Profiled sheet, it is corrugated - this is roofing material made from ...

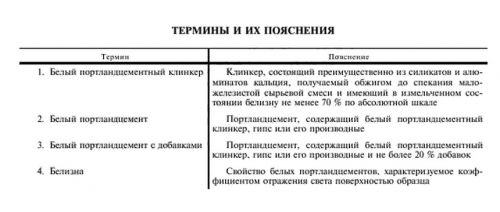

|

|

The sewage system is one of the fundamental engineering systems as in ... |

The slopes on the doors are not only a warming element of door decoration, but also ... |

What is a white sequence. Characteristics and areas of application

The white sequence compared to the traditional counterpart is different in a number of advantages: both in operational characteristics and its aesthetic properties. Thanks to a beautiful color, it is widely used not only for construction work, but also for creating sculptures and other architectural forms. In the article we will consider the main characteristics of white cement and the region in which it is used.

Content:

- What is a white sequence

- The composition and properties of white cement

- Advantages

- Application area

- In what cases is the white sequence used

- Work with white cement. Useful tips

- Manufacturers of white cement and its price

What is a white sequence

The light shade of white cement is due to the composition and special technology of its manufacture.

It is carried out on the basis of a low -stroke clinker, with an admixture of mineral additives, limestone, gypsum, chlorine salts, which give it a whitish color. And firing with sharp cooling provides strength.

Such material is multifunctional. It is used for:

- construction;

- construction of bulk floors;

- it can serve as a component component in the manufacture of dry finishing mixtures.

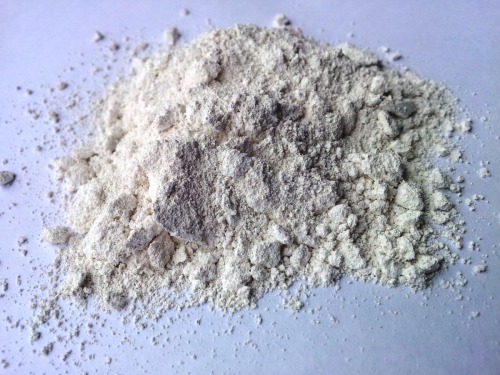

The composition and properties of white cement

Materials. The light color of the cement is achieved by using raw materials, where there are no glandular compounds or are present, but in small quantities. The white sequence is based on a small -legged clinker, where the content of manganese and chromium is minimized. It also includes mineral additives, limestone, gypsum, chlorine salts that give it a whitish color.

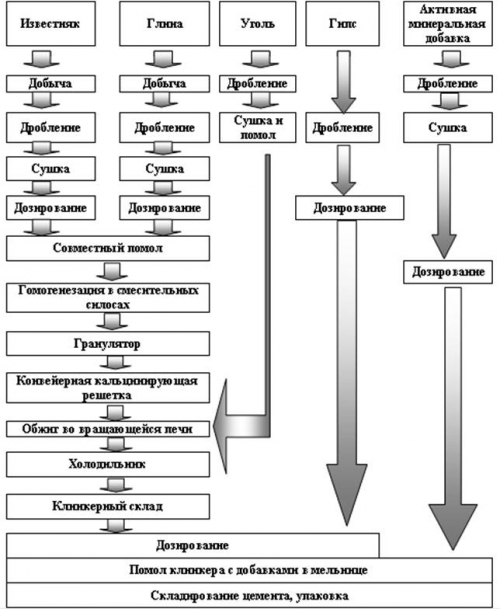

Technology. Crushing of raw materials and clinker grinders occurs in crushers/mills equipped with a special lining. Flint, basalt, porcelain plates are used here. At the same time, the specific surface (thinness of the grinding) is significantly higher than that of ordinary cement:

- the thinness of the grinding of gray cement ̴ 3 500 cm/gr.;

- the subtlety of white grinding ̴ 4 500 cm/gr.

For firing the raw material mixture, liquid, gaseous or other fuel that does not produce particles of soot or ash is used.

The strength and whiteness of the cement are achieved by firing the clinker at high temperatures, and then its cooling in an oxygeneric medium (1200-C). Or a sharp cooling of water (1500-500C) is used, after which a wet clinker is dried in a drying drum at a temperature of 300C.

- Dry way. With low moisture in raw materials, most enterprises use just this method. For this, shaft furnaces are used, where the stages of thin grinding, thorough drying and mixing, and all the necessary components are combined. The resulting clinker is firing at a temperature of 800C.

