Parquet as a floor covering has been known for several centuries. He becomes a sign ...

|

|

Cosiness and comfort of a country house depend not only on reliable walls and roofs, but also on ... |

Building a house for your car is a responsible task. Not so much... |

How to make a frame for drywall

In order to level the surfaces of the ceilings and hide the communications laid on it, drywall sheets are used on a metal frame.

In this article, we will tell you how to make a frame for drywall from a steel or aluminum profile.

Table of contents:

- Description of materials

- Assembly of a single -level ceiling frame

- Assembly of a two -level ceiling frame

To install its design will be required:

- guide profiles

- ceiling profiles

- anchor suspensions;

- extensions are profile

- dyubnaya nails

- self -tapping screws

- connectors Crab

- construction level

- squad

- maslar cord

- a hammer

- scissors for metal

- roulette

- perforator

Description of materials

- Guide profiles serve as the basis for creating the entire structure. Their dimensions are 50x40mm, 75x40mm or 100x40mm with the length of the element 3-4 m and the thickness of its wall 0.6mm.

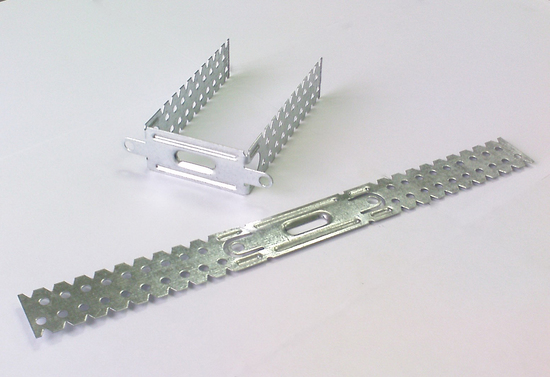

- Suspension is an element of the frame with which the ceiling is mounted. There are two types of such a product: P-shaped and T-shaped. The first is used to attach the profile to the concrete ceiling and walls. And the second for connecting long elements in the places of their intersections. Both types of suspensions give a frame for a ceiling made of drywall the stiffness in the mount.

- The ceiling profile has a channel shape in a section. This is the main element of the frame for creating its single -level or multi -level structure. The profile has a wall thickness of 0.5 0.6 mm and a cross section of 28x27mm or 60x27mm. The length of the element is 3 -4m. Its longitudinal edges are bent inside for attaching clamps and suspensions.

- The connector of the crab serves to install the joints of long elements intersecting in the frame from the profile for drywall at an angle of 90 degrees.

- The fasteners of the frame include plastic dowels, screws and screws. Without them, the assembly of the ceiling system is impossible. When assembling the frame, the screws are not twisted into dowels, but clogged with a hammer. For ceilings, weaved plastic elements are used. The side does not allow them to fall into the voids of drilled holes when clogging. With a 6mm dowel size, screws are used 70 100mm long. Small self -tapping screws, the so -called fleas, serve to connect the profiles with each other and fix them to suspensions.

Assembly of a single -level ceiling frame

We figured out the materials, start work:

First of all, the number and type of lighting devices for your ceiling are determined. The future height of the room depends on this. The minimum value of lowering the ceiling frame depends on the basement of the selected lamps. If you accept this distance a little more than 10 cm, then you will not be mistaken.

Marking and installation of guides

- We proceed to the marking of the walls for installing the guide profiles of the PNP 28x27 of the frame. This is done using the construction level and a painting cord. The result should be a strictly horizontal rectangle outlined around the perimeter of the room. Its location is 10cm from the surface of the lower part of the ceiling. Now these lines are a landmark for guide profiles.

- The guides are attached to the walls using dowel nails. Previously, the profiles are cut in size with scissors for metal and equipped with mounting holes with a step of 0.5m. Then a similar drilling operation must be performed by a perforator in the wall. The holes should coincide in pairs. Through them we fasten a number of profiles using a hammer and dowels.

.jpg)

Fixing straight suspensions

At the next stage, markings are made with mounting straight suspensions. They serve to hold the ceiling profile. On the ceiling, two identical marks are made from the opposite edges of the wall. Between the points, the painting cord is pulled and the line is beaten off. So the entire ceiling is marked every 0.5m. We received landmarks for mounting suspensions. Then the products are installed with a step of not more than 1.5 m using a perforator and dowel nails.

Installation of longitudinal and transverse profiles

- Now we mount the ceiling elements of PP 60x27. This is the main element of the frame. He will carry the main load from drywall.

- The final part of the assembly of the structure is carried out like this. The PP profile is inserted into the PNP profile and is placed between the bent sides of the straight suspension. Then he is attached to him with the help of metal screws. The entire installation of the frame for drywall is controlled by the building level. If the length of the profile is small, its parts can be connected using an extension cord.

- Next is the installation of longitudinal profiles. They are connected to transverse crab profiles - special devices, and self -tapping screws. After the performance of this work, our frame is suitable for lining with drywall.

Assembly of a two -level ceiling frame

- If in your home ceilings from 3m and above, the quality of its decoration can be significantly improved. To do this, the system of a two -level frame is used, which allows you to lower the ceiling to any height. This design makes the ceiling floating, since the planes of the ceiling itself and the plane of its fastening to the base structure are located at different levels.

- Unlike a single -level ceiling, clamping suspensions, metal rods with an ear for fixing and two -level profile connectors include the elements.

- Wall marking and installation of guide profiles is carried out similarly to the above. The difference is only in the selected ceiling height.

Installation of rods with suspensions

Further actions are the following:

- In terms of the marking to the ceiling surface, metal rods are attached with dowels every 0.9m on one line. The step of all lines is not more than 1m. The extreme row of rods is located at a distance of 0.1m from the wall. All fasteners on the ceiling are performed in a checkerboard pattern.

- Then suspensions with clamps are put on the knitting needles. The ceiling elements of the main level are attached to them. This is done by a simple snap of a suspension.

Installation of basic and ceiling profiles

- Further, ceiling profiles are planted on the main rows of profiles. The work is performed by two -level connectors with locks.

- Ceiling profiles are placed on the main elements with a step of not more than 0.5m. The horizon of all load -bearing profiles is established by a decrease or increase in the length of the rods on the clamps. At the end of the assembly of the two -level frame, drywall is attached to the ceiling profiles.

All work is quite possible for the home master. It is painful enough, but

Now you can perform any ceiling frame for drywall with your own hands.

If we take into account the cost of hired labor, which approximately corresponds to the price of all materials, you can congratulate you: you have saved a lot of money!

Additionally, how to make a frame for drywall, the video below.