In order to conduct supporting walls of the frame house, necessary...

|

|

Kesson ceilings in our time received a second birth. This is not to say that the caissons in ... |

For accommodation in a house or apartment to be comfortable at any time of the year, it is important ... |

Types of profiles for stretch ceiling

Among other methods of finishing the ceiling surface, dominance today behind stretch panels. An important component when buying a stretch ceiling is the quality of the baguette, because it is a carrier part of the entire suspension system, which is attached on the ceiling or walls, and therefore must withstand a huge tension force without deforming. We’ll talk about the types of profile for the ceiling made of drywall and the stretch fabric today.

Content:

- Features of the ceiling profile

- Types of baguettes for stretch ceiling

- Types of mounting tension canvases

- Fixing the ceiling profile

Features of the ceiling profile

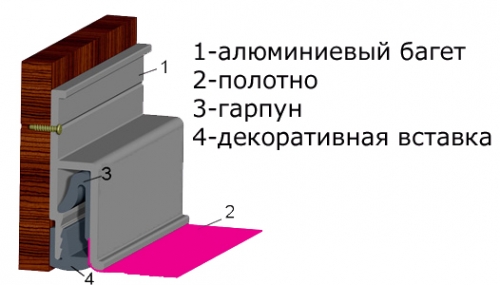

Stretch ceilings are a design from a panel, which is fixed on a plastic or metal baguette (profile) under the main ceiling. Stretch ceilings were first provided to the world in 1984 in France, and later appeared on the Russian market in 1995. The stretch fabrics were originally used in apartments and offices in which it was quite difficult to correct various ceiling defects.

Perhaps it is the baguette that is the most important component of the stretch fabric. This is a special profile designed to fix the ceiling canvas. Typically, the factory length of the baguette is 2.5 meters, but if necessary, it can be cut at the installation site using a grinder for segments of the desired length.

The process of installing stretch paintings itself begins with the mounting of the baguette around the entire perimeter of the room, and only after that they are attached and tent by PVC film. When installing the PVC profile and the fixing in it, the canvas between the film and the wall remains only two millimeters of the visible part of the white canvas. The baguette has special properties that allow the profile to use in the role of Obip, that is, a film for the stretch structure is inserted into it.

Such a fastening is so strong that it can withstand more than 20 kilograms of load per square meter of the ceiling (in some sources up to 100 kilograms!), Which provides the opportunity to hang canvases of rather large sizes - 6 by 12 meters or more, while fixing it reliably in the profile. With this method of attaching the film, you can dismantle and install the canvas quite quickly, it is possible to adjust the stretch ceilings when editing.

The reusable use of the PVC profile for a stretch ceiling makes it possible to make the ceiling repair, replace the film, draining water, if necessary, when you were flooded by neighbors. The ability to install and remove the film in the profile reaches eight times!

Types of baguettes for stretch ceiling

Baget for PVC film there are such types: ceiling, wall, dividing and special.

- The universal profile is designed to work with voluminous and curved structures.

- The wall baguette is suitable for attaching the canvas around the perimeter of the room to the wall structure (similar to mounting the profile of suspended ceilings).

- With the help of a ceiling baguette, the canvas is attached along its edges to the surface of a stationary ceiling, if there is no possibility of fastening to the walls.

There are also special types of profiles, which, depending on the system, are designed for certain connections, complexity of the design and installation location.

Separate baguettes are usually used for too large area of \u200b\u200bthe room - over 60 square meters, when there is a chance of sagging under its own weight of the canvas. Separate profiles allow to equip stretch ceilings from several installation sections. A dividing profile is also used when connecting two different canvases, covering large areas and bypassing columns.

Separate inclined profile or double makes it possible to fix two canvases at once. It is mainly used for ceiling structures, which is difficult to highlight, for example, if translucent canvases are used. This can create the effect of the starry sky.

The corner profile has two parts in its design, which are connected during the installation process. It is used to create all kinds of multi -level ceiling structures, an angular joint of paintings and bypassing building elements. A special structural profile for multi -level stretch ceilings is also used for this purpose.

