Formwork is a design of boards or slab material for pouring concrete ....

|

|

Parquet with proper care and neat operation can last more than one ... |

Automatic doors have recently gained more and more popularity. They are... |

How to make a ceiling from plastic panels

The kitchen and bath are special areas of the apartment that require special care and, accordingly, another approach to the choice of finishing materials. This is due to special microclimate conditions created in these rooms, for example, increased humidity in the bathroom, and harmful factors that can lead to damage to finishing materials. These include sharp changes in temperature and humidity, fat deposits and all kinds of evaporation all this can violate the beauty and comfort of these premises. In addition, not only beginners, but also experienced craftsmen are unlikely to consider the ceiling repair a simple event, since the work at the upper level in itself is a difficult process that takes a lot of effort and time. But, despite the complexity of the process, as well as the spent forces and time, over time, the plastered surface cracked, cracks will appear on it, and it will lose its original appearance and operational characteristics. But the technology is not standing still, and today modern polymer materials come to the traditional methods of ceiling decoration, the use of which allows you to implement any construction measures with your own hands. At the same time, you can be sure of the quality and speed of the implementation of finishing work of any complexity. The materials that meet the above requirements include plastic ceiling panels, and the installation of the ceiling using plastic panels is one of the most common finishing measures that are popular. In this article, we will consider the main advantages of plastic panels, as well as the features of installation of the ceiling from plastic panels.

Content

- Ceiling sheathing with plastic panels: the relevance of the issue

- The main varieties of ceiling PVC panels

- Advantages of the ceiling from plastic panels

- Plastic panels ceiling disadvantages

- Rules for choosing plastic panels: Basic recommendations

- How to make a ceiling from plastic panels: step -by -step instructions

Ceiling sheathing with plastic panels: the relevance of the issue

The ceiling finishing with plastic panels is one of the simplest and most budget options for repairing the ceiling. To carry out the cladding of the ceiling surface with decorative plastic panels, special skills, experience in this area, as well as repair or construction qualifications are not required. Following the instructions presented in this article, as well as approaching work with due accuracy, you can install the ceiling from plastic panels with your own hands without the help of specialists. When choosing polyvinyl chloride material for finishing the ceiling, it is important not to confuse wall panels with ceiling. Wall panels, unlike fragile and light ceiling, are characterized by great weight and rigidity. In this regard, the treatment of ceiling panels requires special accuracy, since, inadvertently pressing them with a hand or a construction tool, you will leave an ugly notch on them, which will spoil the appearance of the material. In this regard, it is necessary to be careful when working with ceiling panels.

The main varieties of ceiling PVC panels

Currently, the construction market offers a wide range of ceiling plastic panels that differ in color, width or texture. A variety of texture solutions for plastic ceiling panels allows them to imitate materials popular in interior decoration, including marble and wood. The development of modern technologies allows you to produce matte and glossy ceiling panels, as well as panels, the surface of which is covered with special varnish. The size is another sign, according to which you can classify ceiling panels. Thus, you can classify plastic ceiling panels in accordance with the technology of applying a decorative coating on them:

- White matte panels, characterized by the absence of any coating. Experts call such material PVC panels in pure form, which belong to a lower price category. It is used mainly in utility rooms, imitating ceilings painted with white paint;

- White PVC panels with a glossy surface indicate that a special varnish was used during their production. Their distinctive feature is high reflective properties, and therefore, they can be used to install ceilings in any room;

- Color plastic panels or panels, on the surface of which a pattern is applied. The presence of a pattern on the surface indicates that in the process of their production more common technologies for decorating plastic panels, which will be considered later.

The most common method of decoration, due to its cheapness, is the use of a thermal panel, which is used to transfer the pattern to a plastic panel;

For the manufacture of panels, on the surface of which more complex drawings are applied, imitating ornaments and structures with a large number of shades (for example, marble or expensive wood breeds), more complex technologies are used, such as direct photo printing, drawings applied with which are characterized by high resolution. For this method of decoration, the use of special equipment will be required, and therefore, such panels belong to a higher price category.

In accordance with the manufacturing form, several categories of plastic panels are also distinguished:

- Seam plastic panels designed to simulate a wooden lining. Their distinctive feature is the presence of small gutters between the panels after their assembly;

- Seamless panels characterized by an almost complete absence of joints on the finished surface between the individual stripes. The joints remaining on the surface after installing the ceiling are so small that if desired, they can be covered with a sealant of a suitable color.