- Wet method. This scheme implies crushing in a mill of solid components, and soft in a special device - a chatterbox using water. After this stage, the moist huts are dried and then its smaller grinding and mixing with the rest of the raw material is carried out, as in a dry method.

Cement is made with two strength indices: M400 and M500.

Peculiarities.The grinding of such a cement is thinner, therefore, when sifting through net No. 008, the remainder should not be more than 12%.

The degree of whiteness determines its decorative properties, based on this indicator, the cement is produced by 3 varieties: 1 (higher), 2 and 3, where the reflection coefficient is 80%, 75%, 68%, respectively.

Grabbing the material occurs after 45 minutes, completely drying after 12 hours.

Color cement is obtained in a similar way with the addition of mineral dyes. Rare colors give:

- escolaite pistachio shade;

- brown cobalt;

- the manganese from blue to deep black.

Advantages

- Maximum strength and accelerated hardening of the material. After 16 hours, the hardening of the solution is already 60%, thereby the construction process is reduced and reduced;

- such a high technological indicator as dispersion does not allow the material to collapse under the influence of aggressive solutions, atmospheric moisture;

- environmental friendliness of cement due to the use of natural mineralogical components in the production of natural mineralogical components;

- ready buildings are durable and stability. They have resistance to the formation of cracks (chips). Such advantages of the material minimize the costs of repair or restoration work;

- the aesthetics of whiteness, the color resistance of cement and versatility, allows you to combine it with other finishing decorative materials;

- multifunctionality: used as building and decorative material; used in casting floor slabs and bricks; It is part of dry adhesive mixtures, colored concrete, grout, putty and so on.

Application area

Now in almost all buildings there is a white sequence, in some cases its use is the best and only solution.

- It is used in the manufacture of a variety of building elements, white concrete looks especially impressive as the facade decoration. Thanks to it, the buildings and architectural fragments become more durable and expressive.

- The high technical characteristics of cement prevent a change in concrete color, and allow it to be used both in closed rooms and in the open air. It has increased resistance to various atmospheric phenomena (sunlight, snow, rain), while maintaining whiteness for a long period.

- It enables manufacturers of cement products and concrete products, as well as architects, an excellent basis for the implementation of various ideas. Allows you to work with forms, fillers, color, as well as use various technologies of concreting, decoration and processing of a hardened surface.

In what cases is the white sequence used

- An amazing similarity with a natural stone is achieved by mixing a white Portland cement with expanded clay gravel, marble or granite gravel of a small fraction and a desired shade with a dye. This kind of mixture is used in the manufacture of terrazite plaster for facing the facade of the structure, paving slabs or decorative bricks.

- It serves as the basis for cement-cement solutions, adhesive compounds, grouts, bulk floors, plastering mixtures.

- It is used in the manufacture of sculptures, columns, steps, borders, flower beds, small architectural forms, decor fragments.

- A high degree of wear resistance and reflective properties allow the use of a white sequence, both for marking the aerodrome and roadway, and as a material for the road surface.

Work with white cement. Useful tips

- The forms used (formwork, various types of container) and tools should be clean: without dust, dirt, fats, rust. This rule applies to a concrete mixer;

- to knead the solution and its subsequent moisture, only pure water is used;

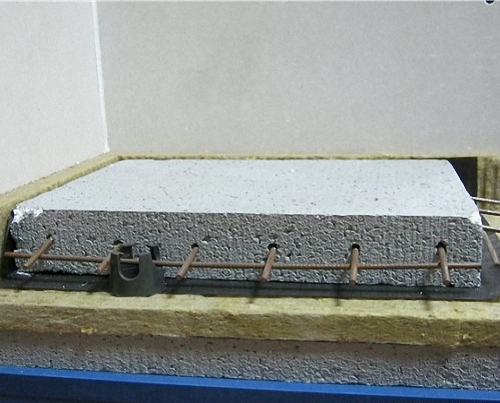

- if steel reinforcement is used in the design, then it should first be covered with a 30 mm layer of concrete. Otherwise, it is likely that over time, rusty smudges will appear on the white surface;

- a bleaching additive can be a titanium dioxide, but its mass should not be more than 1% of the total weight;

- the aggregate for concrete is selected only white and small fraction (up to 2mm). It should not be attended by slanting particles or small -ground. The content of the sulfide class mineral in quartz sand should be excluded, the recommended fraction of 1.5 mm;

- plasticizers, slowing additives are also selected with a shade that will not affect the color of the solution. It is not recommended to use zinc -based white.

