Until recently, we could not imagine what could be done with the ceiling ...

|

|

Today photo printing on suspended ceilings More and more is gaining ... |

If you started a grand repair in your apartment, then it is first of all ... |

How to insulate the roof with polystyrene?

Roof insulation is an important stage in the construction of your own home. These works should be carried out efficiently and conscientiously. It depends on how warm and dry it will be in the house, when the window is raw, cold and uncomfortable.

Modern construction supermarkets and markets offer a huge many different materials for roof insulation: mineral wool, fiberglass, basalt slabs, polyurethane foam and a lot of other materials. But invariably leading positions are still occupied by polystyrene foam, or, as it is popularly called the old fashioned - foam in the slabs. The most suitable for thermal insulation of the roof of Mark is PSB-S-25 and PSB-S-35.

- We determine the amount of material

- Awarding the attic roof with polystyrene instruments and materials

- Surface preparation, gidroisolation and vapor barrier

- Installation of insulation

- Foam on the attic roof

- Foam on an unexplosed flat roof

- How to insulate the roof with foam and avoid common errors?

How is this material good? First of all, with its rather low cost, as well as excellent operational characteristics.

- Strength: The material is characterized by an increased level of resistance to compression and stretching.

- Small specific gravity allows you to use it for insulation even dilapidated structures that are not able to withstand a lot of more heavier material.

- Wear resistance: the material perfectly opposes temperature changes, resistant to mechanical damage and abrasion.

- Moisture resistance: polystyrene does not absorb moisture at all, therefore, the material is not exposed to deformation under its influence.

- Fire resistance: the material is not prone to spontaneous combustion. It is best to choose the material of the G1 group for warming the roof.

- Lightness of installation: work on roof insulation with foam will be able to even inexperienced person.

- The durability of the material: the service life of such insulation is from 25 to 80 years.

Relatively recently, a liquid foam appeared on the shelves. This material has the same characteristics as the foam in the slabs, but is radically different in the application: the foamyizol is sprayed on the surface by means of a special installation. Thus, a seamless continuous layer of thermal insulation is formed on the surface. The only disadvantage of this method is the need for additional surface fixation by installing thin sheets of ordinary foam or drywall.

We determine the amount of material

Before starting work on warming the roof with foam from the inside, you need to calculate the amount of material necessary. For insulation of the attic roof, calculating the optimal amount is not difficult enough to just measure the area of \u200b\u200bthe roof, the step between the rafters and determine the size of the foam plates. However, experts recommend purchasing material with a small margin (6-8 plates), since during the cutting of this, the risk of deformation or breakdown of the plate may occur.

Awarding the attic roof with polystyrene instruments and materials

For work, you will need the following materials and tools:

- styrofoam;

- anticondensit vapor barrier film;

- wooden bars;

- nails;

- scissors;

- sharp knife;

- mounting foam;

- construction Stapler.

The final result entirely depends on how well and conscientiously the main stages of work will be completed.

Roof insulation based on the stages:

- preparatory;

- flooring waterproofing and vapor barrier film;

- installation of insulation;

- interior decoration.

Surface preparation, waterproofing and vapor barrier

The surface on which the foam will be laid should be clean and dry.

Polistyle foam copes with waterproofing perfectly. But in order to extend the operating time of the foam, the vapor barrier is required to be laid.

Please note: it is necessary to leave a gap of at least 2 cm between the film and the crate. If you do not, condensate will constantly accumulate on the inside of the insulation, which can lead to the process of rotting of the rafters, the appearance of an unpleasant odor, mold, etc.

In some cases, the anti -condensate vapor barrier film is laid: overlap directly to the rafters. This is done in cases where the width of the rafters does not make it possible to leave the gap between the polystyrene foam and the plank base. If we are talking about the already finished structure, the option of attaching this anti -condensate film to the rafters by means of wooden rails and nails is quite acceptable. Also, for these purposes, it is quite possible to use a special construction stapler.

Installation of insulation

The most common methods for attaching polystyrene stoves:

- gluing (frost-resistant facade adhesives, liquid nails, mastics for gluing tiles to the ceiling, moment-installation);

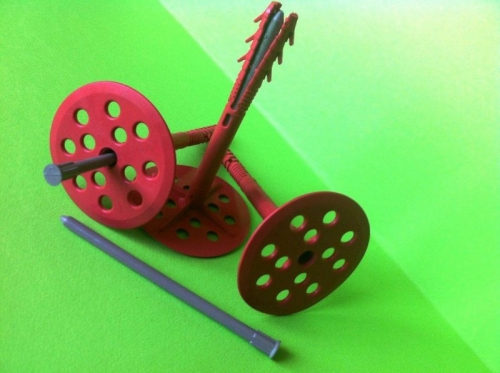

- mechanical fastening (nails-zontics, anchor, wooden rails);

- flooring;

- investing in the crate.

Sometimes the mounting methods are combined. So, the polystyrene is put into the crate, and additionally fixed with nail nails. This fastener is also called a dowel for foam with a thermal head.

Often combine foam gluing and fastening with screws. You can glue polystyrene on brick, drywall, plywood, concrete, iron.

