Very often, the desire to increase the living space of the house comes to naught because of ...

|

|

Many owners of private houses and cottages are thinking about building a veranda. This ... |

It is unlikely that today someone will be satisfied with work or rest in the country, where there is no water. Nor ... |

Roof roof by corrugated board with your own hands

Profiled sheet, it is corrugated - this is roofing material made of galvanized steel by cold rolling. With the help of a press-form, he is given a wave-shaped or trapezoidal profile. Unlike a soft roof or slate, it has large overall dimensions and useful area. The corrugated board is one of the most popular roofing materials due to high stiffness, which adds convenience during installation and operation, since the material is not affected or deformed. In addition, the load on the ceilings and the roof as a whole increases slightly. The article will talk about the roof of the roof with a corrugated board with your own hands.

Content:

- Types of corrugated board

- Advantages of corrugated board

- Roof roof corporal price

- Installation of corrugated board

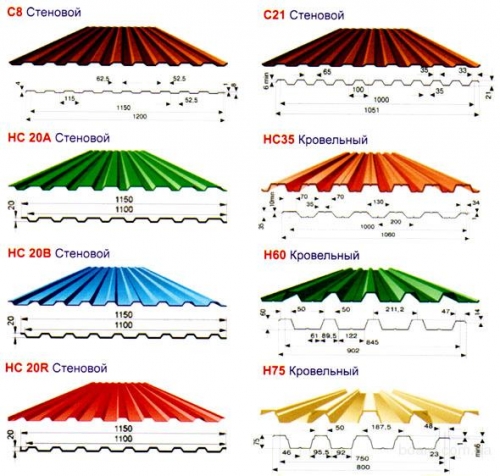

Types of corrugated board

- The profiled sheet is distinguished in thickness, it can be from 0.4 to 1 mm, the choice of thickness depends on the purpose and area of \u200b\u200bapplication.

- The profile also differs in the type and height of the profile - the wave -shaped and trapezoid with a height of 10 to 44 mm and more than 57 mm (such corrugated board is used for non -removable formwork).

- To prevent the effects of an aggressive environment, different coatings are applied to this roofing material - polymer or paintwork. But it is possible to manufacture without it, since galvanized steel itself is not prone to corrosion and rapid wear.

- In addition, there is a differentiation of the sheet according to the material of manufacture, that is, by the type of steel used. These are the following species: a hot -valked sheet, a professionalist of copper, aluminum, chromium -nickel steel. All this is for the most part to increase the service life and a decrease in the effects of corrosion.

- Sometimes corrugated board is divided into areas of application, for example, for a roof, from 10 to 44 mm profile is used, for the installation of fences and a fence of 10-21 mm, both flat and corrugated material with any profile can be used to cover the walls.

Advantages of corrugated board

In addition to the large useful area of \u200b\u200bthe leaf and high stiffness, it has a number of advantages over other types of roof.

- The corrugated board, along with everyone, has a small mass, as well as the roof based on bitumen has a long service life and is not inclined to corrosion.

- Bitumen roofing materials have fewer color schemes than a profiled sheet. It is easily mounted, creating good tightness of the entire roof.

- Large overall dimensions of the sheets allow you to quickly cover the roof, which ultimately saves time in all work.

- The soft roof is inferior to the profiled sheet in many respects, especially in strength. In addition, the cost of the roof roof by corrugated board is significantly lower.

- In general, the corrugated board is quite suppressed and easily processed material, despite the fact that it is made of steel.

Flaws

- He has very few shortcomings and only one can distinguish him - if the protective coating is damaged, the sheet loses high corrosion properties, exposed to a stronger effect of rust.

- Of course, a strong increase in the sound effect is also attributed to the disadvantages, but this moment is easy to correct with high -quality soundproofing of the roof.

Roof roof corporal price

Mostly on the Russian market there is a professionalist of domestic and Belgian production. Quality and technological indicators are not particularly different.

- The Belgian sheet costs from 175 to 285 rubles per square meter, depending on the thickness, height and distance between the profiles.

- Domestic products are sold from 145 to 440 rubles, the same parameters, however, there are also figured corrugated board, but this is already according to individual customer orders.

- Therefore, in the market in this area there is a certain balance and demand for all goods approximately the same, since the price ranges in the regions are slightly different, and the offered goods have the same parameters.

