and more) above the ridge or roof level to ensure normal traction and lack of twisting. The side pipes below the roof in the side wind give reverse traction.

Basic Rules:

1. Separate boiler rooms or auxiliary premises where it is planned to install chimneys for gas boilers must have sufficient traction and the possibility of ventilation.

2. Remember that some leakage of a dangerous gas mixture is possible at:

- turning on the heating system and ignition of boilers;

- durable of solid fuel;

- completion of the combustion process, including forced extinguishing fire.

Attention: a small gas leak is inevitable, and they do not pose threats, but with the incorrect construction of the heating and incorrect operation, troubles are possible due to gas leakage or accumulations of CO.

3. The ventilation hole and chimney are made on one wall to avoid reverse traction and pressure drops that occurs during gusts of wind. This reduces the efficiency and may with a draft drive smoke back into the house.

4. A separate room for installing the boiler is ideal, and if the boiler room is not provided, you can use a basement or a small corridor at the entrance to the house.

5. A deep cellar is convenient in that the boiler at the lower level is able to provide the coolant natural circulation, while minimizing the use of pumps. And it is important to ensure the work of the chimney for solid fuel boilers, if there are interruptions in electricity, especially in a solid fuel boiler. Automatic circulation system is equipped with most boilers:

- electric,

- gas,

- diesel boilers.

6. With improper operation or lack of circulation, a solid fuel boiler can:

- minimize the effectiveness of heating the room,

- deform,

- to rush,

- release carbon monoxide.

Tip: Today, carbon monoxide sensors are available, which experts recommend installing in a boiler room or adjacent room. Set the sensor with a loud signal if everyone is sleeping tightly in the family.

Attention: according to symptoms, it is difficult to identify poisoning with carbon monoxide or COs, since it has neither color nor smell, and signs are manifested gradually. This is lethargy and drowsiness, but you can sleep tightly and hear the signal of the sensor. It differs in density from the air, so it easily crawls into living rooms, but with sufficient ventilation, its harmful effects are minimized.

Purpose and device of the chimney

It is not so important what the chimney pipe is made of, the main thing:

- functionality;

- efficiency;

- safety;

- reliability;

- durability.

The main problems with a great inconsistency of the chimney and the power of the boiler:

- reduces the efficiency of the heating system;

- smoke, CO and other combustion products penetrate the room;

- there is a chance that the chimney freezes at extremely cold temperature;

- the boiler is more difficult to melt.

The diameter of the chimney for the boiler should also correspond to the daily significant load:

- ensuring sufficient traction;

- removal of combustion products and smoke gases;

- ensuring the effective operation of the boiler so that heat does not fly into the pipe, in the literal sense.

The classic chimney has several modifications, for example:

- made as a simple stainless steel pipe or a sandwich type with thermal insulation;

- asbestos -cement pipe or brick masonry.

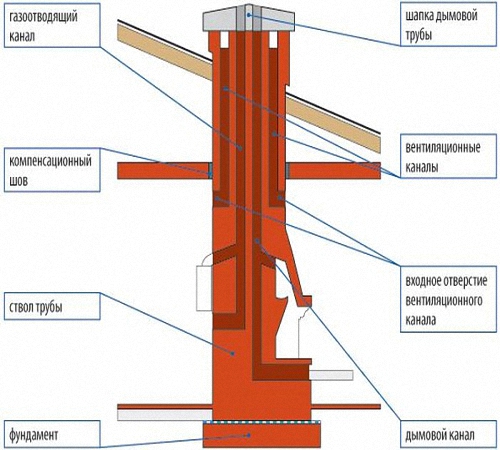

In the brick chimney system, traction limiter is always mounted, which hides at sufficient temperatures in the house to reduce cooling. However, it cannot be completely closed until the process of attenuation can lead to an accumulation of carbon monoxide. The limiter should be not only for the furnace, but also in the chimney for the boiler below the junction of it.

Tip: Do not be too lazy to make an insulated option or a sentwitch pipe, which quickly warms up, provides stable traction with ignition, does not freeze at low temperature and does not carry out cold with a non-working boiler. A brick chimney for a gas boiler is also applicable as thermal insulation. But this is optimal for a solid fuel option, although they will warm up longer.

Chimneys for boilers of different types

1. At the diesel boiler, the circuit has several options, for example, with an expansion tank, and a circulation pump on a return pipe, an emergency removal of excess heat energy with valves is desirable. Since all solid -fuel boilers are sensitive to good circulation, it is important to consider this when building it.

Diesel boiler connection diagram:

For the boiler, it is recommended to allocate a separate room, better adjacent to the house with insulated walls. The chimney of the diesel boiler is vertical, it makes no difference between the cross -section throughout the stainless steel, with special cleaning channels to prevent soot, with insulation made of heat -resistant materials at the wall adjacent to it. Brick masonry for it is not suitable for the mixture of acids, which is released during combustion, destroys it, except that as insulation and isolation of a stainless steel pipe.

