The kitchen and bath are special areas of the apartment requiring special care and, ...

|

|

Roof insulation is an important stage in the construction of your own home. These works need ... |

The glass floor today is an exquisite element of design, recently everything ... |

Do -it -yourself reinforcement

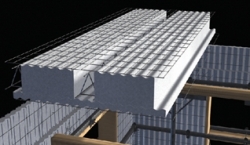

In multi -storey and private construction, it is impossible to do without floor slabs that are of several types: prefabricated reinforced concrete, monolithic and beam. In private and low -rise construction, the procedure for independent reinforcement of floor slabs is often practiced, which, thanks to tandem, concrete and reinforcement have increased strength. In addition, staircases, reinforced and arched jumpers are made in this way.

Content:

- Features of reinforced floor slabs

- Advantages of reinforced floor slabs

- Carriageing scheme of the floor slab

- Do -it -yourself reinforcement

Features of reinforced floor slabs

The manufacture of a monolith is not complete without the use of reinforcement, which acts as a binding material in the iron-concrete structures of reinforced slabs, staircases, reinforced and arched jumpers. The process of reinforcing monolithic floor slabs is carried out using reinforcement, which has a section of 8 - 14 millimeters, according to the condition that the plate differs up to 150 millimeters thick. However, the thickness of the reinforcement can vary, depending on the type of product.

Reinforced floor slabs allow you to solve the concept of building truly warm houses. They are used in housing, commercial and industrial construction for the organization of roofs and inter -story horizontal ceilings. Coatings and floors allow the end result to get warm, inter -story floors, as well as provide reliable protection from the cold of attic and operated attic and the absence of cold bridges.

Concrete reinforced floor slabs, like ordinary concrete, have a specialized marking, and it is recommended to pay attention to it when choosing plates. Mark reinforced concrete notes, which consist of letters and numbers. The semantic load of letters indicates the type of plate. For example, the PC of the floor slabs, the PNO plates are faced lightly, or the NV is internal. According to the numbers that go after the letters (placed through a hyphen), you can recognize the size of the stove: width and length in decimeters.

The most insidious in the decryption is the last figure that means permissible loads on the floor slab in the kilopascal. It is important to remember that any unit contained in the last digit means 100 kilograms per 1 square meter of plates. For example, the number 7 warns you that the maximum load on the product is 700 kilograms per square meter.

When choosing a concrete slab, it is necessary to pay attention that these structures can vary not only in size and their marking, but they are also different in structure. Depending on the cross section, reinforced reinforced concrete slabs are divided into 3 varieties: continuous, ribbed and hollow. The best -selling and popular in the construction market are hollow slabs, which they have many worthy advantages.

Similar slabs of floors have, first of all, by a relatively small weight, which simplifies the procedure for their transportation and installation. Also, such plates better tolerate the test of deformation, have excellent heat and soundproofing properties. You should know that voids in reinforced plates are of various shapes: oval, vertical or round.

Thanks to such differences, reinforced slabs can be selected for specific situations, depending on the natural features and climate of the area in which you plan to build a house. Under the purchase of reinforced concrete, it will also be that if the floor slabs are used as only a ceiling or floor, it is worth practicing reinforcing ribbed floor slabs, ribs should go only on one side.

Advantages of reinforced floor slabs

All reinforced floor slabs are recommended to be used in coatings and ceilings of residential and public buildings and structures with walls from cellular blocks, brick and large blocks. The floor slabs are suitable for buildings with air humidity inside the building up to 60% and for buildings in the presence of vapor barrier on the inner surface of the walls with humidity of up to 75%. The depth of the floor slabs on the bearing walls should be taken at least 80 millimeters.

Reinforced slabs allow not only to achieve high -quality insulation of the construction, but also to speed up the construction process itself, as well as increase sound insulation. The insignificant weight of reinforced plates and concrete jumpers reduces the load on the walls and the foundation, allowing to additionally get the economic effect when erecting the house. For the reinforcement procedure of hollow floor slabs, a huge construction equipment is not required, such as a lifting crane.

The design in the final result is very strong, it withstands tremendous stresses and the effect of fire for a long period without problems. For comparison, it is worth making a reservation that a fire from wood can withstand only 25 minutes, but monolithic floor slabs - for more than an hour.

Construction using floor slabs and huge blocks allows you to build buildings of any complexity and any size. In the manufacture of monolithic floor slabs, it is possible to block the room, which has irregular geometry of the walls. In this way, you can even create a non -standard in overall sizes of the ceiling. The support for such a reinforced ceiling can be not only the walls, but also the columns, which makes the layout of the house more free.