There are still structural and corner profiles with ticks located evenly, so that it is convenient to bend. They are used to install multi -level curved ceiling structures and installation of curved ceilings.

The baguette for the stretch fabric is also divided into invisible and visible, that is, it is classified according to such an indicator as the invisibility or visibility of the baguette below the edge of the canvas, which was established.

PVC Baget plastic

PVC plastic baguette is universal for installing suspended ceilings and can be combined with almost any harpoon for the ceiling. The lowest castle part repeats almost the entire geometry that exists in aluminum baguette for suspended ceilings.

The visible PVC profile is designed to attach the canvas to the wall, as well as to various vertical planes. The mounting step is 10-20 centimeters. The visible part is white, semipomat, 26 millimeters wide. If such a baguette is used, then it is installed with a visible harpoon of the canvas, while there is no need to use a camouflage tape. The smallest loss of height is 3 centimeters.

The invisible PVC profile for the ceiling today is a fairly common baguette, which is used to attach to the wall of the canvas, as well as to different vertical surfaces. Such profiles can repeat all the irregularities of the walls. The mount should be no more than 10-20 centimeters.

Only with the help of the invisible baguette can curved segments of the ceilings be made without visible steps if the radius is less than 200 millimeters. Such a deflection as horizontal is carried out without cutting the rear wall. The minimum loss of the ceiling height is close to 2.5 centimeters. The cracks that form between the ceiling and the wall are usually closed with a masking tape.

Aluminum profile

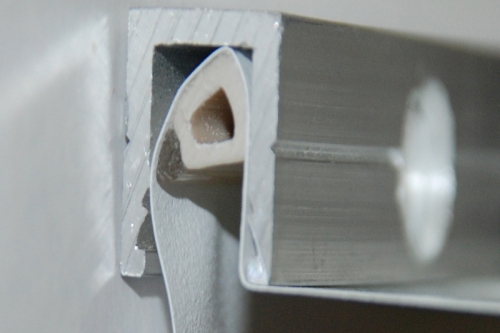

An aluminum profile, which is designed to install stretch paintings using harpoon technology, makes it possible to perform installation in a very short time, as well as quickly dismantle the PVC film. Thanks to a rather cruel profile, the durability and reliability of the fastening are ensured, and the angle holds well with the cut. The front wall has the optimal thickness of the profiles, which allows you to quite well withstand the tension of the canvas.

The ceiling aluminum baguette is designed to attach your stretch fabric to the ceiling, as well as various horizontal surfaces. Minimum loss of heights to reach 2 centimeters. The gap formed between the panel and the wall is covered with a masking tape.

The universal aluminum profile for a stretch ceiling is designed to attach the film to various planes that have high stiffness, it follows that fastening is possible to the ceiling and wall with a step of up to 50 centimeters. The minimum loss of the height of the ceiling reaches 3 centimeters. The gap formed between the ceiling surface and the wall is also covered with a masking tape.

The wall aluminum baguette is designed to attach the stretch fabric to different vertical surfaces and walls. It also has rigidity, without repeating the small irregularities of the wall, is attached with a step of 15-20 centimeters. At the same time, the minimum loss of the height of the ceiling reaches 3.5 centimeters. The gap that appears between the ceiling and the wall is usually closed with a masking tape.

The aluminum separator for the stretch ceiling is designed to connect two stretch paintings, if you need to go around the columns, as well as when overlapping rather large areas. The loss of the ceiling height is close to 2 centimeters. The gap, which is formed between the canvases, is also closed with a masking tape.

Types of mounting tension canvases

For today, there are three fairly common fasteners for suspended ceilings: wedge, harpoon and graduate. Such types of fastening have various disadvantages and advantages.

Skipka technology

The most inexpensive and affordable Russian technology for fastening the stretch canvas. With this type of fastening, PVC canvas is taken a little large than the main ceiling. Bagets are attached on the walls very close to the base surface. The distance between the main and stretch ceiling is only one and a half centimeters. The film is attached to the profile as a plinth, which is foam or plastic.