- Such identity does not greatly affect demand in this type of industry, since a large spectrum of use and permanent construction does not allow to idle production and strongly fill up the sellers.

Installation of corrugated board

It is not difficult and not too expensive to perform the roof roof roof by the corrugated board, of course, the size of the roof plays an important role, but in general, the installation is carried out quickly and without problems.

- First of all, it is worth preparing for work, choose all the necessary tools, calculate the required amount of corrugated board. To do this, first you need to calculate the area of \u200b\u200bthe roof, in a detailed state, then the area of \u200b\u200bone sheet, divide the first into the second and get the number of sheets.

Tip: It is better to take with a margin of several sheets, since if the roof has a complex shape, there are many excesses, then you will have to cut the sheets and a inconsistency may occur.

- The tool is taken simple:

- to cut sheets, you need an angle grinding machine (Bulgarian);

- hammer or screwdriver, depending on the type of fastener;

- stairs;

- insurance;

- level;

- a plumb line, you can use the thread to put the first and second sheets.

- Then, when everything is bought and prepared, it is worth paying attention to the beams and a crate intended for corrugated board. Since the mass of the sheet is small, the cross section of the beams is selected small.

Tip: All beams should be set in level and fixed on both sides to prevent deviations to the side.

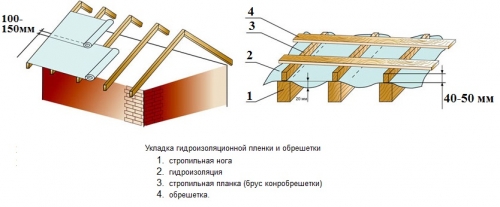

- A membrane moisture -proof film is nailed on the rafters, on top of which a crate is filled.

- The crate is selected depending on the purpose of the structure, if it is a garage or utility building, non-residential structure, then you can nail it with an interval of 20-30 cm, this will be enough for normal fastening of the sheets. It will turn out about 20-50 fasteners per sheet, this is enough to hold the sheet with a strong wind. Boards for the crate are optimally used with a 30 mm thick. They should be strictly parallel to each other and are fixed in level.

Tip: there must be a ledge on each side of the roof, so that the roof goes with the vessel, this will not allow the precipitation to the walls. This should be taken into account for all types of buildings.

- On residential buildings, the crate is usually made up, but this is not necessarily. It is enough to leave the gap between the boards of 150 mm, since the professionalist does not sag and does not bend like a soft roof. In addition, the infrequent crate is also a significant savings in lumber.

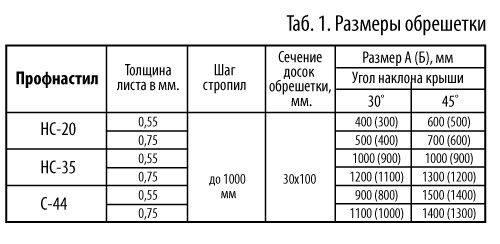

Recommended sizes of the crate

Roof roof by corrugated board scheme

Stages of work

For example, take an ordinary barn -type roof, straight without excesses, the length of the slope is 8 meters, and the length of the entire roof along 12 meters.

- The sheet is taken with a length of 6 m and a width of 1 m. The crate is used, a width of 12-18 cm, with gaps of 25 cm, it turns out that about 20-30 fasteners are connected into one sheet.

- The side of the roof consists of one whole sheet and a piece of 220 cm long. Given the fact that on each side a 15-20 cm will be made, 13 whole sheets will be required on one side, on the opposite side is similar to another 13. Since from one sheet. Only 2 pieces of 220 cm will turn out, and in total 26 pieces are needed on the upper part, then for this you will have to spend another 13 sheets, therefore, you need to purchase 39 sheets for the entire roof.

