The days passed when the glass ceiling was exclusively a prerogative of discos ...

|

|

It is difficult to imagine a comfortable accommodation in a house without constant water supply. However... |

The ceiling decoration is an important stage of repair work, which affects the perception of the final ... |

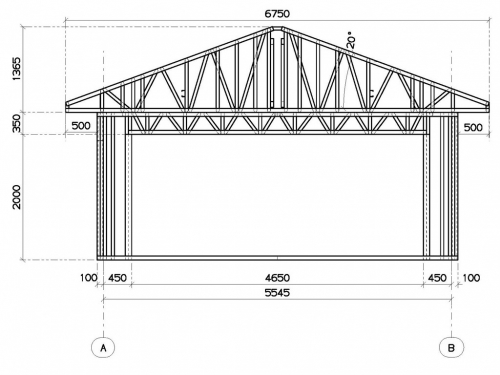

How to build a garage from foam blocks

Building a house for your car is a responsible task. Not so many materials are suitable for the construction of a garage: wood, brick, foam concrete, aerated concrete. And if you choose this, so that both cheap and angry, then in the dry rest there will be foam concrete. This modern material is very easy to install, does not require special skills to work with it, as well as relatively cheap compared to other materials. In this article, we will reveal the question of how to build a garage from foam blocks with our own hands, dwell in more detail at the stages of work and the features of foam concrete.

- Why Penoblock

- Garage design and materials calculations

- Square for a garage

- Foundation for a garage from foam blocks

- Installation of the garage gate

- We build a garage from foam blocks: walls

- The roof of the garage

- Paul in the garage

Why Penoblock

The main reason why foam blocks choose from all available materials is that a garage from foam blocks the price is the lowest. The second reason a light weight This material, which entails smaller waste construction. Wherein strength Pentone with more than enough to provide a reliable dwelling for the car. So, saving on the face.

Also an important advantage of foam concrete is its low thermal conductivity. So, wall insulation is not required.

Foam blocks light in installation, the construction of a garage from foam blocks will not take much time and will not require attracting heavy equipment.

But not everything is so rosy, Penoboton has quite significant disadvantages that are due to the use of the foaming agent and its properties.

Firstly, foam concrete not breathing. You can argue that this is not so important for the garage, and you will be wrong. Excess moisture and condensate for a car in a closed room are worse than if it is on the street in any weather. Imagine you get into the garage on a heated car after a long trip. Close the garage and leave. At this time, the car cools down, condensation appears. Where should he go? In brick garages, steam goes through the walls and the simplest ventilation made using holes in the wall at different heights: the lower for the air supply, the upper for the drive. To save the car in a garage from foam blocks, it is necessary to at least equip a supply and exhaust ventilation using a cooler on an electric drive. This entails unnecessary expenses and minor inconvenience.

Secondly, despite the fact that the surface of the foam concrete is resistant to fire, in the case of a real fire, the entire structure can burn to the ground. In this case, during the burning will be released extremely toxic substances.

Nevertheless, all of the above disadvantages do not block the advantages of foam concrete associated with the efficiency and ease of installation. That is why it is chosen for the construction of garages.

Garage design and materials calculations

Any construction begins with design. First of all, it is necessary to find out at what depths there are groundwater at different times of the year, as well as the features of the structure of the soil. It is on these indicators that the type of foundation and the project of the garage as a whole will largely depend.

Directly, the project can be created independently in the Archicad program or other similar. There you can easily calculate how much foam blocks are needed on the garage, introducing the size of the foam block and the thickness of the wall. An independent creation of the project will make any ideas and calculate the nuances of individual construction.

If you decide to build a garage from foam blocks with your own hands, first of all, decide what tasks it will perform except for the storage of the car. For example, whether an observation pit is needed, a basement for storing products and conservation in the winter, a shelving with a tool or another working area. The garage project, the type of foundation, width and length, as well as the height of the walls will depend on all this. The average garage dimensions: width 3 3.5 m, length 4.5 6 m, height 3 m.