Manufacturers of white cement and its price

You can buy a white sequence in any construction store. It is represented by a wide range of manufacturers.

Aalborg White

The improved technology and the pure raw material base display the Danish cement plant Aalborg White to a leading position. Their products are characterized by high indicators of whiteness and strength, exported in 80 countries of the world. This kind of material is produced by plants located: in Denmark, China, Malaysia, the North American region and Egypt. Of the shortcomings, only its cost can be noted.

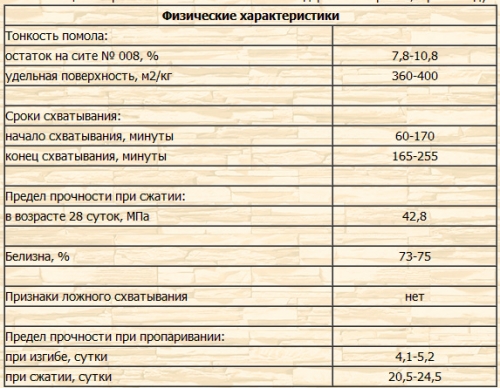

Technical characteristics of the white Portland cement of the M700 brand (Denmark):

- products of 25 kg of branded paper bags are packaged, the price is from 300 rubles;

- first variety, degree of whiteness 85-90%;

- the beginning of the setting after 85 minutes, the end after 130 min.;

- strength on the 2nd day reaches 36-44 MPa, on the 28th day 68-78 MPa;

- expansion up to 2 mm.

Technical characteristics of white cement brand M600 (Egypt):

- the products of 50 kg of branded paper bags are packaged, the price is from 470 rubles;

- first variety, degree of whiteness 87.4%;

- the beginning of hardening after 170 minutes;

- the strength on the 2nd day reaches 32 MPa, on the 28th day 67 MPa.

Holcim (Schurovsky cement and Volskzament)

Another largest manufacturer and supplier of the financial and industrial company Holcim. Two plants produce cement according to the unique technology of this concern in Russia: Schurovsky cement and Volskzcent.

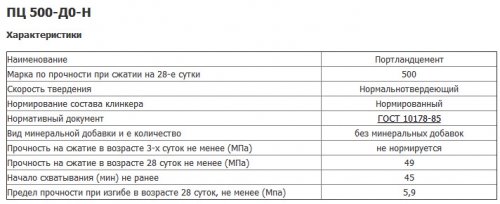

Technical characteristics of white cement brand M500 (Russia):

- the products of 50 kg of branded paper bags are packaged, the price is from 435 rubles;

- first variety, degree of whiteness 82-84%;

- the beginning of the set after 100 minutes, the end after 170 min.;

- the strength on the 2nd day reaches 34-40 MPa, on the 28th day 54-57 MPa

Cimsa

White Portland cement from the Turkish manufacturer Cimsa is a high quality of products and an acceptable cost.

Technical characteristics of the white Portland cement of the M600 brand (Turkey):

- products of 50 kg of branded paper bags are packaged, the price is from 500 rubles;

- first variety, the degree of whiteness is 89-92%;

- the beginning of grasping after 130 minutes, the end after 160 min.;

-strength on the 2nd day reaches 43.7 MPa, on the 28th day 66.7 MPa

- Expansion up to 1 mm.

Such cement allows you to use pigments to give the necessary and stable shade, thus receiving an unlimited color palette. And taking into account such characteristics of this material as: strength and resistance to aggressive influences, you can carry out any, even the most non -standard intentions of architects.

good afternoon interests

good afternoon is interested in the prefabricated steps of B25 on granite rubble

Thank you so much for the article!

Thank you so much for the article! It will be very useful to me in my work !!!

Thank you very necessary for me

Thanks to the information very necessary for me!

Thanks!!! was really

Thanks!!! It was very useful.

What is his expense?

What is his expense?

Thank you very much

Thank you very informative!

Still, it is not clear to me what it is

Still, it is not clear to me what kind of small clinker is this? The bulk of the cement of the cement of what natural material? Here Novorossiysk cement plants are where there is a breed they need, Mergel, as far as I know.

Good article! Answers

Good article! Answers all questions.