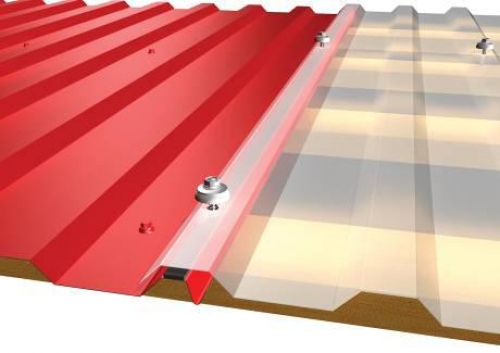

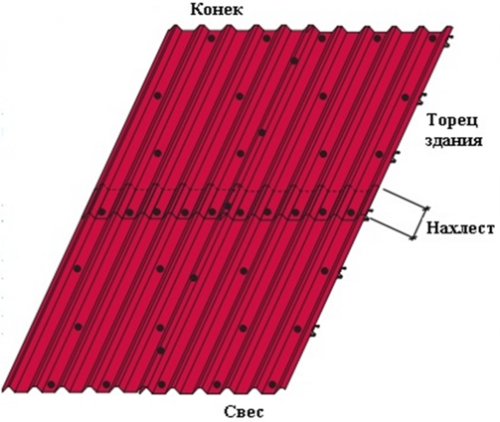

- You should start from the edge from below, the first thing is a whole sheet, it will close 6 meters of height and 1 meter width, but it is necessary to immediately set the letters from all sides. It is important to lay it as smooth as possible so that by the end of the installation there is no distortion (the roof can leave and expose the lower boards or, on the contrary, go forward too much). To do this, it is better to fix the first sheet of the corrugated board with several nails or screws and try on the second, laying it with one wave on the wave of the first, this is done to seal and prevent proters.

Roof roof corporal photo

- The second sheet is fixed and it becomes clear how exactly everything is exhibited. If necessary, the position of the corrugated board is adjusted. Then, according to the same principle, the first row of the roof from below should be completely closed, 12 and a half or 13 sheets will be laid. Do not save much or vice versa, use too many roofing screws. Typically, their approximate number is indicated by the manufacturer. There should not be a fastening of problems, but if nails are used, then you need to beat once to immediately break through the sheet, otherwise you can mole it, and this will no longer be too aesthetically aesthetically pleasing.

Tip: when fastening with self -tapping screws, you must immediately grab 2 sheets at the junction of the joint, this is done for density and tightness, as well as to strengthen the entire system.

- After that, the same procedure for work is carried out from the opposite side, and an identical number of sheets should be fixed.

- Then begins to close the upper part of the roof in halves. They are stacked strictly along the waves of a whole sheet, with a 20-20 cm fuss, such a distance will not allow water to enter under the sheet.

- The sheets are cut off with a length of 215-220 cm, thus, only two sheets of corrugated board will be obtained from one sheet, and the rest of the waste. If you want to avoid unnecessary segments, then it is necessary to more accurately design the roof at the stage of its construction, taking into account all the letters and joints.

- After the sawing, 26 pieces of 220 cm long should turn out, as much as entire sheets were spent on both sides. For this, 13 sheets of corrugated board will be used. The principle of installation here is the same. Laying is carried out on one wave, and necessarily attached to a number of screws along the wave at the junction. In total, a sheet of corrugated board is attached to about 15-20 screws. It is necessary to build on how tightly it is pressed to the crate. Extra holes with self -tapping screws in the roofing material are not recommended.

The result was a completely covered roof, tight, dense, with a good appearance and very practical. But this is not all, for the final completion of the work there are several more points.

- The first of them is the installation of the skate. It is necessary so that there is no water and snow in the area of \u200b\u200bthe roof, in the area of \u200b\u200bthe sheets. It is a triangular profile (corner), with wide sides that completely overlap the sheets on both sides of the roof. It is made, like corrugated board, from galvanized steel or other materials listed earlier, while its color scheme is the same as that of the main roof.

- The second moment is the closure of the end part of the roof, in the area of \u200b\u200bcontacting the crate and roofing sheets, an open area is obtained, into which water is overlapping. To prevent this, in addition to firing with sophims, a similar corner is taken, but with smaller ribs and is installed between the roof sheet and the board. It is best to take care of this moment when laying sheets of corrugated board in the front row, this will facilitate the fasteners of this corner.

Roof roof corporal video

- After the roof roof is completed with a corrugated board, you can install a drainage system from PVC or galvanized steel. It is not difficult to mount it, all components are calculated individually and can be purchased separately. After familiarizing themselves with the simple installation circuit, the gutter is attached, which go into the wastewater and in the drainage system. This will reduce the effect of moisture on the entire structure as a whole.