Plastic panels ceiling photo

Advantages of the ceiling from plastic panels

- The main advantage of the suspended ceiling from plastic panels is its high aesthetic attractiveness and the ability to hide defects of the unprocessed main ceiling surface. Installation of the ceiling in the bathroom made of plastic panels is a great opportunity to reliably protect from the appearance of mold in the cavity above the suspended ceiling, which is formed under the influence of high humidity, and the associated ceiling decoration associated with this cracking, since the cavity formed during the installation process is hermetic;

- Plastic panel ceiling is resistant to moisture;

- Installation of plastic panels on the ceiling provides a home craftsman with the possibility of masking various engineering communications, including electrical wiring, and also allows the implementation of point lighting and the selection of lamps of any configuration;

- Unlike mineral slabs, which, having saturated with moisture, will not only lose their original attractiveness, but will also become dangerous for health due to the fungus formed on them, with plastic panels this will not happen in mind their resistance to moisture;

- Due to the presence of the above dignity, the suspended ceilings are not afraid of flooding on top of the stains just erase with a rag. This favorably distinguishes suspended plastic ceilings from drywall structures, ceiling wallpaper and tiles characterized by the presence of a porous surface;

- Ceiling plastic panels do not require special care, it is enough to wipe them with a damp cloth and use any detergents, since polyvinyl chloride from which plastic panels are made are resistant to chemical influences.

Important! Despite the presence of chemical stability, in the process of washing plastic panels it is not recommended to use abrasive products, since after use on the plastic surface, untidy scratches will remain, which will spoil the appearance of the coating.

- In the case of the use of heat and sound insulation, the master gets the opportunity to significantly improve the consumer characteristics of the enclosing structures;

- Stability and stability of ceilings configuration even in conditions of sharp changes in temperature and humidity;

- The simplicity of installation is another advantage of plastic panels, which allows the installation of a ceiling from plastic panels with your own hands. The installation of plastic ceilings involves the assembly of the frame, to which plastic panels are attached. To carry out the installation of a plastic ceiling, there is no need to prepare the ceiling surface;

- Environmental safety and lack of extraneous smell, unlike stretch structures;

- In the process of installing plastic panels, unlike PVC stamps, there is no need to use specialized adhesive compounds;

- Democratic value of the material is dignity, which we also have no right to ignore.

Plastic panels ceiling disadvantages

- The budgetary appearance of plastic ceilings, but despite this, you can find original colors;

- If you purchase the cheapest thin lining, you can be disappointed in it after installing it, as some models pass the light from the installed lamps;

- Using the cheapest material, you cannot install multi -level structures or bends;

- After installing plastic ceilings, you will notice that you have lost a few centimeters of the ceiling height;

- Cheaper options are suture, which contributes to the fact that after installation on the surface of the ceiling, seams will be visible.

Rules for choosing plastic panels: Basic recommendations

Despite the fact that the choice of plastic panels for mounting the ceiling should be based only on personal preferences of the home master, there are certain recommendations that must be adhere to in the process of their choice. Consider the main ones:

- To visually make the ceiling higher, choose light panels, which, in contrast to similar dark color materials that reduce the height of the room, make it higher;

- If you give preference to glossy panels that, after installing the ceiling, will reflect the space inside yourself, you can create the illusion of depth, as a result of which the ceiling will look more remote;

- So that the room does not look irritably colorful, there should not be more than three colors in the room. But at the same time, white and black colors are considered universal and are not perceived as an additional element of the palette. In this regard, household appliances are most often white or black;

- Due to the fact that the selected seam between the wall panels will emphasize the unnaturalness of the material, experts recommend giving preference to seamless panels, which will less attention to the details of the ceiling.

- Based on the above rules, experts recommend giving preference to seamless glossy panels of a suitable width. To check the quality of the panel, just squeeze a piece of the panel with your fingers and check for the presence of deformations. If they are absent, this indicates that the panel of the proper quality.

How to make a ceiling from plastic panels: step -by -step instructions

Before sheathing the ceiling with plastic panels, we note that the device of a plastic ceiling with their own hands can do each with the minimum tools and wishes of the master.

Necessary materials and tools

To independently install the plastic ceiling, you will need the following materials and tools:

- Punch or drill;

- Sharp knife and hacksaw for metal;

- Self -tapping screws with a puck and dowel;

- Metal profile designed for suspended ceilings, the dimensions of which 2.5 x 2.5 cm (UD profile) and a profile with a size of 2.5 x 6 cm (CD profile);

- Plastic panels of the required width;

- Ceiling plinth or starting bar;

- Building level;

- Suspensions.

Preparatory work: what to look for?

Before starting the installation of the ceiling, carefully inspect the surface. Most masters, in this case, prefers to simply measure the size of the ceiling, which is fundamentally wrong. By refusing to prepare the ceiling, you can purchase a large amount of unnecessary material and do many useless work. To avoid this, carefully study the ceiling surface. If it is perfectly flat, and during the installation process you are not going to hide various utilities under the ceiling, you can start fastening the panels. You ask how to do it? For this, it is necessary to install the frame.