It is also possible to connect with flexible inserts if the planes on the bends have small curvatures. With this type of fastening, it is quite easy to reach the main ceiling, if necessary (for the repair of the ceiling, wiring, as well as eliminating flooding). On such a mount, you can also install a rather easily seamless canvas.

Clinical technology

The Dutch wedge type of fastening demonstrates a pretty good combination of quality and price. First, the fastener metal profile for the ceiling at a distance of 3 centimeters from the main ceiling is installed around the perimeter of the room. After that, the canvas is heated and then, using special wedges, the edges of the canvas are clamped in the profile. Then, when it cools tightly, it pulls, while a perfectly flat surface forms.

Next, excess PVCs are cut or hidden behind decorative skirting boards. Of course, the wedge technology is more expensive than the head -ups, but it provides a rather high reliability of the film connection to the profile and makes it possible to lie down on uneven surfaces. This technology also allows you to quickly and easily disassemble the ceiling for laying communications and repair work.

Harpoon technology

Harpular technology is one of the most reliable and expensive technologies for attaching the stretch fabric. This is the harpoon technology: along the perimeter of the PVC film in the form of a hook from a rather strong metal, a trim is made. Using such a edging, the canvas is fixed in the profile. This technology makes it possible to reduce the size of the canvas, due to the fact that the film tension is made at the time of fasteners.

The film is heated before tension, and then for fixing it is started in the profile groove. First, the film is pulled diagonally, and only after that - along the perimeter of the ceiling. After that, the film cools and pulls, while a flat surface is formed. The main advantage of harpoon technology is that you can use any type of profile for a stretch ceiling, you also do not need to install skirting boards on the walls - that is, the entire PVC film fastening system is hidden.

Fixing the ceiling profile

Before attaching the ceiling to the ceiling, you need to choose it. It is better to give your preference in favor of aluminum profiles, they are stronger, more reliable, durable and look much more solid. But plastic profiles for a stretch ceiling are used much less often.

The most reasonable will be the purchase of a hidden wall profile. This profile provides the opportunity to create direct and curved forms. Less commonly, a ceiling profile for a stretch ceiling is used, which is attached directly to the ceiling surface itself and has a P-shaped shape.

After you have chosen a baguette, you need to decide on the type of fastening of the canvas to the profiles that you will install. We described the fastening options above. The most running option is harpoon. Manufacturers even at the stage of manufacturing PVC film to the canvas weld special harpoons. And the baguettes already have a docking elements, clothespins and plugs. All these elements must be selected in advance, taking into account the size of the stretch fabric.

During fastening the profile, it is important to make sure that at the place of its fastening there is no hidden wiring. Then it will be necessary to find the lowest angle, a horizontal level is beaten off along the perimeter of the room, which sets the position of the ceiling, taking into account the height of the baguette. The profile can minimally go almost back to the floor slabs, or be located at a certain height of them.

The ends of the profile in the corners must be cut at an angle of 45 degrees. And between 2 baguettes you should leave a technological gap of about 5-8 millimeters. The plywood platform is made according to the size of the ceiling suspension and then make labels under the chandelier. And the mounting of point boxes occurs in a different way, which allows them to be lowered directly into the plane of the canvas using a laser or hydraulic level.

When using the laser, you can also transfer the marks to the floor surface, you can find the location of the lamps on them. In places where the curtains are attached, it is necessary to organize embedded elements with a reliable mount to the plate.

It is better not to use ceiling suspensions, because they do not differ in sufficient rigidity. Therefore, it is necessary to give preference to wooden bars, which to the level of the stretch fabric in height. And after you stretch the PVC film, all the hinged elements will be attached to their mortgage sites. In the places of puncture, the canvas for fidelity must be glued with plastic washers.

Thus, you understand why it is so important to competently approach the choice of a ceiling profile, because the entire stretch ceiling will stay on it! And this is no longer a joke, given that it is able to withstand up to 100 kilograms of weight per 1 meter square, you can imagine how strong the baguette should be.

nofuya for yourself bugots!

nofuya for yourself bugots!

The article was written by Putano and

The article was written confused and inconsistent.