2. In a solid fuel boiler, the scheme is assumed in its instructions, since their assortment is quite extensive, and everyone has distinctive features. But in all varieties, the scheme is associated with fire measures, especially with the proximity of the roof with the chimney of high garden trees or a forest. Be sure to put the sparking and passing cartridges. Scheme:

3. The chimney scheme for the gas boiler also has options, but the installation of a vertical stainless pipe is considered optimal. The capacitance for condensate and the mandatory correspondence of the cross section of the chimney and the divert of the boiler is supposed:

Tip: When buying parts for any type of chimneys for boilers, it is important to have the necessary set:

- adapter for fastening the pipe for the chimney to the boiler pipe;

- telescopic pipes or equal section;

- conical tips and bends;

- a tee with an audit opening and a fitting for removing condensate;

- wall mounts (clamps, brackets, etc.).

Varieties of chimneys according to the type of materials

1. A stainless chimney for the boiler is collected from galvanizing or steel pipe, and in the domestic construction market these components are presented in a large assortment. They are the easiest for independent assembly, easily removed through the roof if the chimney was not originally planned during the construction of the house. But this design is not highly resistant to damage and aggressive effects of external factors. Therefore, additional insulation and protection in the form of additional masonry is recommended. Ideal varicity arrangement on the principle of a sandwich system with filling space with heat-resistant basalt wool. In the room where the boiler stands, a stainless steel pipe looks quite presentable.

2. Brick chimneys for boilers are quite reliable, but involve competent installation of the diverted pipe in the system. Today this is not the most popular method, since it is considered the most archaic. Often, masters of the old formation offer in rural areas it is this method, as the most proven, and for solid fuel boilers it is quite suitable. However, the construction of a brick chimney requires special building materials, knowledge and skills, as well as enough time for construction.

3. Coaxile chimneys for boilers belong to the most modern systems, and they lead in their design, practicality and presentability. They have a specific form and a device that prevents the formation of condensate during the operation of a gas boiler. Pay attention to what is the difference between the coaxial chimney and the usual.

4. Ceramic chimneys for boilers are not so popular, but they have their admirers, since they are used in houses covered with ceramic tiles. In the construction of elite houses, they are rarely used, but they find their admirers among supporters of environmentally friendly housing, because:

- simple and reliable;

- easily assemble from several modules;

- available in price.

5. The most curled are the glass chimneys that are made of refractory material, are highly removable and aesthetic, but rare in the domestic construction market. They are durable because they are not subject to corrosion, do not absorb moisture and gases, unlike other varieties.

6. Along with ceramics and glass, chamotis chimneys made of refractory chamotte clay are used. Fireproof brick is also made from it, so it is quite acceptable for chimneys for boilers of some varieties.

Attention: sometimes, in case of illiteracy, asbestos -cement pipes are placed in a chimney for a boiler or fireplace, which are not intended for this when overheating, they can explode.

Installation of a coaxial chimney

It is not so difficult to make a chimney for a boiler with your own hands if there is experience and qualification of a brick or welder. If you need to assemble a modular chimney from finished parts, it is enough to rely on the instructions and the corresponding video.

Installation of a coaxial chimney is also quite simple.

The wall under the chimney is chosen closer to the boiler, and if it stands in the corner, it is better to bring the pipe to the side that leads to a high part of the roof. The closer from the boiler to the outer wall, the lower the cost of the pipe. Along the wall, it is important to remove flammable finishing materials and objects that may deteriorate when heated or lead to a fire.

In a climatic zone with a high level of snow snowdrifts, the chimney lifts the pipe air for the internal combustion chamber of the boiler above the level of the air fence. And a small bias of the pipe will provide an outflow of condensate by gravity, then the chimney does not threaten waterlogging.

Before you make a chimney for the boiler, we will consider this type of assembly in more detail:

1. Check the availability of a working tool and all the details for the assembly:

- chimney pipe;

- chimney knee;

- connecting clamp;

- chimneous pipe;

- adapter for connecting the boiler and chimney;

- flanges;

- decorative overlays for installation to the wall.

2. Choose the place in the wall where the pipe will be removed from there from the side of the street, the chimney should rise. If the boiler is removed or the wall is very high, the coaxial chimney is lengthened, but it is important to correctly make the joints of the pipes with additional clamps or knees.

3. At the final stage, be sure to process all sharp edges to avoid the possibility of petty injuries. The hole in the wall under the chimney around the pipe is discouraged and closed with decorative overlays on liquid nails or in another convenient way.

Tip: If the chimney needs to be removed through the roof, it is important to accurately determine the place of the pipe and carefully disassemble the roof on this fragment. A hole in the roof is cut out from the inside and the pipe is removed. It is important that a whole fragment passes through the roof, without joints on the pipe. Do not forget about the installation of a visor to prevent accumulation of precipitation in a chimney.

hello very good

hello a very good topic I myself suffer with these issues Z89608585058@yandex.ru