Carriageing scheme of the floor slab

If we talk about the components, then the traditional scheme for reinforcing the floor slabs looks like this: working rods at the bottom of the plate, working rods at the top, reinforcement, which redistributes the load, stands of rollever. The drawings used can have some differences. But in any case, it is important to correctly calculate the planned load and the necessary thickness of the concrete. The thickness is calculated from the proportion of 1:30, in such a way as to find out the required thickness of the concrete, you need to divide the length of the flight by 30 and you will get the optimal thickness.

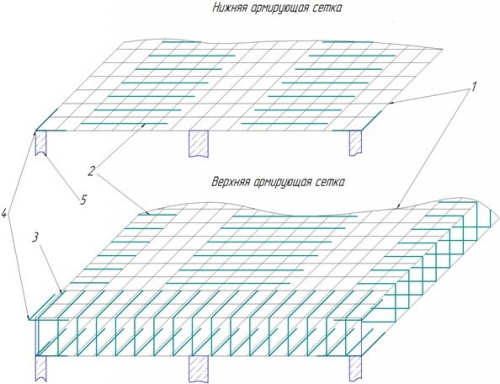

If the thickness of the plate is more than 150 millimeters, then reinforcement in these cases is performed in 2 layers, where they are located on each other and are binded by wire among themselves. The size of the cells should not be more than 200 by 200 millimeters, but not less than 150 by 150 millimeters. So, for example, if the width between the supporting walls is six meters, then the thickness of the reinforced plate should be 0.2 m.

If you specifically reduce the thickness of the concrete, then the consumption of metal rolling increases, if the thickness increases, then the cost of concrete will also become greater. For the strength of the products, it is advisable to use the reinforcement of the same section. Additional reinforcement can be done using rods, which have a length of 400-1500 millimeters.

The main loads are on the lower reinforcement, and the top load receives the upper, which concrete will cope with perfectly. Remember that the process of reinforcing a monolithic floor slab should be performed over the entire length of the product, as well as the use of formwork, which is the most important stage in the installation of the slab. You can use even a tree for this - ordinary boards of 50 by 150 millimeters or inexpensive plywood.

The main thing is to firmly and reliably fix the racks of the formwork, because the weight of the concrete, which is used during this operation, often reaches 300 kilograms per square meter. The only thing that is difficult to do without installing a reinforced floor slab is telescopic racks. This is a convenient and reliable tool. The stand is able to withstand 2 tons of weight, unlike boards in which there can be microcracks or knots.

Do -it -yourself reinforcement

When installing such an overlap, the correct calculation of the reinforcement of the floor slabs will be very important. For floor slabs at home, it is recommended to use hot -rolled steel reinforcement, which has a class A3. The diameter of such reinforcement is 8 - 14 million and depends on the calculated load.

The plate is customary to reinforce in two layers. The first grid is laid in the lower part of the stove, the second in the upper. The nets should be located in the middle of the concrete, the protective layer created by the formwork should be at least 15-20 millimeters. The reinforcement in the grid is tied with a knitting wire. The sizes of cells are 200 for 200 or 150 by 150 millimeters.

In the grid, the reinforcement should be whole, without tears. If the length of the reinforcement is not enough, additional reinforcement must be tied with an overlap, which is 40 diameters of the reinforcement. If you reinforce the overlap with reinforcement D 10, then you need to make a overlap of 400 millimeters. The joints of the reinforcement should be located in a checkerboard pattern, in a run. The edges of the lower and upper reinforcement in the grids should be connected with the P-shaped reinforcement.

The load on the reinforced concrete plate is transmitted from top to bottom and distributed to the entire area of \u200b\u200bthe coating. Thus, we can draw a similar conclusion: the main working reinforcement is the lower, experiencing stretching loads. The top receives compression loads. In engineering calculations, you need to calculate additional reinforcing amplifiers, but there are general rules.

During the reinforcement of the lower grid, additional reinforcement is laid between supporting supports in the middle. When connecting the upper grid, reinforces are laid over supporting supports. Additional reinforcement in the places of accumulation of holes and loads also needs. Additional reinforcement is made by separate whips, which have a length of 400,000 millimeters, depending on the width of the spans. The lower grid is enhanced between the load -bearing walls in the opening.

The upper grid needs to be strengthened above the load -bearing walls. Reinforcing the floor slabs with your own hands in places where they rest on the columns, are very different from traditional reinforcement, these areas additionally require the creation of volumetric strengthening.

The floor slab is poured with a concrete pump. When pouring it, it is necessary to compact concrete without fail, for which a deep vibrator is usually used. The concrete hardening process will be accompanied by its shrinkage, which increases when concrete dries, and appears on its surface of the microcrack. Therefore, for 2-3 days after the pouring of concrete, it is recommended to shed this design with water. It is better to moisturize concrete not by a straight stream, but by spraying.

Hello. Tell me

Hello. Please tell me very urgently. It is necessary for the consequences if the ropes are incorrectly arranged in the reinforcement scheme of the floor of the PB floor. Whether its bearing capacity and load will be reduced.