Before building a home, you need to ask yourself the question of what material it will be ...

|

|

When choosing finishing materials for the roof, experienced specialists pay attention to ... |

Wallpaper is a rather popular type of interior decoration. However, non -compliance with their technology ... |

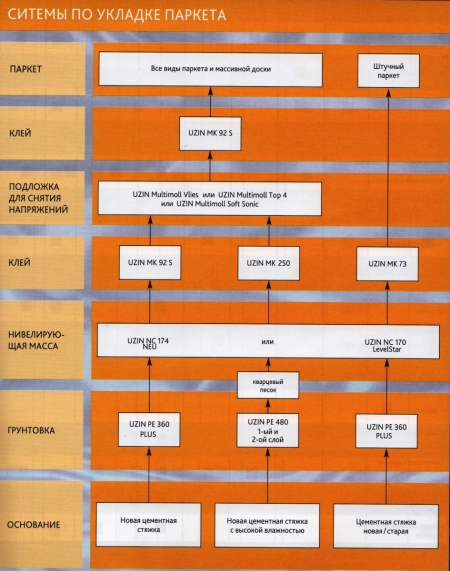

Laying piece parquet: step -by -step instructions

Parquet as a floor covering has been known for several centuries. He becomes a sign of luxury and wealth. The locks of the Middle Ages were replete with interiors with parquet floors. In the world -famous Versailles palace, halls with a parquet coating laid back in the 17th century were preserved. But years passed, and the parquet has become available to everyone who wants to decorate their interior a little.

Content

- Characteristics of piece parquet

- Methods of laying piece parquet

- Warm floor and parquet

- Choosing glue for laying parquet on a warm floor

Characteristics of piece parquet

The piece parquet is made of whole wood planks. As a material, different wood species are used for it. The main difference from the parquet board is geometric sizes. The length of one PARKET planet is 150-500mm, width 40-75mm, thickness 8-25mm. When laying a piece parquet, a spike-paz technology is mainly used, which provides a reliable connection of neighboring strips.

The layer of wear of the piece parquet is 6-10mm, which is much more in the parquet board (the wear layer in the parquet board very rarely exceeds 6 mm). Small geometric dimensions allow you to create various styling techniques and patterns, up to artistic parquet.

The use of small sizes without a spike made it possible to successfully use parquet when laying underfloor heating.

Methods of laying piece parquet

Roughly speaking, there are two ways to lay piece parquet.

- floating method without connecting parquet with the base;

- on glue using various adhesive compounds.

All other ways are particular, which originates in these two.

Floating way

The floating method of laying parquet provides for laying parquet planks of the stud-paz technology on the base without fasteners to it. When laying in this way, it is necessary to remember the change in the temperature and humidity. To do this, during installation, a gap between the coating and the wall is left the temperature seam.

The floating way of laying allows you to easily replace any damaged area of \u200b\u200bthe parquet.

Laying on glue

Laying parquet on glue requires more labor and time during installation. It is also necessary to responsibly approach the choice of glue. For each base, whether it is concrete, tiles, wood, there are its types and brands of glue. Parquet manufacturers also offer their recommendations for the choice of glue. It should be remembered that additional processing of the base with a specialized primer will improve adhesion of glue to the base and will contribute to the reliable consolidation of lamellas.

Warm floor and parquet

The disease, which in recent decades covered many builders and owners of country houses, is characterized as a warm floor. Regardless of whether it will be electric or water, manufacturers of the parquet are wary of it and do not always allow the use of their products above the warm floor. In these cases, the consumer may lose a guarantee.

A change in humidity, temperature, even a hot summer sunny day, comprehensively affect the condition of the coating. As you know, the tree has the ability to dry out and swell, changing its geometric dimensions. For solid wood, this parameter will be:

- with a tangential cut 8-12%;

- with radial 5-8%;

- along the fibers, it does not change size.