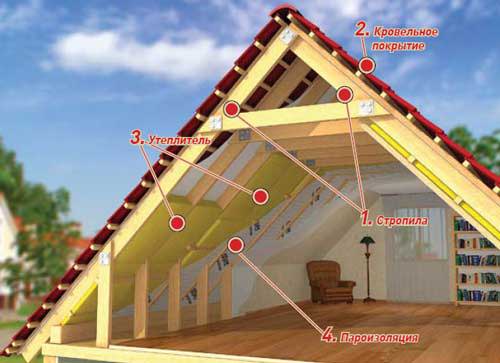

Foam on the attic roof

After arranging a vapor barrier layer, it's time to start the installation of a foam sheet insulation. Traditionally, the attic roof is performed on the rafter frame, between these rafters and foam slabs should be placed. In the process of choosing these, preference should be given to slabs, the size of which is equal to the width of the step between the rafters. But modern materials allow you to insulate the roofs with a step width up to 2 m without gaps.

The foam plates of insulation should be located between the rafters along the crate or on top. In order for the insulation to keep more firmly and reliably, experts recommend using glue and dowels at the same time. In the process, the formation is possible between the rafters and the stoves of the foam of the gaps and cracks. They must be thoroughly recorded by means of ordinary mounting foam (it is quite possible to use any type of sealant).

After all these stages, you can perform external surface finish - if you plan to equip the attic. The best option with the least labor and financial costs is the surface finish with drywall sheets, which are attached to the rafters using dowels. Further, it is quite possible to paint the surface or paste it with wallpaper.

Foam on a flat roof

The method of insulation by polystyrene and flat roofs is quite common. The surface is cleaned, covered with waterproofing film. Polistyle foam can be laid on a flat roof freely, fastened with cold and hot, nailed.

It is important to lay the slabs close to each other.

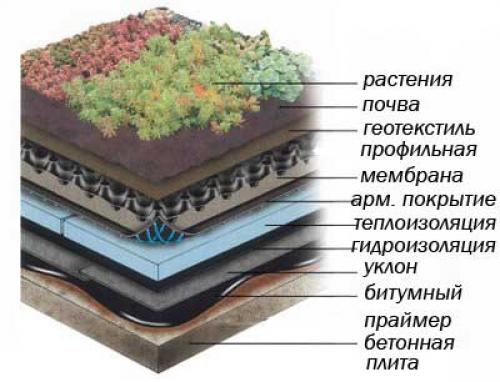

Polistyle foam often participates in the creation of a roofing cake:

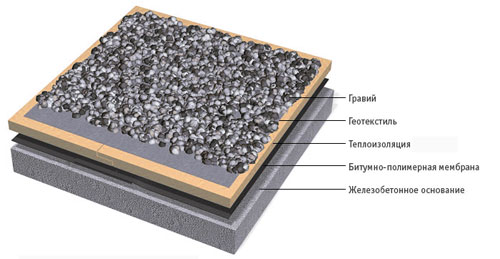

Option 1

If the polystyrene foam is laid on a flat roof, then it is combined with geotextiles, after a layer of which a layer of gravel of the fraction of 16/32 is poured with a thickness of at least 5 cm. The type of roof is increasingly used in modern urban planning. This makes it possible to equip a recreation area, lawns and even parking on the roof.

Option 2

Option 3

The third version of the insulation cake: vapor barrier, polystyrene stoves, expanded clay layer, reinforced cement-sand screed 30-40 cm thick.

The use of the above technologies allows you to equip such oases on the roofs of houses. This is called inversion roof. For its arrangement, polystyrene foam - material No. 1.

How to insulate the roof with foam and avoid common errors?

Installation of insulation, made incorrectly, will make itself felt by unpleasant consequences in the near future. The leaks that are formed as a result of poorly performed work will not only violate the aesthetic picture, but also contribute to the process of decorating the rafters.

Let's look at the main possible errors, most often made in the installation process:

- the formation of hollows and cavities on the surface of the insulation. This can lead to the formation of cold bridges. In the process of installing insulation, such defects should be avoided;

- the incorrectly selected width of the insulation slab also leads to a violation of tightness with all the ensuing consequences;

- the use of cellophane film instead of anti -condensate vapor barrier is perhaps the most common mistake that can cause many troubles and troubles.

In order for the house to always be warm, dry and comfortable do not neglect the rules and standards in the process of installing the insulation. All work must be carried out strictly in accordance with generally accepted canons. Also, special attention must be paid to the quality of the materials used.

Many owners of private houses are wondering whether it is possible to insulate the roof with foam. Of course it is possible. The material does not harm health, and is also distinguished by excellent operational characteristics and a fairly acceptable cost. But it is sensitive to tar and oil paints, should be operated at -50 ...+75 degrees, its installation provides for the presence of gaps that need to be additionally processed.

Comparing polystyrene foam with other types of insulation (mineral wool, foam, polyurethane foam), it is impossible to unambiguously say that the foam is the best insulation for the roof. But in some cases, it is simply indispensable and one of them is the arrangement of the inversion roof.

Construction insulation

Warming of building structures using mineral silling cotton wool is an effective way to arrange thermal insulation of attic, attics, ceilings, coatings, floors and walls. Superior cotton wool-spray mineral insulating material, which is blown out using a special screw-compressor equipment through the hose to building structures. https://www.youtube.com/watch?v\u003djgxrgbkmib8