It is possible to use ready -made projects of garages from foam blocks from the Internet only if they completely take into account your individual conditions: the structure of the soil and the level of water.

Square for a garage

On the site where the garage is planned, we mark. In the corners we insert pegs at least 50 mm thick. Between them we pull on the contour a construction or nylon cord. At the same time, we check that the angle between the threads is strictly 90.

In fact, we must transfer what we drew in the project.

After the corners were marked with pegs and pulled the thread, become from the side of the future gate. Try to imagine that they are opening. See if anything interferes: wood, building, fence or other. If everything is fine, you can start earthwork.

Foundation for a garage from foam blocks

Due to the fact that foam block is light material, it does not require heavy foundations. But the weight of the walls of the walls is not the only criterion that affects the type of foundation. A more important factor is the soil and its properties.

In optimal construction conditions: the level of groundwater is below 2 2.5 m, the soil is a homogeneous, dense non -povidious, it will be enough light strip foundation 40 50 cm depth.

If the soil is abrupt, you will have to make a foundation for a garage from foam blocks in the form monolithic concrete slab. The fact is that foam blocks, which does not tolerate the load on the bend, simply crack and destroy. So that in the case of the grounds of the soil, the walls of the garage do not crack, it is installed on the stove, which swims in the ground with the garage as a whole.

If it is planned to equip the observation pit and a basement in the garage, then the monolithic slab is not suitable as the foundation, you will have to make a deepened strip foundation or a combined pile-lane.

To perform a strip foundation for a garage from foam blocks, it is necessary to make the following:

- Remove the upper layer of soil to a depth of 70 80 cm in the form of a trench. The width is equal to the width of the foam block plus 10 15 cm.

- We seal the soil into the trench.

- We fill the sand with a layer of 10 15 cm, trim.

- We fill the crushed stone with a layer of 7 10 cm, also compact.

- Install the formwork for the foundation.

- We weld the frame from the reinforcement. We insert it into the trench, it will be reinforcing the foundation.

- Cooking concrete for filling the foundation. Pour into one appointment.

Further work can only be done after the foundation completely dries.

Installation of the garage gate

Before you start erecting the walls of the garage, it is necessary to set the gate, since during the masonry they will partially be fried into the walls.

To begin with, waterproofing the foundation around the perimeter of the entire structure so that capillary moisture does not rise into the walls. This can be done using a roofing material in 2 3 layers.

We weld a rod of a 40 cm long from a reinforcement with a diameter of 10 12 mm to the gate frame. On each side there should be at least 4 of them in height. Try to calculate so that the rods are in places of connection of two foam blocks. Before installing the gate, we primer and paint them.

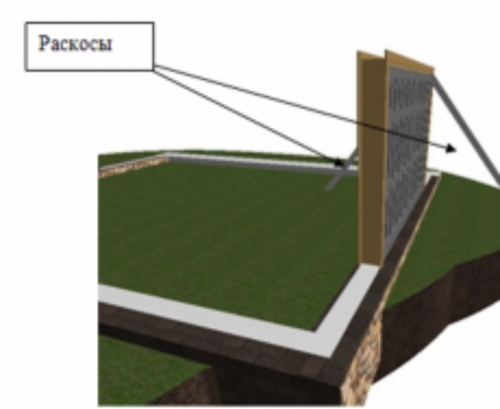

We install the gate strictly vertically in the opening designed for this. We control the position with a level and a plumb line. We fix the position with wooden braces on both sides.

We build a garage from foam blocks: walls

The construction of the walls always start with the corners. For the garage, there will be enough wall thickness of 200 mm. Therefore, we select such dimensions of foam blocks so that their width is 200 mm, we will install them with a long part along the walls. So less material will go, and there will be less work.

The price of foam blocks is largely dependent on the brand of the selected foam blocks, their size and masonry option. To simplify the installation, you can purchase special angular foam blocks, you do not have to thoroughly verify the angle during masonry.

To fasten foam blocks, we use either a cement-sand mortar or a special glue. The consumption of such adhesives is not high, and they provide thermal insulation much better.