By simple mathematical calculations, we get that the parquet board with a width of 140-180mm under the influence of the temperature of the warm floor can smell 6-7mm. With such a vocabulary, it will fall out of the grooves.

But still, what to do: and the warm floor I want and the parquet too. The technology of production of the parquet also did not stop and there was a necessary solution of industrial or industrial parquet. A small width of a separate lamella and the absence of spike-paz technology provide the reliability of a parquet coating for a warm floor.

Each coating block is a set of small lamellas 200-300mm long and up to 20 mm wide. The lamellas are collected in small blocks that are laid by any pattern.

With small overall dimensions of one lamella (up to 20mm), the human eye is not able to notice a change in the geometric dimensions of the lamella, they are up to 0.4 mm. This ensures the reliability and durability of the coating.

The tree is a good heat insulator, worse than polystyrene foam, stone or mineral wool, but still much better than concrete, tile and ceramic tiles. When laying on a warm floor, this property of a tree must be reduced as much as possible. In this case, the thickness of the parquet lamella directly affects the floor temperature. The lower it is, the better. The thickness of 8-10mm is considered optimal. With this thickness, the maximum service life of the parquet will be preserved and the maximum heat transfer from the warm floor will be.

The tree is a good heat insulator, worse than polystyrene foam, stone or mineral wool, but still much better than concrete, tile and ceramic tiles. When laying on a warm floor, this property of a tree must be reduced as much as possible. In this case, the thickness of the parquet lamella directly affects the floor temperature. The lower it is, the better. The thickness of 8-10mm is considered optimal. With this thickness, the maximum service life of the parquet will be preserved and the maximum heat transfer from the warm floor will be.

Choosing glue for laying parquet on a warm floor

The use of a warm floor is becoming more and more popular every year. Often, coating manufacturers do not recommend using their products combined with warm floors, otherwise they remove the guarantee from the product. There are manufacturers who allow the use of their products with a warm floor.

In this case, the problem of choosing glue for parquet using a warm floor arises. Many adhesive manufacturers on banks write that glue can be used for heating floors, while in small letters they add that the temperature of the base should not exceed 18-25C. Will it occur to you to arrange a warm floor with a temperature of +25C? I think no.

Before laying parquet on a warm floor, it is necessary to check the quality of the screed. The humidity of the screed should be below 1.8%, the strength of the compression of 30mpa or more, the surface with drops of not more than 2 mm by 2m is leveled.

The MK-92 glue of the German manufacturer Uzin has proven itself. This is a two -component polyurethane glue that does not contain a solvent and water. Suitable for all types of wood, has great elasticity, has no shrinkage even in thick layers. When used strictly according to the manufacturer's instructions, withstands the temperature up to +65C under an electric warm floor.

The disadvantage of glue is the small life of the composition, up to 60 minutes after mixing the components, which increases the number of kneels when laying parquet. Uzin also offers its consumer frost -resistant glue MK-250it is used for laying in periodically freezing rooms.

Glue for Artelit PB-140 parquet is two-component polyurethane glue, withstands a temperature of +40-45C, can be used for installation on a water and electric warm floor. The maximum schedule of the mixture is up to 15 minutes.

The glue artelite NB-810 is one-component, hybrid, does not contain water, isocyanates and solvents, ideal for the installation of a parquet board, has great elasticity, and settings of up to 90min.

As a glue, for warm parquet floors, you can use gluing basement, among them: ANED A-1 and ANSERCOLL 5-10-15-20 production of Poland. They well withstand the temperature up to +50C. The glue is quickly settled, creating a strong and elastic compound. The disadvantage of the compositions is the time of grasping, the term from applying glue and does not exceed 15 minutes to laying the board.

When laying parquet on a warm floor, it is not recommended to use:

- water -based adhesives;

- dispersion adhesive;

- epoxy polyurethane adhesives.

After laying, the parquet is not varnished, but covered with mineral oil and wax, which gives the coating an even richer look.

The choice is yours.