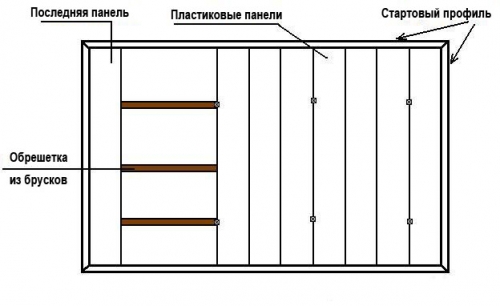

How to install the frame?

First of all, it is necessary to mark the ceiling. To do this, you need to measure the level around the perimeter and apply on the walls of the line where the ceiling will begin.

Important! If you carry out the installation of the ceiling in the kitchen from plastic panels, and tiles are exactly on the walls, you can refuse to use the level, and all measurements are made from the seams of the tiles.

Important! In addition, you need to plan the location of lighting devices in advance and purchase the appropriate lamps, since in the process of installation it may require lowering the ceiling up to 10 cm or more.

- Next, cut the UD profile in accordance with the length of the walls and drill holes under the dowels with a step of 50 cm in it;

Important! Before drilling the walls and the ceiling, check them for the presence of hidden wiring, since often, along the ceiling, there are hidden wires and decaying boxes, a drill enters into which, at best, threatens with knocked out traffic jams and repair of the wiring, and in the worst, a current blow And the exit of the punch. To search for hidden wiring, it is necessary to invite an electrician or use special devices-detectors.

- Next, attach the profile to the wall and, according to the marks made, drill holes for the dowels in the walls in the walls of the profile attachment. Fix the profile on the wall with dowels;

Important! For work, experts recommend using quick installation profiles, as they can be scored with a hammer, which will greatly facilitate the work.

- Cut the cd profile in accordance with the measured length and width of the room. In this case, consider that the ceiling panels are mounted perpendicular to the direction of the profile. Having implemented this, insert it into the guide profile, while the distance between the supporting profiles should be at least 40 cm;

Important! It must be borne in mind that in the case of a greater distance between the profiles, the panels can sag.

- If the length of the profile exceeds 1.5 meters, it must be fixed using metal suspensions, which will give the profile additional rigidity. The profiles in the inserts are twisted with screws.

- After you have installed the frame, you can start installing plastic panels.

Important! If you do not plan to use spotlights as lighting devices, but give preference to a classic chandelier, install an additional profile at the place of its fastening to subsequently carry out its installation.

How to install plastic panels?

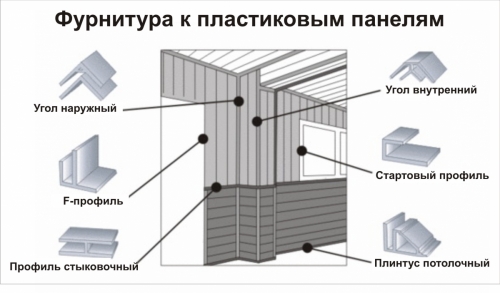

- Before starting the installation of panels, along the perimeter of the room, mount the starting bar with screws to the guide profile. In addition to the starting rail, you can use a ceiling baseboard.

Important! Installing the starting rail is not a mandatory event, since instead you can use a ceiling skirting board, which is glued to the tiles on liquid nails.

- Plastic panels are cut off in accordance with the size of the wall. After that, one end of the plastic panel is inserted into the starting rail, slightly bend and insert the other end. Then slightly pushed to the wall and screwed with screws with a puck.

- Installation of the following panels is carried out in the same way, pressing the VST to the previous one. At the same time, it is necessary to ensure that the panel enters the same way along the entire length. Along with this, it is important not to overdo it with the force of pressing, as this can lead to deformation of the panel, since polyvinyl chloride is a fairly fragile material.

- The last panel is cut with a knife along the length and fixed, inserted into the starting bar. At the same time, it is not necessary to fasten it.

- Upon completion of the work, remove the traces of the workflow and you can start operating the room.

Installation of lamps: fundamental moments

- Before starting the installation of plastic panels, you need to take care of the future lightening of the room. After you have installed the frame, to the places of installation of the alleged lamps. At the same time, do not save on the length of the wire and leave the tails more authentic, since you can always cut off the excess. Ideally, the wiring should be protected by double insulation and plastic corrugated hose. In addition, immediately see its performance. Subsequently, when installing plastic panels and reaching the installation site of the lamps, mark the places and fasteners on the panels and make the holes according to the markup, respectively.

- Next, immediately install the lamp and fasten the panels to the ceiling. Pull the wires through the holes made and complete the installation of the ceiling. In conclusion, connect the power to the lamps and install the bulbs.

Important! By placing the panels in the right direction, you can visually change the size of the room. The fastening of plastic panels can be done diagonally, although this is extremely rare. Having installed a plastic ceiling, you will not only save money, but also get a lot of positive emotions from the process.

Plastic panels ceiling video