First of all, we set the corners. Then we pull the cord between them, according to which we will put the walls. We alternate the laying of corners and walls. Every two rows of foam blocks, we reinforce the masonry with a special net.

The rods welded to the frame of the gate, we are embedded in the masonry between foam blocks.

The most difficult moment in the construction of the garage is the installation of a jumper above the gate and further laying of the upper part of the front wall. To make a jumper, for a start, we weld a frame from a 50 mm corner, repeating the size of the gate. We install it from the inside of the garage to the inside to the inside of the wall of their foam blocks. We fix it on a cement mortar. Then we take a beam in the form of an I -beam and install on top of the gate and frame. The edges should go into the laying of walls by at least 20 cm.

On top you can continue to put foam blocks.

The cost of a garage from foam blocks depends on the type of roof, which is planned to be built. The cheapest option is a single -sided roof.

Important! Please note that if you are going to make a single -sloping roof, the most common for garages, the walls must be made not even, but with a slope from the gate to the rear wall of the garage. With each meter, the height should decrease by 5 cm.

The task of erecting walls from foam blocks with a slope is quite simple, since foam blocks are easily cut even by a regular saw.

If you are going to make a gable roof, think about which material you sew the front and rear wall of the roof. To do this, you can use the same foam block, simply continuing the laying of the walls up. And you can use a tree.

The roof of the garage

Foam blocks are light material, so the arrangement of the most common roof of the garage in the form of concrete slabs laid on top on the walls and covered with several layers of roofing material is not suitable for us.

We have already decided, the roof can be made in two ways: single -sloping or gable. Let us dwell in more detail on a single -shift:

- Along the walls of the garage, we install double -barrel beams a length of 20 25 cm larger than the width of the walls. We make the distance between the beams 80 cm. All beams must be embedded in the walls.

- We lay boards with a thickness of 40 mm on the lower shelves of the beams. We try to shift them as tightly as possible.

- On top of the boards we lay the roofing material, bending the edges 10 cm up.

- We pour any insulation of dry material on the rooferoid: for example, expanded clay, slag or other.

- The future roof should protrude by the walls of the garage from all sides by at least 20 cm. This will protect the walls from precipitation.

- On top of the insulation, we make a screed from a concrete mixture. There is enough thickness of 2 3 cm.

- When the screed is completely dry, we process it with a primer.

- Then we waterproof with roofing material or by salary, or using bitumen mastic. We glue the roofing material across the garage, starting from below. So that each subsequent canvas lay overlapping, this will allow water to drain down.

The last bar over the gate. To date, the market can offer many ready -made inexpensive designs.

Paul in the garage

The construction of a garage from foam blocks is not completed if a strong floor is not equipped. After all, the car gives heavy loads to the surface. The only option for a durable floor for the garage is a concrete floor. But already in the pedestrian area (working, extension) you can also perform a wooden floor.

Do not forget about adding to the concrete floor:

- Crushed stone 10 15 cm;

- Sand 5 10 cm;

- Gravel 5 -10 cm.

We thoroughly trim each layer. On top of gravel, pour the concrete screed with a thickness of at least 20 cm.

Very often, construction requires the use of bulky equipment, in the manufacture of which a gearbox is used.

In conclusion, I would like to say that the acquisition of foam blocks themselves for the garage will be only 25 30 % of its real value. Most of the money will go to the arrangement of the foundation, accompanying materials, arranging the roof and calling heavy equipment as necessary. However, the garage from foam blocks remains the cheapest option.

Especially about the gearbox

Especially about the gearbox helped. He raised his head: "What is used in the manufacture of equipment"

The theme of the gearbox is not disclosed! AT

The theme of the gearbox is not disclosed! In the manufacture of what equipment is used, what kind of gearbox (worm, gear, can belong)?

one question how will I help me

one question how a line about gearbox will help me

Hello everyone, the gearbox is

Hello everyone, the gearbox is me. If you have questions - call at any time: +74959529161